Drying Grains CFD, A DDPM-DEM Fluent and MATLAB Coupling Tutorial

Drying Grains CFD, A DDPM-DEM Fluent and MATLAB Coupling Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€245 Original price was: €245.€199Current price is: €199.

Proper grain drying is a critical post-harvest process in the global agriculture industry, essential for preventing spoilage and ensuring long-term food security. The core challenge is to remove moisture from the individual grains efficiently without damaging them. This involves complex Heat and Mass Transfer phenomena, where heat is transferred from hot air to the grains, and moisture is transferred from the grains into the air. Traditional drying methods are often inefficient, leading to high energy consumption and non-uniform drying, which can cause significant financial losses.

To optimize this process, engineers are turning to advanced simulation. A Drying CFD analysis offers a powerful way to investigate the airflow, temperature, and moisture distribution within a grain bed. However, simulating Drying Grains presents a unique challenge: the grains are a dense collection of discrete particles. To capture this physics accurately, we must use a coupled simulation approach. This project details a DDPM – DEM CFD Fluent simulation. We use the Discrete Element Method (DEM) to model the particle-to-particle interactions and the Dense Discrete Phase Model (DDPM) to handle the two-way coupling between the thousands of grains and the continuous air phase. This methodology is based on leading research, such as the work by Azmir, et al. [1].

- Reference [1]: Azmir, Jannatul, Qinfu Hou, and Aibing Yu. “CFD-DEM simulation of drying of food grains with particle shrinkage.” Powder Technology343 (2019): 792-802.

Figure 1- An example of traditional grain drying systems which modern CFD simulations aim to improve.

Simulation Process: CFD Modeling of Drying, Coupling DDPM-DEM in Fluent with MATLAB

The simulation was built upon a simple 2D rectangular geometry created in ANSYS Design Modeler, with a structured mesh applied to accurately resolve the flow. The complexity of this project lies entirely in the physics setup within ANSYS Fluent. Given the multiphase flow nature of the problem, an Eulerian-Lagrangian approach was selected.

Three critical models were combined to make this Drying Fluent simulation possible. First, the Dense Discrete Phase Model (DDPM) was activated. This is essential because the volume fraction of grains is high, and DDPM is specifically designed to account for the effect of the particle volume on the continuous air phase. Second, to simulate the physical interactions between individual grains (collisions and friction), the Discrete Element Method (DEM) was enabled. A standard Drying DPM CFD simulation would fail here because it cannot account for these crucial particle-level forces. Third, to track the evaporated moisture, the Species Transport model was used to define and solve for water vapor in the air. A key innovation in this workflow was the ANSYS Fluent and MATLAB coupling. A custom MATLAB script was written to generate an initial particle position file. This file was used for the DPM Injection, ensuring the grains started in an organized array without any unrealistic overlap, a critical step for a stable DEM CFD simulation.

Post-processing: CFD Analysis of Moisture and Temperature Dynamics in the Grain Bed

