HVAC CFD Simulation

€155 Original price was: €155.€125Current price is: €125.

€190 Original price was: €190.€145Current price is: €145.

€205 Original price was: €205.€165Current price is: €165.

€210 Original price was: €210.€185Current price is: €185.

€190 Original price was: €190.€165Current price is: €165.

€125 Original price was: €125.€99Current price is: €99.

HVAC systems

HVAC systems—short for Heating, Ventilation, and Air Conditioning—are essential for maintaining indoor comfort, air quality, and energy efficiency in buildings, vehicles, and industrial spaces. These systems regulate temperature, control humidity, filter contaminants, and ensure proper ventilation. But ensuring their optimal performance before installation is a challenge that engineers tackle using HVAC CFD simulation. Through Computational Fluid Dynamics (CFD), experts can model and analyze airflow, temperature distribution, humidity control, and air filtration within a space, enabling smarter HVAC design decisions. By using HVAC CFD analysis, especially with tools like ANSYS Fluent HVAC, engineers can detect inefficiencies, improve system layout, and reduce energy consumption, leading to better-performing and more sustainable HVAC equipment and systems.

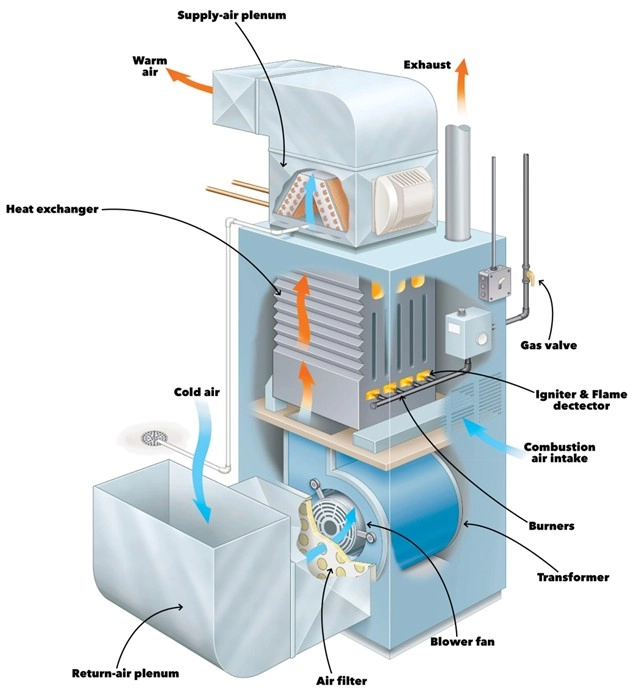

Figure 1- HVAC systems: Heating, Ventilation, and Air Conditioning

What Is the Meaning of HVAC?

HVAC meaning refers to the systems and equipment responsible for:

- Heating: Adding warmth to indoor spaces.

- Ventilation: Moving and exchanging air for freshness and safety.

- Air Conditioning: Removing heat and humidity for cooling purposes.

In short, the HVAC meaning revolves around maintaining indoor comfort and air quality year-round. These systems include various HVAC equipment like air handlers, ducts, filters, blowers, compressors, chillers, coils, and thermostats. But to ensure performance, engineers increasingly rely on HVAC CFD modeling to evaluate these systems under real-world conditions—virtually.

How Does an HVAC System Work?

An HVAC system is designed to regulate indoor temperature, humidity, and air quality through a combination of heating, cooling, ventilation, and filtration processes. In heating mode, a furnace or heat pump generates warm air that is distributed via ductwork and blowers to maintain thermal comfort. During cooling, an air conditioner or heat pump uses a refrigerant cycle to extract heat from indoor spaces and release it outdoors, while delivering cool air evenly throughout the HVAC room. Proper ventilation introduces fresh air and removes stale or polluted air, while humidity control prevents discomfort and mold growth by managing moisture levels. Integrated air filters remove dust, allergens, and pollutants to improve indoor air quality. By applying HVAC CFD simulation, engineers can model and enhance airflow, heat transfer, humidity control, and static pressure in HVAC systems—resulting in more energy-efficient and high-performance designs. Tools like ANSYS Fluent HVAC help HVAC CFD engineers visualize and optimize these systems before installation, making HVAC CFD analysis a critical step in modern HVAC design.

