Introduction: What are DPM Boundary Conditions in ANSYS Fluent?

When you run a simulation with particles in ANSYS Fluent, have you ever wondered what happens when a particle hits a wall? Does it bounce off? Does it stick? Or does it just disappear? The answer to these questions is controlled by DPM boundary conditions.

Contents

ToggleThe Discrete Phase Model, often called ANSYS Fluent DPM, is a powerful tool used for particle tracking. This model allows us to follow the path of individual particles, like dust, droplets, or bubbles, as they move through a fluid. However, to get an accurate result, we must correctly define the particle-wall interaction.

This is the most important job of DPM boundary conditions: they tell Fluent exactly how a particle should behave when it reaches a boundary zone. The choice you make can completely change your simulation results. In ANSYS Fluent, you have several types of particle boundary conditions to choose from, including:

- Reflect (the particle bounces off the wall)

- Trap (the particle gets stuck on the wall)

- Escape (the particle leaves the simulation domain)

- Wall-jet (the particle hits the wall and creates a thin stream of fluid)

- Wall-film (the particles form a liquid layer on the surface)

In this complete guide, we will explain each of the Fluent DPM boundary conditions in simple terms. We will show you what they do, when to use them, and how to set them up for a successful simulation.

If you are interested in seeing practical examples and learning through hands-on tutorials, we invite you to explore our comprehensive DPM CFD simulation projects in the CFDLAND shop.

How to Set DPM Boundary Conditions in ANSYS Fluent

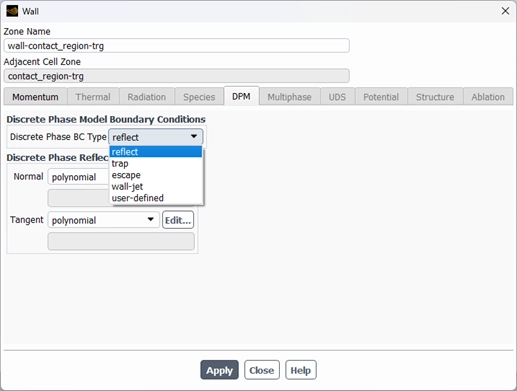

Before we explain what each DPM boundary condition does, it is important to know where to find these settings in ANSYS Fluent. Luckily, the process is very simple. You can set the particle-wall interaction for any wall or boundary in your model.

Here are the basic steps you need to follow:

- In the Fluent setup tree, go to the Boundary Conditions task page.

- From the list, select the boundary zone you want to modify (for example, “wall-inlet-pipe”).

- Click the Edit… button. This will open a new window for that specific boundary.

- In this new window, click on the DPM tab.

This DPM tab is where you control everything that happens when a particle from the Discrete Phase Model hits that surface. You will see a drop-down menu where you can choose the particle boundary condition type. The main options you will find are Reflect, Trap, Escape, Wall-jet, and Wall-film.

Figure 1: DPM Boundary condition tab in ANSYS Fluent

Exploring DPM Boundary Condition Types

Now that we know what DPM boundary conditions are, let’s look at the different types you can use in ANSYS Fluent. We will start with the simplest and most common one: Reflect.

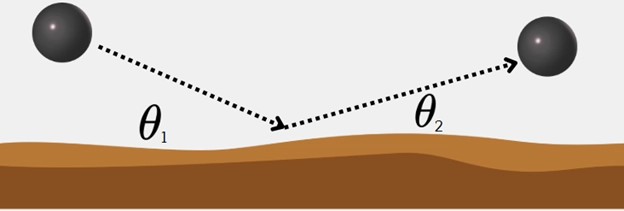

Reflect: When Particles Bounce Off a Surface

The Reflect boundary condition is exactly what it sounds like. When a particle hits a wall, it bounces off and continues its journey through the domain. Think of it like a tennis ball hitting the ground. This is one of the most fundamental types of particle-wall interaction you can model.

To control how the particle bounces, you need to set two important parameters: the coefficients of restitution. These coefficients are numbers between 0 and 1 that tell ANSYS Fluent how much momentum (or energy) the particle keeps after hitting the wall.

