Heat Transfer CFD Simulation

€185 Original price was: €185.€135Current price is: €135.

€195 Original price was: €195.€155Current price is: €155.

€155 Original price was: €155.€125Current price is: €125.

€125 Original price was: €125.€99Current price is: €99.

€175 Original price was: €175.€135Current price is: €135.

€185 Original price was: €185.€155Current price is: €155.

What is Heat Transfer?

Heat transfer is the movement of thermal energy between systems at different temperatures, occurring through conduction, convection, radiation, and advection. It’s a fundamental principle in physics, guided by the second law of thermodynamics, and essential in countless real-world applications — from solar heating and weather formation to industrial design and heat exchanger CFD simulations. Engineers use heat transfer methods to manage temperature effectively, ensuring performance, safety, and energy efficiency across systems. Advanced tools like ANSYS Fluent heat transfer modeling and conjugate heat transfer CFD allow precise simulation of thermal behavior, enabling optimized designs for HVAC, electronics, power plants, and more. Whether it’s calculating the heat transfer coefficient in ANSYS Fluent, analyzing heat conduction, or simulating heat transfer CFD, mastering thermal energy control is key to modern engineering solutions.

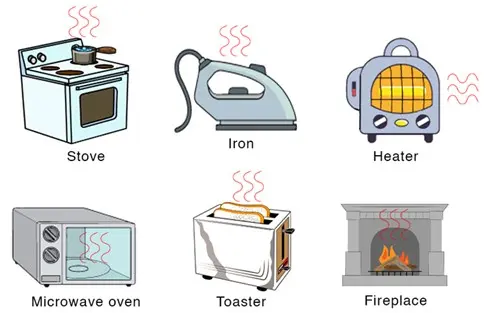

Figure 1- Examples of Thermal (Heat) Energy in Daily Life

Fundamentals of Heat Transfer

Understanding the fundamentals of heat transfer is essential for engineers, scientists, and CFD practitioners working in fields like thermal management, energy systems, and industrial design. Core concepts such as convection currents, thermal conductivity, heat transfer coefficient, and phase change play a vital role in predicting and controlling temperature distribution in physical systems. This guide summarizes the essential terms and their applications to help you master the basics and optimize your heat transfer CFD and conjugate heat transfer simulations more effectively. Here are some important terms used in heat transfer and their meaning.

Temperature

Temperature measures the kinetic energy of atoms and molecules, which directly influences heat transfer rates.

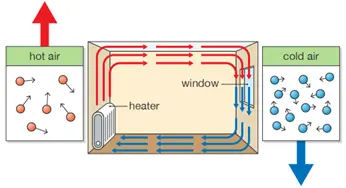

Convection Currents

Convection currents occur when a fluid experiences localized heating, causing its temperature to rise and density to decrease. This density difference creates a buoyancy force that pushes the warmer fluid upward until it cools and sinks again, creating a circulation pattern. These currents are a classic example of convective heat transfer seen in everyday situations like boiling water, where the fluid movement helps transfer heat efficiently.

Figure 2- Convection Current in a Room

Heat Capacity or Thermal Mass

Table 1- Heat Capacity (Thermal Mass) Values for Common Materials

| Material | Specific Heat Capacity (J/kg·K) | Notes for CFD/ANSYS Use |

| Water (liquid) | 4186 | High thermal mass; excellent for cooling simulations |

| Aluminum | 900 | Common in heat exchangers; good conductor |

| Copper | 385 | Excellent thermal conductor but low heat capacity |

| Steel (carbon) | 490 | Used in structural applications; moderate thermal mass |

| Air (at 25°C) | 1005 | Essential for convection modeling in ANSYS Fluent |

| Concrete | 880 | High thermal mass; used in building heat transfer models |

| Glass | 840 | Transparent solids; used in radiative and conduction studies |

| Ice | 2100 | Important for phase change and melting simulations |

| Wood (dry) | 1700 | Varies with moisture content; used in natural convection |

| Glycerin | 2410 | Common in chemical processes; high heat capacity |

Heat Flux

Heat flux quantifies the amount of heat energy transferring through a unit surface area over time. It is a crucial parameter for engineers performing heat transfer CFD analysis, helping to determine the rate at which heat moves between solids, fluids, or across system boundaries.