Figure 2- How Does HVAC System Work in a High-Rise Building?

HVAC Applications

Overall, there are five typical HVAC applications, and how HVACCFD analysis makes them more efficient:

Heating

Heating provides comfort during colder seasons. It’s vital in homes, offices, greenhouses, and factories. CFD allows HVAC engineers to visualize temperature gradients, hot spots, and heat losses in a room or duct system. A HVACCFD engineer can run simulations to optimize heating unit placement, reduce thermal stratification, and ensure uniform heating. This not only enhances comfort but also reduces energy consumption and operational costs.

Figure 3- Heater in a Room CFD Simulation, ANSYS Fluent HVAC Tutorial

Cooling

Cooling is essential for thermal comfort and equipment protection. In commercial spaces, inefficient cooling can cause discomfort and affect productivity. Using HVACCFD simulation, engineers can test how cool air disperses across a HVA Croom. It can reveal dead zones or overheating spots and recommend design changes to fans, diffuser vents, or duct angles. For instance, HVACCFD modeling can help you decide if a certain layout will overcool one area while undercooling another.

Figure 4- Room Ventilation by Cooling Duct CFD Simulation: ANSYS Fluent HVAC Tutorial

Ventilation

Ventilation ensures fresh air supply and pollutant removal. CFD helps model airflow paths and velocities, especially in densely occupied or sealed buildings. Engineers can use HVACCFD analysis to:

- Improve air mixing and oxygen levels

- Reduce CO₂ concentrations

- Prevent contamination in cleanrooms or hospitals

This results in healthier spaces and compliance with ventilation codes.

Table 1- Types of Ventilation Applications in HVAC Systems

| Ventilation Application | Description |

| Air Quality Improvement | Removal of dust, pollutants, and contaminants, and providing fresh air in residential and work environments. |

| Odor Control | Reduction and removal of unpleasant odors from the environment. |

| Reducing Excess Humidity | Preventing the growth of mold and fungi in humid environments. |

| Increasing Environmental Efficiency | Creating suitable air conditions for comfort and increasing people’s concentration. |

| General Environment Ventilation | Providing fresh air in public places such as offices, shops, and schools. |

| Exhausting Polluted Air | Removing polluted air and providing clean air using simple systems like fans. |

Figure 5- Natural Ventilation in Buildings 2D CFD Simulation, HVACCFD simulation

Humidity Control

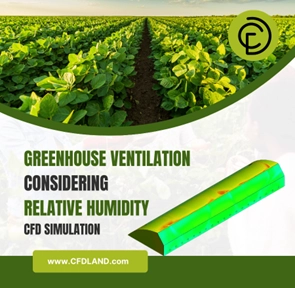

Humidity affects comfort and building integrity. Too much moisture promotes mold, while dry air causes irritation. CFD allows precise simulation of airflow with moisture transport, helping designers choose ideal humidifier/dehumidifier placements and fan speeds. In HVACCFD simulation software, moisture levels and condensation risks can be analyzed over time, under various seasonal conditions, providing insight into system reliability and efficiency.

Figure 6- Greenhouse Ventilation Considering Relative Humidity: HVAC CFD simulation

Air Filtering

Air filtration removes allergens, pollutants, and pathogens. This is crucial in healthcare, labs, and homes. HVACCFD helps determine airflow around filters, pressure drops, and particle removal efficiency. When combined with static pressure in HVAC assessments, simulations help ensure that air filters are placed strategically without introducing excessive resistance or noise.

