Separators CFD Simulation

€205 Original price was: €205.€175Current price is: €175.

€180 Original price was: €180.€165Current price is: €165.

€220 Original price was: €220.€155Current price is: €155.

€205 Original price was: €205.€169Current price is: €169.

€195 Original price was: €195.€135Current price is: €135.

Separators are used to separate materials based on material type, phase, density, and particle size. Separators have many uses in the oil, chemical, pharmaceutical, food, and other industries.

Types of Separators

There are different classifications of separators. For example:

- Vertical separators: They are vessels designed to separate liquids or solids from a mixture primarily using gravitational force. They are widely used in the oil and gas industry to separate oil, water, and gas from the well stream, ensuring effective processing and extraction of each component.

- Horizontal separators: Like vertical separators, they are vessels used in industries to separate liquids or solids by gravity, particularly suited for high liquid-to-gas ratios. They are favored for their versatility, low processing costs, and ease of installation and maintenance. Their large gas-liquid interface area aids in efficiently separating bubbles from crude oil to the gas phase, ensuring effective gas-liquid separation to meet industry demands.

In another classification:

- Two-phase separators: In this type of separator, two liquid or solid-liquid phases are separated based on differences in density, filtration, settling, centrifugation, etc. They are widely employed in oil and gas production facilities, refineries, chemical plants, and refrigeration systems.

- Three-phase separators: As their name implies, these separators are specifically designed to divide a well stream, comprising a mixture of oil, gas, and water produced from an oil well, into its three distinct components.

Based on the type of separator function, they can be classified into:

- Gravity separator: It uses the density difference of materials and gravity force for separation.

- Centrifugal separator: In this type of separator, centrifugal force is utilized to separate materials based on density differences. A rotating component within the separator causes heavier particles to move toward the outer edges of the rotation axis, where they are separated from the lighter particles.

- Cyclone separator: This type of separator is similar to a centrifugal separator but operates without a moving part to generate centrifugal force; instead, it functions by creating a vortex. It is primarily used to separate solid particles from gas.

- Magnetic separator: Uses magnetic fields to attract and remove magnetic particles from a mixture.

- Electrostatic separator: Electrostatic separators charge particles within a gas or liquid stream, causing charged particles to be drawn towards oppositely charged collecting electrodes, thereby separating them from the original mixture.

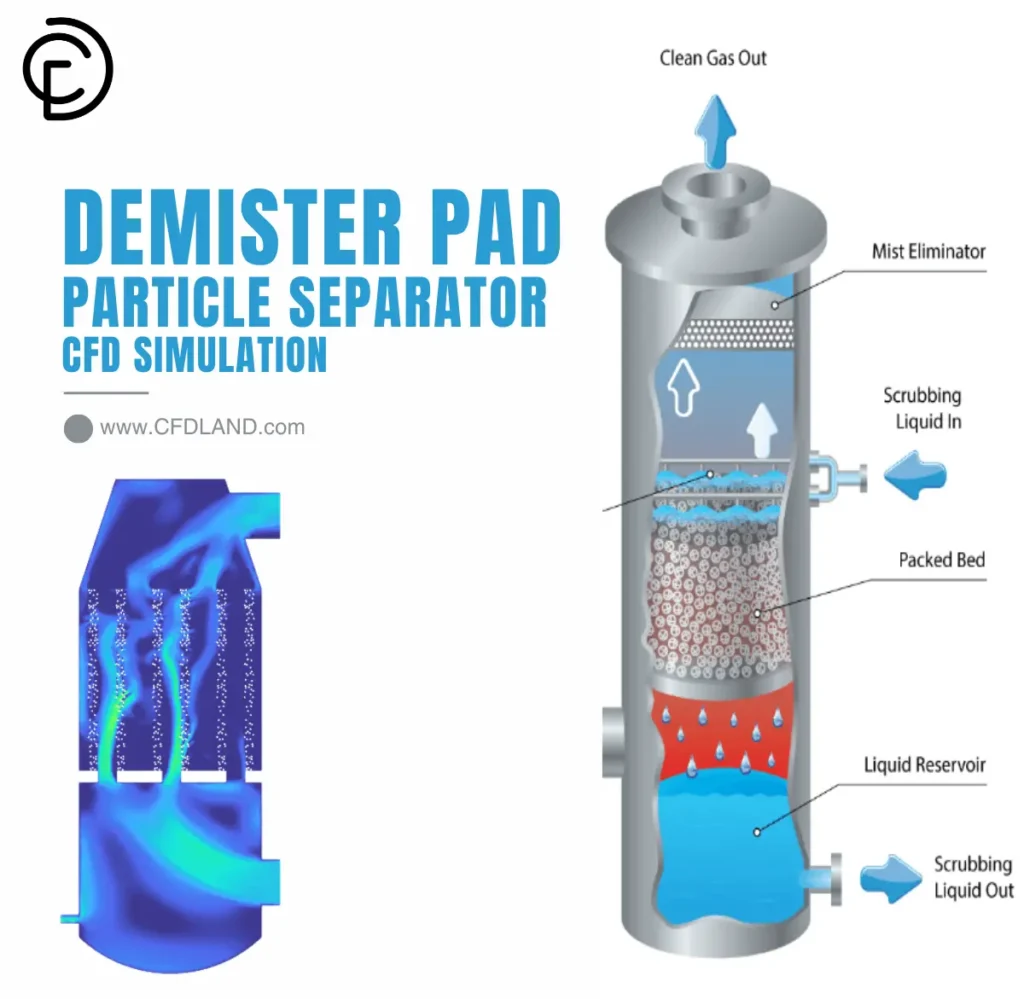

- Filtration separator: A filtration separator utilizes a porous medium such as a membrane or filter to selectively block particles from a fluid stream, allowing clean fluid to pass through based on size or chemical affinity.

