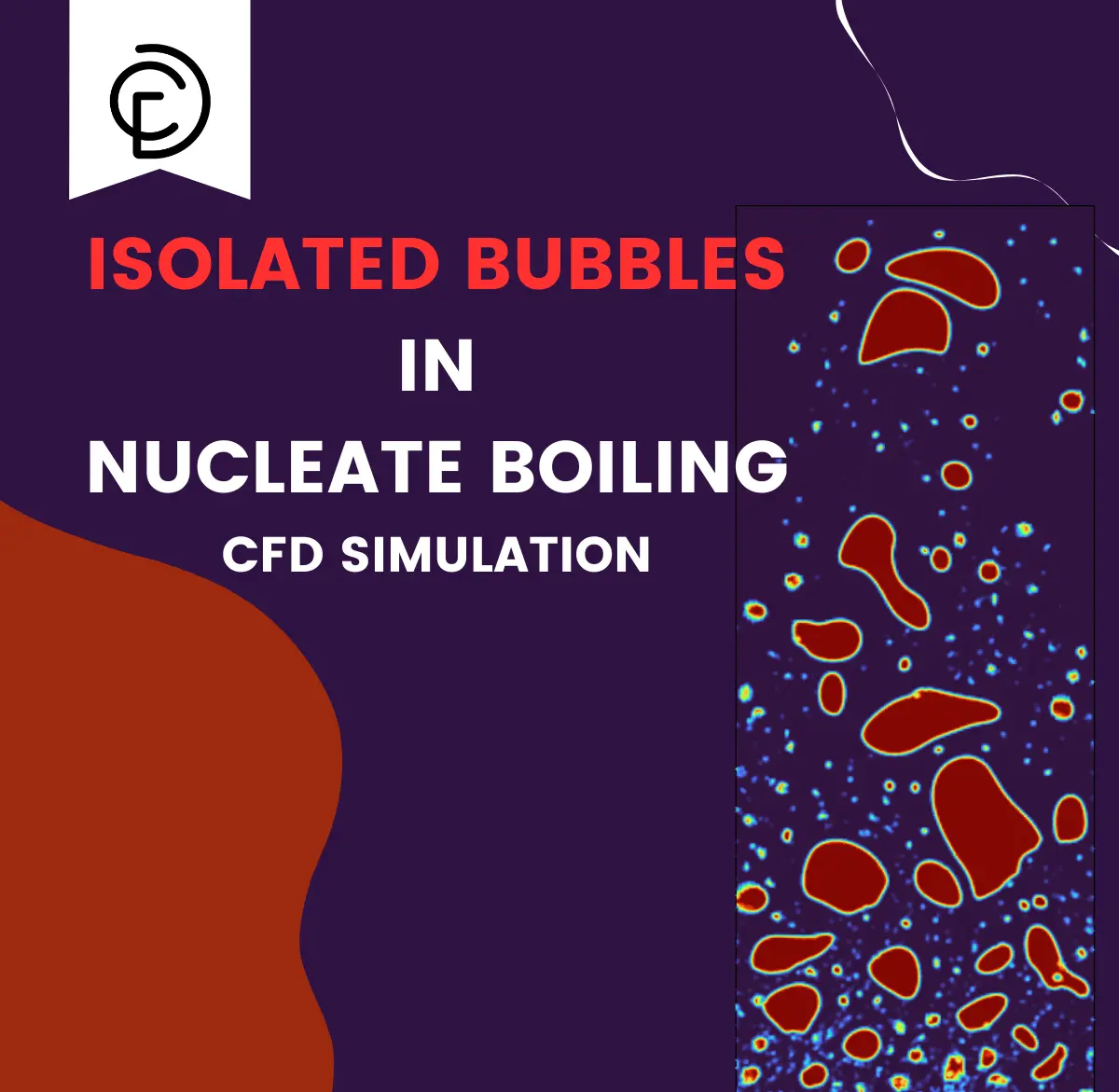

Isolated Bubble CFD Simulation in Nucleate Boiling – A VOF & Mass Transfer Fluent Tutorial

Isolated Bubble CFD Simulation in Nucleate Boiling – A VOF & Mass Transfer Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€155 Original price was: €155.€125Current price is: €125.

