CFD in Chemical Engineering

€230 Original price was: €230.€199Current price is: €199.

€205 Original price was: €205.€175Current price is: €175.

€155 Original price was: €155.€125Current price is: €125.

€160 Original price was: €160.€135Current price is: €135.

€190 Original price was: €190.€175Current price is: €175.

Chemical engineers are the masterminds behind the large-scale production of many products, achieved through controlled chemical reactions. They design special setups to efficiently mix ingredients, ensuring good contact for the reactions to happen. They also manage the temperature and figure out the best way to get the final product out. By constantly checking the results, they can fine-tune the process to run smoothly and produce high-quality goods consistently.

application of cfd in chemical engineering

Chemical engineering has a wide range of applications across various industries. Here are some of the most prominent ones:

- Energy industry: Chemical engineering is used to improve and refine fossil fuels and biogas. The final products have suitable characteristics for efficient energy production and also produce less pollution. CFD chemical engineering simulations are widely used to optimize and analyze energy industry projects.

- Food and beverage industry: Chemical engineering is used to produce food products, ensuring the quality and health of the products. For example, it is applied in the preparation of milk powder. Traditional methods of food production are often slow and require a significant amount of manpower.

- Water treatment: The treatment of water or sewage involves various steps and methods aimed at removing biological pollutants, such as bacteria, and separating unwanted salts and soil particles. To achieve these objectives, substances such as chlorine, which kills bacteria, and flocculants, which aggregate soil particles, are added to the water. CFD chemical engineering simulations are useful in the study of water treatment projects due to the capabilities of CFD in the analysis of multiphase systems.

Aerial view recirculation solid contact clarifier sedimentation tank, Water treatment solution, Industrial water treatment

Common Tools in Industrial Chemical Processes

In the following, some commonly used tools in industries to perform chemical reactions are introduced:

Fluidized bed reactors

In a fluidized bed, solid materials are placed in a tank as small particles. Gas or liquid enters the system from below, under pressure. This process causes the bed of solid materials to behave like a fluid physically. During this process, chemical reactions can occur between the entering fluid and the solid particles, facilitated by their extensive surface area. Additionally, the solid particles can be coated with another material, or they can be classified at different heights within the bed based on their size. fluidized bed CFD simulations are used for analysis and optimization of fluid dynamics and heat transfer within the reactor.

Mixing and stirred tank reactors

In mixing and stirred tank reactors, materials are blended using various methods, typically involving a rotating component such as a stirrer, to facilitate chemical reactions or achieve uniform mixtures. These materials can exist in solid, liquid, or gas phases. CFD simulations help in optimizing the mixing efficiency and understanding the flow patterns within the reactor for better reaction kinetics and heat transfer.

Heat exchanger

A heat exchanger is used to transfer heat from boilers to chemical reactants. These devices come in various types. Heat exchanger CFD simulations aid in designing heat exchangers with optimal heat transfer characteristics and minimal pressure drop, enhancing efficiency and performance.

Boiler

In boilers, the combustion process generates heat used for various purposes. This heat facilitates numerous chemical reactions within the boiler system. Moreover, the design of boilers exemplifies the principles of chemical engineering. CFD simulations are employed to optimize combustion efficiency, heat distribution, and pollutant emissions within the boiler chamber.

Pumps and compressors

Pumps and compressors are utilized to increase pressure and transfer fluids in industrial processes. CFD simulations are used to analyze fluid flow patterns, and pressure distribution, and optimize the performance and energy efficiency of pumps and compressors. CFD simulations assist in optimizing tray or packing design, vapor-liquid distribution, and overall column efficiency for improved separation performance.

Distillation columns

Distillation columns are used to separate fluid mixtures based on their boiling points. For instance, when oil enters a distillation column, its temperature is raised, causing a substantial portion to evaporate. As these materials ascend with the gas phase inside the column, their temperature decreases, leading to condensation. Different materials condense at various heights and temperatures within the column, thereby facilitating their separation based on boiling points.

A distillation column, Used for the separation of oil components

Simulation of Chemical Engineering Processes by ANSYS Fluent

ANSYS Fluet has many capabilities in chemical engineering CFD simulations. Among the capabilities of this software, the following features can be mentioned as CFD applications in chemical engineering:

- Mass transfer: ANSYS Fluent helps chemical engineers simulate key mass transfer processes like absorption and diffusion. It tracks how chemicals move in fluids, aiding in optimizing reaction and separation processes for efficient chemical production.

