Axial Fan with Perforated Blades: A Fluent CFD Simulation

Axial Fan with Perforated Blades: A Fluent CFD Simulation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€195 Original price was: €195.€135Current price is: €135.

An Axial Fan With Perforated Blade Fluent simulation is a computer model of a new type of fan designed to be very quiet. This Perforated Blade CFD analysis is important for Quiet Fan Design. Like a normal fan, it has blades that spin to move air. But these special blades have small holes, or perforations, on them. A Perforated Blade Fluent simulation shows how these holes change the airflow to reduce noise and improve how the fan works. This study uses the methods from the key reference paper by Yadegari et al. [1] to make sure our model is accurate and reliable.

- Reference [1]: Yadegari, Mehdi, et al. “Reducing the aerodynamic noise of the axial flow fan with perforated surface.” Applied Acoustics215 (2023): 109720.

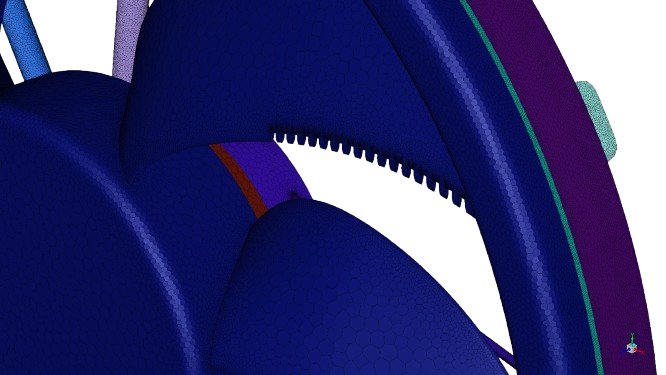

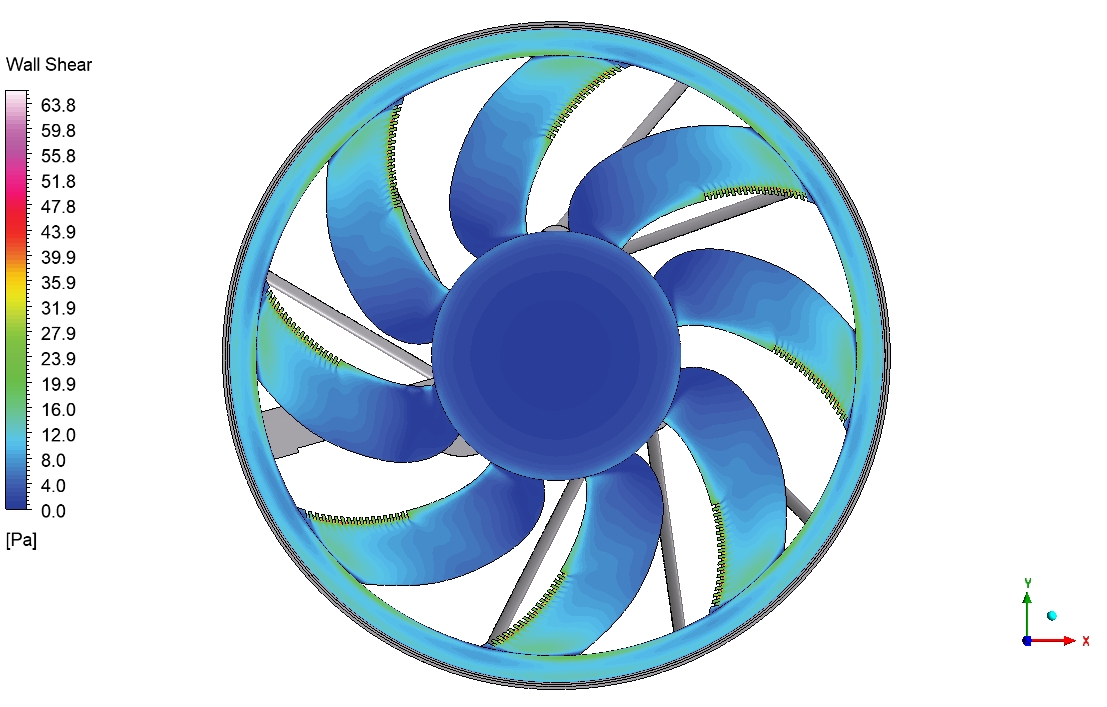

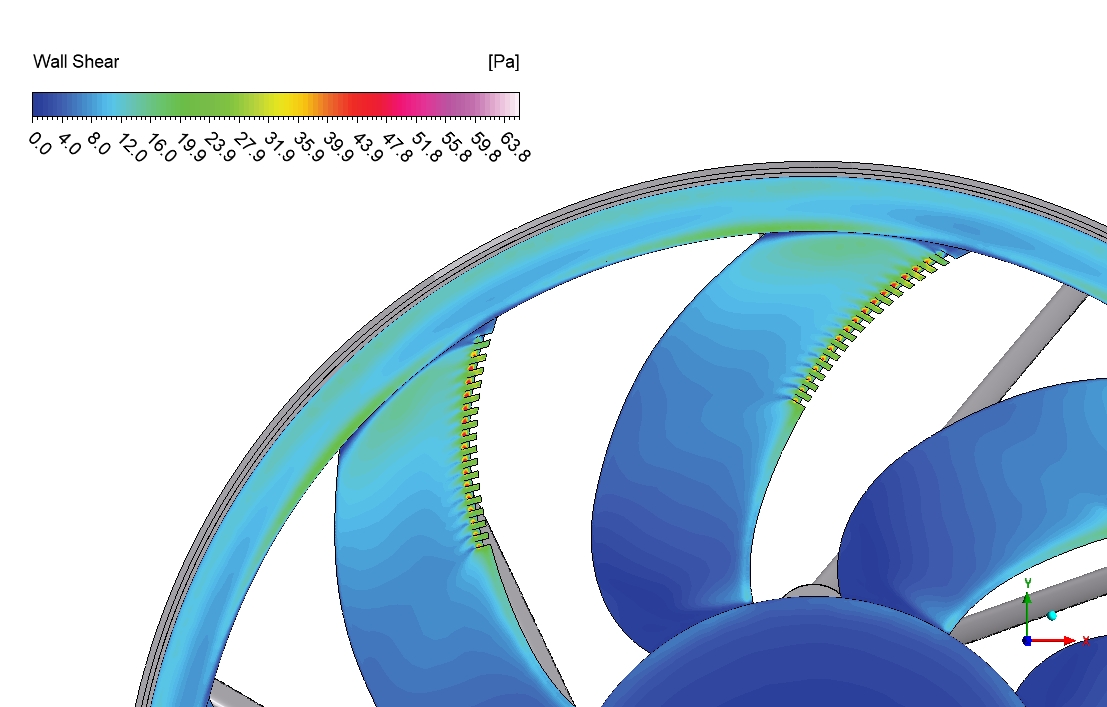

Figure 1: A schematic of the 3D geometry used for the Axial Fan With Perforated Blade CFD simulation.

Simulation Process: Fluent MRF Setup, Modeling Steady-State Flow for a Perforated Fan