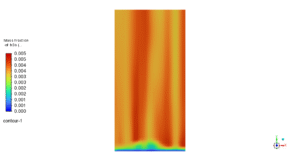

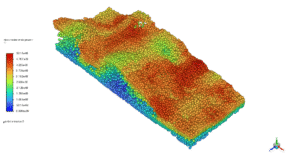

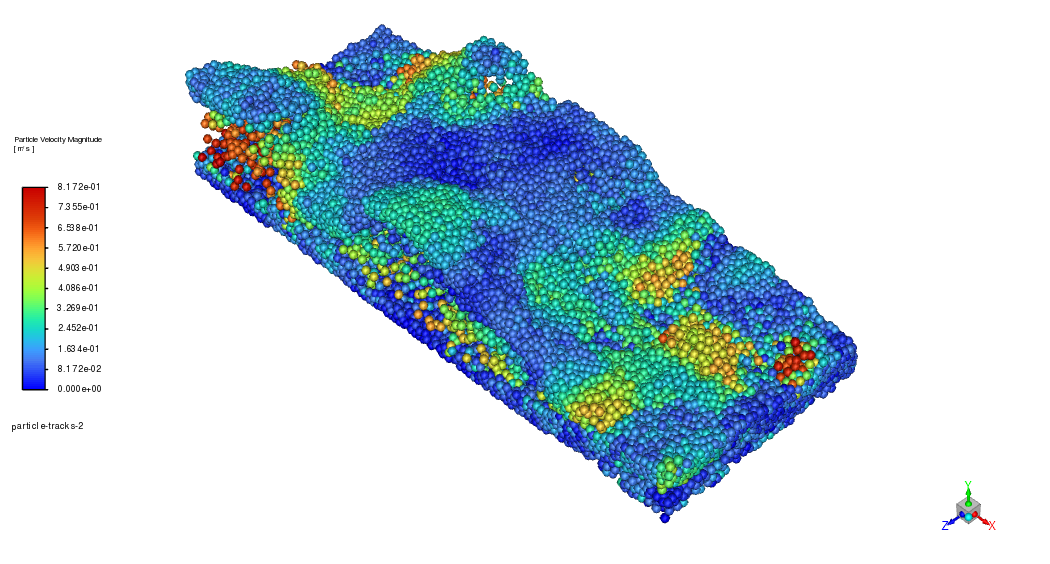

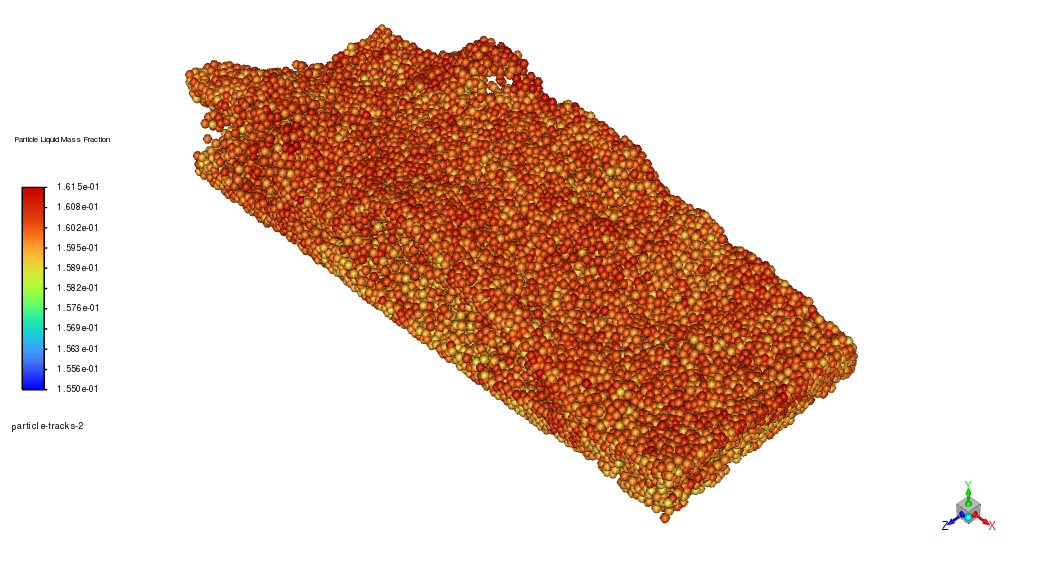

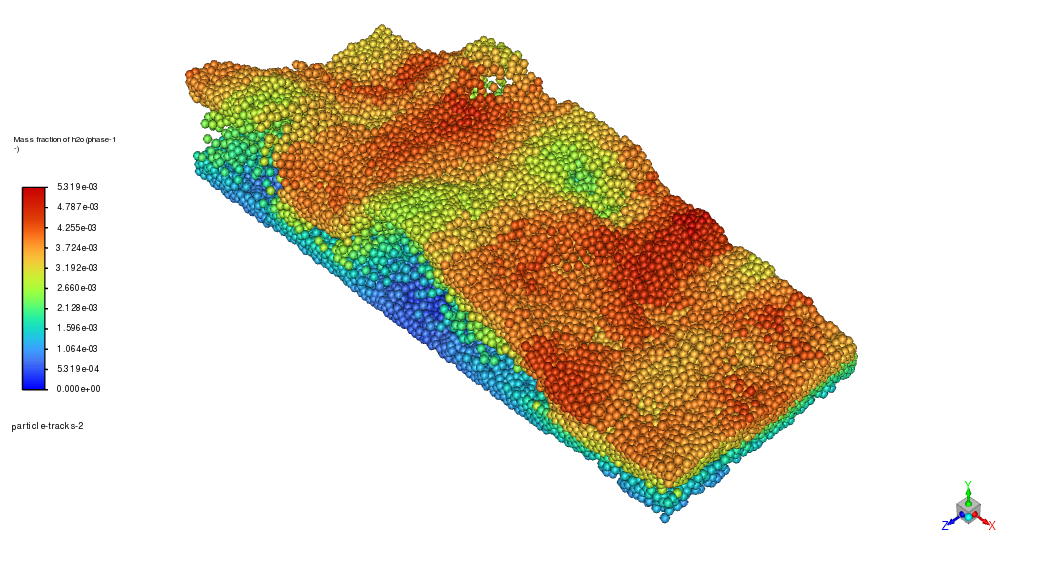

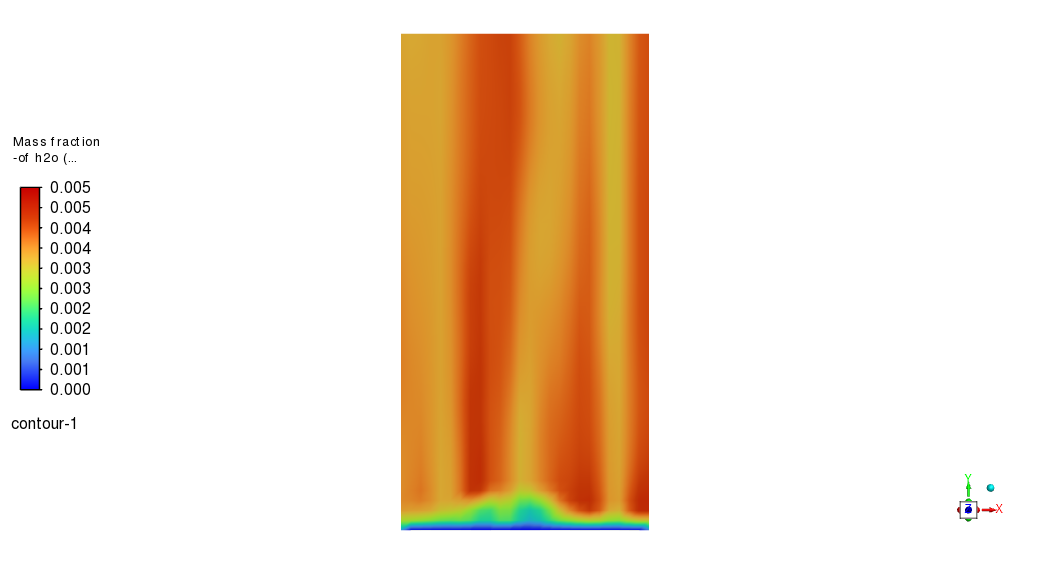

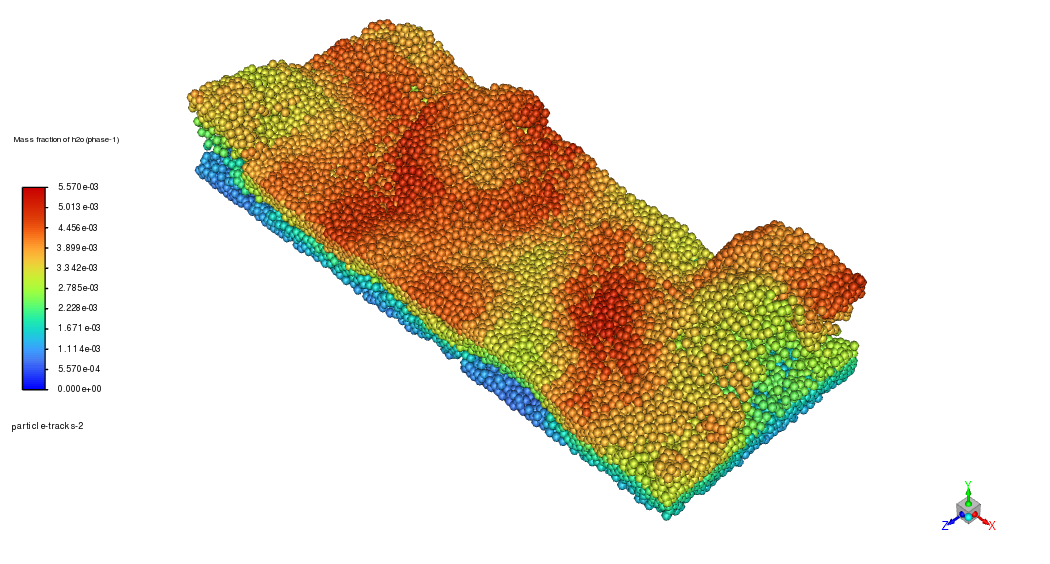

The simulation results provide a clear and detailed insight into the drying process. Figure 2 shows the water mass fraction within the individual grains over time. The analysis of over 5,000 particles reveals a highly non-uniform drying pattern, with moisture mass ratios ranging from 0 up to 0.005319. The highest moisture content remains concentrated in the upper layers of the bed. This is because the hot drying air enters from the bottom and loses its capacity to absorb more water as it travels upwards. The simulation accurately captures the formation of “moisture channels,” which are preferential paths the air takes through the grain bed. This non-uniform behavior is a well-known phenomenon, and its successful prediction serves as a strong validation of our DDPM-DEM model.

Figure 2: Water mass fraction distribution showing moisture content within the particles during the DEM-CFD drying simulation.

