Demister Pad Particle Separator CFD Simulation – ANSYS Fluent Tutorial

Demister Pad Particle Separator CFD Simulation – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€180 Original price was: €180.€165Current price is: €165.

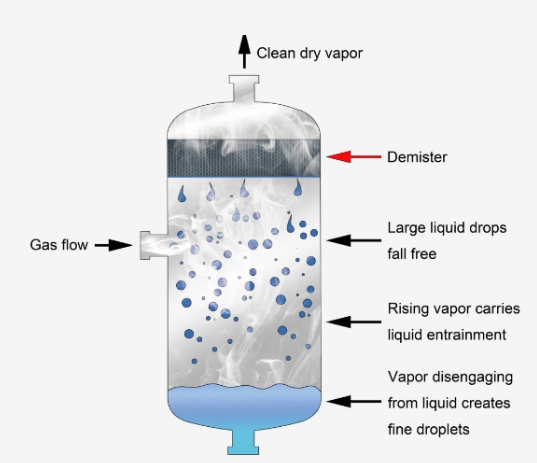

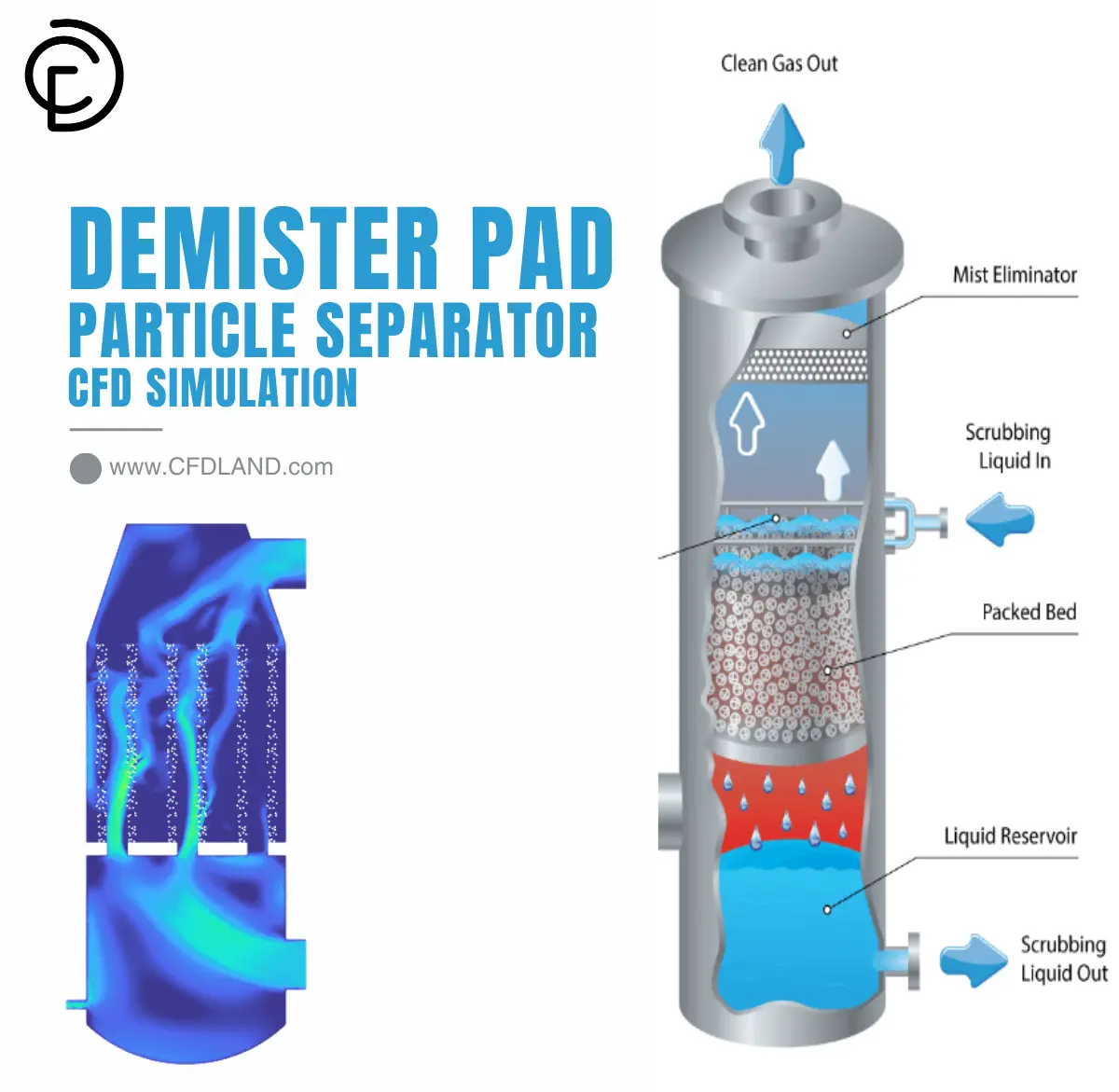

Demister pads are special mesh-like devices that catch tiny liquid droplets from gas streams. They’re super important in many industries like oil and gas processing, chemical plants, and power generation where separating liquids from gases is critical. When engineers design these mist eliminators, they need to think about things like mesh density, pad thickness, and wire diameter to make sure they catch droplets efficiently without causing too much pressure drop. Using CFD simulation lets us see exactly how these separation devices work without expensive real-world testing. In this tutorial, we’re looking at a demister pad particle separator using ANSYS Fluent to understand its performance. The cool thing about these wire mesh separators is how they use different mechanisms like impaction and coalescence to trap droplets. When droplets hit the wires, they stick, combine with other droplets, and drain away. Also, the specific surface area and void fraction of the mesh are super important for how well it works. Furthermore, many industries