Floating Boat on Water CFD Simulation Using Dynamic Mesh – ANSYS Fluent Tutorial

Floating Boat on Water CFD Simulation Using Dynamic Mesh – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140

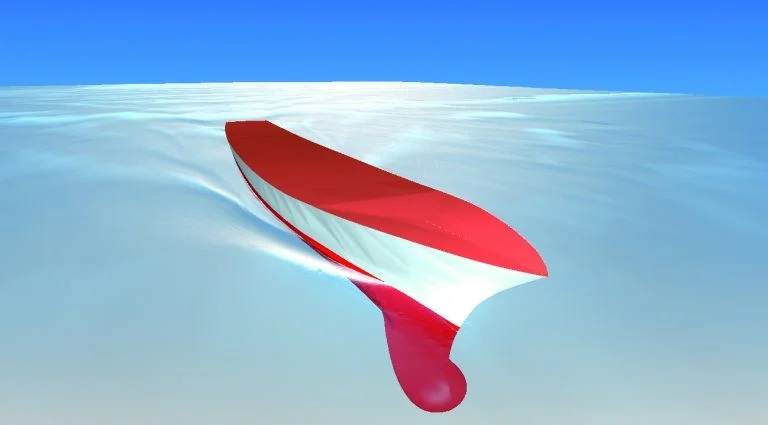

Designing a Floating Boat is a complex task because the water surface is always moving. The hull of the boat must handle waves, weight changes, and speed without sinking or flipping over. Traditional testing in water tanks is very slow and expensive. To solve this, naval architects use CFD simulation to test designs on a computer. However, a standard simulation cannot handle a boat that moves up and down. Therefore, we use the advanced 6DOF Dynamic mesh Fluent technique.