Figure 7- Air Purifier Fan Considering Filtration CFD Simulation: ANSYS Fluent HVAC Tutorial

What is Autonomous HVAC?

An Autonomous HVAC system is a smart, self-regulating climate control solution that automatically adjusts heating, cooling, and ventilation based on real-time data from sensors. Without requiring manual input, it responds to changes in temperature, humidity, occupancy, and weather conditions to maintain optimal indoor comfort and energy efficiency. By integrating CFD simulations into the design and control process, engineers can enhance airflow optimization, thermal distribution, and overall system performance, making autonomous HVAC systems more intelligent, efficient, and adaptable.

Types of HVAC Systems

There are several types of HVAC systems, each designed for specific needs and preferences. Here we mention some HVAC systems:

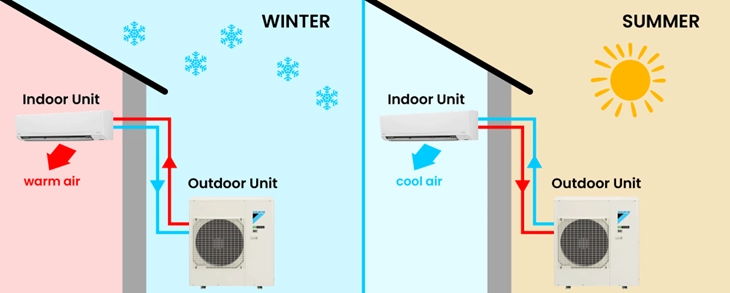

Split System

A split system HVAC is one of the most common HVAC systems, consisting of separate indoor and outdoor units that work together to regulate indoor climate. The indoor unit uses an evaporator coil and fan to circulate conditioned air—absorbing heat during summer for effective cooling, and extracting warmth from indoor air during winter for heating. The outdoor unit, equipped with a compressor and condenser coil, expels the absorbed heat during cooling operations. This system is highly efficient and provides reliable year-round temperature control, making it ideal for residential and commercial spaces. To enhance performance and efficiency, engineers can apply HVACCFD simulation using advanced tools like ANSYS Fluent HVAC. This allows for precise modeling of airflow, heat transfer, and static pressure in HVAC environments, leading to optimized HVAC design. With HVACCFD analysis, you can refine split system layout, airflow distribution, and equipment placement—ensuring superior comfort, energy savings, and long-term system reliability.

Figure 8- Comparison of Split System Air Conditioners in Winter and Summer

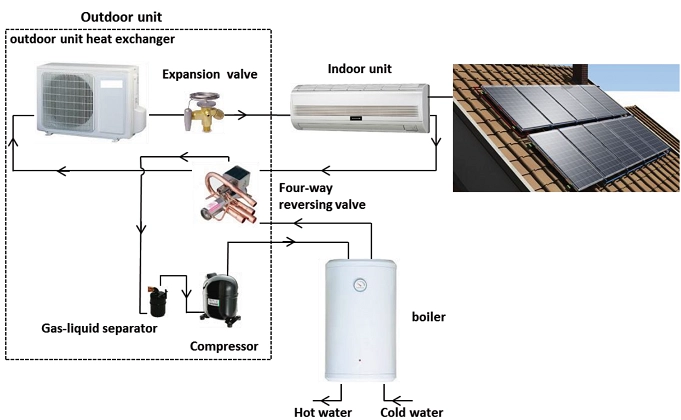

1-1- Hybrid Split System

A hybrid split system combines the functionality of a traditional split HVAC system with energy-efficient components like heat pumps or furnaces, offering enhanced flexibility in heating and cooling operations. This system intelligently switches between electric and gas heating based on external weather conditions, optimizing energy use while maintaining indoor comfort. Its adaptability makes it an excellent choice for regions with variable climates. Engineers and HVACCFD engineers can leverage HVACCFD simulation software to analyze and refine system performance under different environmental scenarios. Using tools like ANSYS Fluent HVAC, it’s possible to simulate airflow, heat exchange, and humidity control for improved HVAC design. By conducting a detailed HVACCFD analysis, designers can determine the best system configuration, equipment placement, and operational strategy, ensuring maximum efficiency and comfort in real-world conditions.