Introduction to Isolated Bubble CFD Simulation

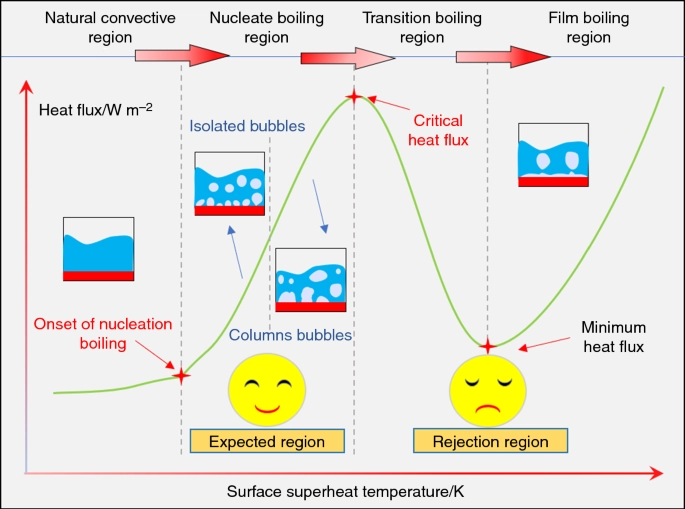

A Nucleate Boiling CFD simulation studies a very efficient type of heat transfer where liquid turns into vapor. This phase change simulation is crucial for many cooling systems. This tutorial explains how to perform a Bubble CFD/Fluent simulation of a single isolated bubble. This process starts when a liquid is heated above its boiling point on a surface, creating a “superheated” layer. Tiny imperfections on the surface act as nucleation sites where an isolated bubble can begin to form. For the bubble to grow, the vapor pressure inside it must overcome the surrounding liquid pressure and the surface tension force.

This Nucleate Boiling Simulation uses the multiphase capabilities of ANSYS Fluent. We use the VOF (Volume of Fluid) method, which is excellent for a VOF Bubble CFD/Fluent analysis because it can accurately track the sharp interface between the liquid and the vapor. To control the rate of evaporation, we use a Mass Transfer CFD/Fluent model called the Lee model. This model uses the temperature difference between the liquid and the vapor to calculate how quickly the isolated bubble grows.

Figure 1: the boiling process diagram [https://link.springer.com/article/10.1007/s10973-023-12292-0]

Simulation Process | Modeling an Isolated Bubble in Fluent

For this Bubble CFD/Fluent tutorial, we first designed a simple 2D domain in ANSYS Design Modeler. The geometry is a rectangle with a heated wall at the bottom, which is the perfect setup to study the formation of an isolated bubble. Next, we created a high-quality structured grid for the whole domain. The main part of this Mass Transfer CFD simulation is the evaporation and condensation model available in ANSYS Fluent. This is used together with the VOF method to track the interface between the liquid and the vapor of the isolated bubble.