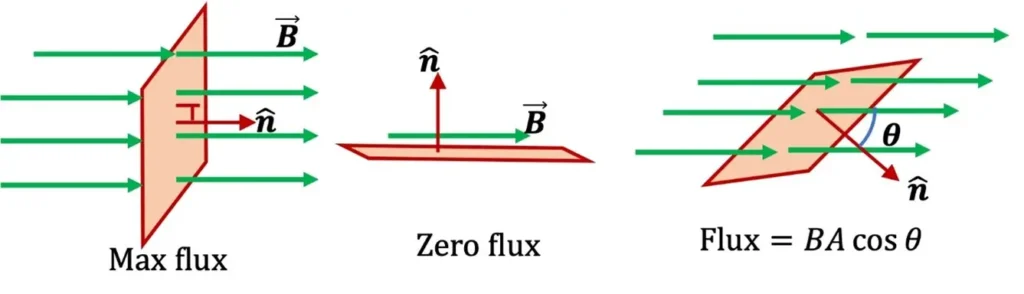

Figure 3- Magnetic Flux Through Different Surfaces

Heat Generation

Heat generation refers to the creation of thermal energy within a system, caused by processes such as chemical reactions, combustion, electrical resistance, friction, or pressure changes. Accurately modeling heat generation is vital for effective heat transfer modeling in tools like ANSYS Fluent heat transfer simulation.

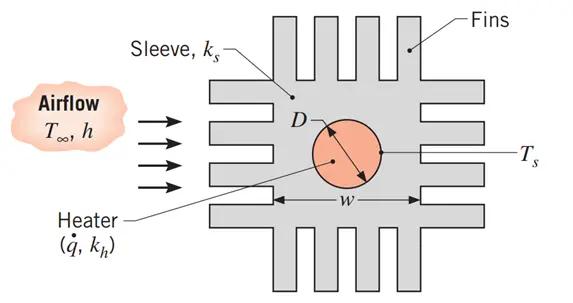

Figure 4- The elemental unit of an air heater consists of a long circular rod of diameter D, which is encapsulated by a finned sleeve and in which thermal energy is generated by ohmic heating.

Heat Transfer Coefficient

The heat transfer coefficient (h) describes the efficiency of heat exchange between a surface and a contacting fluid. It links the heat flux to the temperature difference between the two and depends on fluid velocity and thermal properties. This coefficient is often used in ANSYS Fluent heat transfer coefficient calculations and is critical for designing heat exchangers and cooling systems.

Mass Transfer

While heat transfer focuses on energy movement, mass transfer involves the physical movement of mass between systems. Because mass carries thermal energy, understanding mass transfer helps improve the accuracy of heat transfer models, especially in fluid flows over heated surfaces like heat sinks.

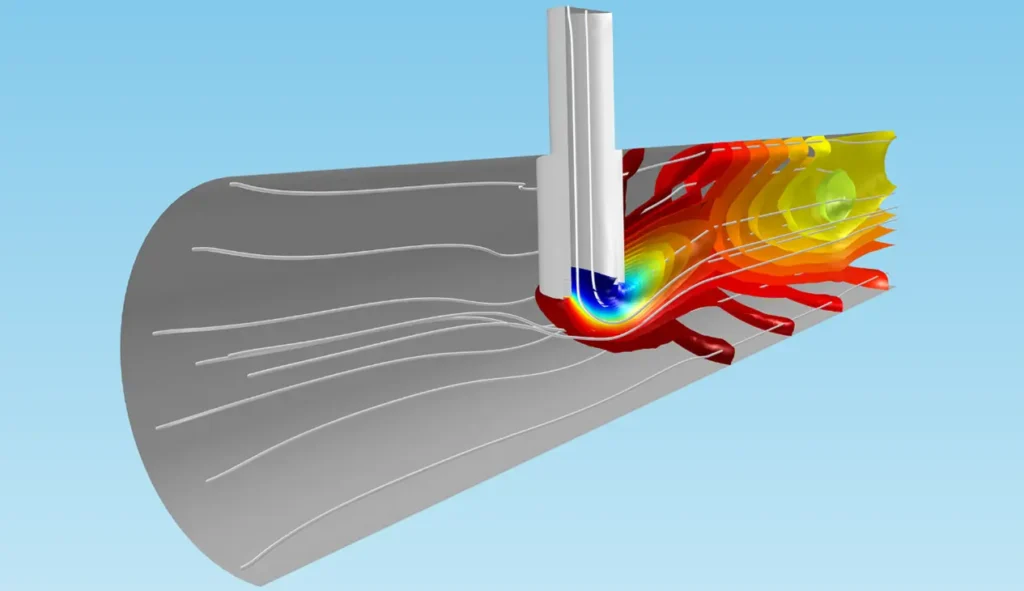

Figure 5- Transport and reactions in a reactor: The concentration isosurfaces reveal mass transfer through diffusion and convection.

