Automotive Paint Curing CFD Simulation Using S2S Radiation – ANSYS Fluent Tutorial

Automotive Paint Curing CFD Simulation Using S2S Radiation – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€160.00 Original price was: €160.00.€145.00Current price is: €145.00.

The automotive paint curing process is a key step in car manufacturing where newly applied paint layers need to be properly dried and hardened. Car makers use special curing ovens where hot air flows around the vehicle body to make sure the paint sets correctly. Getting the airflow and temperature just right is super important – too hot or too cold in certain spots can cause problems like bubbles, uneven finish, or dull areas in the paint. Most paint curing systems have different zones. First, there’s a section where solvents evaporate (the flash-off zone), then areas where hot air circulates (the convection zones) to heat the paint to about 140-180°C for a specific amount of time. Many car makers now use a mix of traditional hot air with newer methods like infrared or UV curing to save energy while still getting great results. Setting up these paint booths costs a lot of money, so companies want to make them as energy efficient as possible without slowing down production. That’s why CFD simulation is so helpful – it lets engineers test and improve their oven designs on a computer before building them!

Figure 1: Automotive Paint Curing In industry

Simulation Process

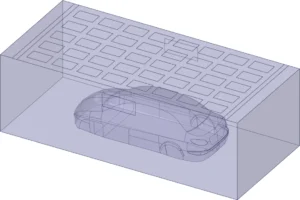

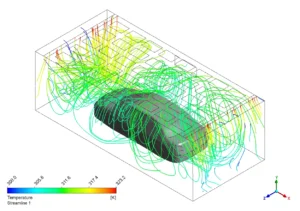

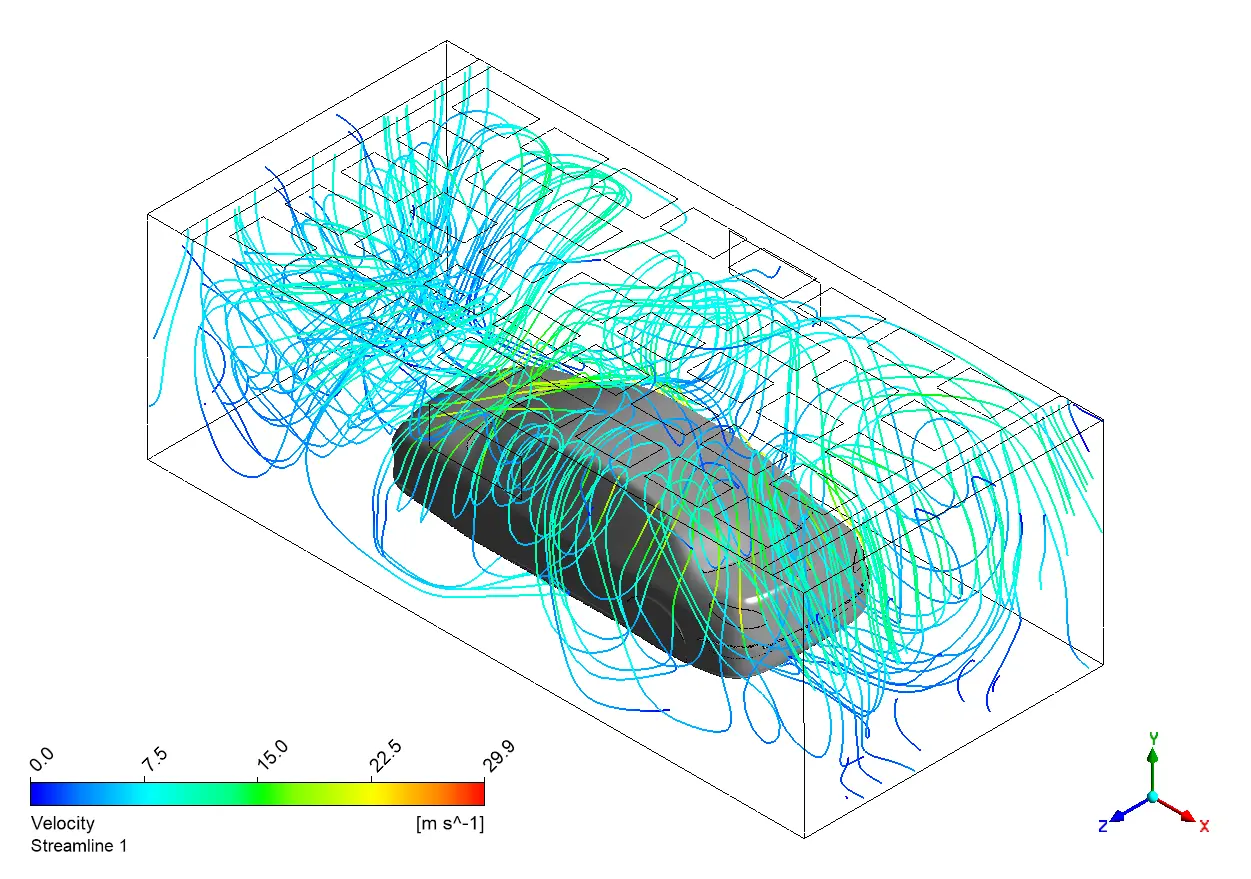

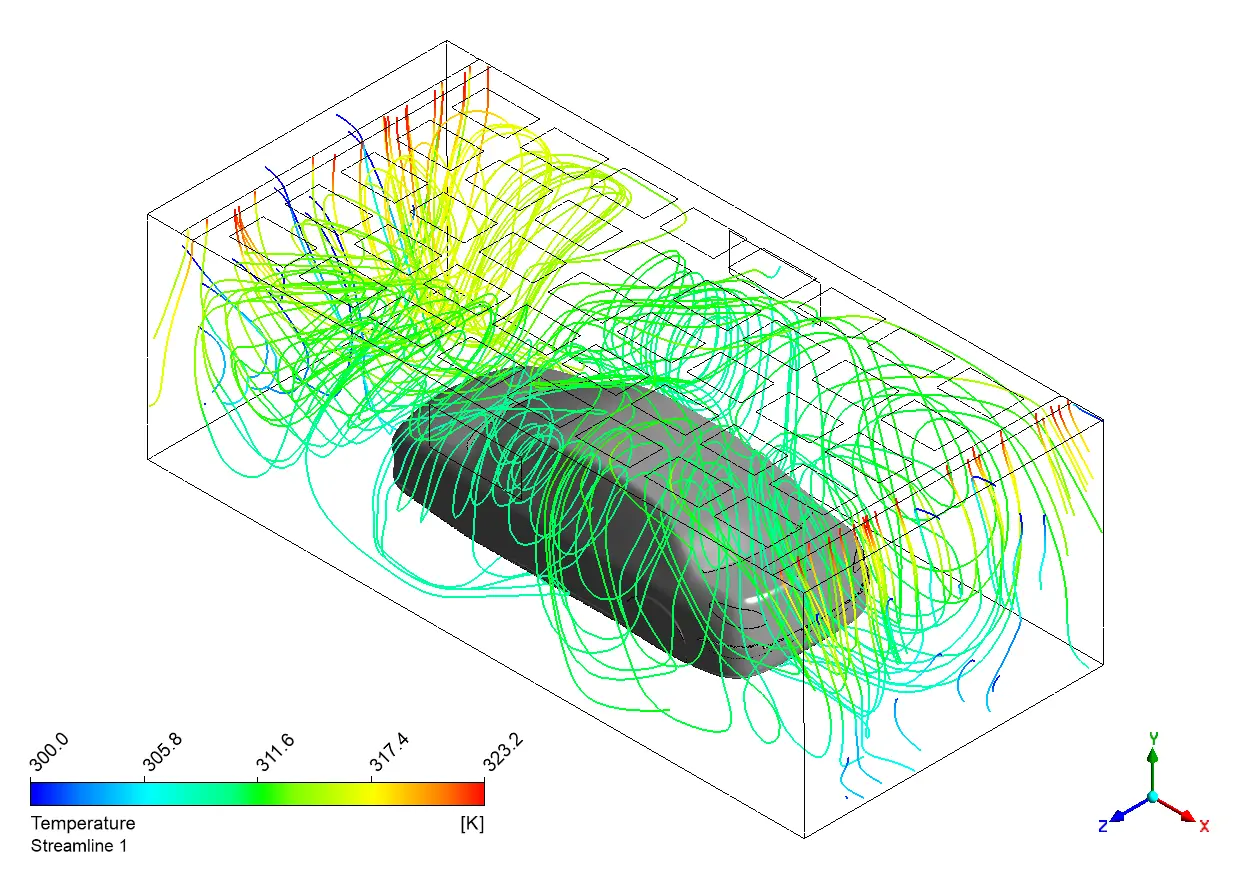

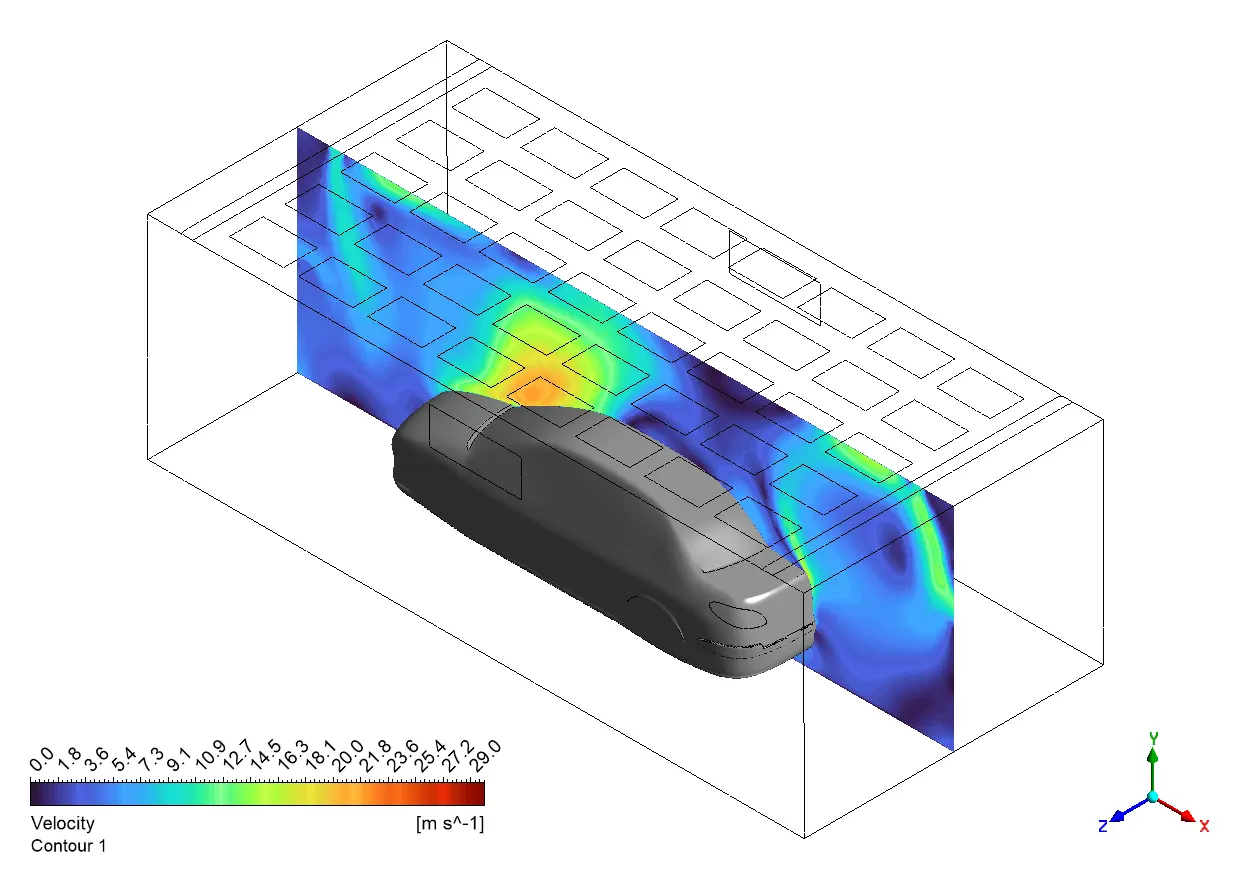

The paint curing oven was accurately modeled in ANSYS SpaceClaim, creating a rectangular chamber with the vehicle positioned centrally as shown in the image! The ceiling features multiple ventilation inlets arranged in a grid pattern to ensure proper airflow distribution throughout the chamber. This geometry was then meshed using Fluent Meshing, with refinements near the vehicle surfaces to capture the critical boundary layer effects that influence heat transfer. Our simulation incorporates the Surface-to-Surface (S2S) radiation model to account for the significant thermal radiation component in paint curing processes, as radiation can contribute up to 30% of total heat transfer at typical curing temperatures! The inlet vents were carefully positioned to create uniform temperature distribution across all vehicle surfaces, preventing localized hot spots that could damage the paint or leave under-cured areas that compromise finish quality.