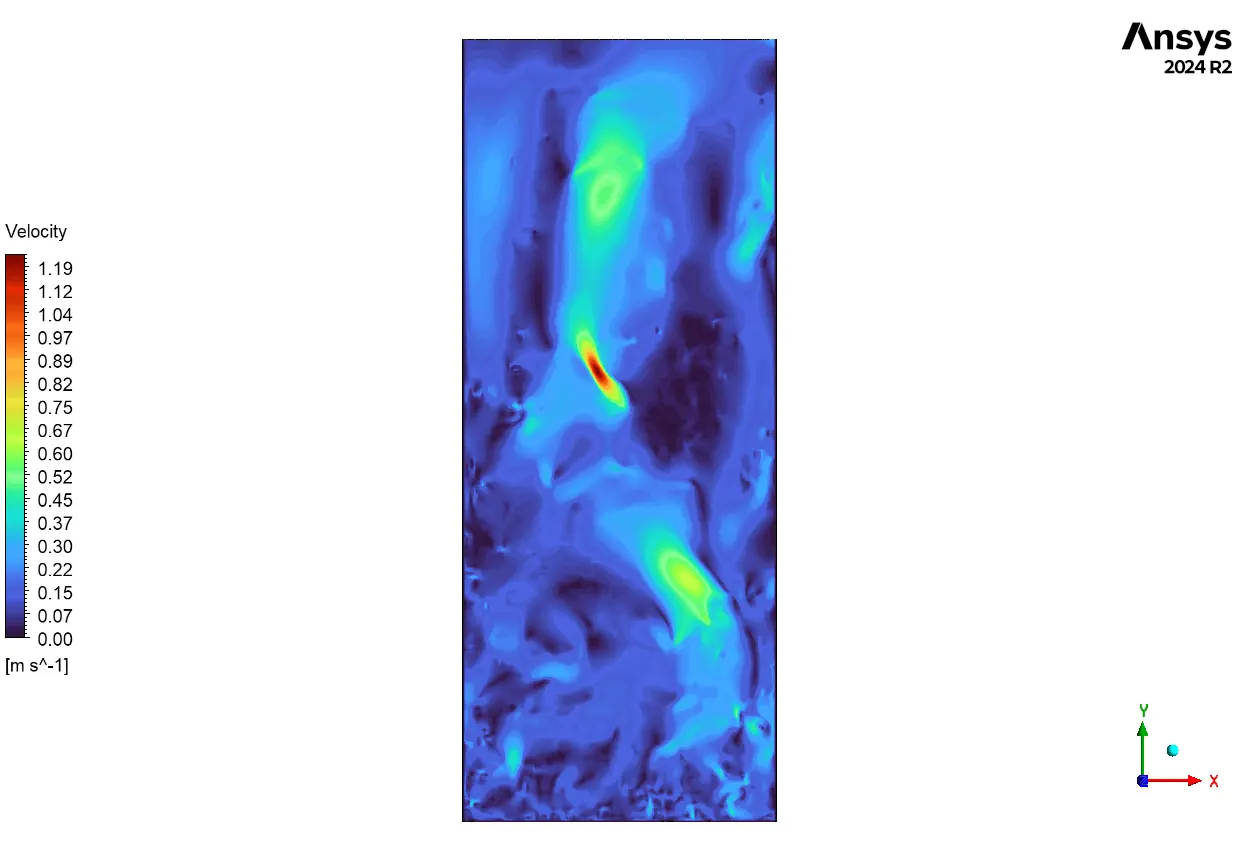

Specifically, we used the Lee model to control the mass transfer. The Lee model is perfect for a Nucleate Boiling Simulation because it calculates the rate of evaporation based on temperature. Boiling starts when the liquid gets hotter than its saturation temperature. Our multiphase model also includes surface tension to give the isolated bubble its round shape and buoyancy to make it rise.