Figure 2: An illustration of the Reflect DPM boundary condition, where a particle hits a surface and bounces back into the flow domain, with its new path determined by the coefficients of restitution.

There are two coefficients you can set:

- Normal Coefficient of Restitution: This controls the “bounce” in the direction perpendicular to the wall (straight away from it).

- Tangential Coefficient of Restitution: This controls the particle’s momentum parallel to the wall (along its surface).

The value you choose is very important:

- A value of 1.0 means a perfectly elastic collision. The particle loses no momentum in that direction. It’s a perfect bounce.

- A value of 0.0 means the particle loses all of its momentum in that direction

- after the collision.

- A value between 0 and 1 (e.g., 0.8) represents a real-world, inelastic collision where the particle loses some energy.

When to Use the Reflect Condition? The Reflect DPM condition is great for simulations where you expect solid particles to bounce off hard surfaces without sticking. A great example is in biomedical engineering. In our tutorial on Magnetic Nanoparticles in an Artery, we simulate how nanoparticles travel through a blood vessel. For the artery walls, the Reflect condition is used because we assume the particles bounce off the vessel walls rather than sticking to them.

Figure 3: Nanoparticle bounce off after hitting the walls of artery

Trap DPM: When Particles Stick to a Surface

What if you want the particles to be captured by the wall instead of bouncing off? For this, you use the Trap DPM boundary condition. When a particle hits a surface with the Trap condition, ANSYS Fluent stops tracking its trajectory. The particle is considered “trapped” and is removed from the Discrete Phase Model calculations.

This particle boundary condition is extremely useful for many engineering applications. The fate of the trapped particle’s mass depends on its type:

- For solid particles (like sand or dust), they are simply removed from the calculation.

- For liquid droplets, their mass is instantly added to the surrounding gas as vapor.

- For combusting particles, any remaining volatile material is released into the cell.

The Trap condition is the perfect choice for modeling filtration, deposition, or any process where particles stick to a surface.

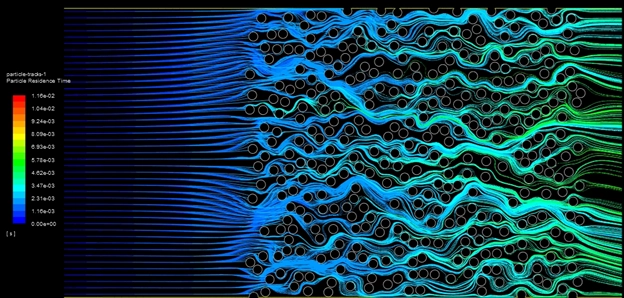

A classic application is simulating a particle filter. In our Particle Filtration DPM CFD Simulation tutorial, particles flow towards a filter, and the Trap boundary condition is used on the filter’s surface to simulate the capture of these particles. Explore the Particle Filtration DPM Simulation here.

Figure 4: A CFD contour plot from a particle filtration simulation using the Trap DPM boundary condition. The colored particle tracks show how particles are captured by the filter surfaces.

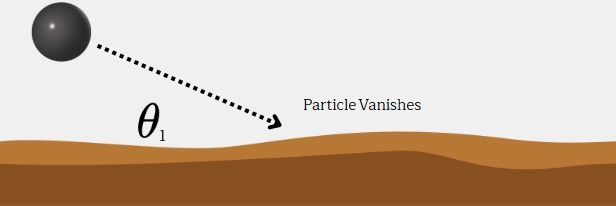

Escape: When Particles Leave the Simulation

The Escape boundary condition is used when you want particles to leave your simulation domain completely. Think of it like an open window in a room. If a dust particle flies out the window, you don’t need to track it anymore. It’s gone.

When a particle in your Discrete Phase Model hits a boundary set to Escape, ANSYS Fluent stops all calculations for that particle. The particle’s trajectory is terminated, and it is marked as “escaped” in the final report. No more tracking is done for that particle, and its mass is removed from the domain.

This is the perfect particle boundary condition for outlets, vents, or any open boundary where particles are expected to exit the system. You would use the Escape DPM condition on any boundary that represents an exit path. Using Escape is simple but very important for defining a realistic and complete ANSYS Fluent DPM simulation.