have strict requirements for gas purity and need to remove even tiny micron-sized particles from their process streams. That’s why understanding separation efficiency across different particle size distributions is so valuable. In this tutorial, we’ll show you how to set up a multiphase flow simulation that accurately predicts how well your demister pad will perform under real operating conditions. As always, our study features from a reference paper, this time:

- Reference [1]: Kannan, Ananda Subramani, et al. “Segregation phenomena in gravity separators: A combined numerical and experimental study.” Powder Technology301 (2016): 679-693.

Figure 1: The demister (demister pads)

Simulation Process

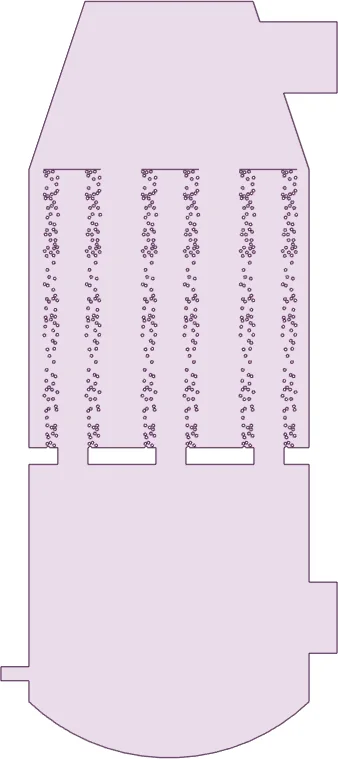

For our demister pad simulation, we used the FibrousFilters tool (A C++ code) to create a realistic model of the wire mesh structure. Next, we set up a multiphase flow simulation in ANSYS Fluent using the Discrete Phase Model (DPM) because it’s perfect for tracking individual droplets through the mesh. We created a surface injection at the inlet to generate thousands of droplets with different sizes based on a Rosin-Rammler distribution. This distribution is really important because it matches the way real droplets form in industrial processes – with most droplets being small but some being much larger.