- Heat transfer: It is possible to simulate all three types of heat transfer, radiation, convection, and conduction, simultaneously in Fluent. By simulating the heat transfer processes in boilers, heat exchangers, and other equipment, chemical engineers can ensure and determine the desired temperature of the products. CFD chemical engineering simulations always include heat transfer calculations.

- Fluid flow: Fluent excels in its ability to simulate flow, accurately predicting pressure distributions and flow velocities. It effectively handles both laminar and turbulent flows, offering extensive capabilities for simulating turbulent phenomena. Moreover, Fluent supports the simulation of non-Newtonian fluids, further broadening its applicability in diverse industrial and engineering scenarios. Fluid flow simulation is based on fluid mechanics rules. Fluid mechanics for chemical engineers with microfluidics and CFD allows for precise modeling of complex fluid interactions, enhancing process optimization and innovation.

- Multiphase simulation: In all industrial chemical processes, multiphase flow is common. Fluent offers extensive capabilities for simulating multiphase flows, including scenarios where solid particles are suspended in fluids. The software can simulate the interaction between the fluid and the particles, the mutual interaction among the particles themselves, and the impact of particles on the fluid. This comprehensive approach allows for detailed analysis and optimization of processes involving complex multiphase phenomena. Multiphase simulation is the most important CFD application in chemical engineering.

Mentioned simulation fields are common applications of CFD in chemical engineering.

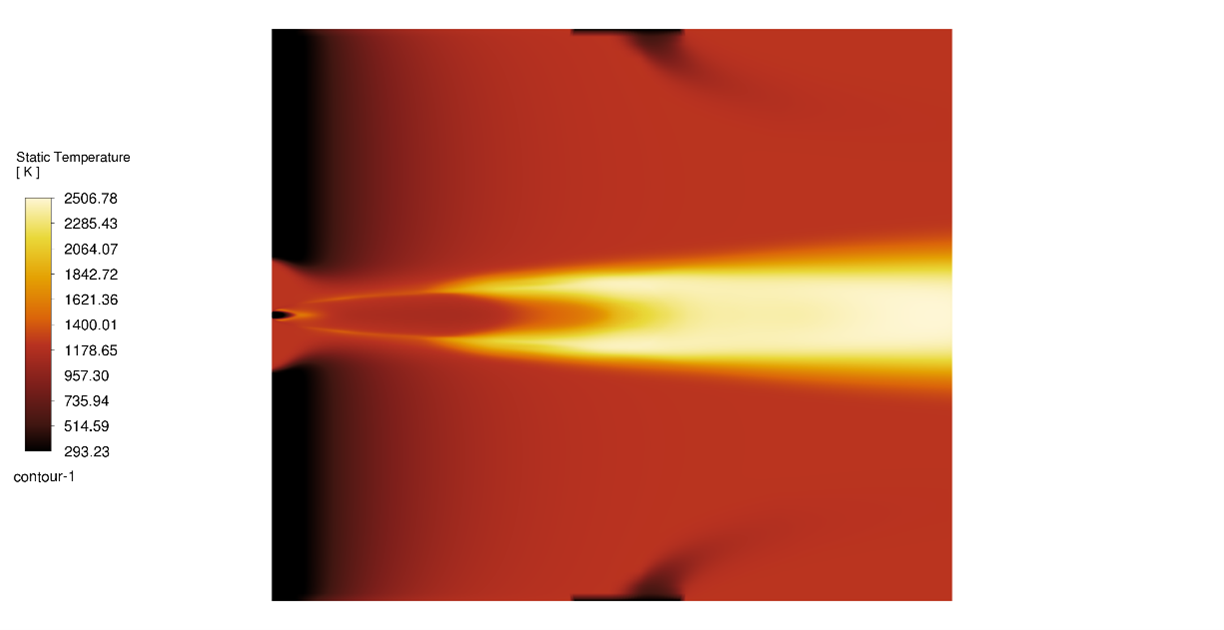

Static temperature contour, from “Methane-air Combustion Using GRI CHEMKIN Mechanism”

CFDLAND expertise in Chemical Engineering Processes Modeling Using ANSYS Fluent Software

Looking to optimize and evaluate the performance of your industrial processes? Trust us and order your CFD chemical engineering simulation projects from ORDER CFD PROJECT. You will be amazed by the quality of our work.

We have completed numerous CFD simulation projects using Fluent software at CFDLAND. Take a look at our ready-made projects in the CFD SHOP; they might be suitable for your needs. Projects related to chemical engineering processes can be found at the top of this page.