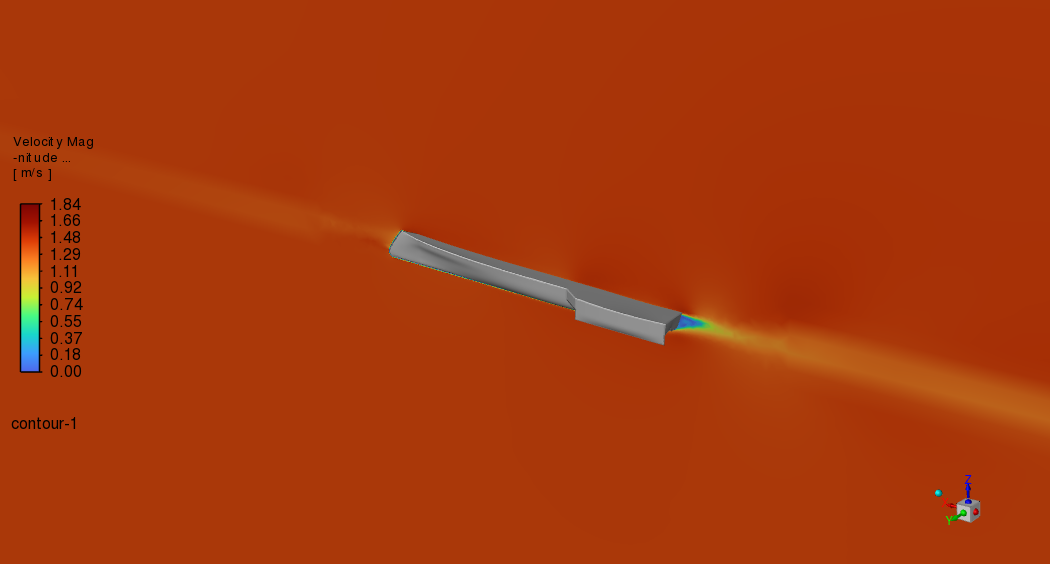

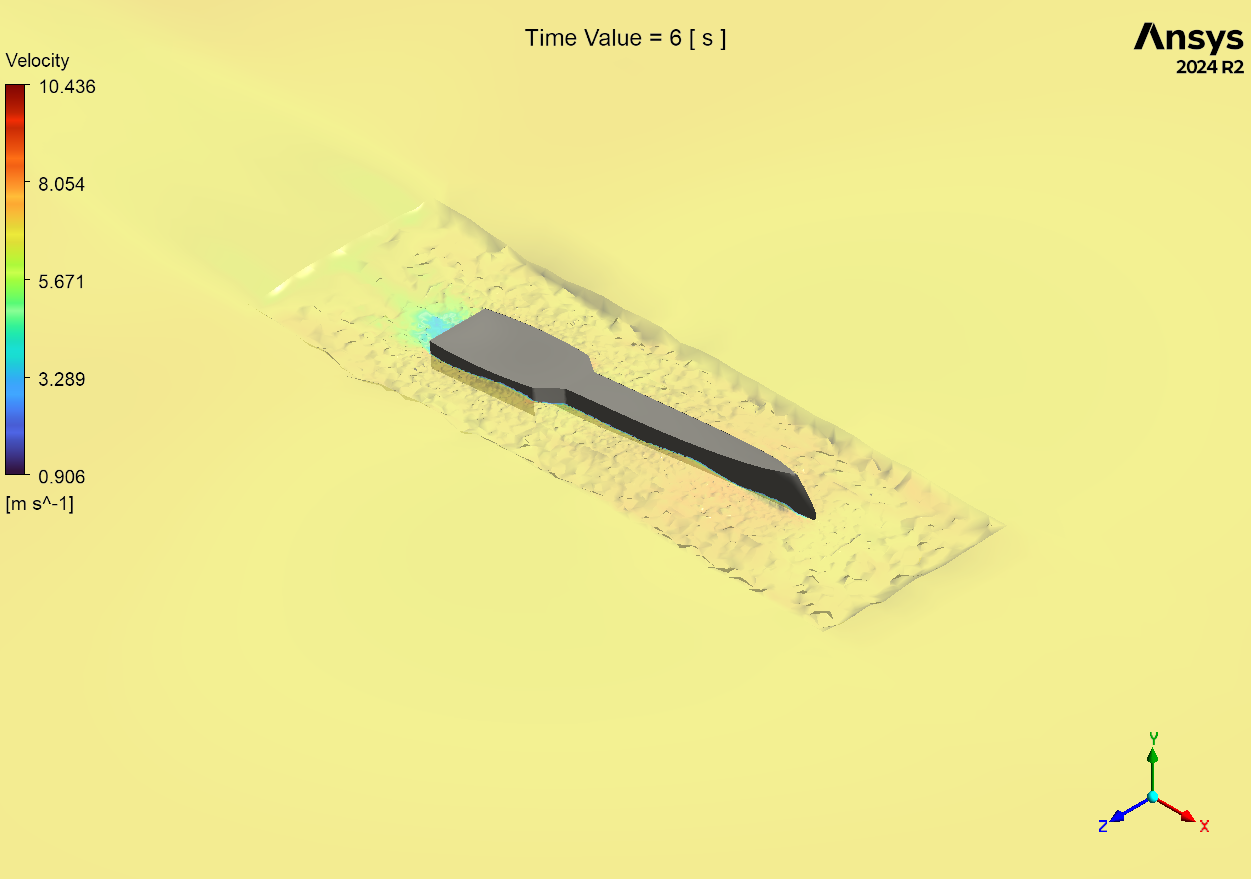

In this report, we perform a Floating Boat CFD simulation. We use ANSYS Fluent to model the interaction between the solid hull and the liquid water. The Floating object Fluent setup allows the boat to move freely in six directions (Six Degrees of Freedom or 6DOF). This simulation tracks the heave (vertical motion) and surge (forward motion) as the boat hits the water flow. This CFD Analysis of Floating Boat on Water helps engineers predict stability and resistance accurately. For more details on moving parts, please explore our Dynamic Mesh tutorials: https://cfdland.com/product-category/module/dynamic-mesh-cfd-simulation/

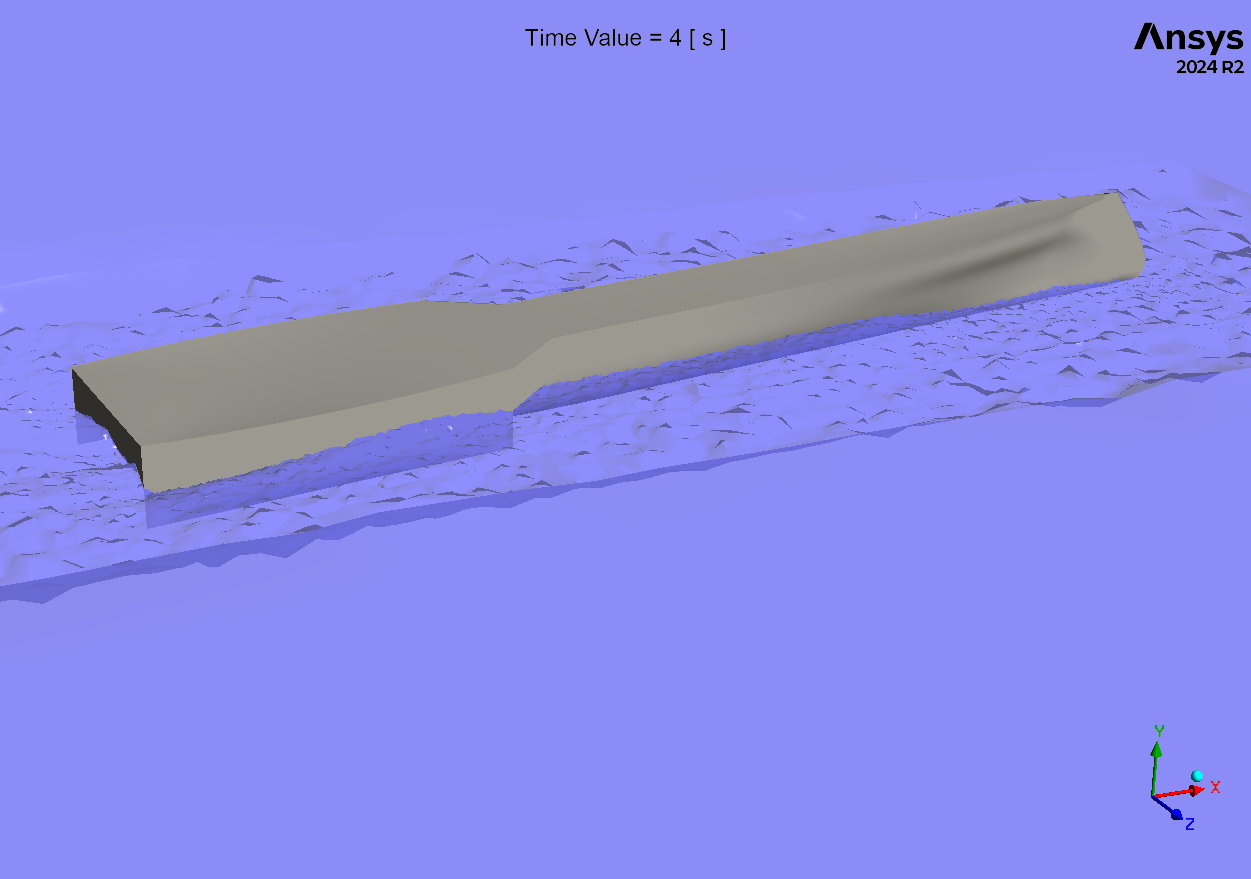

Figure 1: Floating boat on see surface CFD Model

Simulation Process: 6DOF Motion Setup and VOF Configuration

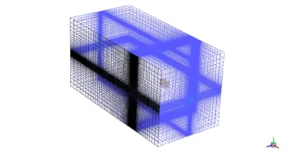

For this Floating Boat ANSYS Fluent project, we created a precise 3D model. The model includes the bow shape, hull curvature, and stern. We used a hybrid mesh with 1,406,288 cells. We mixed tetrahedral and hexagonal cells to get the best accuracy near the water surface. We utilized the Volume of Fluid (VOF) model. This model is essential because it tracks exactly where the water ends and the air begins. The most important part of the setup is the 6DOF Dynamic mesh fluent simulation settings. We defined the boat as a “rigid body” with a mass. We wrote a UDF (User Defined Function) to control the motion. This code allows the boat to move naturally based on the water pressure. The mesh physically deforms and updates every time step as the boat moves. This captures the real physics of a Floating object Fluent scenario.

