Aerodynamics & Aerospace CFD Simulation

€180.00 Original price was: €180.00.€150.00Current price is: €150.00.

€175.00 Original price was: €175.00.€150.00Current price is: €150.00.

€190.00 Original price was: €190.00.€175.00Current price is: €175.00.

€210.00 Original price was: €210.00.€170.00Current price is: €170.00.

€190.00 Original price was: €190.00.€170.00Current price is: €170.00.

€180.00 Original price was: €180.00.€150.00Current price is: €150.00.

Introduction to Aerodynamics and Aerospace

Aerodynamics is the science of moving air and its impact on solid bodies placed in the flow field as an obstacle. In other words, Aerodynamics meaning refers to the study of how gases interact with moving bodies. This branch of fluid mechanics is crucial in the design of vehicles, aircraft, spacecraft, buildings, and even sports gear. The four main aerodynamic principles that govern motion are lift, drag, thrust, and weight. An understanding of these forces allows engineers to predict performance, enhance efficiency, and improve safety. Today, most of this analysis is no longer performed through expensive wind tunnel testing alone. Instead, engineers use aerodynamic simulation and aerodynamic CFD analysis tools to model fluid flow and visualize pressure, velocity, and turbulence fields in great detail.

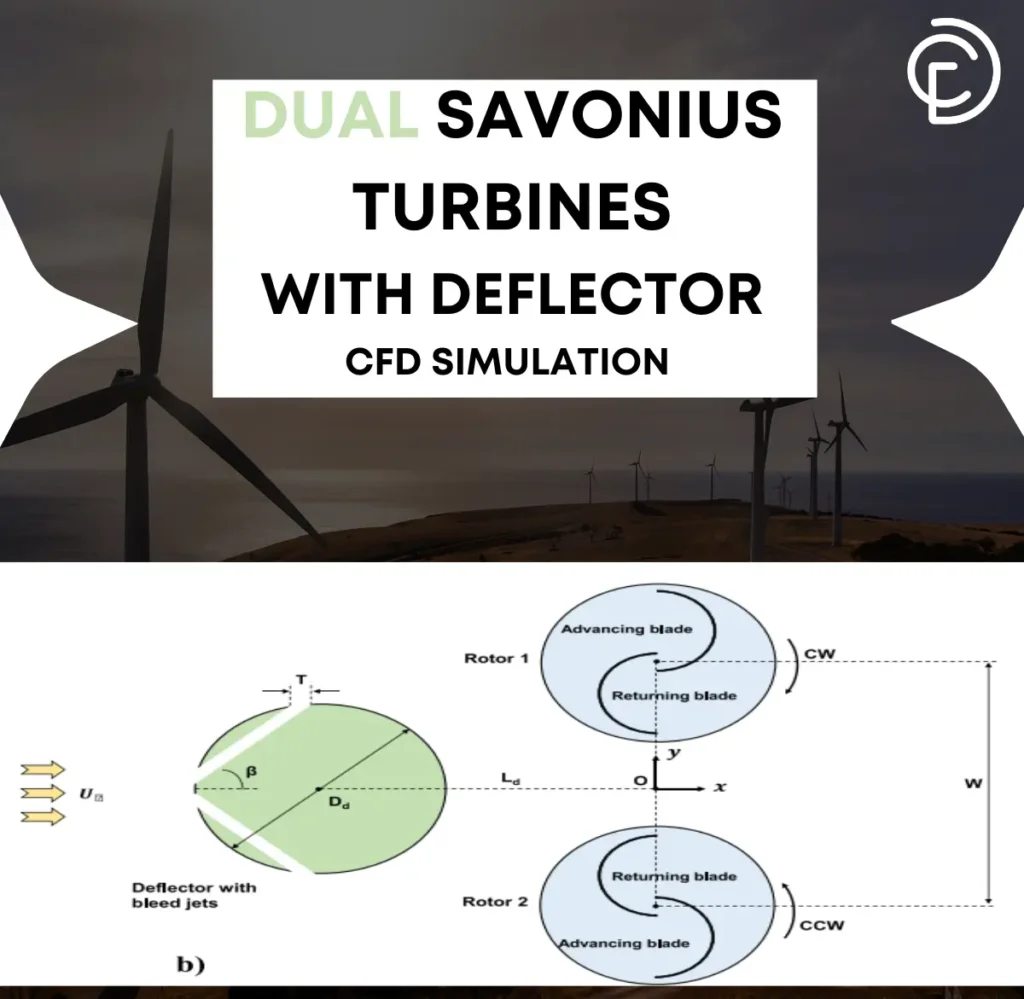

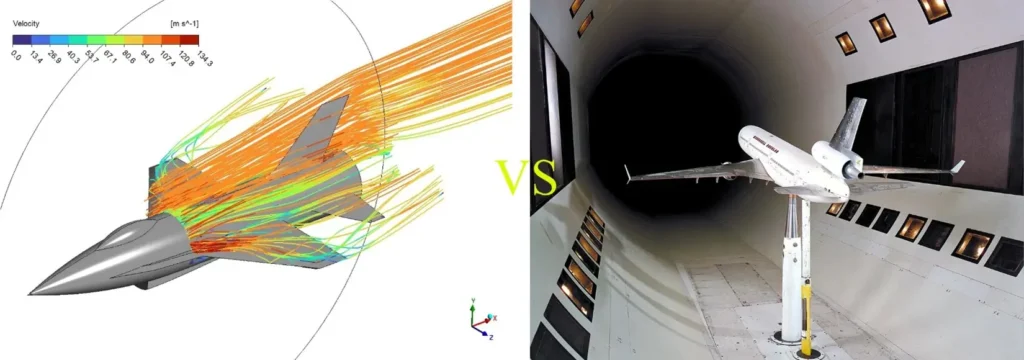

Figure 1- CFD Aerodynamics Simulation vs. Wind Tunnel Testing in Aerospace Engineering

The aerospace industry was one of the earliest to benefit from aerodynamic science. From the Wright brothers’ basic gliders to hypersonic aircraft and space shuttles, advancements in aerospace systems have always relied on improvements in aerodynamic simulation software. Aerospace engineering requires highly accurate simulations due to the extreme conditions encountered in subsonic, supersonic, and hypersonic flows. CFD aerodynamics software enables the simulation of these environments, minimizing the need for full-scale testing and reducing development costs. Aerodynamics analysis in ANSYS, particularly with ANSYS Fluent aerodynamics, has become an industry-standard practice due to its robustness and versatility.

