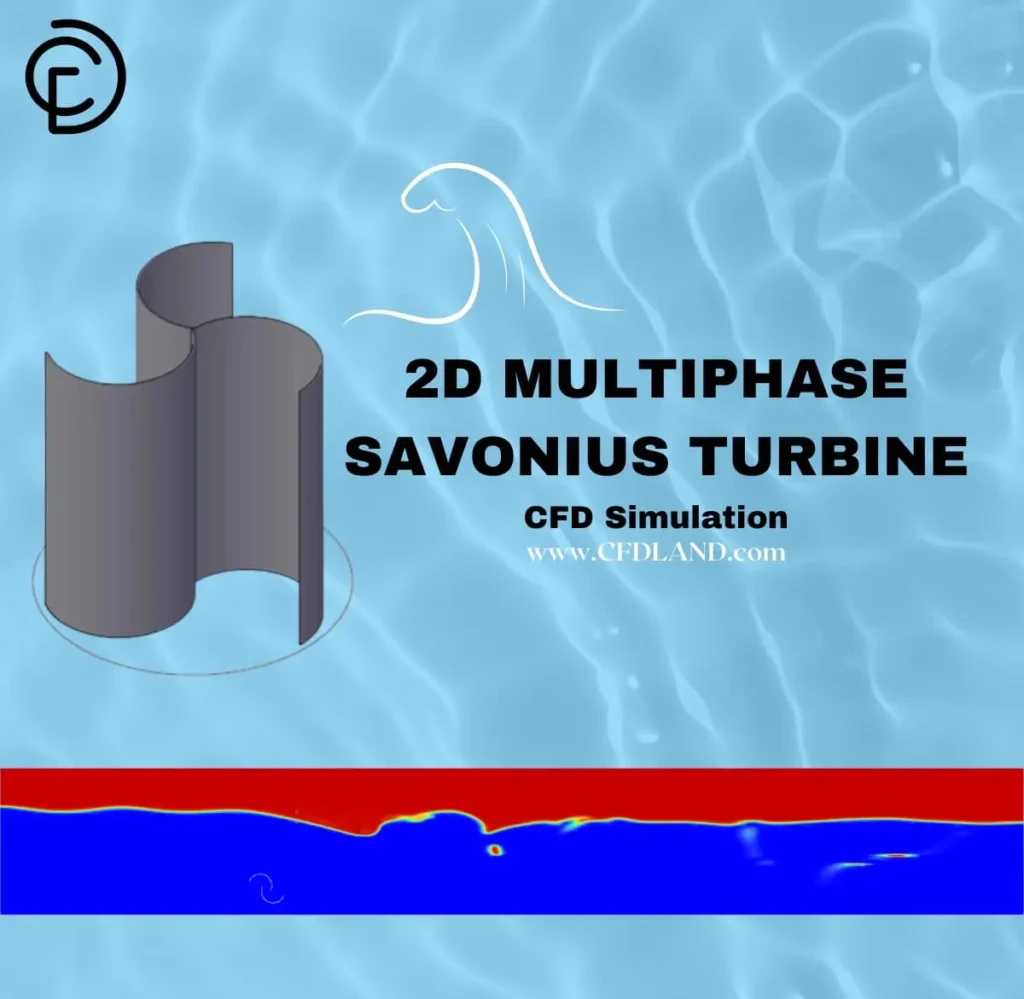

Multiphase CFD Simulation

€235 Original price was: €235.€165Current price is: €165.

€215 Original price was: €215.€165Current price is: €165.

€190 Original price was: €190.€175Current price is: €175.

€155 Original price was: €155.€125Current price is: €125.

What is a multiphase flow?

Multiphase flow involves the simultaneous movement of two or more distinct states of matter within a single system. A ‘phase‘ represents a thermodynamic state of matter, which can be solid, liquid, or gas. These phases can exist in various combinations, such as gas-liquid, liquid-liquid, gas-solid, or even more complex multiphase states. CFD multiphase flow simulations are crucial for accurately predicting and analyzing the behavior of these complex systems.

The smoke from many industrial processes contains different gases and various floating particles, which means it is a multiphase flow.

What are multiphase flow analysis applications?