Figure 9- Modified Split Air Conditioner Coupled with a PV/T System

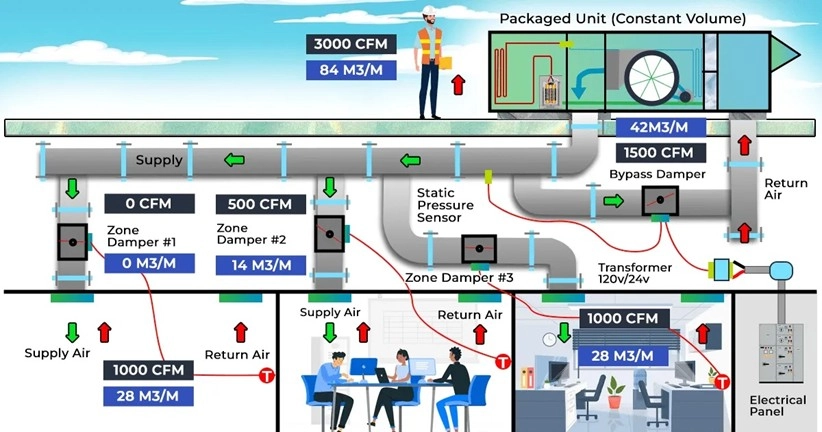

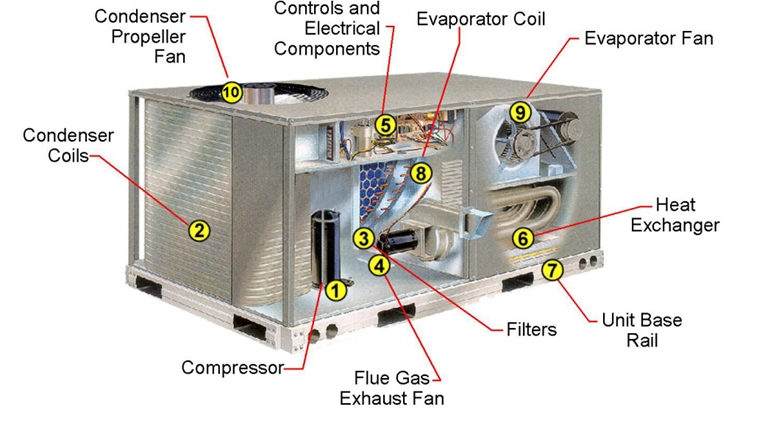

Packaged HVAC System

A packaged HVAC system integrates all essential HVAC equipment—including the compressor, condenser, evaporator coils, air handlers, and fans—into a single compact unit. Typically installed on rooftops or concrete slabs outdoors, these systems are ideal for buildings with limited interior space. Packaged HVAC systems offer a space-saving, energy-efficient solution suitable for both residential and commercial applications. Due to their consolidated design, they are easier to install and maintain while still delivering reliable heating, cooling, ventilation, and air quality control. Engineers can enhance performance and efficiency using HVACCFD simulation tools such as ANSYS Fluent HVAC. Through HVACCFD analysis, it’s possible to evaluate how the system performs under varying environmental conditions and internal loads, ensuring optimal placement and configuration. By incorporating HVACCFD modeling, professionals can tailor HVACdesign to the specific demands of each project, resulting in higher efficiency, improved comfort, and reduced operational costs.