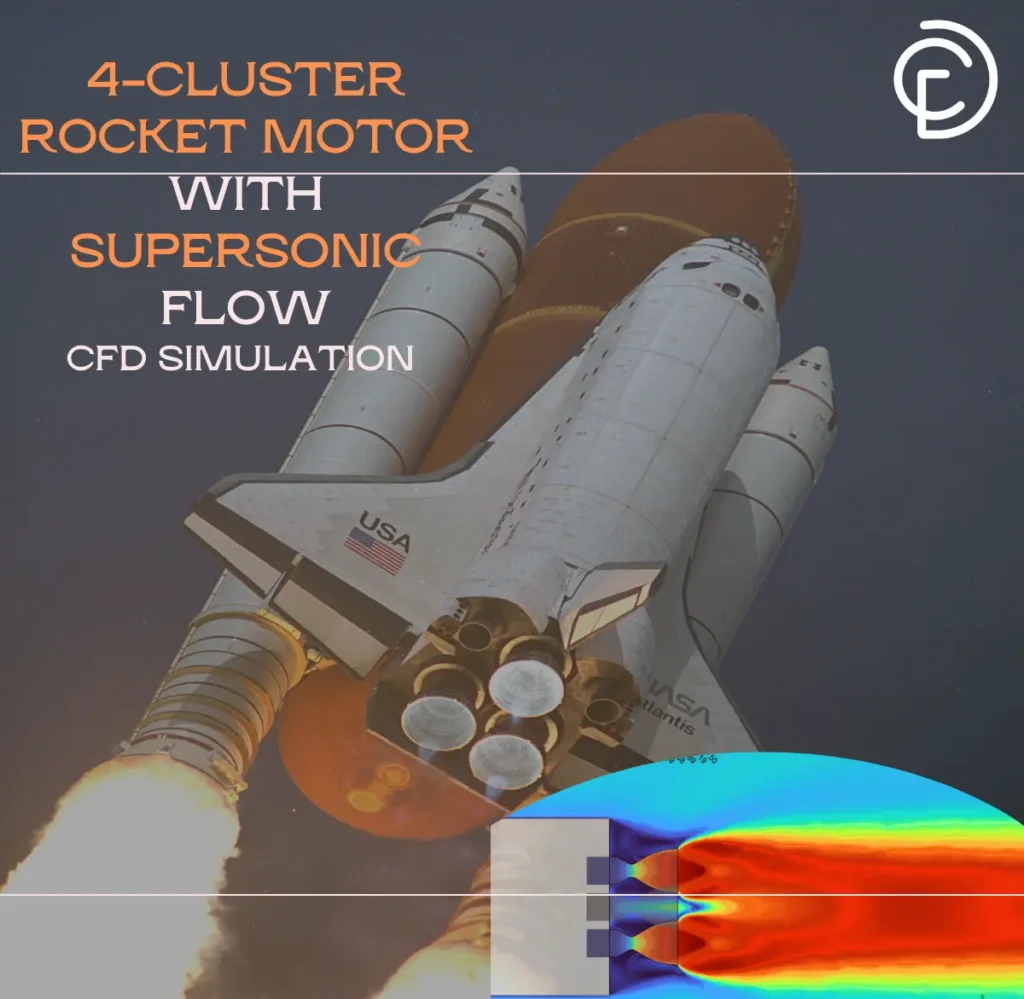

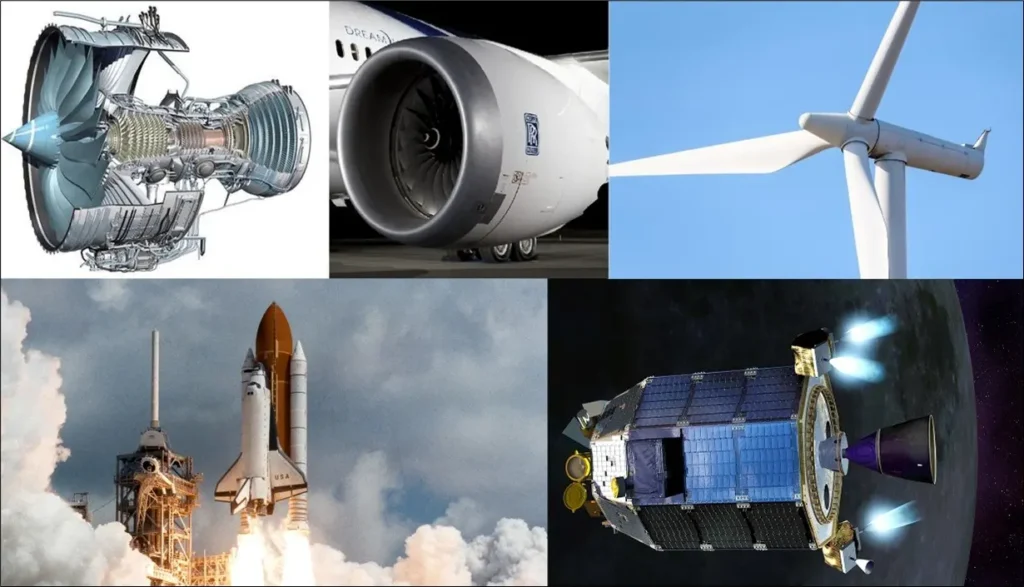

Figure 2- Aerodynamics and Aerospace CFD Simulation Applications: From Jet Engines and Aircraft to Wind Turbines, Rockets, and Spacecraft

Aerodynamics and Aerospace Applications

Understanding the applications of aerodynamics and aerospace CFD simulation is essential in a variety of engineering fields. These disciplines play a critical role not only in aircraft and spacecraft development but also in automotive engineering, civil infrastructure, sports, and more. The integration of aerodynamic simulation and aerodynamic analysis software helps engineers and designers optimize performance, reduce energy consumption, and enhance safety. Below, we explore some of the most prominent applications where aerodynamics and aerospace CFD are making a significant impact.