Figure 2: Hybrid computational grid (Tetra + Hexagonal) containing 1,406,288 cells, refined near the hull to capture the fluid-structure interaction.

Post-processing: Seakeeping Analysis and Hydrodynamic Forces

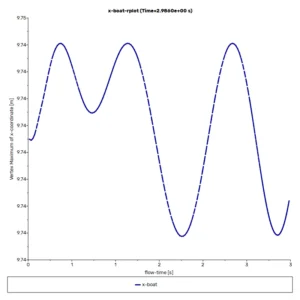

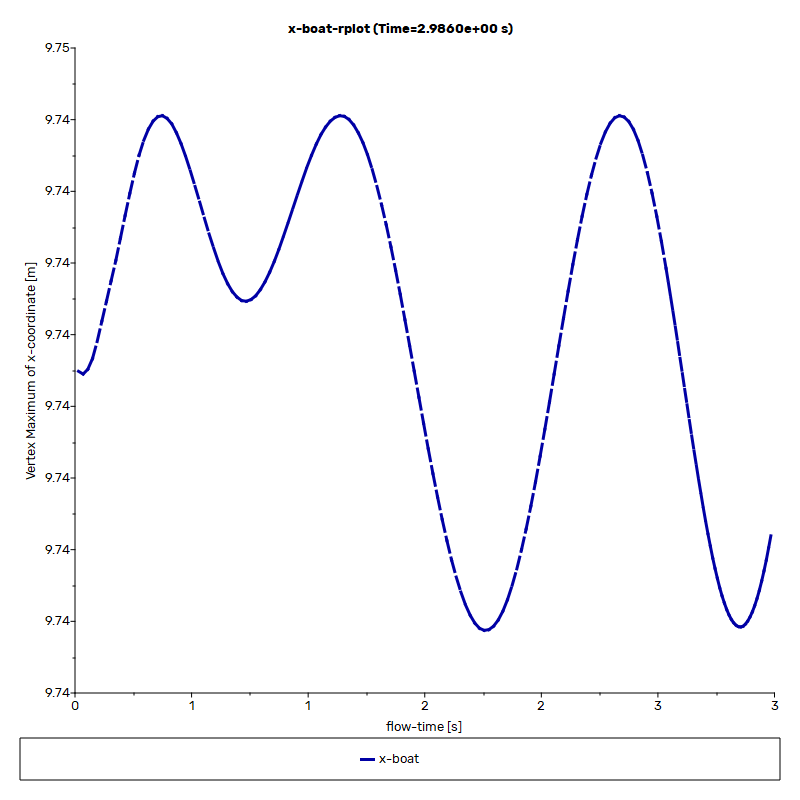

This section analyzes the engineering data to understand how the boat behaves in the water. We study the motion graphs and force plots to see if the hull design is stable and efficient for the manufacturer. First, we look at the X-Direction Displacement in Figure 5 to check horizontal stability. The graph shows a very clear repeating pattern. The boat moves back and forth between 9.740 m and 9.741 m. This total movement is only 0.001 m (1 millimeter). This is a very small number. It proves that the Floating Boat has excellent horizontal stability against the 7 m/s water flow. The oscillation happens about once every second (1 Hz). This confirms that the 6DOF Dynamic mesh simulation has reached a “dynamic equilibrium” where the forces are balanced and the boat is not drifting away.