Multiphase flow finds applications in numerous fields due to its relevance in various industrial processes and natural phenomena. Some of the key applications include:

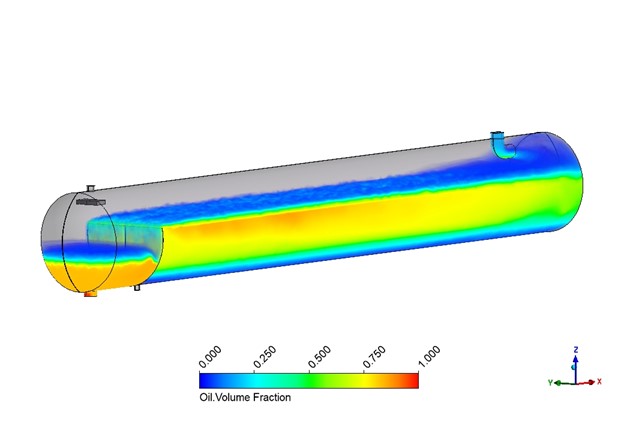

Oil and Gas Production

In the oil and gas sector, multiphase flow is encountered across the production spectrum, from the extraction of resources underground to their transportation via pipelines. A thorough grasp of multiphase flow dynamics is essential for enhancing production efficiency, ensuring the safe and effective conveyance of resources through pipelines, and efficiently separating oil, gas, and water components at surface facilities.

Multiphase CFD simulations play a critical role in modeling and optimizing these processes to improve overall operational performance.