Phase Change

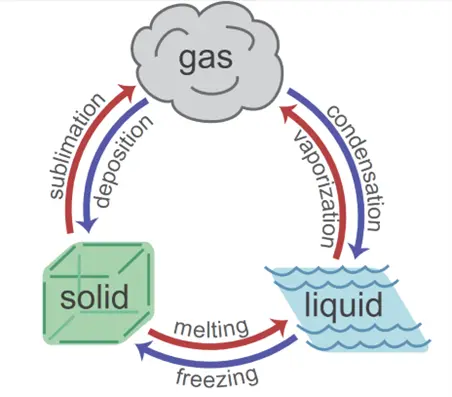

When matter undergoes a phase change—from solid to liquid (melting) or liquid to gas (vaporizing)—it absorbs heat, while changing from gas to liquid (condensation) or liquid to solid (freezing) releases heat. Although phase change itself isn’t heat transfer, it plays a vital role in heat transfer systems to control temperature. Engineers use phase change processes to efficiently manage heat in applications like heat exchangers, heat transfer in ANSYS Fluent, and other heat transfer simulations.

Figure 6- Types of Phase Changes between States of a Matter

Thermal conductivity

The thermal conductivity (k) of a material defines its ability to conduct heat, with higher conductivity indicating faster heat flow. This property is essential in selecting materials and modeling heat conduction in heat transfer ANSYS projects.

Thermal Energy

Heat refers to the internal energy of matter, driven by the microscopic motion of subatomic particles, atoms, and molecules. As temperature rises, this energy increases. In heat transfer physics, heat specifically means the thermal energy in transit between systems. However, in most heat transfer applications, including ANSYS Fluent heat transfer simulations, the terms heat and thermal energy are often used interchangeably.

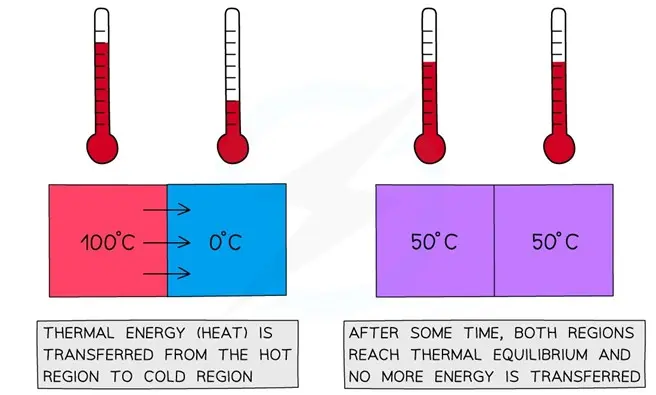

Thermal Equilibrium

Thermal equilibrium occurs when two objects in contact reach the same temperature, causing heat transfer between them to stop.

Figure 7- Thermal Equilibrium Definition

Thermodynamics and Heat Transfer Physics

Thermodynamics is the physics branch that studies heat, work, temperature, and energy transformations. Heat transfer physics is a subfield focusing on how heat energy moves within and between materials, governed by the laws of thermodynamics. This knowledge underpins advanced heat transfer ANSYS Fluent simulations and practical engineering designs.

Heat Transfer Coefficient CFD

In Computational Fluid Dynamics (CFD), the heat transfer coefficient is a fundamental parameter that quantifies how effectively heat is transferred from a surface to a fluid. In ANSYS Fluent, the heat transfer coefficient CFD analysis enables engineers to evaluate thermal performance across various applications such as heat exchangers, electronic cooling systems, and HVAC design. The ANSYS Fluent heat transfer coefficient is typically derived using surface heat flux and temperature differences between the wall and fluid.