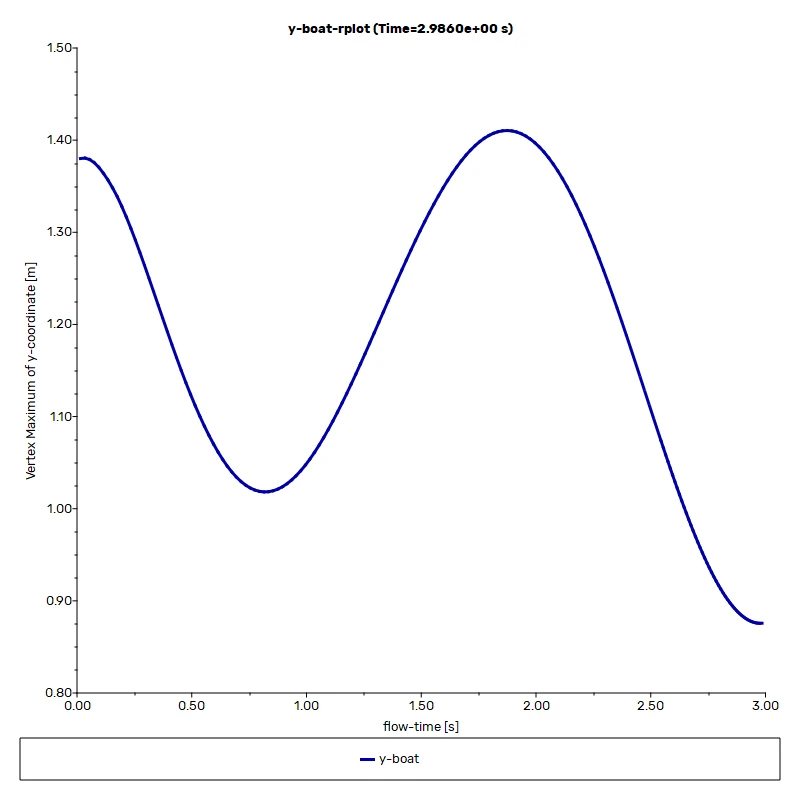

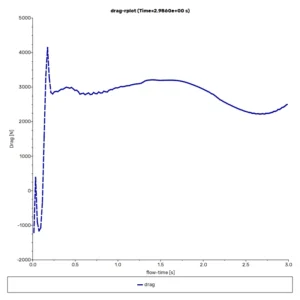

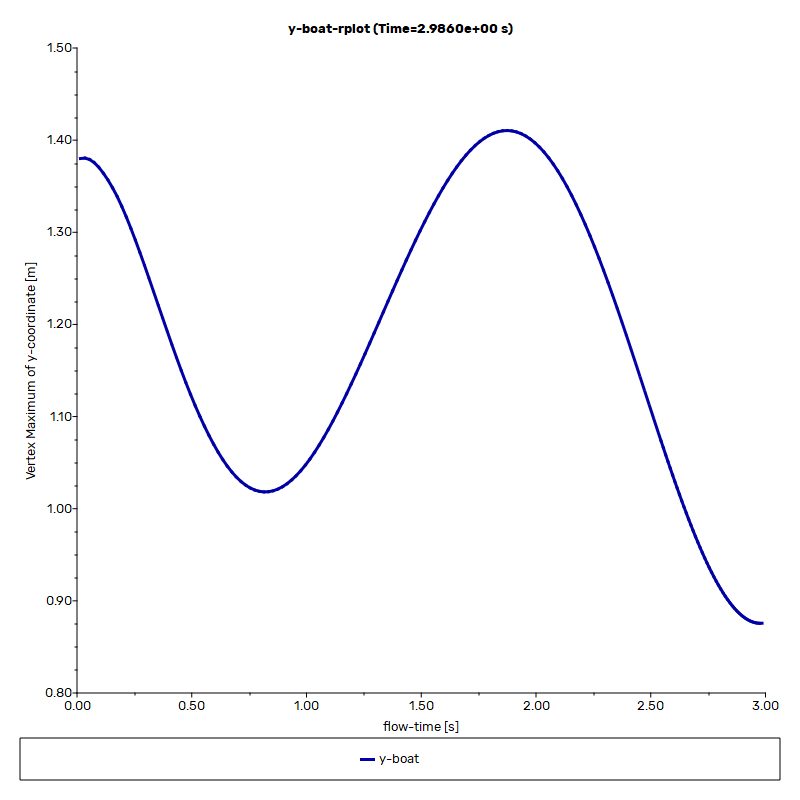

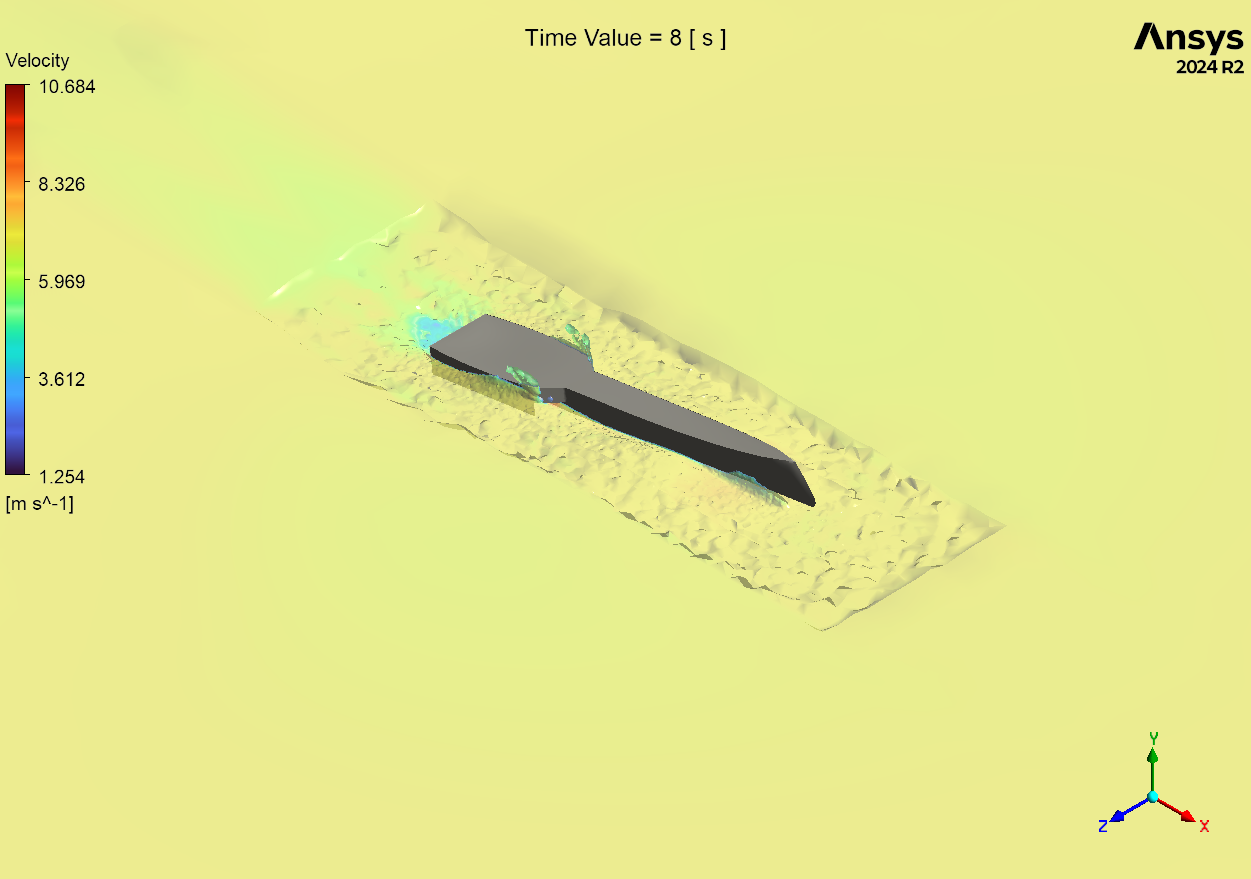

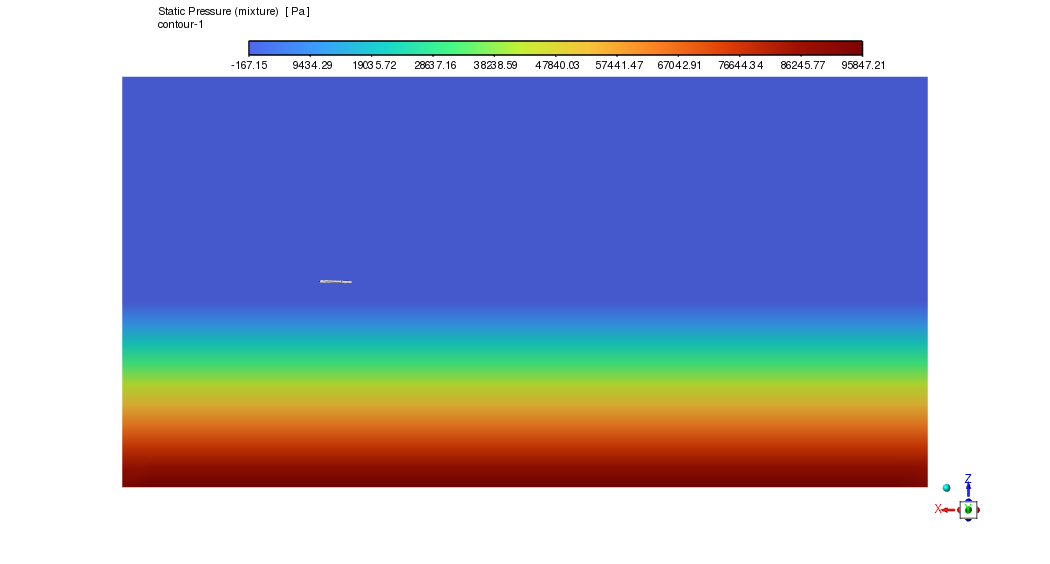

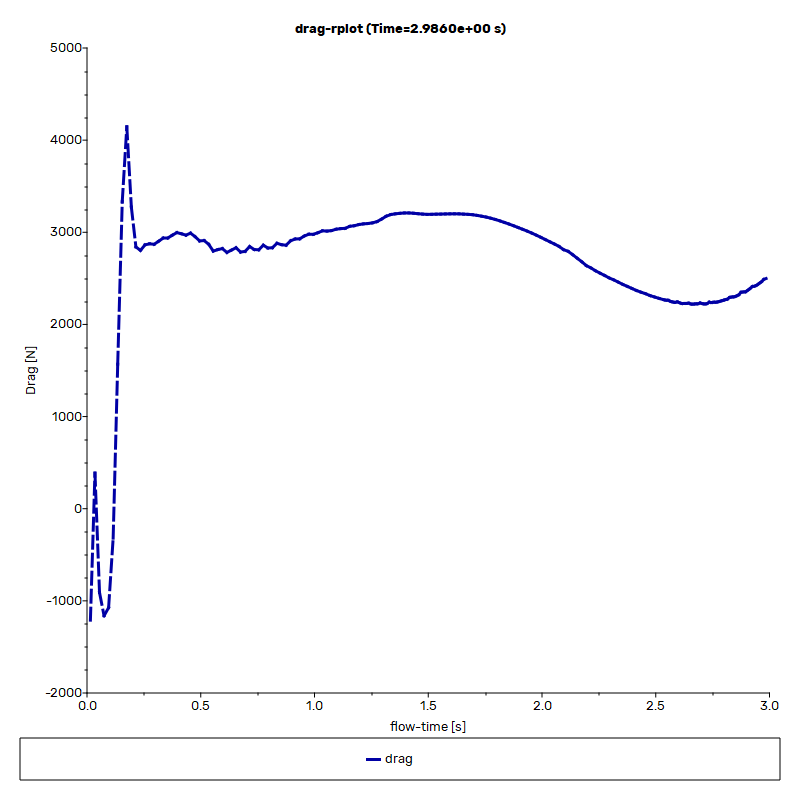

Next, we analyze the Heave Response (Y-Motion) in Figure 3. This is the most critical part for passenger comfort and safety. The graph shows the boat moving up and down significantly. The position ranges from 0.88 m to 1.40 m. The simulation captured a large Heave Amplitude of 520 mm. This is a big movement. The curve shape is “asymmetric” (not a perfect circle), which means the force pushing the boat up is different from gravity pulling it down. The CFD Analysis of Floating Boat on Water reveals that the hull shape creates strong lift forces. A manufacturer can use this data to modify the hull bottom. If 520 mm is too bumpy for passengers, they need to flatten the hull to reduce this vertical bounce. We also examine the Hydrodynamic Drag Force in Figure 4 to understand the engine power needed. At the start (0 to 0.15s), the force jumps wildly from -1200 N to +4200 N. This is the “transient phase” where the boat first hits the water. After 0.15 seconds, the drag stabilizes between 2800 N and 3200 N. This is the most important number for the engine maker. The boat needs an engine that can push against a continuous force of 3000 N. The small wiggles (±200 N) happen because the boat is bobbing up and down, changing the amount of hull under the water surface.

Figure 3: Y-direction displacement plot illustrating the significant heave motion (vertical movement) with an amplitude of 520 mm.

Figure 4: Hydrodynamic Drag Force graph showing initial transient fluctuations followed by a stabilized resistance load of approximately 3000 N.

Figure 5: X-direction displacement plot showing the minor periodic oscillation (surge) of the floating object over time due to flow impact.