Post-processing | VOF Bubble CFD Analysis of an Isolated Bubble

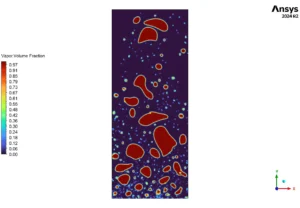

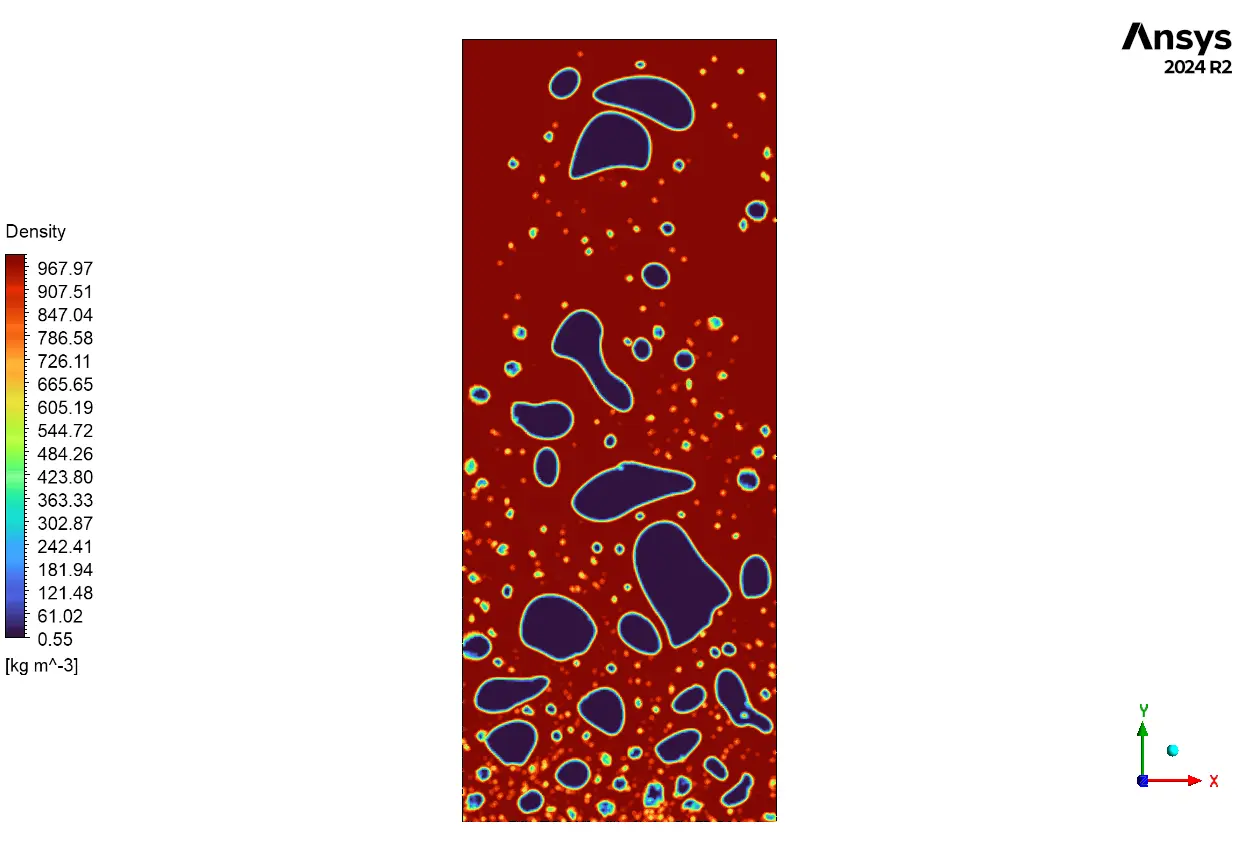

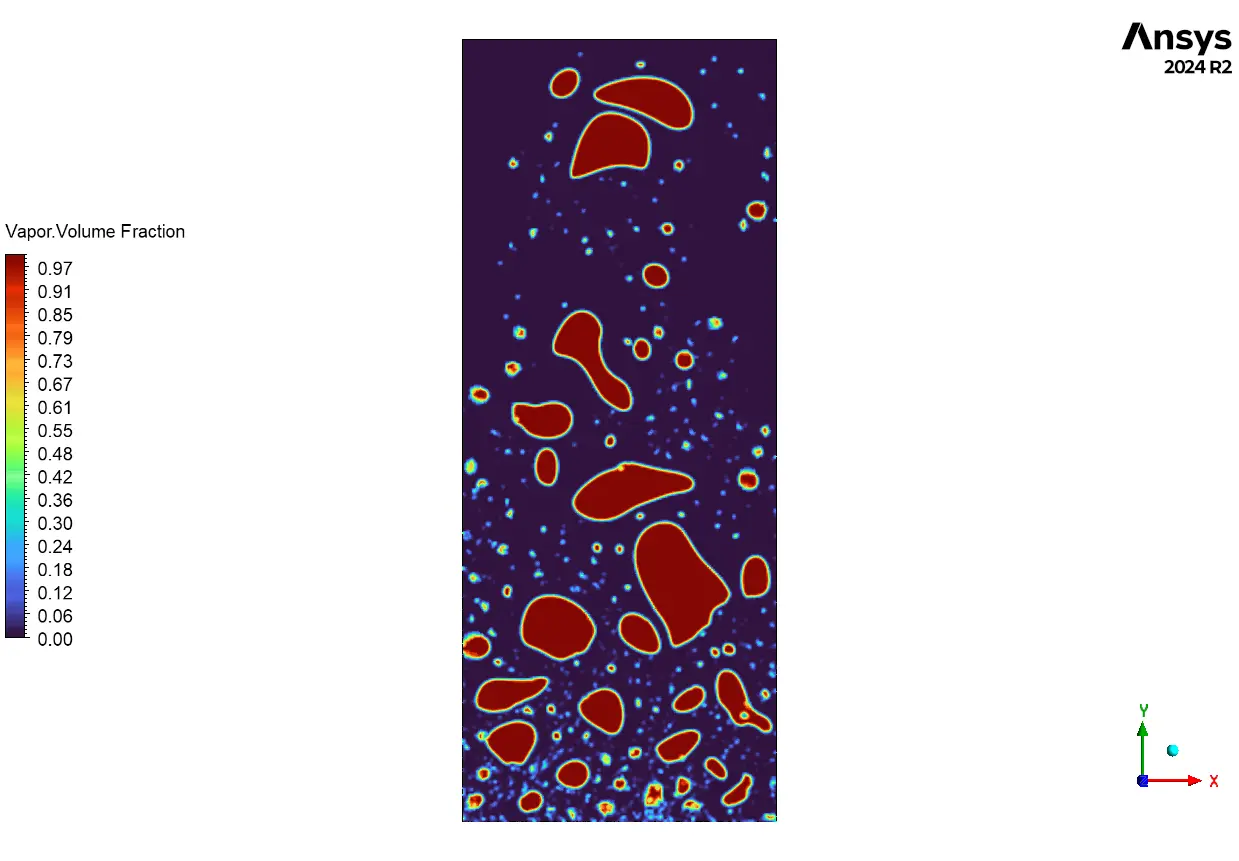

The results of our VOF Bubble Fluent simulation give us a clear view of the isolated bubble. The vapor volume fraction contours show the bubble as a red area. A significant finding is that this red area has a vapor fraction up to 0.97, which means it is almost pure vapor. The surrounding blue area is pure liquid. This Nucleate Boiling CFD result shows how the VOF method accurately captures the round shape of the isolated bubble, which is caused by surface tension. The analysis shows the isolated bubble dynamics as it forms at a hot spot on the surface and grows larger as more liquid evaporates.

Figure 2: Vapor Volume Fraction from a VOF Bubble CFD simulation showing an isolated bubble.