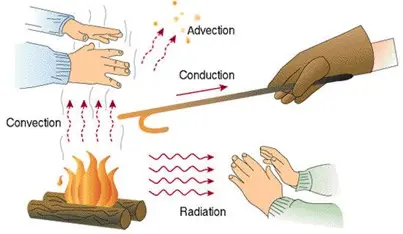

The Four Types of Heat Transfer

Heat transfer refers to the movement of thermal energy from a hotter object to a cooler one. This energy transfer occurs through four primary mechanisms: advection, conduction, convection, and radiation. In real-world applications, more than one method of heat transfer often occurs simultaneously—depending on the surrounding environment, material properties, and fluid flow.

Figure 8- Four Types of Heat Transfer: Advection, Conduction, Convection, and Radiation

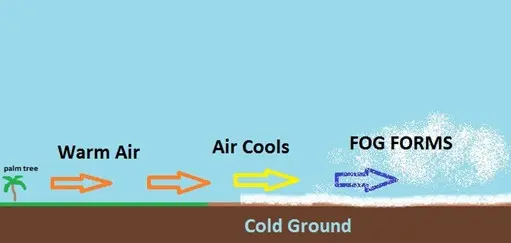

Advection

Thermal advection is the mechanism of thermal energy transfer where heat is transported from one location to another through the motion and momentum of a fluid. Advection is sometimes referred to as forced convection to differentiate it from the strict definition of convection because the fluid flow in advection is not caused by buoyancy forces but instead is imparted by adding energy to the system.

Example: A fan cooling a computer motherboard is an example of advective heat transfer.

Figure 9- Advection Fog by Wind

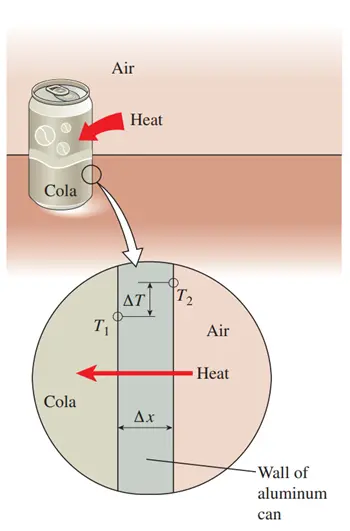

Conduction

Thermal conduction is the transfer of heat through direct contact or within a solid due to a temperature difference. Governed by Fourier’s law of heat conduction, this mode depends heavily on the material’s thermal conductivity and the existing temperature gradient.

Example: A metal spoon getting hot after being left in a pot of boiling water demonstrates heat conduction.

Figure 10- Heat conduction from warm air to a cold canned drink through the wall of the aluminum can.

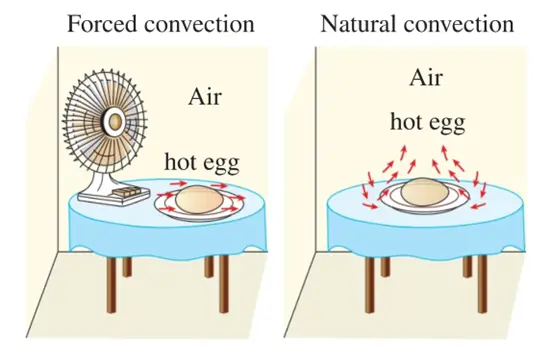

Convection

Convection heat transfer occurs when heat is carried away by fluid motion driven by temperature-induced density differences. This is referred to as free convection or natural convection, and it’s highly relevant in systems like HVAC, heat exchangers, and electronic cooling.

Example: A cup of hot coffee cooling down as warm air rises from its surface is an example of convective heat transfer.

Figure 11- The cooling of a boiled egg by forced and natural convention

Radiation

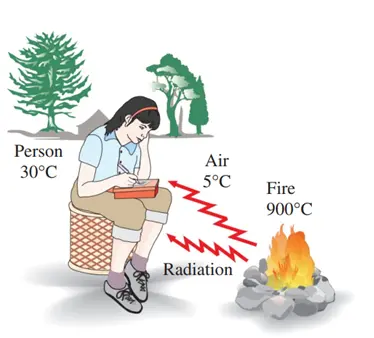

Radiation heat transfer is the emission of thermal energy via electromagnetic waves—typically in the infrared spectrum. Unlike conduction or convection, radiation does not require a medium and can occur in a vacuum. All bodies emit radiant energy based on their temperature.