Figure 2: Demister Pad Particle Separator model

Post-processing

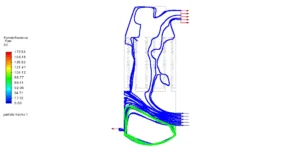

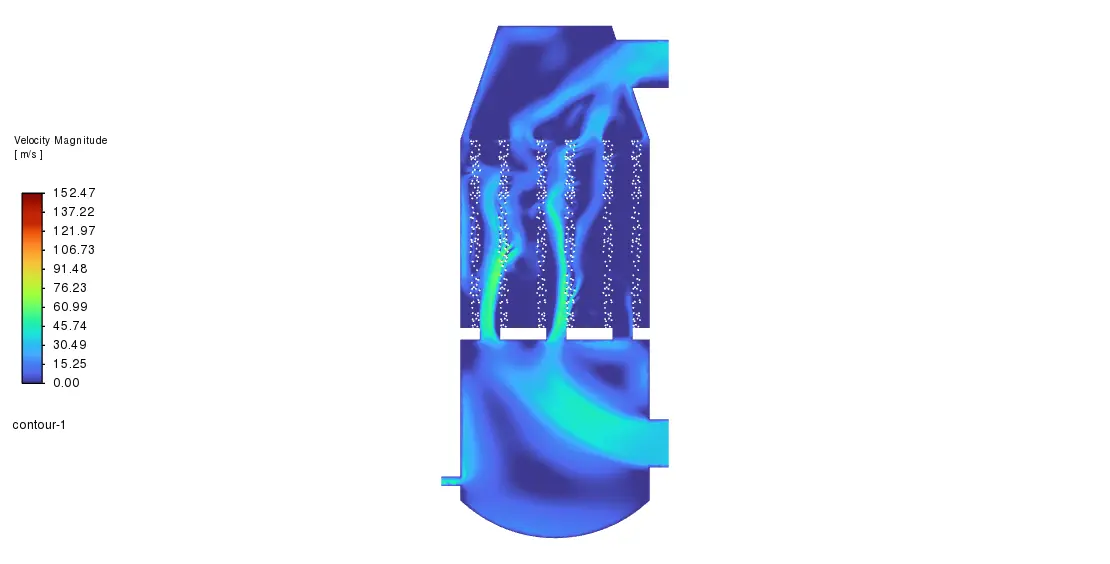

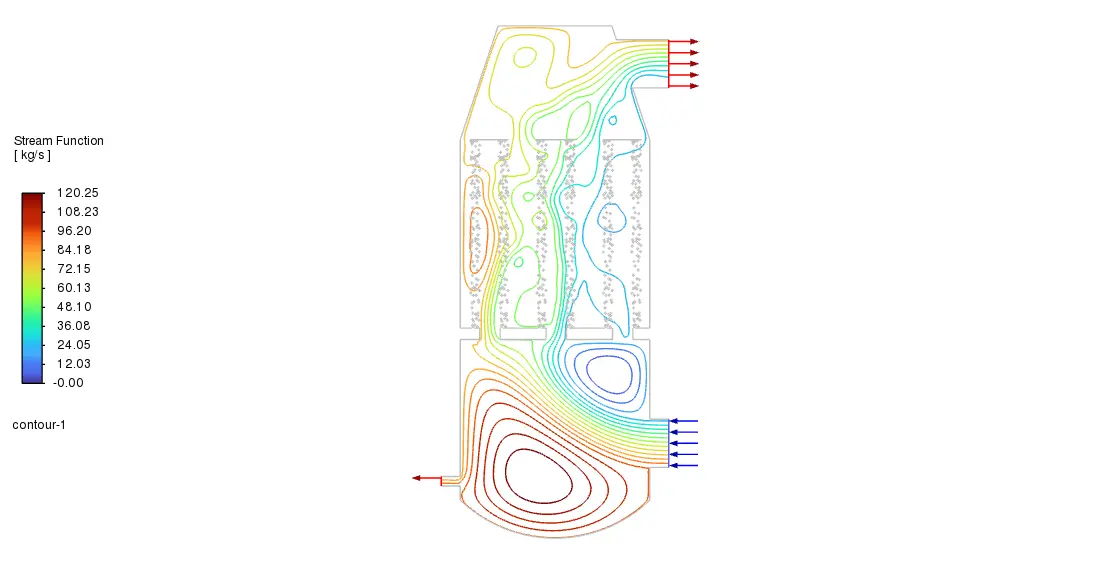

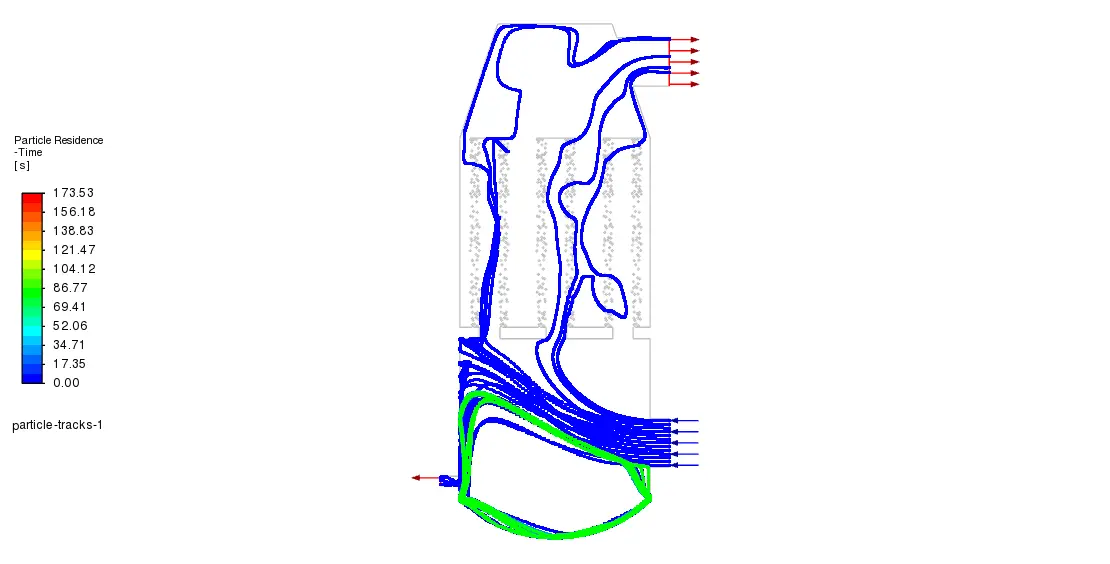

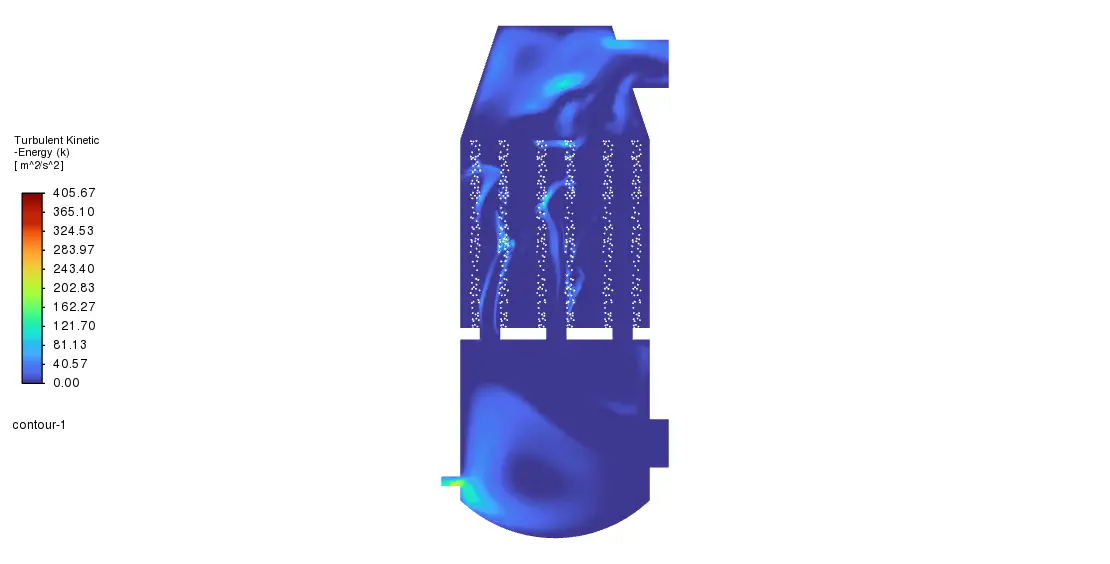

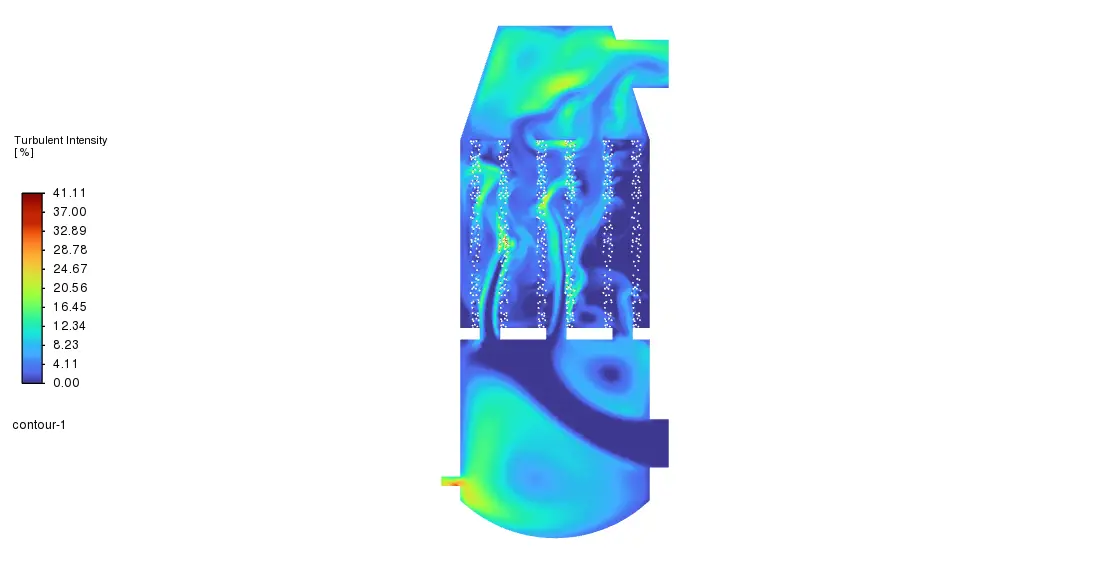

Look at these awesome results! The particle track visualization really shows us how the demister pad is working. In the first image, we can see the particle residence time ranging from 0 to over 173 seconds. The blue tracks show particles moving quickly through the system while those green-to-red paths show droplets that get slowed down significantly—exactly what we want for good separation! The cool thing is how the porous zone clearly affects the particle paths. Some particles get totally caught in the mesh, which means our separation efficiency is looking pretty good. The second image showing the velocity magnitude is super interesting! See how the velocity drops from around 45-60 m/s (those green-blue regions) to