-

Automotive Engineering

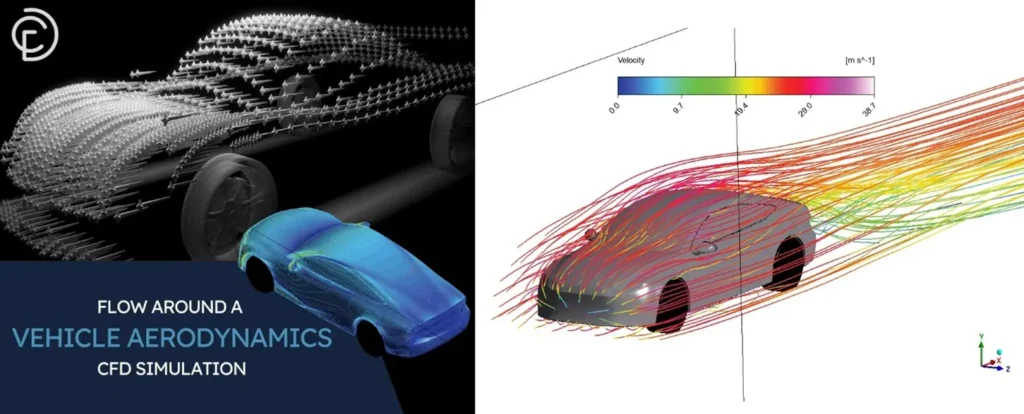

The use of aerodynamics in cars is a growing area of interest, especially with the global push for fuel efficiency and high-performance vehicles. In automotive engineering, aerodynamic simulation is used to reduce drag force and improve vehicle stability. For racing cars, an efficient car aerodynamics CFD design can lead to higher speeds and better cornering performance by generating downforce.

Every curve and vent in a modern car is influenced by CFD analysis of car aerodynamics. Engineers rely on aerodynamic simulation software to visualize airflow around the vehicle, making informed design decisions to reduce turbulence, enhance cooling, and lower fuel consumption. This integration of aerospace CFD simulation methods into the automotive industry showcases the crossover potential of aerodynamic cfd simulation technologies.

Figure 3- Flow around a Vehicle Aerodynamics CFD Simulation, ANSYS Fluent Aerodynamics Tutorial

-

Aircraft Design

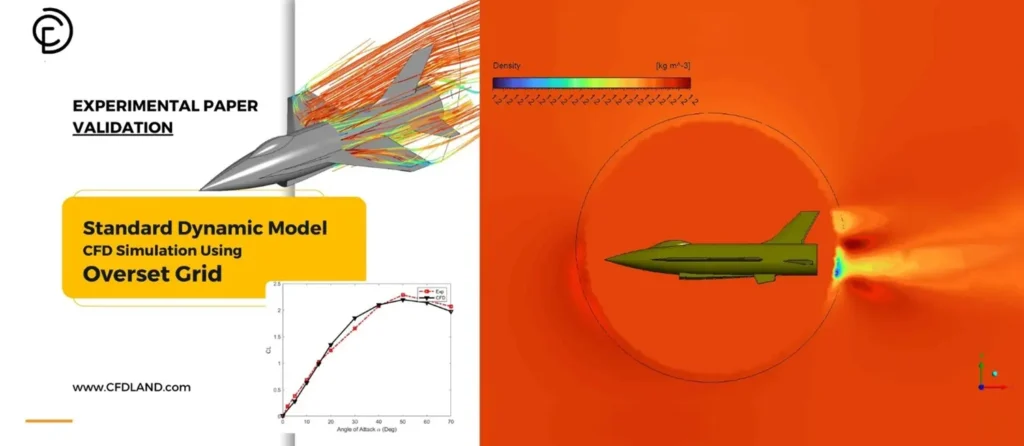

Aircraft are perhaps the most iconic application of aerodynamics and aerospace CFD simulation. Every component, from the aircraft engine to the wings and tail fins, is designed using aerodynamic principles. The objective is to reduce drag, enhance lift, manage airflow-induced vibrations, improve fuel efficiency, and ensure overall flight stability and safety.