Example: The heat felt from sunlight is due to radiative heat transfer from the sun through space.

Figure 12- Unlike conduction and convection, heat transfer by radiation can occur between two bodies, even when they are separated by a medium colder than both of them.

Heat transfer formulation

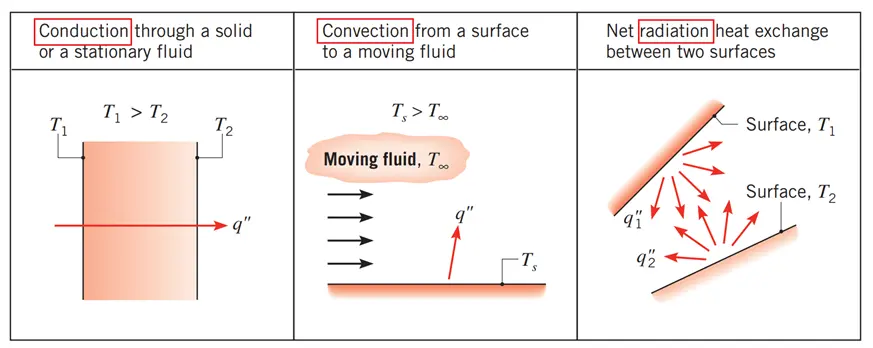

Fig.13 illustrates the three primary modes of heat transfer: conduction, convection, and radiation. On the left, conduction is depicted as heat transfer through a solid or stationary fluid, where thermal energy moves from a region of higher temperature (T1) to a region of lower temperature (T2), indicated by the heat flow (q′′). In the center, convection is shown as heat transfer from a surface (Ts) to a moving fluid, where the surface temperature is greater than the fluid temperature (T∞). The arrows represent the movement of the fluid and the direction of heat transfer. Finally, on the right, radiation is illustrated as the net heat exchange between two surfaces at different temperatures (T1 and T2), with the arrows indicating the emission and absorption of thermal radiation between the surfaces. Together, these modes explain how heat energy is transferred in various physical situations.

Figure 13- Modes of Heat Transfer: Conduction, Convection, and Radiation

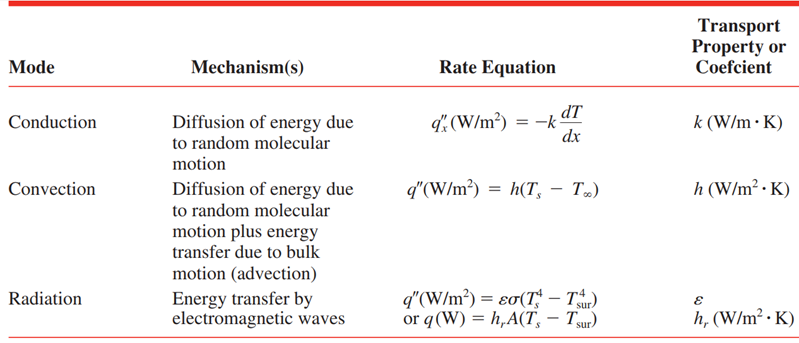

The Fig.14 presents a comprehensive overview of the three primary modes of heat transfer: conduction, convection, and radiation. Each mode is described in terms of its mechanism and associated rate equations. For conduction, the energy transfer occurs through the diffusion of energy due to random molecular motion, represented by the equation , where k is the thermal conductivity. Convection involves both molecular diffusion and bulk motion (advection), characterized by the rate equation , with h being the convective heat transfer coefficient. Lastly, radiation is defined as energy transfer via electromagnetic waves, with its rate described by the equation , where ε is the emissivity and σ is the Stefan-Boltzmann constant. In the context of heat transfer, represents the surface temperature of an object, is the temperature of the surrounding environment or surface, and , denotes the temperature of the fluid far away from the surface or object.

Figure 14- summarizes the fundamental principles governing heat transfer processes in various applications.

Heat Transfer Applications

Heat transfer plays a critical role in physics, engineering, and everyday life. Whether it is heat conduction, convection, or radiation, managing thermal energy effectively is key to optimizing system performance. In industries ranging from electronics to aerospace, the application of heat transfer in physics is supported by advanced modeling tools like ANSYS Fluent and CFD simulations. Below are several high-impact applications where heat transfer mechanisms are crucial.