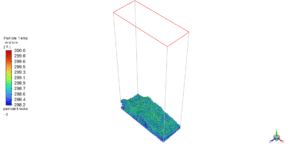

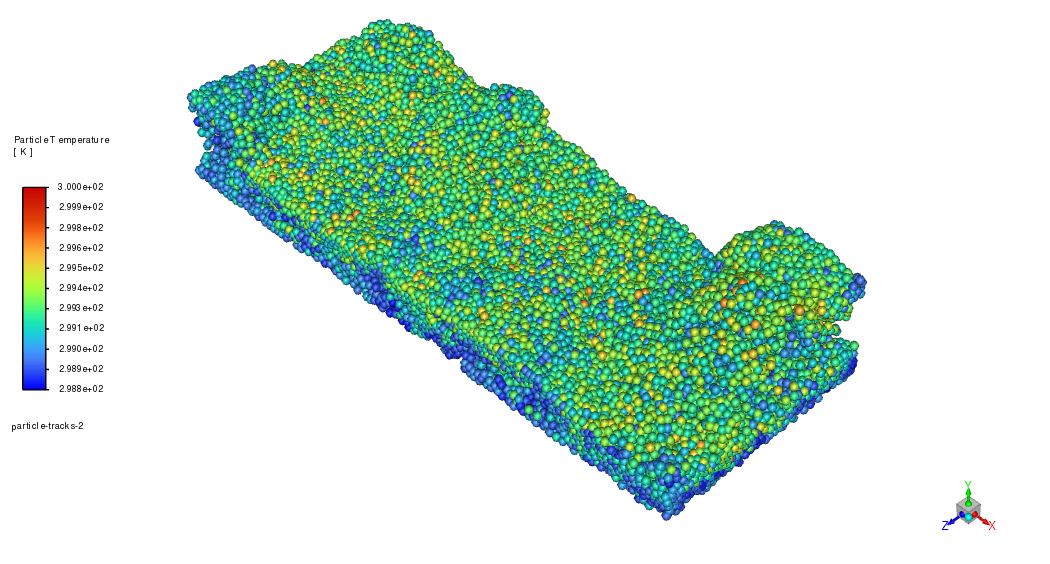

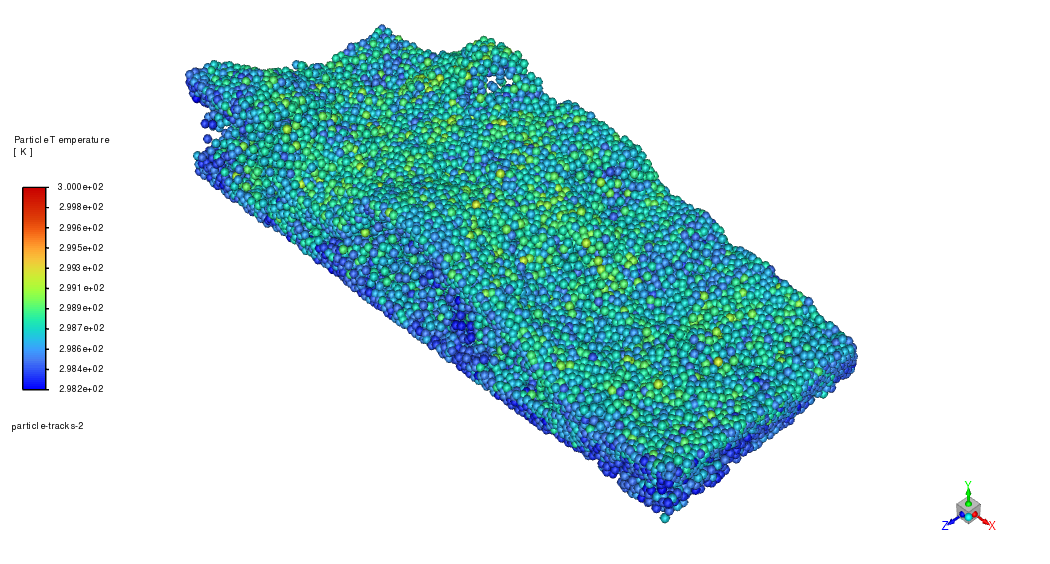

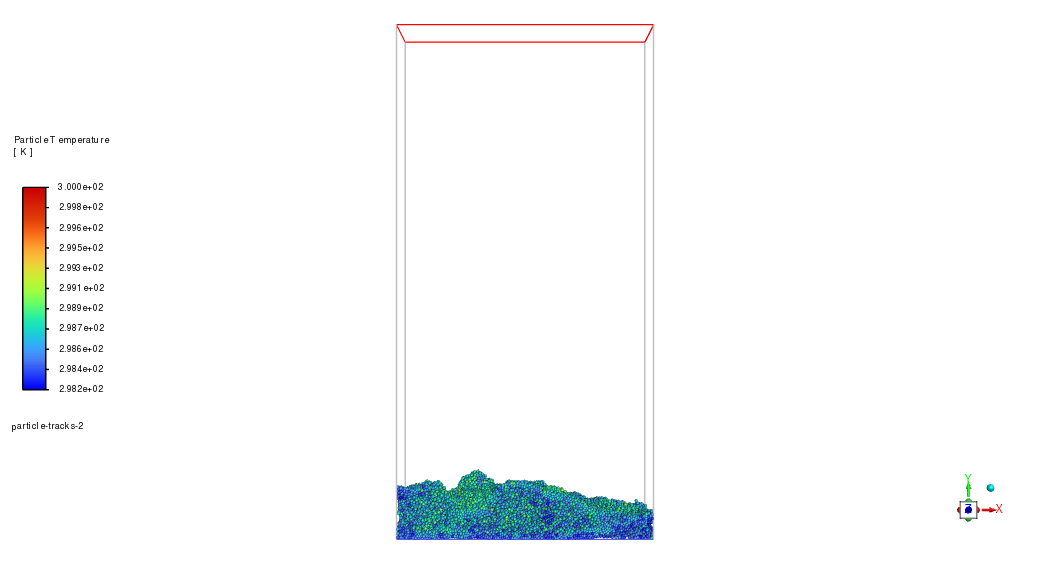

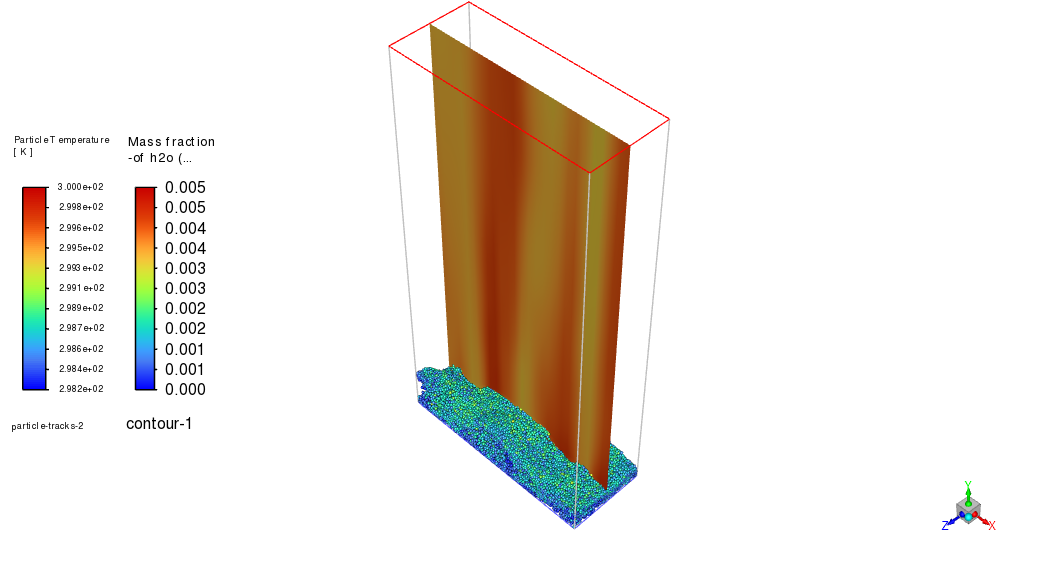

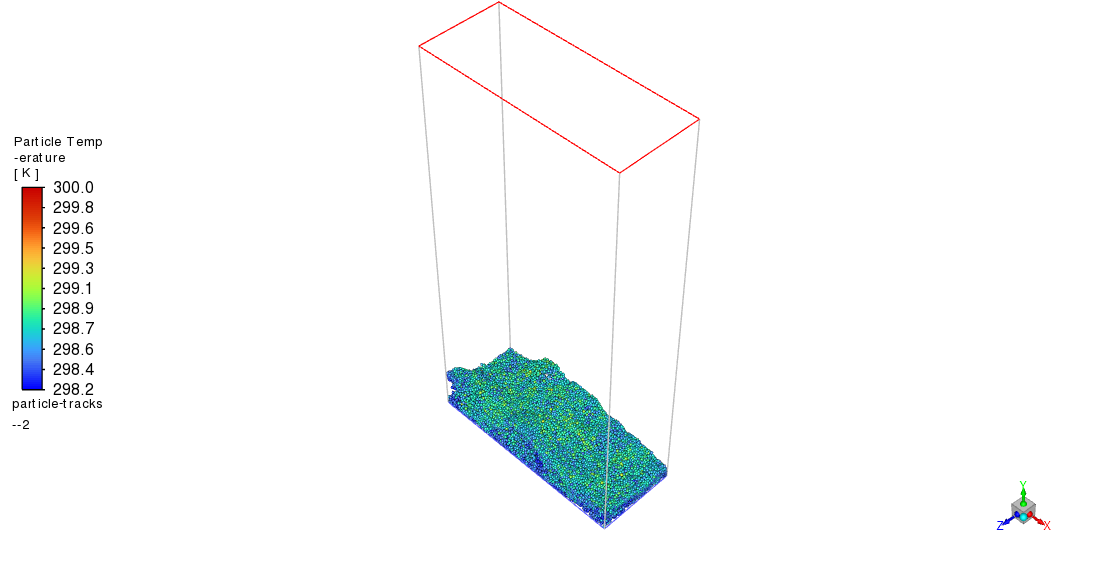

Figure 3, which shows the temperature distribution of the particles, completes the story. We observe a temperature range from a cool 298.2K to 300.0K. Crucially, the coolest spots in the bed correspond perfectly with the areas that have the highest moisture content. This is a direct consequence of the physics of evaporation: as water turns into vapor, it absorbs energy from the grain in a process known as the latent heat of vaporization, actively cooling it down. The small overall temperature difference (1.8K) indicates that heat transfer from the air to the grains is relatively fast. However, the persistence of these cool, wet zones demonstrates that the mass transfer—the physical removal of moisture—is the much slower, rate-limiting step in the drying process. This fundamental insight, revealed by our Drying Grains CFD simulation, is exactly the kind of knowledge engineers need to design more efficient and effective drying systems.

Figure 3: Particle temperature distribution across the grain bed, highlighting cooler zones where evaporation is most active.

The animation extracted from the transient (unsteady) CFD simulation is shown below:

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€140 Original price was: €140.€85Current price is: €85.

€180 Original price was: €180.€150Current price is: €150.

€170 Original price was: €170.€99Current price is: €99.

€360 Original price was: €360.€185Current price is: €185.

€190 Original price was: €190.€145Current price is: €145.

€245 Original price was: €245.€185Current price is: €185.

Reviews

There are no reviews yet.