Separators Applications

Separators find extensive application in a variety of industries, including:

Oil and gas industry

Crude oil is a complex mixture of various hydrocarbons, each with different uses. It also contains small amounts of solid particles and impurities like sulfur, nitrogen, and oxygen compounds. Separators are essential tools in the oil and gas industry for separating these components from crude oil during processing.

Food and Beverage Industry

Food preparation relies heavily on separators to achieve a variety of tasks. These tools can be used to gently separate cream from the rich fat content of milk, or to efficiently remove fruit pulp and achieve a clear, refreshing juice.

Environmental Industry

Many industries produce gas or liquid waste that can harm the environment. Separators play a crucial role in pollution control by helping to remove these harmful substances. For example, factory smoke might be passed through a separator to remove soot particles before exiting the chimney. Similarly, separators can be used to partially purify city sewage before it’s released into the environment.

Mining and minerals industry

After mining, many materials undergo processing steps that may involve them being mixed with liquids, often water. These mixtures then sometimes go through separators for further processing.

Pharmaceutical industry

Separators are vital in the pharmaceutical industry for ensuring product purity and consistency. For example, in vaccine production, centrifuges use centrifugal force to separate viral particles from cell debris, ensuring a highly pure vaccine product.

Oil fraction contour from “Two-phase Oil-water Separator CFD Simulation, ANSYS Fluent Training”

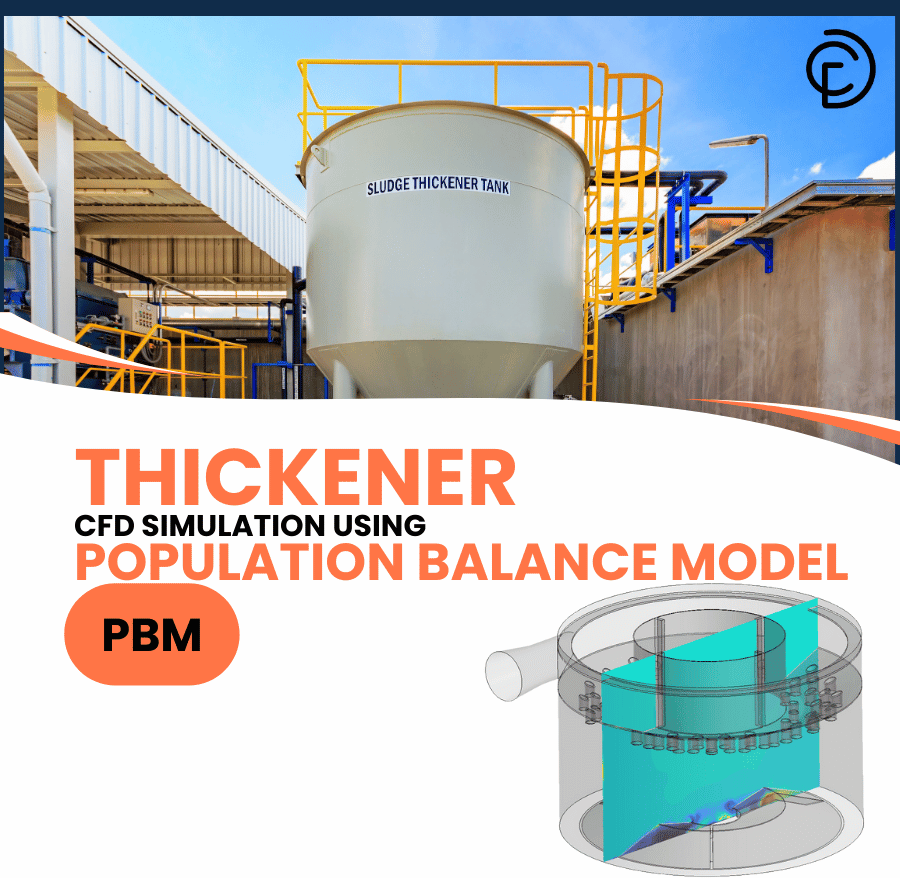

Simulation of Separators by ANSYS Fluent

ANSYS Fluent has the capability to simulate multiphase and turbulent flows effectively, and it also allows for the application of centrifugal, magnetic, and electric forces within the solution domain. Therefore, this software meets all the requirements for simulating separators. With ANSYS Fluent, it is possible to analyze the performance of separators, and it can be used for their design and optimization.

In addition to its efficient solver and algorithms, ANSYS Fluent allows users to draw complex geometries, generate meshes, solve simulations, and perform advanced post-processing.

Particle distribution in Cyclone Separator from “CFD-DEM Particles in Cyclone Separator, ANSYS Fluent & Rocky Coupling”

CFDLAND Expertise in Separators Modeling Using ANSYS Fluent Software

Our experts at CFDLAND excel in simulating separators. Submit your CFD projects to us at Order Project, and you will be surprised by the results of our work. We have many ready-made projects in the field of separators available in CFD Shop. Delve into them; the project you want might be among them.