Cooking and Food Processing

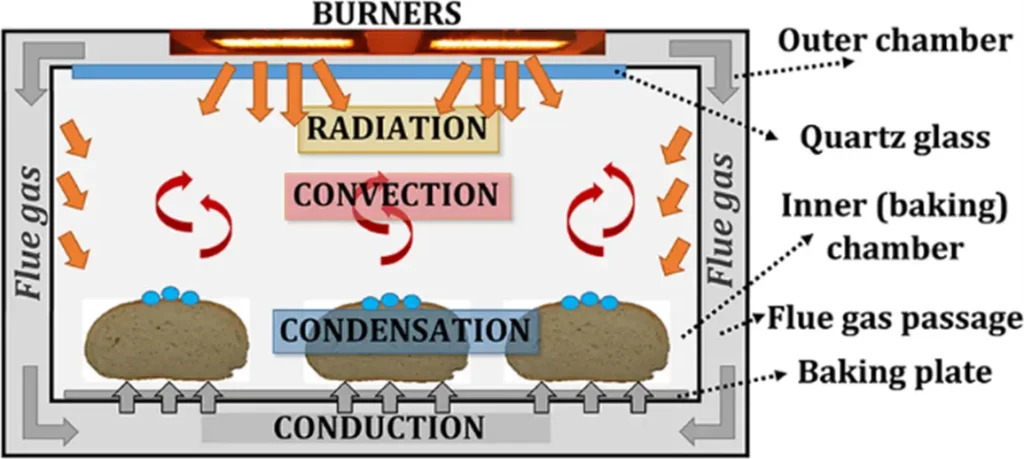

Cooking is a classic example of heat transfer in daily life. Traditional ovens utilize convection and radiation heat transfer to cook food, while modern devices like air fryers apply forced convection (advection). In industrial food processing, CFD heat transfer simulations ensure uniform heating in sterilization, pasteurization, and freezing processes. These simulations enhance food safety and optimize heating equipment design.

Figure 15- Role of Individual Heat Transfer Mechanisms Within a Model Baking Oven Heated by Porous Volumetric Ceramic Burners

Electronics Thermal Management

Electronic components generate heat due to electrical resistance. In smartphones and computers, conduction transfers heat to the casing, followed by natural or forced convection into the air. Using ANSYS Fluent heat transfer simulation, engineers can model heat distribution and improve cooling system design, from heat sinks to active fans.

Figure 16- Active Cooling in Photovoltaic System CFD Simulation, Numerical Paper Validation: ANSYS Fluent heat transfer tutorial

HVAC Systems and Building Climate Control

Heating, ventilation, and air conditioning (HVAC) systems manage indoor temperature and air quality using all three heat transfer modes. ANSYS Fluent HVAC modeling allows for CFD analysis of airflow patterns, thermal insulation, and radiative heat loss through windows. This optimizes comfort while minimizing energy use.

Figure 17- HVAC System of Amphitheater CFD Simulation, ANSYS Fluent heat transfer tutorial

Thermal Power Plants

In thermal power plants, fuel combustion heats water into steam, which drives turbines. Here, conduction, convection, and radiation heat transfer work together. Engineers use heat transfer CFD analysis and heat exchanger CFD simulations to boost thermal efficiency, reduce losses, and ensure safe operation.

Refrigeration and Cooling Systems

The refrigeration cycle is a controlled process of heat extraction. CFD simulations help optimize refrigerant flow, improve heat exchanger performance, and design efficient evaporators and condensers. Whether in household fridges or industrial cooling towers, CFD heat transfer modeling improves both design and energy efficiency.

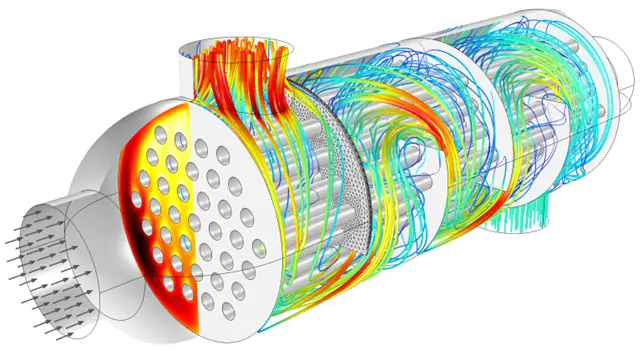

Figure 18- Performance Improvement of Shell & Tube Heat Exchanger with Baffle CFD Simulation: Heat exchanger ANSYS Fluent

Automotive and Electric Vehicles

Internal combustion engines (ICEs) generate immense heat that must be dissipated. Using conjugate heat transfer modeling in ANSYS Fluent, engineers simulate coolant flow, radiator heat exchange, and airflow from vehicle motion or fans. In electric vehicles, thermal management of batteries and motors is critical. Engineers rely on ANSYS Fluent heat conduction simulations to ensure optimal performance.