Modern CFD aerodynamics software, such as ANSYS Fluent, is widely used to simulate real flight conditions before any physical prototype is built. This simulation capability not only saves time and cost but also increases design precision. Aerodynamics CFD has become an essential part of aircraft development pipelines. Tools like aerodynamic analysis software allow engineers to fine-tune the smallest design details, ensuring the final product performs optimally under diverse atmospheric conditions.

Figure 4- Standard Dynamic Model CFD Simulation Using Overset Grid – Experimental Paper Validation

-

Airfoil Design

Airfoils are fundamental to multiple applications, including airplane wings, wind turbines, HVAC systems, and steam turbines. The shape of an airfoil determines how air flows around it, influencing lift, drag, and overall performance. Research and development in airfoil design heavily rely on aerodynamic CFD analysis. Rather than costly wind tunnel experiments, engineers often opt for aerodynamic simulation using high-resolution meshes and turbulence models within CFD aerodynamics software. Whether you’re designing the blade of a wind turbine or a fan in a data center, understanding airfoil behavior through aerodynamics cfd simulation is crucial.

Figure 5- Wavy Wing Airfoil CFD Simulation – ANSYS Fluent Aerodynamics Tutorial

-

Civil Engineering

In civil engineering, particularly for skyscrapers and long-span bridges, external aerodynamics CFD is essential for safe and efficient structural design. Tall buildings must be designed to withstand wind loads that can cause dangerous vibrations, discomfort, and even resonance-induced failure. Civil engineers use CFD analysis aerodynamics to evaluate how air flows interact with structures, minimizing noise and optimizing energy efficiency in ventilation systems. Tools like ANSYS Fluent aerodynamics are common in civil engineering simulations.

Figure 6- Ventilation of Courtyard Building CFD Simulation, ANSYS Fluent Aerodynamics Tutorial

-

Spacecraft and Satellite Design

In space applications, aerospace systems push the boundaries of science and engineering. Satellites, rockets, and space probes must navigate both atmospheric and space environments. Designers must consider factors such as supersonic airflow, heat transfer, and re-entry dynamics, all of which are governed by aerodynamic principles. Because physical experiments for space missions are extremely costly, aerospace CFD simulation becomes indispensable. Engineers use CFD aerodynamics to model airflow and thermal stresses on vehicles during launch and atmospheric re-entry. Due to the high cost of experimental studies in the branch space exploration projects, CFD simulation is a suitable way for studying that branch.

Figure 7- Missile Launching CFD Simulation Using Dynamic Mesh – ANSYS Fluent Aerodynamics Tutorial

-

Sports and Athlete Performance

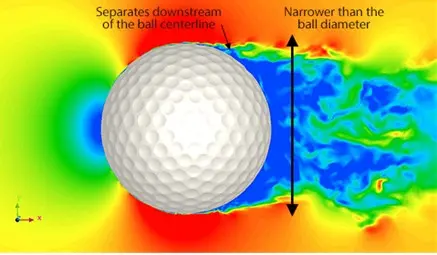

You may not immediately associate aerodynamics with sports, but it plays a huge role in optimizing performance and equipment. Cyclists, for example, adopt aerodynamic postures to reduce drag and ride faster. In swimming, athletes train to minimize drag through body position and gear. Golf balls are designed with dimples that improve airflow and reduce drag through controlled turbulence.

Figure 8- CFD Simulation of Airflow around a Golf Ball: Visualizing Turbulence and Drag Reduction

Even in sports like skiing, running, and skating, aerodynamic simulation software is employed to analyze how clothing and equipment interact with air. CFD simulations have become common in sports research facilities, helping to improve athlete performance and gear design. Universities and performance labs often run aerodynamics simulation free software to study these interactions in controlled environments.