Power Generation

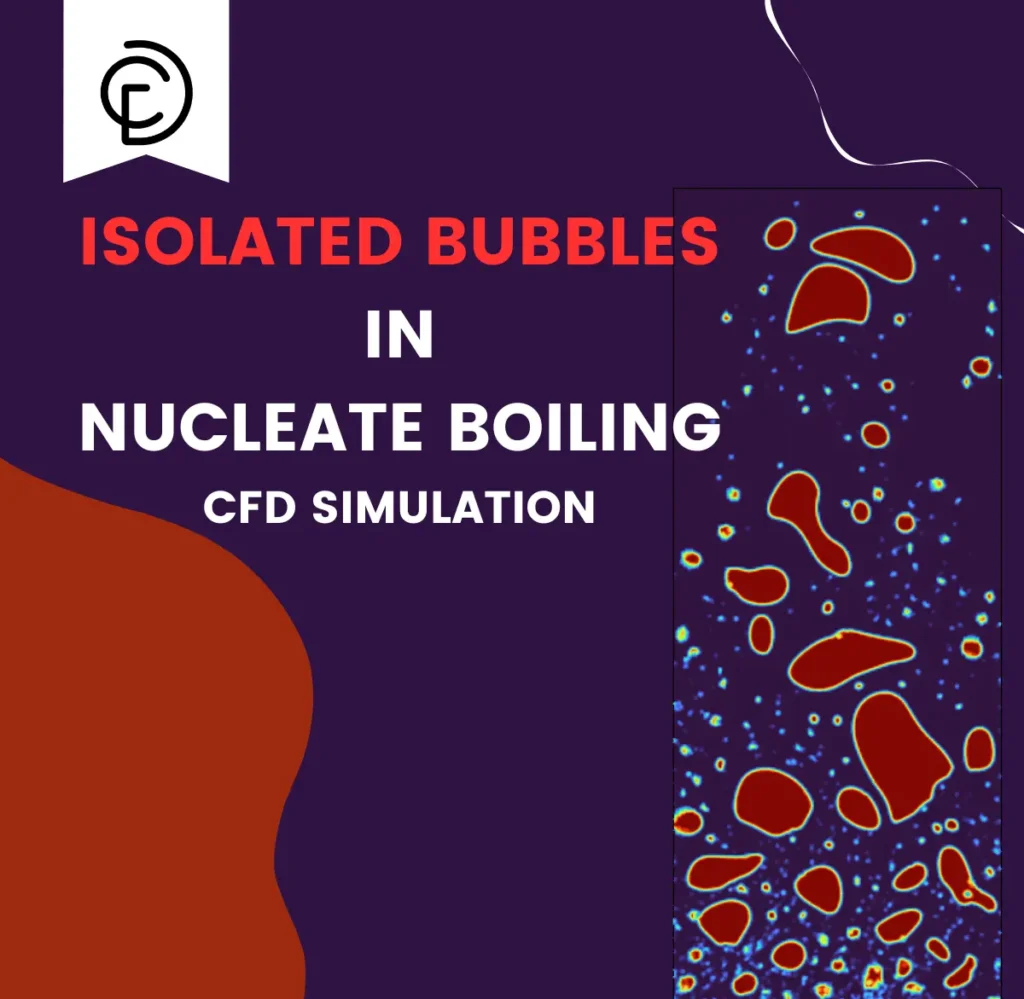

Multiphase flow is involved in various power generation methods, including fossil fuel power plants, nuclear power plants, and geothermal power plants. Combustion of fossil fuels in fossil fuel power plants, as well as the phase change of coolant fluid (usually water) in nuclear and geothermal power plants, are examples of multiphase flows.

Multiphase flow CFD is essential for accurately simulating these processes to enhance efficiency, safety, and performance in power generation systems.

Mining and Minerals Processing

In mining and minerals processing, multiphase flows occur during the transportation of ores, slurries, and tailings. Efficient separation processes, like flotation and sedimentation, depend on the management of multiphase flow dynamics.

Multiphase flow in ANSYS Fluent provides advanced simulation capabilities to optimize these processes and improve overall efficiency and effectiveness in the mining industry.

Chemical Engineering

In chemical engineering, multiphase flow plays a fundamental role in numerous processes. For instance, in distillation, components of a mixture are separated based on their boiling points, highlighting the importance of multiphase dynamics. Additionally, multiphase reactors are utilized for various chemical reactions, where the interaction between different phases is indispensable for reaction occurrence and efficiency.

Multiphase flow modeling using ANSYS Fluent provides comprehensive tools for accurately simulating and optimizing these complex processes, enhancing both reaction efficiency and overall process performance.

Environmental Engineering

In environmental engineering, grasping multiphase flow phenomena is critical for applications like groundwater remediation, sediment transportation in rivers and coastal regions, and the dispersion of pollutants in the atmosphere.

Multiphase flow ANSYS Fluent provides powerful simulation tools to analyze and address these complex environmental challenges effectively.

These examples underscore the broad significance of multiphase flow across industries and scientific fields. It plays a vital role in process optimization, efficiency enhancement, and addressing intricate engineering and environmental issues. ANSYS Fluent multiphase capabilities offer advanced simulation solutions to tackle these complex challenges, ensuring improved outcomes and innovations across various sectors.

In a phase change, at least two phases are present, which makes this phenomenon a multiphase flow.

Multiphase flow simulation models

Multiphase flow simulation models are mathematical frameworks used to predict the behaviour of flows containing two or more distinct phases. There are several types of multiphase flow simulation models, including:

1. Eulerian-Eulerian Models

In the Eulerian-Eulerian model, the fluid mixture is regarded as a unified continuous phase, and the equations governing fluid flow are individually solved for each phase. While this method proves efficient for simulating dilute dispersed flows, it may encounter challenges when dealing with highly concentrated phases or intricate interface interactions. From the subset models of the Eulerian-Eulerian model (EEM), the following can be mentioned:

-

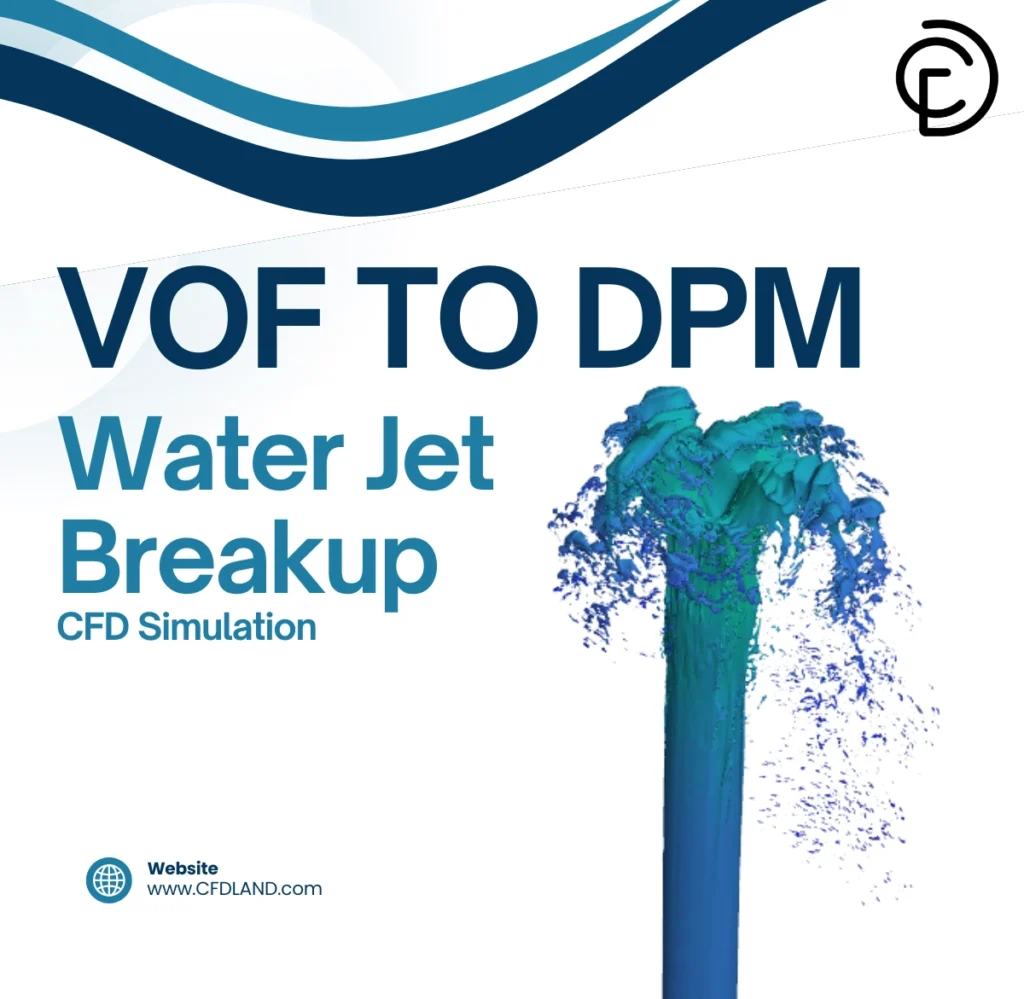

- Volume of Fluid (VOF) Model: It explicitly tracks the interface between the phases by solving a transport equation for the volume fraction of each phase within each computational cell. This approach is versatile and can handle complex interface dynamics but can be computationally demanding for highly contorted interfaces. The VOF method is best suited for flows featuring a distinct phase interface where the curvature radius is significantly larger than the mesh size. This method is designed to explicitly capture this interface within the computational domain, ensuring that the two phases remain separate and do not intermingle.

- Eulerian Model: The Eulerian model employs a distinct formulation compared to VOF, as it does not explicitly capture the interface. Therefore, the interface does not need to exist on length scales much larger than the mesh. In this model, the two continuous phases are assumed to interpenetrate each other, allowing for scenarios where one phase, such as bubbles, may be smaller than the mesh size, which VOF cannot handle.

- Mixture Model: The mixture model treats the multiphase flow as a single continuous mixture with averaged properties. It assumes that phases are uniformly mixed and uses conservation equations for the mass, momentum, and energy of the mixture. While less computationally intensive compared to other approaches, it may not capture phase separation or interface dynamics as accurately.