Figure 19- ANSYS Fluent: CFD simulation for 3D radiator

Advanced Manufacturing and Material Processing

Processes like metal casting, plastic molding, and glass tempering depend on precise thermal control. CFD analysis of heat transfer ensures uniform temperature distribution and phase changes. Simulations help reduce energy consumption while maintaining material quality.

Figure 20- Glass Greenhouse CFD Simulation Using Solar Ray Tracing: Heat transfer ANSYS Workbench

Aerospace and Spacecraft Systems

In space, thermal control is unique due to the absence of air. Systems rely heavily on radiation, conduction, and engineered phase-change materials. Using ANSYS Fluent conjugate heat transfer simulations, engineers model temperature regulation of sensitive instruments like CMOS sensors, balancing incoming solar radiation and outgoing infrared emission.

Medical Device Cooling and Heat Treatments

Medical lasers, RF ablation tools, and diagnostic equipment use radiative and conductive heat transfer. ANSYS Fluent simulations help design thermal profiles for safety and efficiency. CFD modeling ensures precise heat targeting during treatments and effective cooling systems for electronic health equipment.

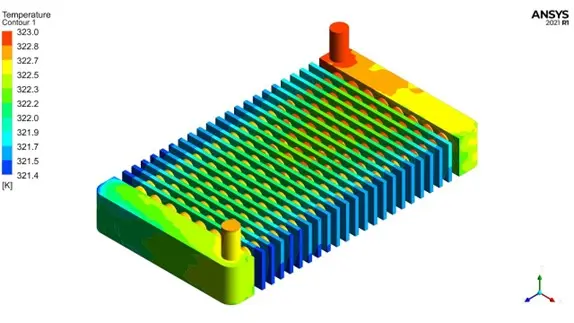

What is Conjugate Heat Transfer?

Conjugate heat transfer refers to the simulation of heat transfer that occurs simultaneously in both solid and fluid domains, including the interface between them. This comprehensive modeling approach captures conduction in solids and convection (and possibly radiation) in fluids, enabling accurate prediction of temperature distribution across different materials. In ANSYS Fluent, conjugate heat transfer CFD simulations are widely used for analyzing systems such as heat exchangers, electronics cooling, and thermal insulation, where fluid-solid interactions significantly affect thermal performance. The ANSYS Fluent conjugate heat transfer setup includes defining material properties, applying appropriate boundary conditions, and ensuring mesh continuity at interfaces. Engineers often follow an ANSYS Fluent heat transfer tutorial to learn best practices for ANSYS Fluent heat transfer modeling and improve solution accuracy.

Figure 21- Heat exchangers are Example of Conjugate Heat Transfer Method

Simulation of Heat Transfer by ANSYS Fluent

ANSYS Fluent is a powerful software widely used for simulating various types of heat transfer in engineering and physics applications. This advanced tool allows for the simultaneous simulation of multiple heat transfer models, including conduction, convection, and radiation. One of the key features of ANSYS Fluent is its support for phase change simulation, enabling accurate calculation of the latent heat of materials during melting, boiling, or condensation processes. Additionally, ANSYS Fluent can handle materials with temperature-dependent properties, allowing users to define thermal parameters that vary with temperature for realistic modeling.