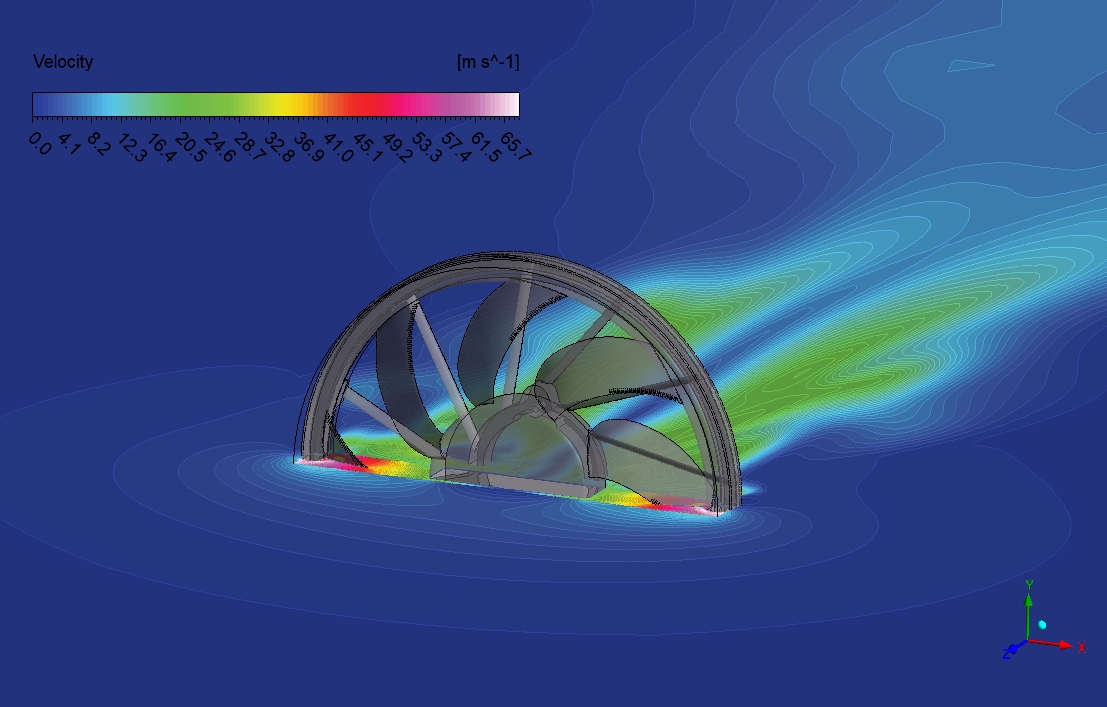

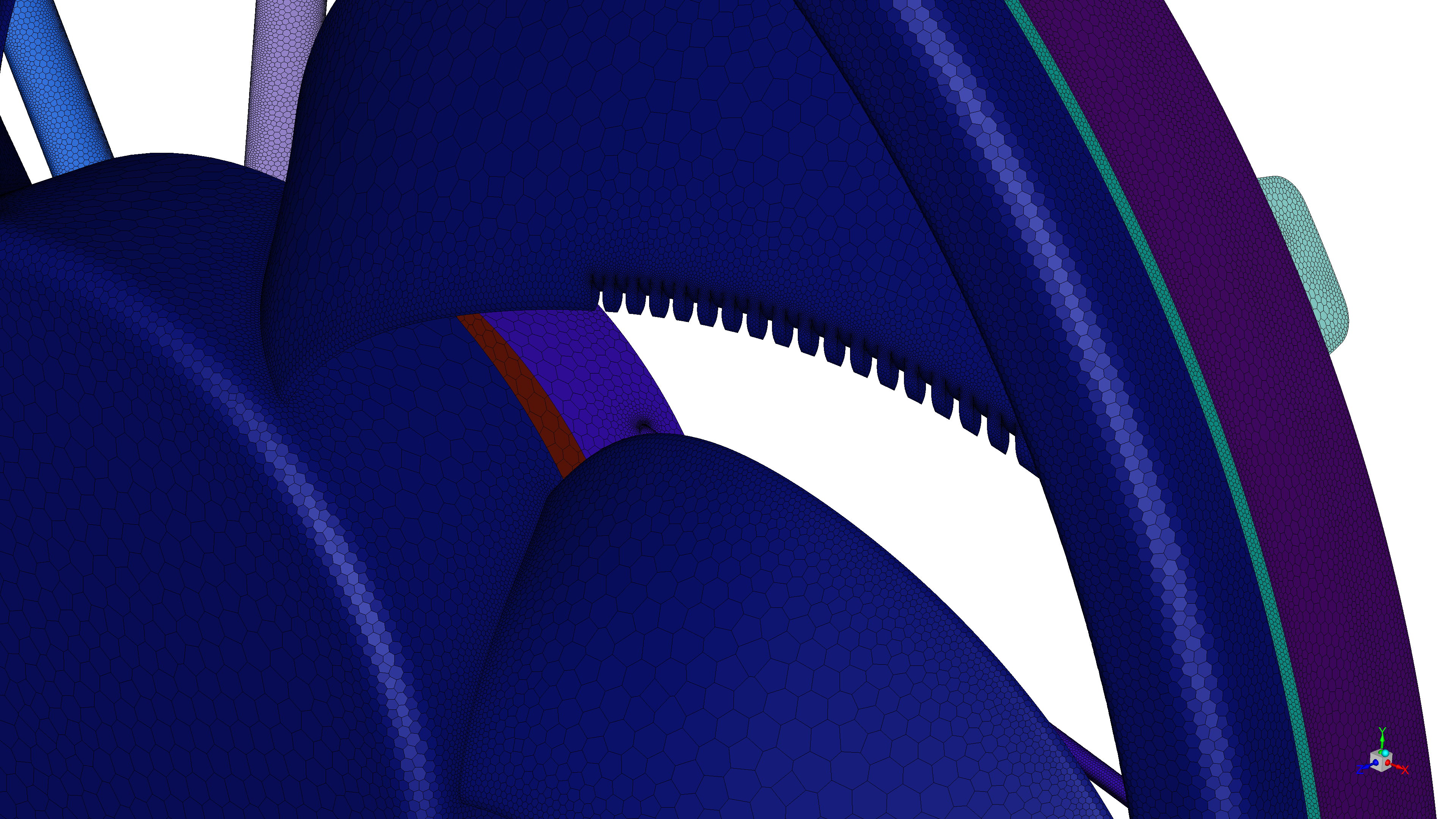

To perform this Axial Fan CFD study, we first built the 3D geometry. This geometry had two main parts: a smaller, rotating cylinder zone that contained only the fan rotor, and a larger, stationary zone for the air around the fan and its housing. We then created a high-quality hybrid mesh using 10,132,179 polyhedral and hexahedral cells to accurately capture the flow around the complex blade shapes. In ANSYS Fluent, we used the Multiple Reference Frames (MRF) model. The MRF method is a steady-state approach that is excellent for Turbomachinery CFD Fluent problems because it calculates the flow in the spinning zone and the stationary zone separately and connects them, which is much faster than a full transient simulation. The fan’s rotational speed was set to 2818 rpm. To correctly model the turbulent airflow, we used the SST k-ω turbulence model, which is very good at predicting flow close to walls like the fan blades.