Figure 10- A Packaged HVAC System installing on Rooftop

Figure 11- Typical Components of a Packaged Rooftop Unit (RTU)

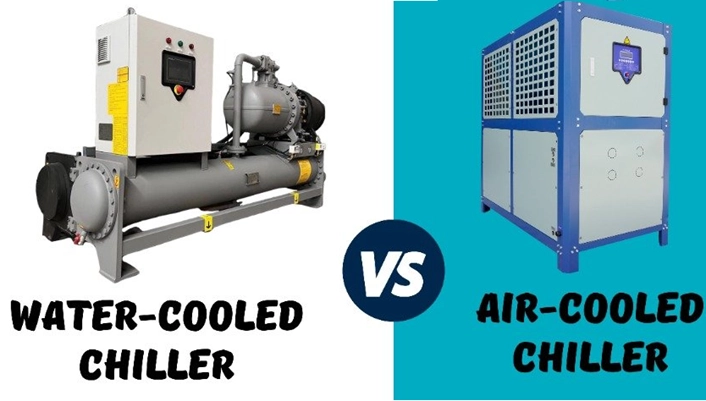

Chillers

Chillers are essential HVAC systems widely used in commercial and industrial facilities to provide reliable cooling by extracting heat from a liquid—usually water or a glycol solution. This chilled fluid is then circulated through a heat exchanger to cool air or equipment, making chillers ideal for applications like manufacturing plants, data centers, and large office buildings. Based on how they reject heat, chillers are classified as either air-cooled or water-cooled. Known for their high efficiency in large-scale cooling operations, chillers ensure accurate temperature control and contribute significantly to energy savings. Whether you’re looking to design a new system, optimize an existing one, or evaluate equipment location within the building, HVACCFD modeling are powerful methods for achieving superior results in both performance and sustainability.

Figure 12- Air-Cooled Chillers vs. Water-Cooled Chillers

Here’s a clear comparison of air-cooled and water-cooled chillers in the table 2, suitable for SEO-focused blog content:

Table 2- comparison of air-cooled and water-cooled chillers

| Feature | Air-Cooled Chiller | Water-Cooled Chiller |

| Cooling Medium | Uses ambient air to reject heat via fans | Uses water from a cooling tower to remove heat |

| Installation Location | Typically installed outdoors (rooftop or open area) | Usually installed indoors, with a cooling tower placed outside |

| Initial Cost | Lower installation cost due to simpler setup | Higher initial cost due to need for cooling towers and piping |

| Maintenance | Easier to maintain with fewer components | Requires more maintenance (cooling tower, water treatment, etc.) |

| Efficiency | Less efficient, especially in hot and humid climates | More efficient, especially in large commercial/industrial buildings |

| Space Requirement | Requires less indoor space, but needs open air around for ventilation | Requires significant mechanical room space and external space for cooling tower |

| Application Suitability | Ideal for small to medium buildings and where water is scarce | Preferred for large facilities, high heat loads, or where energy efficiency is critical |

Main Components of an HVAC System

An HVAC (Heating, Ventilation, and Air Conditioning) system consists of various essential components that work together to regulate temperature, humidity, and indoor air quality. Here’s a breakdown of the key components found in standard HVAC systems:

Figure 13- List The Main System Components of An HVAC System

Fan (Blower Fan)

The fan is the heart of any HVAC system. It circulates air throughout the space, either supplying fresh air (Supply Fan) or expelling stale air (Exhaust Fan). Proper airflow ensures effective heating, cooling, and ventilation.

Air Ducts

Ducts are pathways for distributing air from the fan to different areas of a building. They can be made of metal or plastic and are available in spiral or rectangular designs. Well-designed air duct systems reduce energy losses and maintain balanced airflow.

Air Filters

Air filters are critical for maintaining indoor air quality. They trap dust, allergens, and airborne contaminants from incoming or outgoing air. Clean filters also improve system efficiency and extend equipment life.

Air Grilles or Vents

These components allow conditioned air to enter or exit rooms. Grilles and vents are typically installed in walls, ceilings, or floors, playing a key role in air distribution and room comfort.

Dampers

Installed within air ducts, dampers regulate or block airflow to specific zones. They are essential in zoning systems for energy savings and customizable temperature control.