Figure 9- Wingsuit Flyer CFD Simulation – ANSYS Fluent Aerodynamics Tutorial

Important Items in Aerodynamic Design

When it comes to aerodynamic design, whether for aircraft, automobiles, or high-performance sports equipment, understanding the key flow characteristics is crucial. These parameters determine how air interacts with surfaces, affecting lift, drag, stability, and overall performance efficiency. Below are the most important factors engineers and researchers consider in aerospace simulation and aerodynamic analysis:

-

Fluid Compressibility

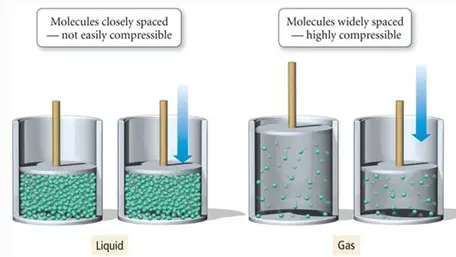

Compressibility refers to whether a fluid’s density changes with pressure. In aerospace applications, air is typically treated as a compressible fluid, especially at high velocities. Compressible flows are more complex to analyze in CFD aerodynamic simulations, but they’re essential in aircraft and missile design, where pressure and temperature changes are significant. A flow is defined as compressible if its velocity exceeds 30% of the speed of sound in that fluid. However, for slower speeds, the air can be assumed incompressible, simplifying the CFD modeling.

Figure 10- Comparison of Compressibility between Liquids and Gases Based on Molecular Spacing

-

Flow Speed (Mach number)

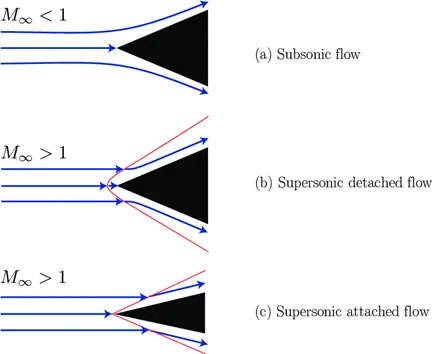

One of the critical aspects of aerodynamic simulation is the flow speed relative to the speed of sound—described by the Mach number. The design considerations vary significantly for subsonic, transonic, supersonic, and hypersonic flows. In supersonic design, shock waves and expansion fans must be accurately modeled to optimize performance and ensure safety.

Figure 11- The propagation of disturbances in (a) subsonic and (b) supersonic flow and attached (b) with detached (c) shock properties. The shock waves are indicated by a red line. The stream lines are depicted by blue arrows.

-

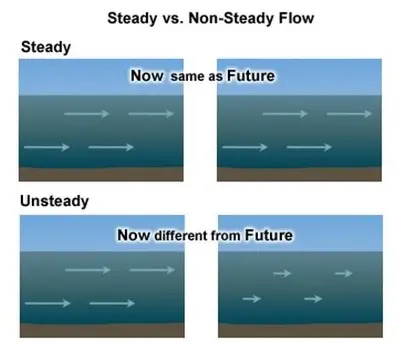

Steady vs. Unsteady Flow

Flow is termed steady if its properties (velocity, pressure, etc.) do not change over time. In contrast, unsteady flow fluctuates with time, which is often the case in real-world aerospace simulations, such as during turbulence, gust encounters, or wing flapping in drones and birds. CFD tools can model both steady and unsteady flows, depending on the engineering need.