Figure 2: The high-quality hybrid mesh with 10,132,179 polyhedral and hexahedral cells used for the MRF Simulation Fluent analysis.

Post-processing: CFD Analysis, How Perforations Improve Pressure and Stability

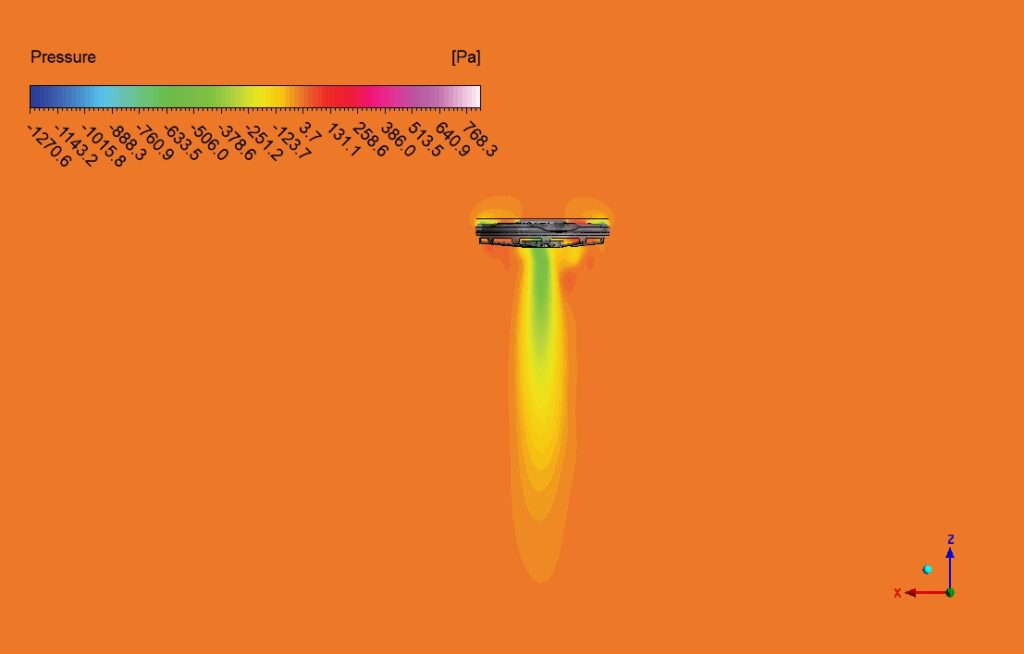

The pressure contour is a diagnostic map that tells the story of how the fan is working. From an engineering standpoint, it clearly shows the fan creating a pressure difference, which is how it pushes air. The key result is the smooth pressure gradient across the fan blades. The colors change gently, without sharp, sudden shifts. This is a very important finding. In fan design, sharp pressure changes create turbulence, and turbulence creates noise. The smooth change here suggests that the perforations are successfully breaking up the air swirls, leading to a quieter operation. The design is doing exactly what it was meant to do: reducing the pressure differences that are a major source of aerodynamic noise.

Figure 3: A contour of static pressure from the Pressure Distribution CFD analysis, showing the pressure gradient across the fan blades.

This analysis also confirms the fan’s overall performance. The large, concentrated low-pressure zone in the wake region behind the fan shows that momentum is being effectively transferred to the air, which means the fan is creating thrust efficiently. Furthermore, the pressure distribution is very symmetrical across the fan’s face. This balance is critical for the fan’s mechanical health. It means the load on the blades is even, which leads to less vibration and a longer operational life for the fan’s components. The most important achievement of this simulation is its ability to visually prove the design concept: it directly connects the physical feature (the perforations) to the desired engineering outcome (a smoother pressure profile), providing clear evidence that this design will be quieter and more stable than a standard solid blade fan.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€155 Original price was: €155.€95Current price is: €95.

€135 Original price was: €135.€85Current price is: €85.

€130 Original price was: €130.€115Current price is: €115.

€185 Original price was: €185.€125Current price is: €125.

€255 Original price was: €255.€135Current price is: €135.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.