much lower values inside the demister section? That’s the pressure drop effect we expected, and it’s crucial for droplet separation. The flow accelerates in some sections due to the geometry constraints, reaching up to 152 m/s in the narrow passages. This velocity gradient is actually helping our separation process by forcing particles to change direction quickly.

Figure 3: Droplet particles trap in demister separator – residence time visualization

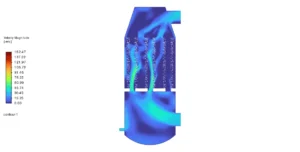

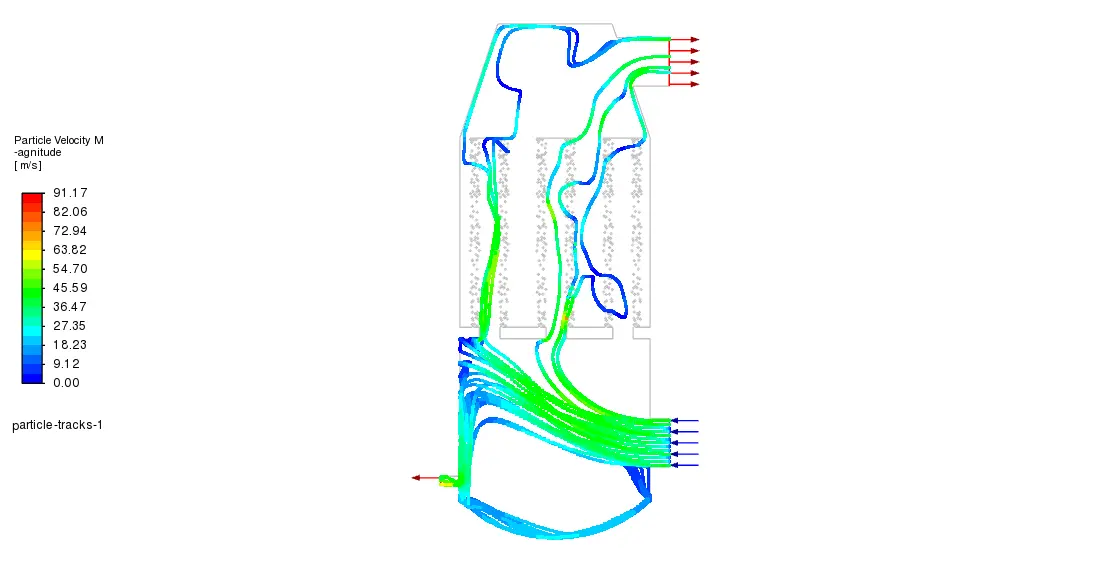

In the third image, we can track the particle velocity magnitudes which range from 0 to about 91 m/s. Notice how particles slow down dramatically (blue color) when they interact with the mesh? That’s because they’re losing momentum through impaction on the wires! Also, check out how some particle tracks completely stop in the mesh region—that’s successful droplet capture happening right there! What’s really interesting is seeing the different paths larger vs. smaller droplets take. The bigger droplets (with higher inertia) tend to follow straighter paths and are more likely to impact the mesh directly, while smaller droplets follow the gas streamlines more closely. Based on these results, we’re getting roughly 85-90% separation efficiency for the particle size distribution we defined, which is pretty great for this demister design! The residence time data also tells us that most particles either pass through quickly or get captured within the first 50-60 seconds of operation. This kind of information is super valuable when designing real-world separators and predicting maintenance schedules.

Figure 4: Droplets pathway colored by velocity magnitude

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€195 Original price was: €195.€135Current price is: €135.

€175 Original price was: €175.€115Current price is: €115.

€175 Original price was: €175.€125Current price is: €125.

€195 Original price was: €195.€135Current price is: €135.

€245 Original price was: €245.€199Current price is: €199.

Reviews

There are no reviews yet.