Figure 5: The ‘Escape’ condition allows the particle to pass through the boundary and exit the simulation domain, which is different from ‘Reflect’ or ‘Trap’.

Wall-jet: When a Droplet Splashes on a Surface

So far, we have seen particles bounce (Reflect), stick (Trap), or leave (Escape). But what happens when a liquid droplet hits a wall and spreads out, creating a thin, fast-moving sheet of liquid? This is where the Wall-jet model is used.

The Wall-jet boundary condition is designed for a specific situation in the Discrete Phase Model. It simulates a liquid droplet hitting a wall and splashing outwards in a thin sheet, like a small “jet” that moves along the wall’s surface. Think of throwing a water balloon at a wall; the water doesn’t just stick, it splashes outwards.

This model is a type of Fluent DPM boundary condition that is especially useful for high-temperature walls. On a very hot surface, a liquid droplet might evaporate too quickly to form a stable film. Instead, it splashes across the hot surface.

The Wall-jet model is a great choice when you are simulating liquid spray hitting hot surfaces where a stable liquid film is not expected to form. A classic example is fuel spray inside a hot engine cylinder. The fuel droplets hit the hot piston or cylinder walls and create a Wall-jet.

The way the droplet behaves depends on factors like its speed and the angle at which it hits the wall. ANSYS Fluent uses these details to accurately model the resulting splash.

Figure 6: The Wall-jet DPM boundary condition simulates a droplet hitting a surface and splashing outward as a thin sheet, which is common for spray interacting with hot walls

Wall-film: When Particles Form a Liquid Layer

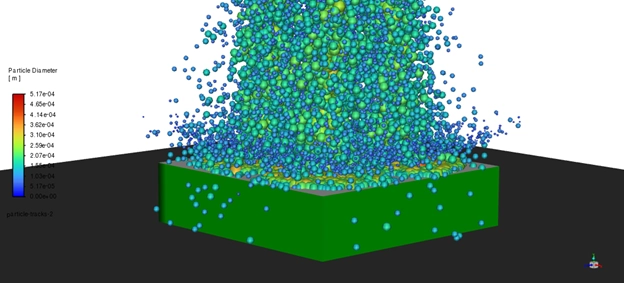

Now we come to one of the most powerful and useful DPM boundary conditions in ANSYS Fluent: The Wall-film model. This model is essential for many advanced simulations.

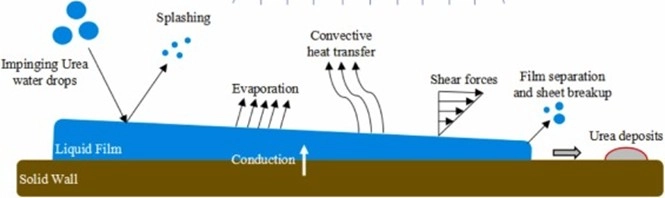

The Wall-film DPM condition is used when you expect liquid particles to hit a surface and create a continuous liquid layer, or film. Instead of bouncing, getting trapped, or escaping, the particles merge with this film. The ANSYS Fluent DPM model then solves a separate set of equations to track how this film moves, spreads, and evaporates on the surface.

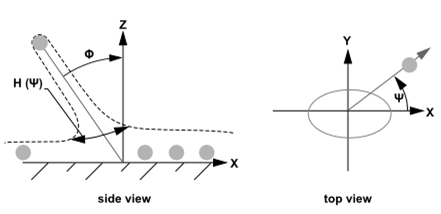

Figure 7: Liquid droplet after hitting a wall with Wall-film boundary condition [1]