Figure 12- Comparison of Steady and Unsteady Flow Dynamics

-

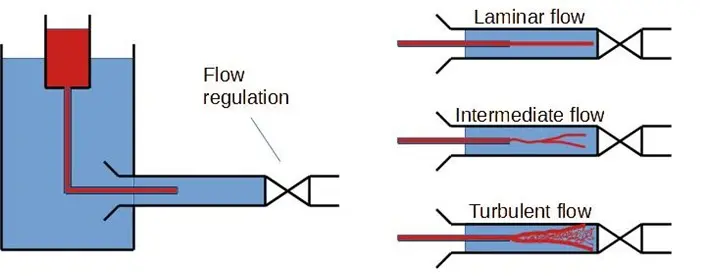

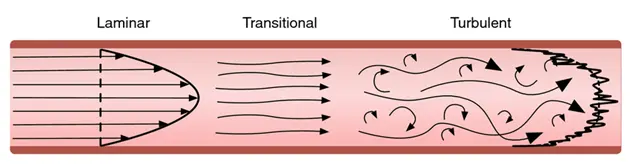

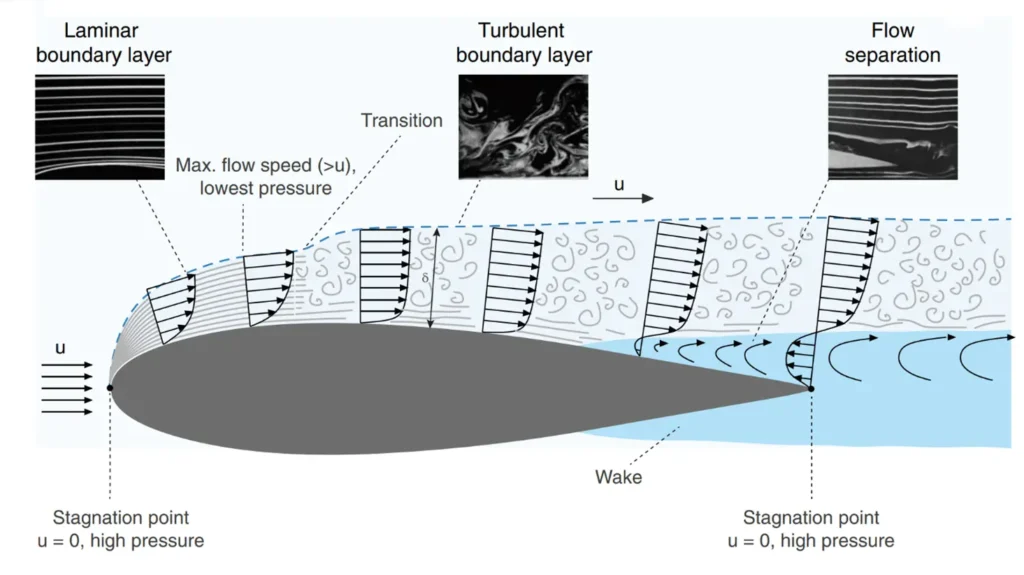

Flow Regime: Laminar and Turbulent

The flow regime—whether it is laminar (smooth and orderly) or turbulent (chaotic and mixed)—has a direct effect on aerodynamic performance. Turbulent flows are common in high-speed applications and significantly impact drag and heat transfer. Accurately modeling the transition from laminar to turbulent flow is a key challenge in CFD aerodynamic design.

Figure 13- Reynolds Experimental Setup for Showing Different Flow Regime

Figure 14- Flow Regimes: Laminar, Transitional, and Turbulent Flow Behavior for Inner Flow

-

Viscosity Effects

Viscosity is another critical factor in aerodynamic analysis. While early aerodynamic theories ignored viscosity and assumed inviscid flow, modern simulations incorporate advanced turbulence and viscosity models to capture real-world behavior more precisely. This is particularly vital in boundary layer analysis and predicting flow separation.

Figure 15- Visualization of Viscosity Effects on Boundary Layer Transition and Flow Separation: External aerodynamics CFD

Simulation of Aerodynamics and Aerospace Applications Using ANSYS Fluent

-

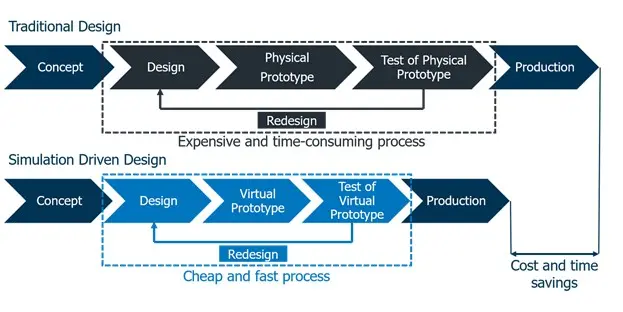

The Challenge of Traditional Aerodynamic Analysis

Conducting analytical work in aerodynamics is highly complex and time-consuming. In many advanced aerospace designs, analytical methods alone are no longer sufficient to handle the nonlinearities and turbulent effects of real-world aerodynamic behavior. While experimental studies offer valuable insights, they are often expensive and time-intensive—especially for high-speed or large-scale models.