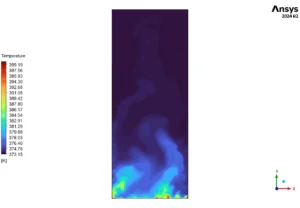

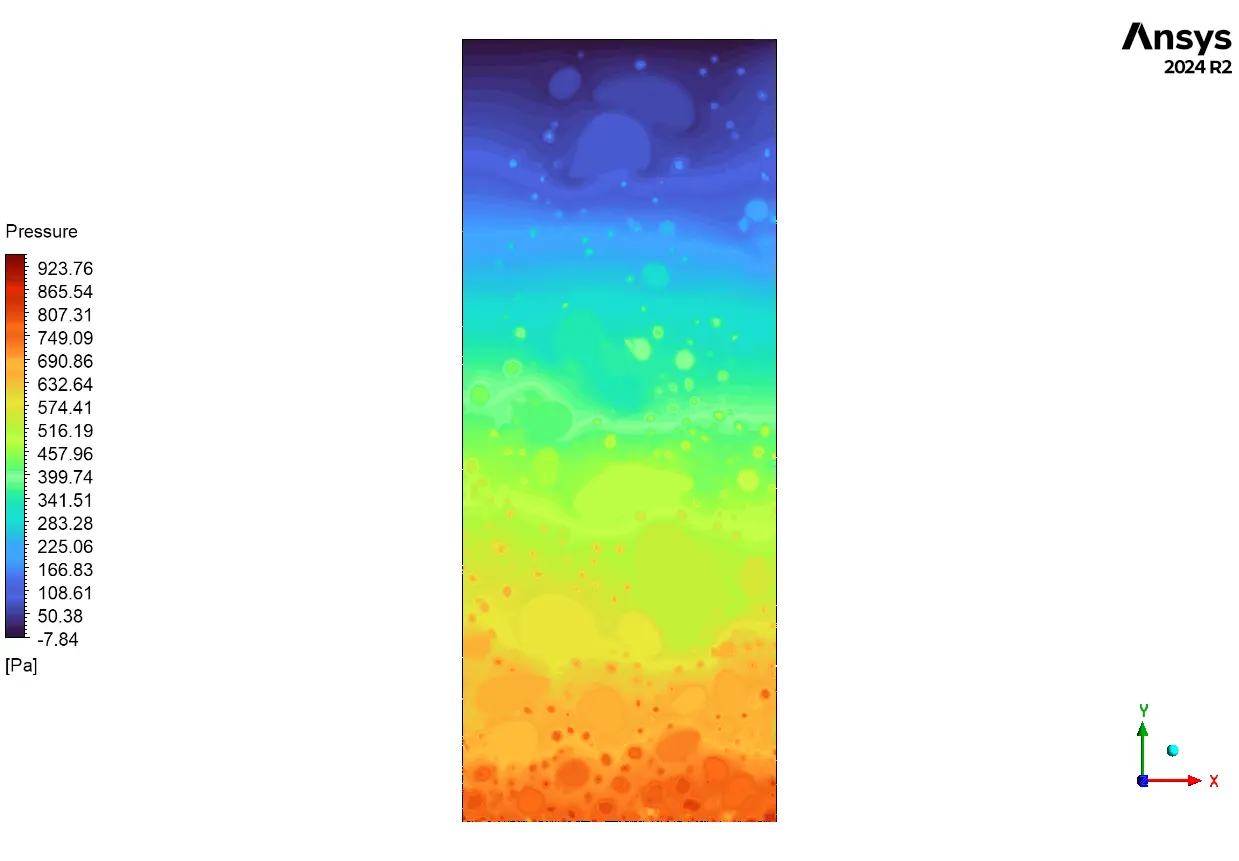

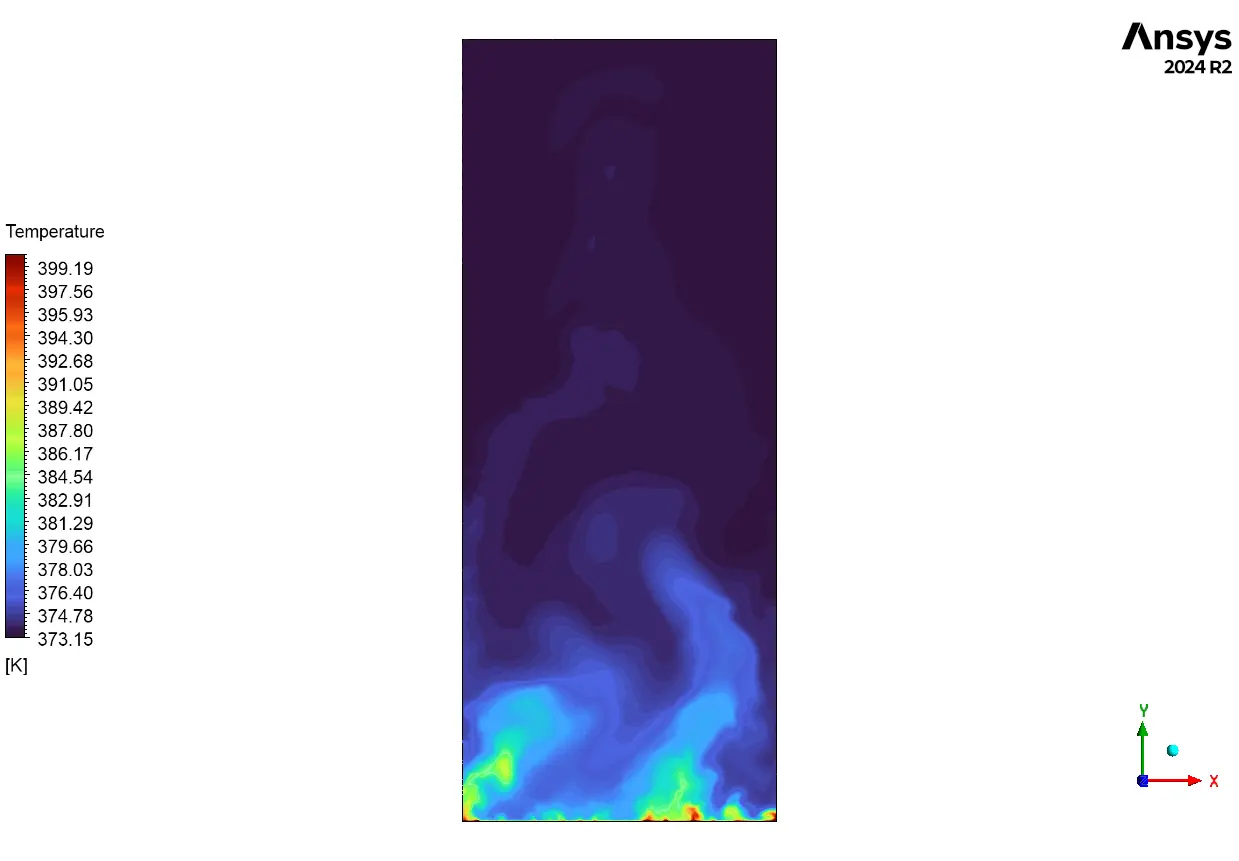

The temperature results explain the heat transfer that drives the Nucleate Boiling Fluent process. A key finding is the clear temperature difference, with the hot bottom wall at 399.19 K and the cooler liquid at the top at 373.15 K. This temperature gradient provides the energy for the phase change. The Lee model uses this temperature data to calculate how fast the isolated bubble grows. The pressure field, which has a range from -7.84 Pa to 923.76 Pa, also works with the temperature to control the exact point where boiling begins.

Figure 3 Temperature distribution driving the growth of an isolated bubble in a Mass Transfer CFD simulation.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€360 Original price was: €360.€185Current price is: €185.

€190 Original price was: €190.€125Current price is: €125.

€295 Original price was: €295.€175Current price is: €175.

€360 Original price was: €360.€185Current price is: €185.

€200 Original price was: €200.€125Current price is: €125.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.