2. Eulerian-Lagrangian Models

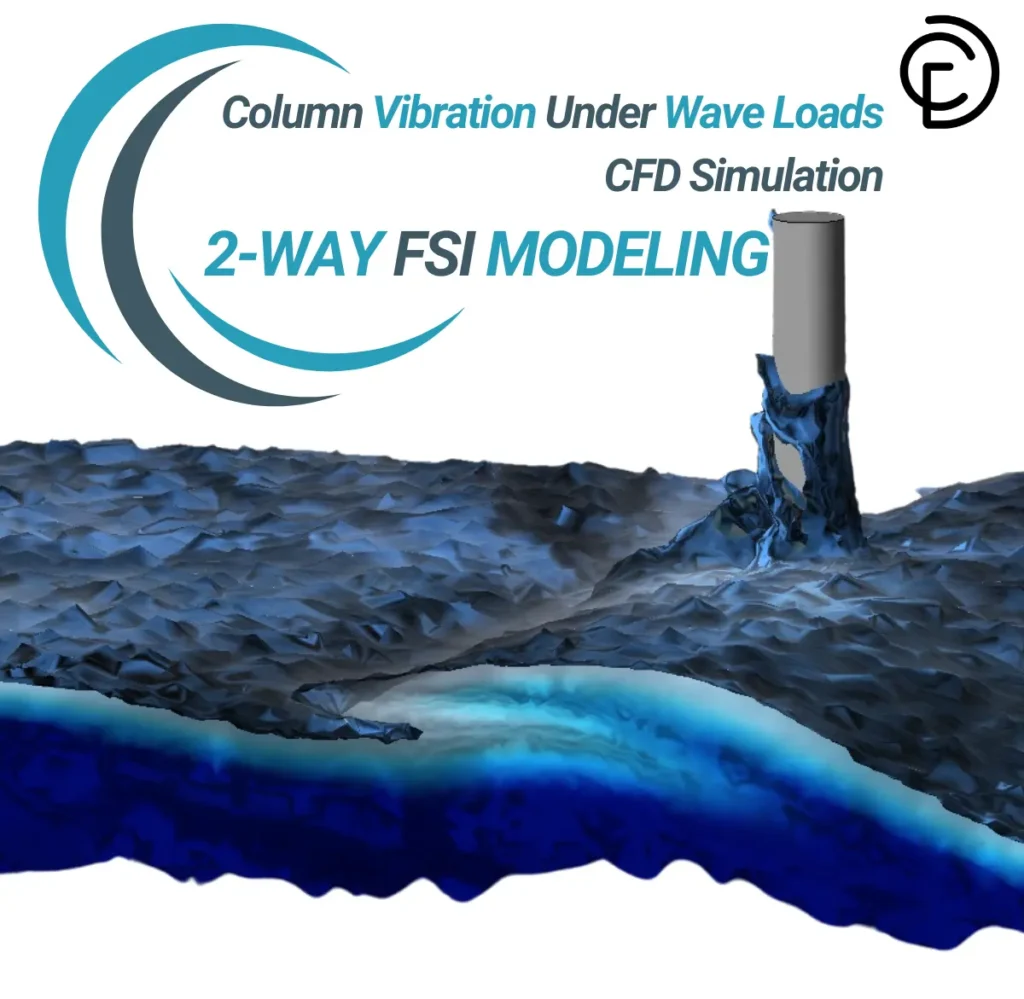

Eulerian-Lagrangian (EL) models are a computational approach used to simulate multiphase flows where one phase is treated as a continuous medium (Eulerian), while the other phase is represented by discrete particles (Lagrangian). In EL models, the Eulerian framework solves the governing equations for the fluid phase, such as the Navier-Stokes equations, capturing the continuous behaviour of the fluid.

Meanwhile, the Lagrangian framework tracks the trajectories of individual particles, considering their interactions with the fluid phase and among themselves. Within EL approach, there are different specific methods depending on the needs of the simulation. For more information about this approach.

Blood is a multiphase flow because it contains different fluids and particles.

Simulation of Multiphase Flows by ANSYS Fluent

ANSYS Fluent multiphase flow capabilities are essential for tackling a wide range of complex engineering challenges. ANSYS Fluent multiphase flow modeling offers detailed insights and optimization potential for processes involving multiple phases. For those looking to get started, numerous resources, including ANSYS Fluent multiphase flow tutorials, are available to guide users through the intricacies of these simulations, ensuring effective and accurate results.

ANSYS Fluent offers comprehensive capabilities in multiphase flow simulation, including Eulerian-Eulerian models such as the Volume of Fluid model for detailed interface tracking, Eulerian models for phase interpenetration, and the mixture model for uniform phase mixing. It also supports Eulerian-Lagrangian models to simulate discrete particle interactions within a continuous fluid phase. These features enable Fluent to accurately model and optimize complex multiphase flow behaviors across diverse industrial and engineering applications.

Oil volume fraction, adopted from “Three-phase Oil-water-air Separator CFD Simulation”

CFDLAND expertise in Multiphase Flows Modeling Using ANSYS Fluent Software

Looking to harness the power of multiphase flow simulations? Look no further! Our expertise in simulating multiphase flow problems is at your service. Dive CFD SHOP into where you’ll discover a plethora of multiphase flow projects waiting to be explored. Whether you’re delving into fuel injection or pollutant dispersion in the atmosphere, rest assured that our proficiency in multiphase flow simulations will exceed your expectations. You can easily order your project for outsourcing.