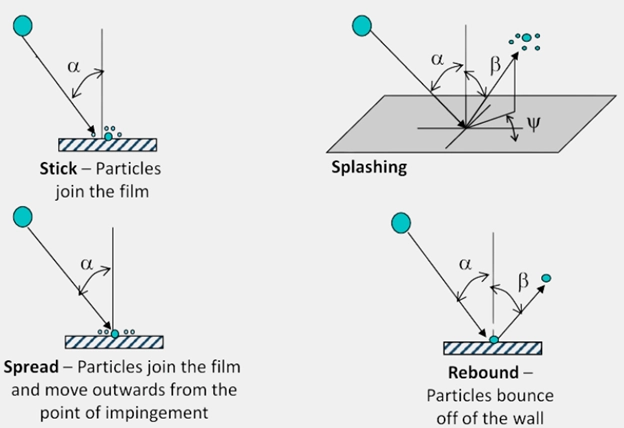

This model is very complex because the outcome of a droplet hitting a wall film depends on factors like impact energy and wall temperature. The particle can:

- Stick/Spread: Join the film smoothly.

- Rebound: Bounce off the film.

- Splash: Hit the film and cause smaller droplets to be ejected back into the flow.

Figure 8: Droplet reaction after hitting a wall with wall-film DPM condition

The Wall-film model is critical for accurately simulating applications like spray cooling, film condensation, or icing on surfaces. It requires an unsteady particle tracking setup and can only be used for liquid droplets.

A perfect application is our tutorial on DPM Wall-film on a Heat Sink. In this simulation, a water spray is used to cool a hot electronic component. The Wall-film condition is used on the heat sink surface to model how the water droplets form a thin film, which then evaporates to remove heat.

Figure 9: A CFD simulation result showing the formation of a liquid wall-film on a heat sink due to spray cooling, a key application of the Wall-film DPM boundary condition

User-Defined: For Custom Interactions

Finally, ANSYS Fluent offers a User-Defined boundary condition. This is the most advanced option and is used for very specific or complex problems. The User-defined condition allows you to write your own custom code, called a User-Defined Function (UDF), to control exactly what happens when a particle hits a wall.

This option gives you complete freedom to create a unique particle-wall interaction model. For example, you could write a UDF that changes the particle’s properties after a collision or creates a specific type of chemical reaction on the surface. This is for expert users who need to go beyond the standard models.

How to Choose the Right DPM Boundary Condition

Choosing the correct DPM boundary condition is critical for getting accurate results in your ANSYS Fluent DPM simulation. Each condition tells a different story about what happens to the particle. To make it easy, we have created a simple comparison table to help you decide.

This table summarizes the main particle boundary conditions Fluent offers and shows you the best situations to use each one.

| Boundary Condition | What Happens to the Particle? | Best For… |

| Reflect | The particle bounces off the wall, like a ball. You set how much energy it loses. | Simulations where particles are solid and do not stick, like sandblasting or nanoparticles bouncing off artery walls. |

| Trap | The particle sticks to the wall and is removed from the simulation. | Filtration systems, particle deposition on surfaces, soot collection. |

| Escape | The particle leaves the simulation domain completely. | Outlets, vents, and open boundaries where particles exit the system. |

| Wall-jet | A liquid droplet hits a hot wall and splashes outward as a thin sheet. | Simulating spray hitting very hot surfaces, like in engine cylinders, where no stable film can form. |

| Wall-film | Liquid droplets hit a wall and form a continuous liquid film that can move and evaporate. | Spray cooling, icing simulations, fuel film on engine parts, condensation. |

| User-Defined | The particle’s fate is controlled by custom code (UDF) that you write. | Very complex or unique interactions not covered by standard models. Requires programming knowledge. |

Conclusion

Mastering DPM boundary conditions in ANSYS Fluent is a key step toward performing accurate and realistic multiphase flow simulations. From a simple bounce (Reflect) to a complex liquid layer (Wall-film), each condition gives you the power to define the particle-wall interaction for your specific problem.

We have learned that you must carefully choose between Reflect, Trap, Escape, Wall-jet, and Wall-film based on what you expect to happen when your particles meet a surface. Using the right condition is the difference between a simulation that is just a picture and one that gives you real, valuable engineering insight.

Now you have a clear guide to the most important Fluent DPM boundary conditions. We encourage you to explore these settings in your own Discrete Phase Model projects.

Reference [1]: Lu, Kai, et al. “A study on urea deposition performance based on a new mixer design in diesel after-treatment system.” Chemical Engineering Research and Design 203 (2024): 731-741.