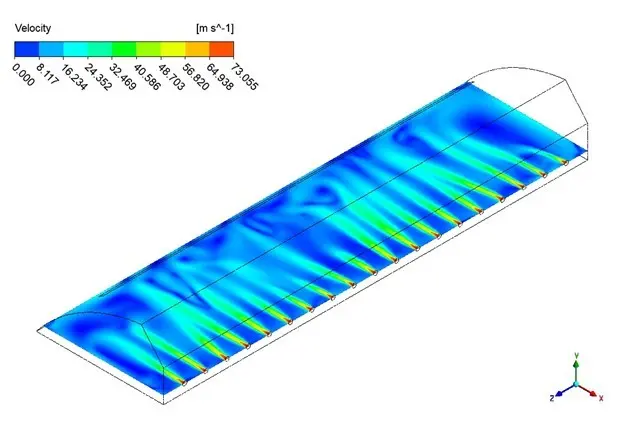

Figure 22- velocity contour from “Greenhouse Ventilation Considering Relative Humidity CFD Simulation”

At its core, ANSYS Fluent uses Computational Fluid Dynamics (CFD) based on the finite volume method to solve heat transfer problems. When it comes to convection heat transfer, Fluent excels at accurately defining fluid flow parameters, which is essential for precise thermal analysis and heat transfer coefficient calculation. Whether you are performing heat exchanger modeling, conjugate heat transfer analysis, or general heat transfer simulations, ANSYS Fluent provides robust and versatile tools to meet the demands of complex thermal engineering challenges.

Recommendations for Simulating Heat Transfer

Accurate heat transfer simulation is essential for engineers designing efficient thermal management systems. Simulation enables faster iteration, early-stage design validation, and exploration of more scenarios compared to physical testing. As heat transfer phenomena grow more complex, engineers rely on advanced computational methods such as finite element analysis (FEA), computational fluid dynamics (CFD), and ray tracing to model conduction, convection, and radiation. Here are key recommendations to ensure your heat transfer simulations are both accurate and efficient:

Determine Whether to Use Steady-State or Transient Simulations

Heat transfer is inherently time-dependent, as thermal energy moves between objects until thermal equilibrium is reached. Before starting your simulation, decide if you need to capture transient heat transfer behavior (time-varying) or if a steady-state solution (equilibrium conditions) suffices. This decision impacts simulation complexity and computational resources.

Use Accurate Material Properties

Material properties such as thermal conductivity, heat capacity, and emissivity significantly influence simulation accuracy. Tools like ANSYS Granta provide reliable databases to obtain and manage thermal properties, ensuring realistic simulation inputs.

Define Boundary Conditions and Control Volumes Precisely

Incorrect or incomplete boundary conditions are among the most common causes of simulation errors. Carefully outline all regions in your model, specifying heat fluxes and heat generation rates. Properly defining control volumes around objects is crucial for reliable results.

Accurately Model Fluid Velocities for Convection

Convection, both natural and forced, depends heavily on fluid velocity, which directly affects heat transfer rates. For simpler systems, finite element or finite difference programs (like ANSYS Mechanical or ANSYS Thermal Desktop) can use a heat transfer coefficient if fluid velocities are well known. When velocity profiles are complex, full CFD simulations with software like ANSYS Fluent provide detailed predictions of fluid flow, turbulence, and mixing.

Combining solid thermal conductivity with fluid flow simulations—known as conjugate heat transfer simulations—is essential for accurate thermal management design in automotive engines, aerospace systems, nuclear plants, and more.

Simplify Models When Possible

Expert thermal engineers often simplify geometries or use 1-D network models to reduce simulation complexity without sacrificing accuracy. Simplifications speed up simulations and facilitate early-stage design assessments. Tools like Thermal Desktop and TD Direct in Ansys SpaceClaim help convert detailed CAD geometry into simplified thermal models optimized for transient analysis.

Use Specialized Vertical Applications for Electronics Cooling

Heat transfer modeling in electronics requires specialized tools due to unique geometries and boundary conditions. Software like Ansys Icepak is designed specifically for electronics cooling, offering automated workflows and domain-specific features that save time and reduce the learning curve for non-experts.

CFDLAND Expertise in Heat Transfer Modeling Using ANSYS Fluent Software

At CFDLAND, our experts have completed numerous projects showcasing advanced heat transfer modeling using ANSYS Fluent software. You can explore our wide selection of ready-to-use heat transfer projects featured at the top of this page on CFDSHOP — find the perfect solution tailored to your needs.

Trust CFDLAND with your heat transfer simulation projects by placing an order through ORDER PROJECT. We guarantee you’ll be impressed by the high quality and accuracy of our work.

Rely on our proven expertise and extensive experience in simulating complex heat transfer problems. Order your next project with ORDERPROJECT today and prepare to be amazed by the professional results.