Air Intake or Exhaust Port

This is the point where fresh air enters the system or stale air is expelled. Proper intake and exhaust placement ensures healthy air circulation and compliance with building codes.

Compressor

The compressor pressurizes the refrigerant and initiates the cooling cycle. It plays a vital role in transferring heat from indoor air to the outside environment.

Evaporator Coil

Located inside the air handler or indoor unit, the evaporator allows refrigerant to absorb heat from the indoor air, cooling the air in the process.

Condenser Coil

Usually placed outdoors, the condenser releases the absorbed heat from the refrigerant into the external environment. It’s a key component in air conditioning systems.

Air Handling Unit (AHU)

The AHU is responsible for controlling temperature, humidity, and air filtration. It is commonly used in large-scale HVAC systems for commercial and industrial buildings.

Pumps

Pumps are used to circulate chilled water, hot water, or refrigerant across different parts of the HVAC system—especially in chiller or boiler-based systems.

Thermostats and Control Systems

Modern HVAC systems rely on digital thermostats and automation controls to maintain desired indoor conditions, optimize energy use, and provide smart, real-time adjustments.

Burners

Burners in HVAC systems generate heat by mixing fuel and air, then igniting the mixture. They are key to efficient heating in furnaces and boilers, and their performance can be optimized using CFD simulation for better energy use and lower emissions.

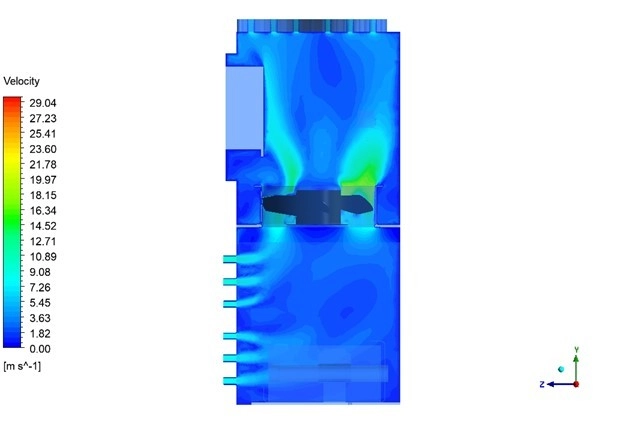

Simulation of a HVAC system by ANSYS Fluent

Fluid mechanics and heat transfer are fundamental to every HVAC system, and ANSYS Fluent stands out as one of the most powerful tools for simulating both. From evaluating the full performance of an HVAC system in a building to designing individual components like condensers, air handling units, or ventilation ducts, ANSYS Fluent enables detailed, physics-based analysis. This HVAC CFD simulation software allows engineers to optimize airflow, temperature distribution, and humidity control, ensuring maximum energy efficiency and indoor comfort. Whether you are working on room-scale ventilation simulations or equipment-level performance, ANSYS Fluent provides the insights needed for better HVAC design and operation.

Figure 14- Air purifier HVAC CFD Simulation by means of ANSYS Fluent

CFDLAND expertise in HVAC Systems Modeling Using ANSYS Fluent Software

At CFD Land, our expertise in HVAC systems modeling using ANSYS Fluent is reflected across all our product categories—including HVAC room simulations, ventilation optimization, heat exchanger design, and component-level CFD training.

ANSYS Fluent enables accurate simulation of fluid flow, heat transfer, humidity control, and air quality, allowing engineers to analyze and optimize the performance of complete building systems or individual components like chillers, air handling units, or nozzles. Our CFD SHOP offers a wide range of ready-to-use projects, from greenhouse ventilation to water mist spray systems, all powered by Fluent. Whether you’re learning, outsourcing, or customizing a simulation, our Fluent-based HVAC CFD simulations help you design smarter, run cleaner, and perform better. Visit the Order CFD Project page to get started with your custom HVAC simulation today.