-

Benefits of ANSYS Fluent for Aerodynamic Simulation

Here are some reasons why ANSYS Fluent aerodynamics tools stand out in the industry:

- Offers accurate simulation of aerodynamic forces

- Reduces time and cost compared to wind tunnel testing

- Enables rapid design iterations

- Provides visual insights into flow patterns

- Supports multi-physics coupling in aerospace CFD simulations

- Compatible with parallel computing for large-scale projects

The software also includes ANSYS Fluent car aerodynamics modules and ANSYS Fluent aerodynamics tutorials for engineers and students who want to sharpen their CFD skills.

Figure 16- Benefits of ANSYS Fluent for Aerodynamic Simulation: Design and validation of processing systems using CFD

Aerodynamics and Aerospace CFD Simulation: Overview Formulations

Understanding the fundamental aerodynamic principles and their mathematical formulations is essential for accurate aerodynamic CFD simulation and aerospace systems analysis. Whether you’re modeling lift, drag, or shock waves in ANSYS Fluent, these core equations serve as the backbone of all simulations. The following table provides a comprehensive overview of the most important aerodynamic forces, dimensionless numbers, and physical concepts—along with their corresponding formulas and applications in CFD analysis. This reference is especially valuable for anyone working on aerodynamic CFD analysis, aerospace design, or preparing ANSYS Fluent aerodynamics tutorials.

Table 1- Aerodynamic Principles: Key Parameters and Formulations in Aerodynamics and Aerospace CFD Simulation

| Concept | Formula (LaTeX) | Description | Application in CFD |

|---|---|---|---|

| Lift Force | Generates upward force opposing gravity. CL is the lift coefficient, A is reference area. | Evaluated in CFD lift simulations using pressure and viscous forces on wings, rotors, etc. | |

| Drag Force | Resistance to motion due to fluid. CD is the drag coefficient. | Central to aerodynamic optimization in automotive, aerospace, and sports applications using CFD | |

| Mach Number | Determines flow regime: subsonic (M < 1), transonic (~1), supersonic (>1), hypersonic (>5). | Critical for selecting compressible solvers and applying shock-capturing schemes in CFD. | |

| Reynolds Number | Governs laminar vs turbulent flow transition. | Defines turbulence model selection in ANSYS Fluent (k-ε, k-ω, SST, etc.) | |

| Skin Friction Coefficient | Measures viscous drag at the wall. | Extracted from CFD wall data to assess drag reduction techniques like riblets or surface coatings. | |

| Pressure Coefficient | Indicates surface pressure distribution. | Used in CFD post-processing to assess flow behavior around airfoils, fuselages, and car bodies. | |

| Moment Coefficient | Measures pitching moment about a reference point. c is chord length. | Used in stability analysis of airfoils and aircraft via CFD simulations in Fluent. | |

| Buoyancy Force | Describes natural convection effects due to density gradients. | Applied in low-speed aerospace systems, ventilation, and re-entry thermal analysis using Boussinesq approximation. | |

| Strouhal Number (St) | Characterizes vortex shedding and oscillatory behavior. | Applied in unsteady CFD simulations like flutter and bluff-body dynamics. | |

| Vorticity | Measures local rotation in the flow. | Used for post-processing and identifying flow structures like vortices, separation zones, etc. |

CFDLAND Expertise in Aerodynamics and Aerospace CFD Simulation Using ANSYS Fluent

At CFDLAND, we specialize in delivering high-quality solutions in aerodynamics and aerospace CFD simulation using industry-leading tools, ANSYS Fluent aerodynamics software. Our team is highly experienced in conducting aerodynamic CFD simulations and analysis, advanced modeling of compressible and turbulent flows, and CFD of external aerodynamics and turbomachinery. Whether you’re looking for an ANSYS Fluent aerodynamics tutorial, a complete CFD analysis in aerodynamics, or need assistance with your aerospace CFD projects, we’ve got you covered.

You can explore our portfolio of completed aerodynamics CFD software projects at the top of this page or browse through our ready-made simulations in the CFD SHOP.

Need a custom project? Place your order confidently via ORDER PROJECT and let our experts handle your aerodynamic analysis in ANSYS Fluent with precision and speed.