Ramjet Combustion CFD: Simulating Solid Fuel Engines with ANSYS Fluent

Ramjet Combustion CFD: Simulating Solid Fuel Engines with ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€380 Original price was: €380.€185Current price is: €185.

A ramjet is a special type of engine used for very fast flight, like in missiles. It’s very simple because it has no moving parts. It uses its own high speed to scoop up air from the front, mix it with fuel, and burn it to create a powerful push, or thrust. The type we are studying is a solid fuel ramjet, where the fuel is a solid block lining the inside of the engine. To understand how the burning, or combustion, happens inside, we use powerful computer tools called Computational Fluid Dynamics (CFD). This Ramjet Engine Combustion CFD study is very important because it helps engineers design better and more efficient engines. We are checking our computer model against a trusted research paper [1] to make sure our results are accurate.

- Reference [1]: Musa, Omer, et al. “Effect of inlet conditions on swirling turbulent reacting flows in a solid fuel ramjet engine.” Applied Thermal Engineering113 (2017): 186-207.

- Reference [2]: Hu, Ming, et al. “Numerical investigation of a combined solid fuel scramjet combustor.” Acta Astronautica148 (2018): 210-219.

Figure 1: An artistic image illustrating the intense process of Ramjet Engine Combustion.

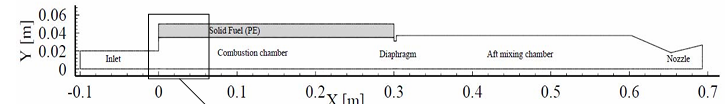

Figure 2: The schematic of the solid fuel Ramjet Engine CFD model being investigated, based on the reference paper [1].

Simulation Process: Modeling Ramjet Combustion with a Custom UDF

To perform the Ramjet Engine Combustion Fluent simulation, we first created a 2D computer drawing of a slice of the ramjet engine. Then, we divided this drawing into many small, neat boxes to create a high-quality grid (Figure 3), which helps the computer make accurate calculations. The biggest challenge in a Ramjet Engine CFD simulation is that the solid fuel only turns into a gas that can burn when the engine wall gets very hot. This is not a standard option in the software. So, we wrote a special piece of computer code called a User-Defined Function (UDF). This Ramjet Engine Combustion UDF CFD told ANSYS Fluent exactly how to add fuel gas from the wall, but only when the wall surface temperature was high enough. We also used the Species Transport model to keep track of all the different chemicals involved: the incoming air, the fuel gas (ethylene), and the hot gases created after burning.

C2H4 + O2 ===> 2Co + 2H2

2Co + O2 ===> 2Co2

2H2 + O2 ===> 2H2o

Post-processing: Analyzing Supersonic Flow and Heat Release

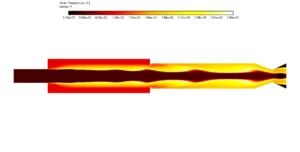

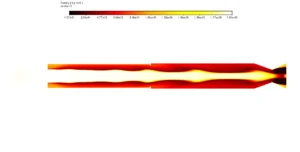

The simulation results tell a fascinating story of cause and effect, revealing how the ramjet creates immense power from a simple design. The main cause of the engine’s power is the UDF-controlled fuel injection, which starts a powerful chemical reaction. The direct effect is a massive increase in temperature and speed, as seen in Figure 4. The temperature contour shows an incredibly hot core (bright red, reaching 2900 Kelvin) right where the fuel is burning along the walls. This proves our UDF is working correctly, creating intense heat just as it should. This extreme heat causes the gas to expand and rush out of the back of the engine. The effect, shown in the velocity profile, is a huge acceleration of the gas from almost zero speed to an amazing 1410 m/s, which is faster than the speed of sound (supersonic).

Figure 3: Temperature and Density contours from the Ramjet UDF CFD analysis, showing the intense heat and density changes during supersonic combustion.

This high-speed exit is what produces the powerful thrust. A key achievement is that our model shows how the combustion process sustains itself: the heat from burning releases more fuel gas, which then burns and creates more heat. The most important achievement of this Ramjet UDF CFD analysis is the successful simulation of the entire thrust-generation process, from the temperature-dependent fuel release modeled by the UDF to the final supersonic exhaust velocity. This validates our complex CFD model as a powerful and reliable tool for designing and predicting the performance of real-world solid fuel ramjet engines without needing expensive physical tests.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€235 Original price was: €235.€155Current price is: €155.

€130 Original price was: €130.€85Current price is: €85.

€250 Original price was: €250.€195Current price is: €195.

€160 Original price was: €160.€135Current price is: €135.

€140 Original price was: €140.€125Current price is: €125.

1 review for Ramjet Combustion CFD: Simulating Solid Fuel Engines with ANSYS Fluent

Chibuzo –

Very helpful and very supportive team. I 100 percent recommend this package as they are experts in this field.