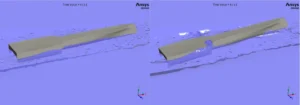

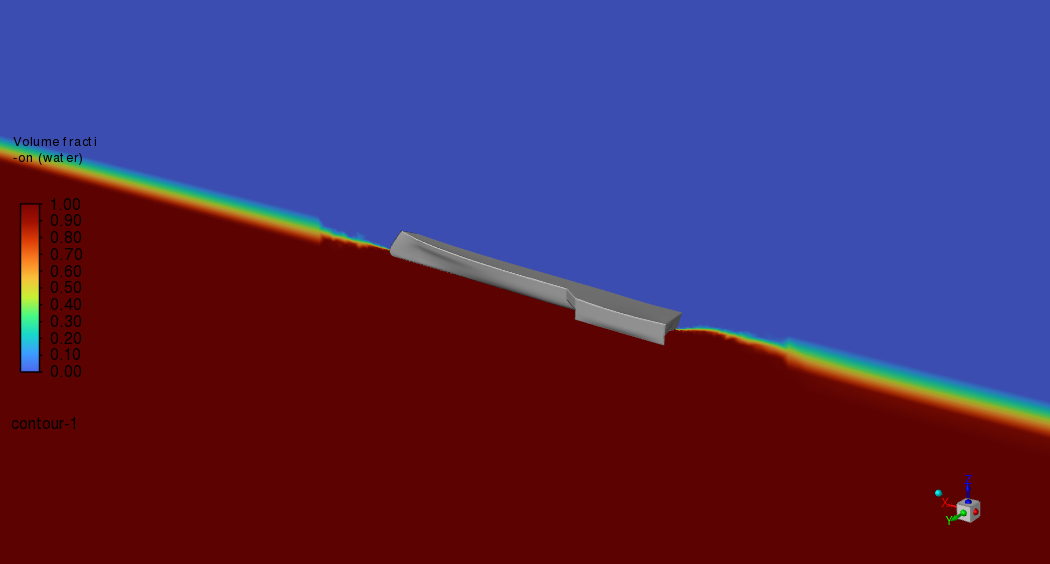

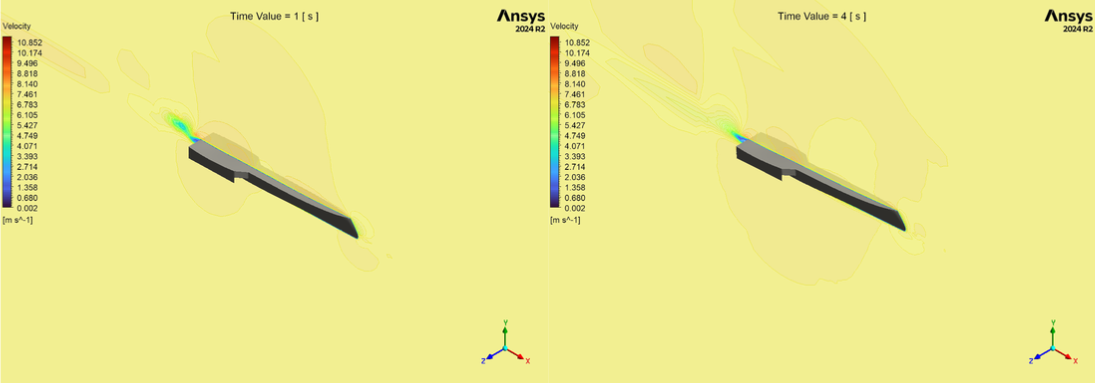

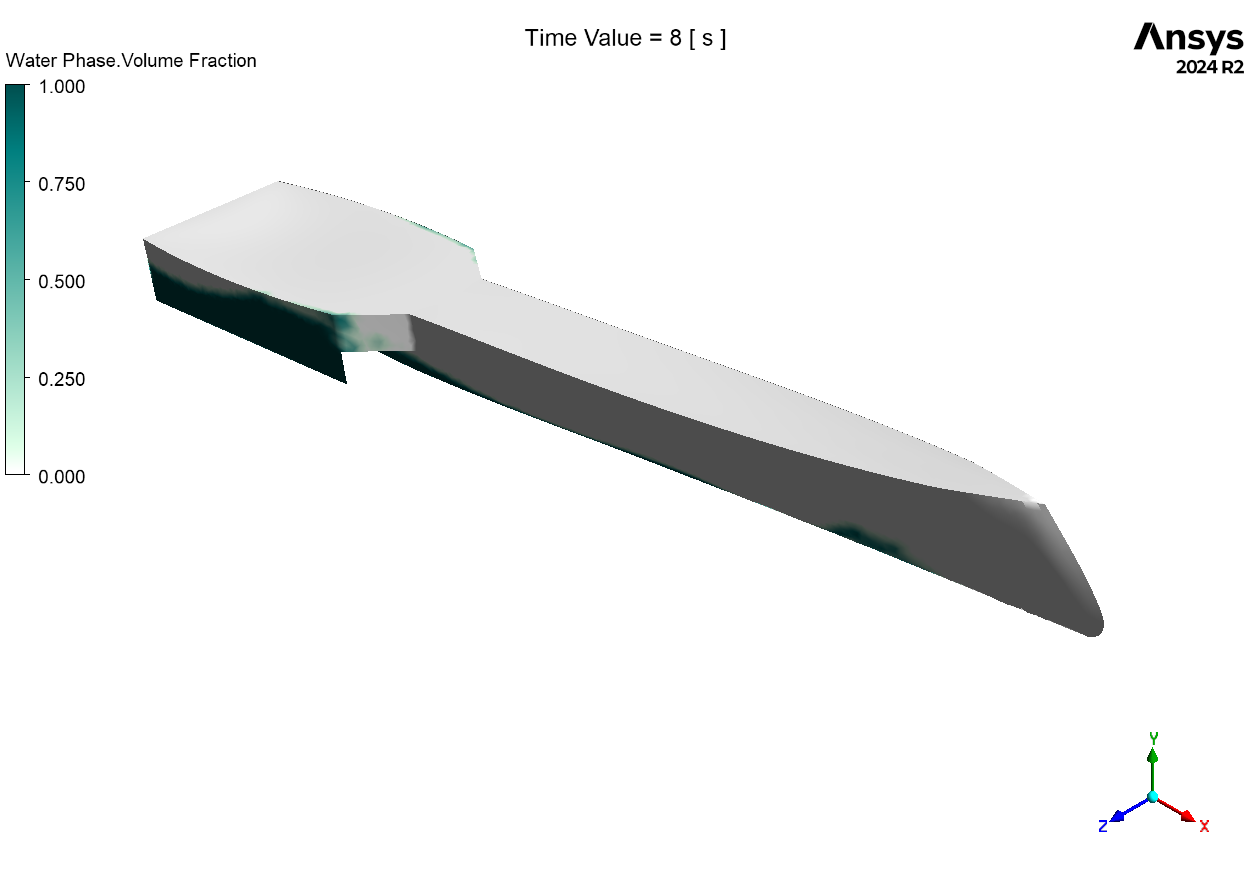

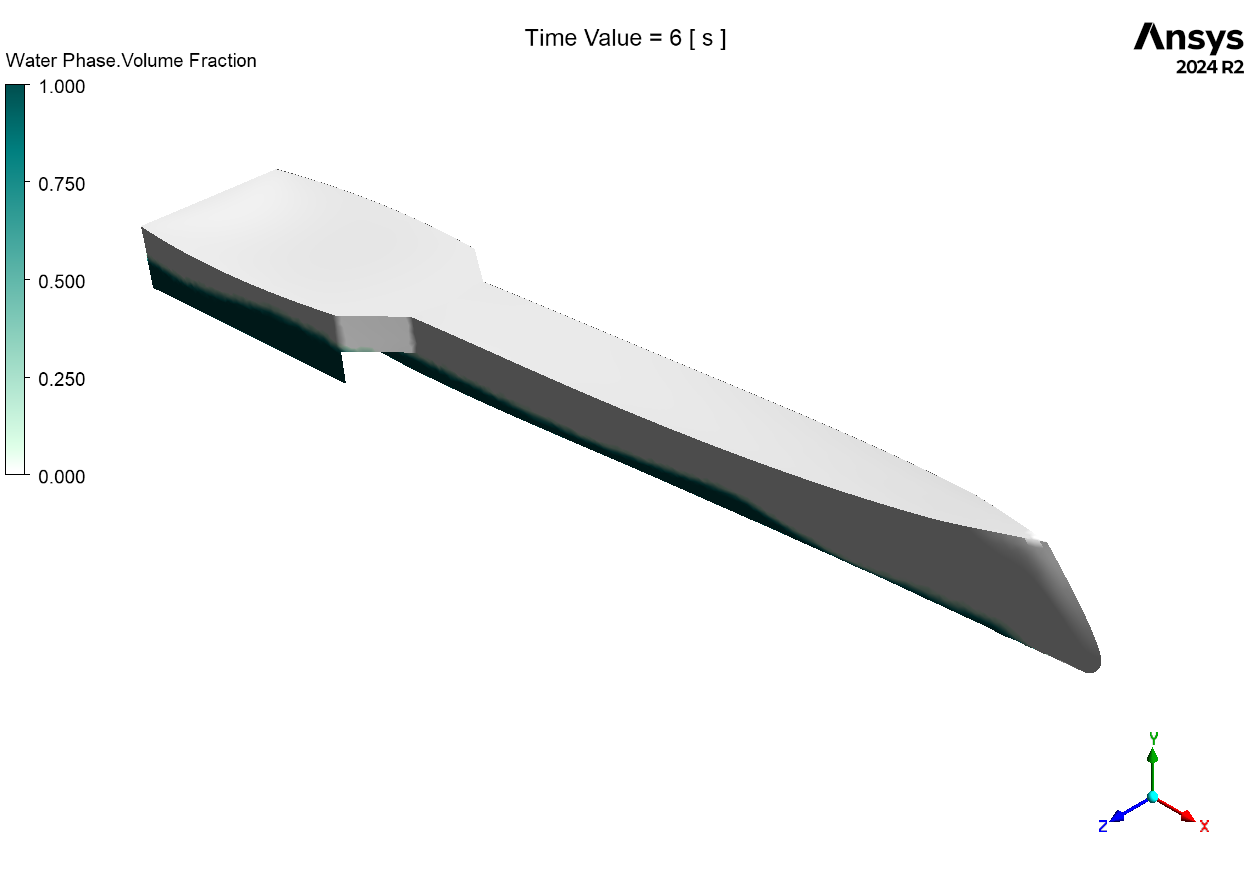

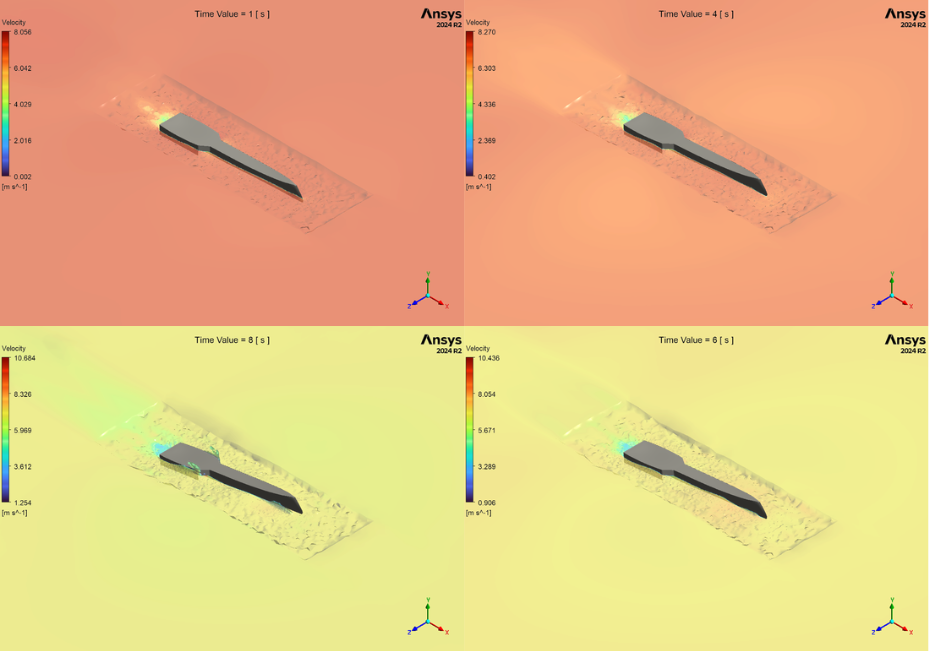

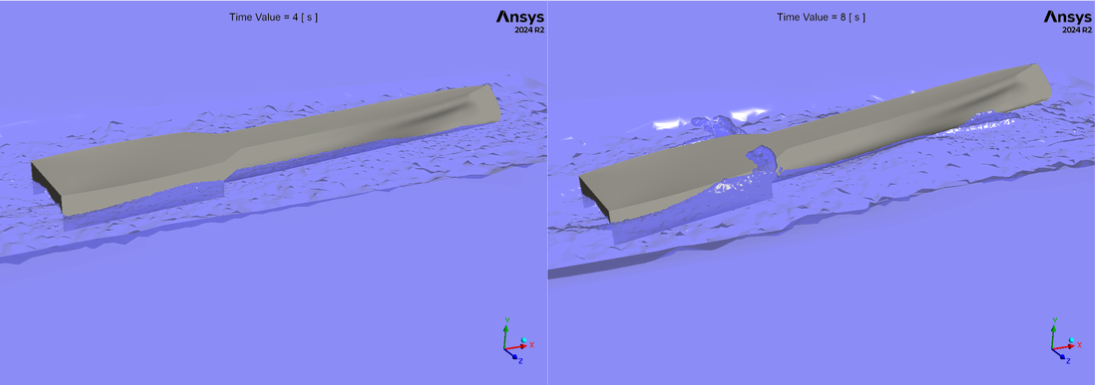

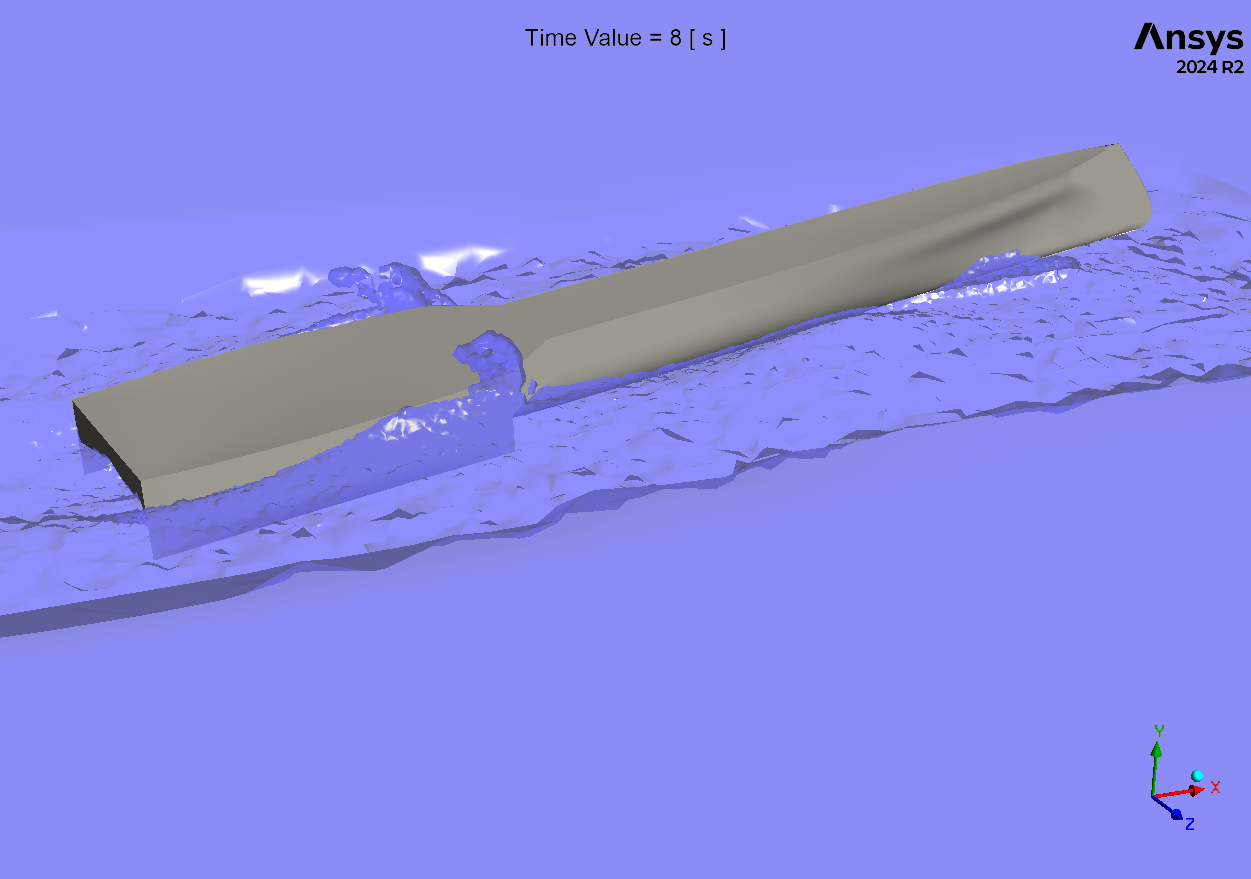

Finally, we observe the VOF Contours in Figure 6. These images verify the numerical data visually. At 4 seconds (Left image), the boat sits high in the water and the surface is smooth. At 8 seconds (Right image), the boat has sunk lower into the water. We can clearly see wave formation near the middle and turbulence at the back (wake). These contours confirm that the 6DOF Dynamic mesh fluent solver correctly calculates the physical connection between the boat’s weight and the water’s buoyancy. The simulation proves the boat will float and validates the hull’s watertight integrity for the designer.

Figure 6: VOF contours at 4 seconds and 8 seconds, visualizing the water surface deformation and the changing immersion depth of the Floating Boat.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€195 Original price was: €195.€145Current price is: €145.

€280 Original price was: €280.€145Current price is: €145.

€240 Original price was: €240.€125Current price is: €125.

€265 Original price was: €265.€135Current price is: €135.

€220 Original price was: €220.€155Current price is: €155.

€205 Original price was: €205.€155Current price is: €155.

Reviews

There are no reviews yet.