Figure 2: Geometry model of curing oven

Post-processing

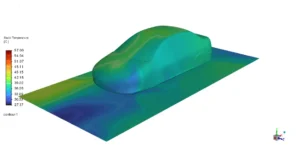

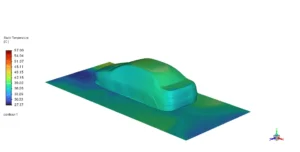

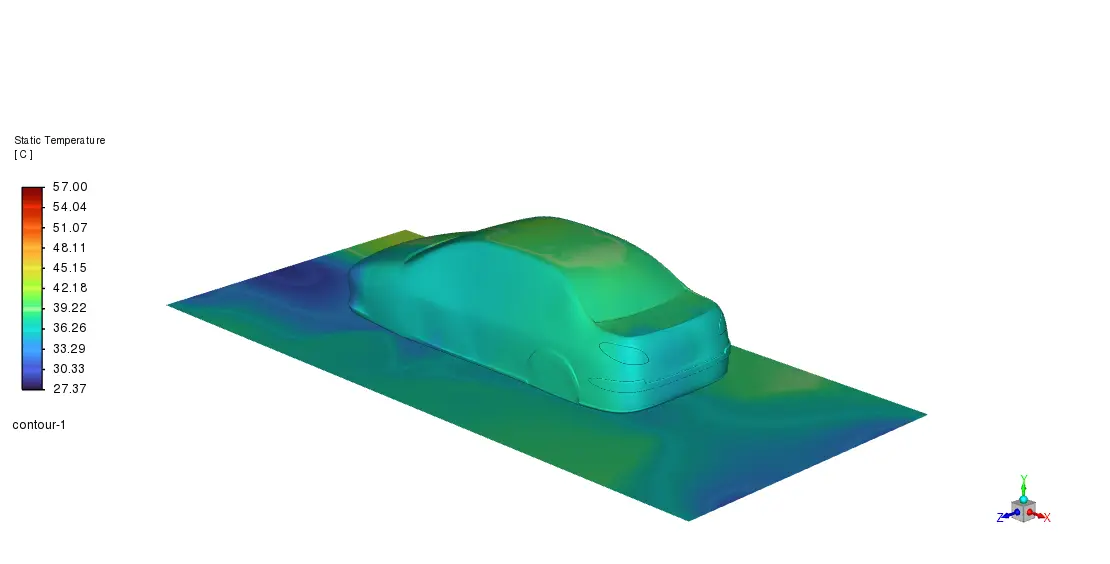

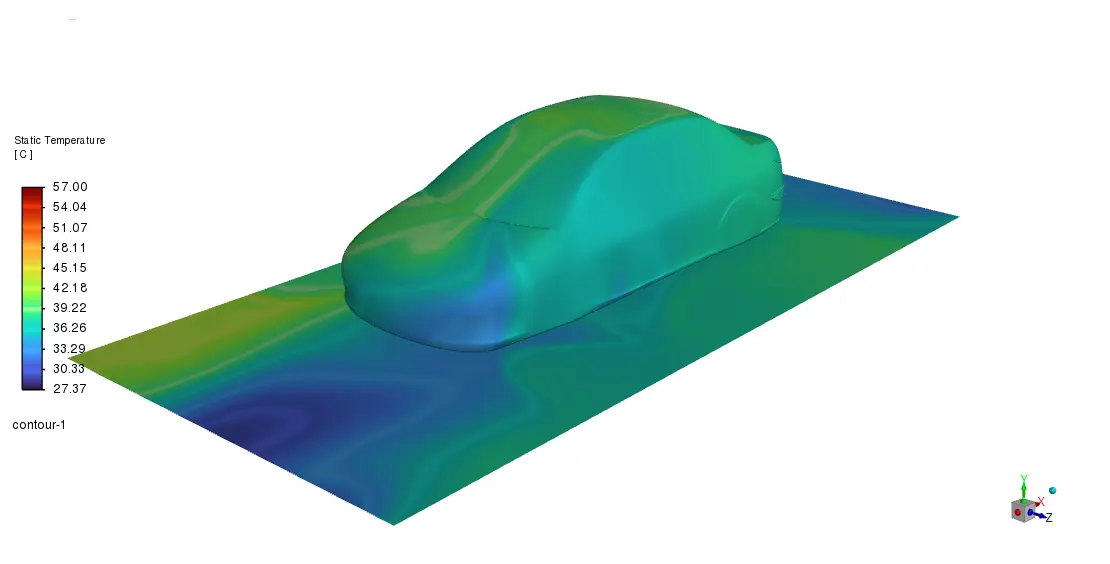

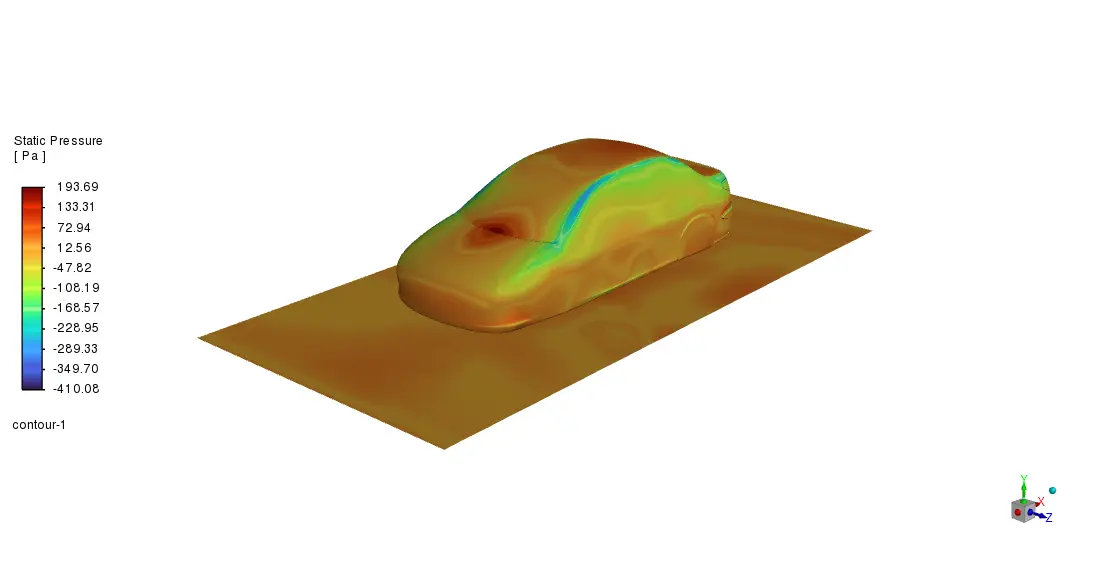

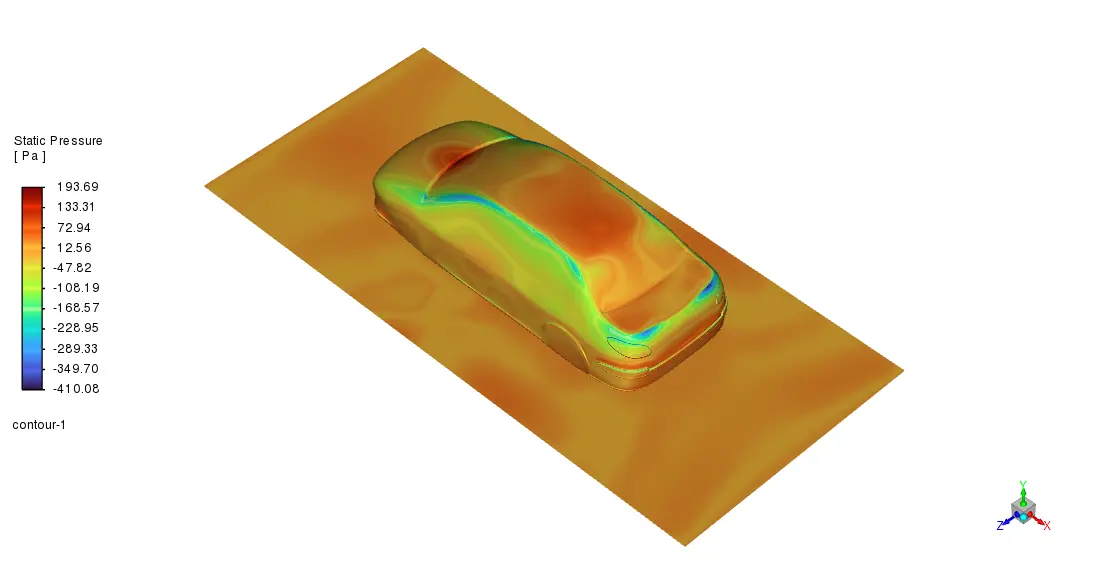

The temperature distribution results show how heat spreads across the car body during the curing process. Looking at the first two images, we can see the temperature ranges from about 27°C in the cooler blue areas to around 57°C in the warmest spots. Most of the car surface stays in the middle range (around 37-42°C), which is actually good for this early stage of curing! The average car temperature is 37.35°C, but it’s the temperature uniformity that really matters – notice how some areas like the roof show slightly warmer temperatures while lower sections and edges tend to be cooler.

Figure 3: Temperature pattern in curing room

The surface incident radiation contour (measured in W/m²) provides valuable insight into why this temperature variation occurs. As shown in the image, radiation values range from 481 W/m² in the coolest areas to 711 W/m² in the hottest zones, with the highest radiation intensity clearly concentrated on horizontal surfaces facing upward. This pattern suggests the current heating system delivers disproportionate thermal energy to the vehicle’s upper surfaces, likely due to ceiling-mounted infrared heaters or improperly balanced convection flows. To achieve optimal paint quality, modifications to the oven design are necessary – either by repositioning existing vents, adding supplementary heating elements along the sides, or adjusting airflow rates to ensure more uniform curing across all vehicle surfaces. This targeted approach to heat management will minimize the risk of paint defects such as under-cured areas or excessive solvent evaporation!

Figure 4: circulation pattern essential for curing oven for uniform heating

Figure 5: Surface incident radiation on car during paint curing

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€190.00 Original price was: €190.00.€95.00Current price is: €95.00.

€240.00 Original price was: €240.00.€125.00Current price is: €125.00.

€295.00 Original price was: €295.00.€175.00Current price is: €175.00.

€320.00 Original price was: €320.00.€175.00Current price is: €175.00.

€120.00 Original price was: €120.00.€65.00Current price is: €65.00.

€240.00 Original price was: €240.00.€135.00Current price is: €135.00.

Reviews

There are no reviews yet.