Air Purifier Fan Considering Filtration CFD Simulation, ANSYS Fluent Training

Air Purifier Fan Considering Filtration CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€185 Original price was: €185.€125Current price is: €125.

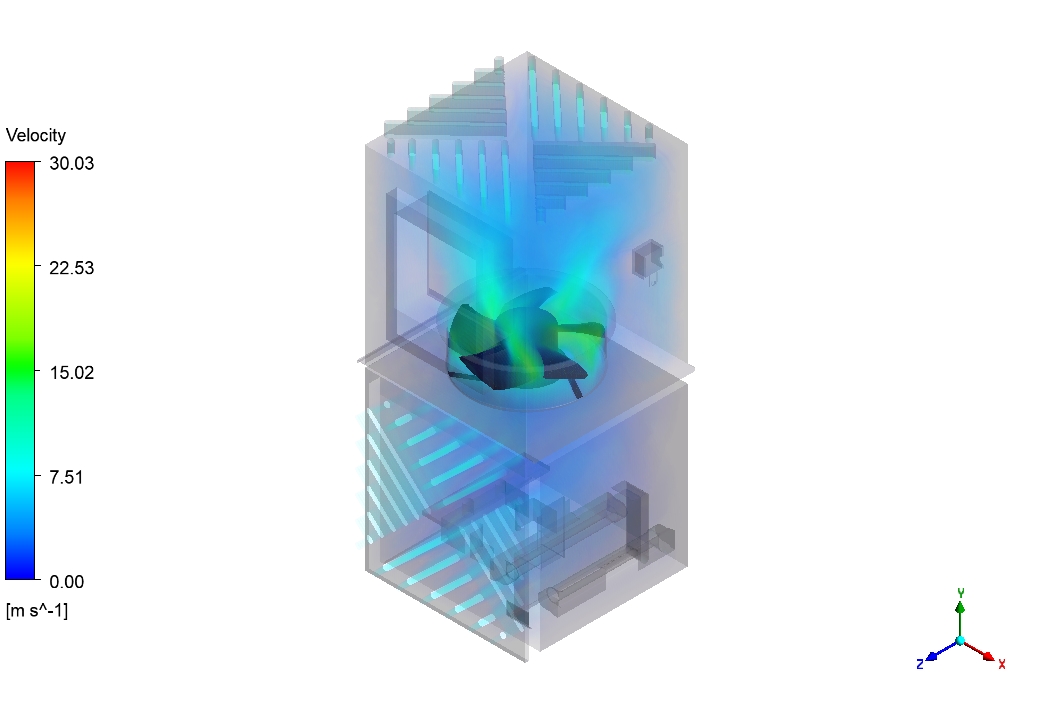

An essential part of an air purification system, the air purifier fan circulates and filters air to improve indoor air quality. The fan pulls air in from outside the surrounding area. It passes it through various filters, including activated carbon filters, UV light sterilizers, and HEPA (High-Efficiency Particulate Air) filters. This report shows how we used computational fluid dynamics (CFD) to study an air purifier fan with filtration using ANSYS Fluent. Air purifiers are super important for cleaning indoor air and removing harmful particulates like dust, pollen, and other airborne contaminants. The fan performance in an air purification system directly affects how well it can improve indoor air quality and create healthy living environments. Our numerical simulation looks at how the air purifier pulls in dirty air, pushes it through multiple filters including HEPA filters and activated carbon filters, and then releases clean air back into the room.

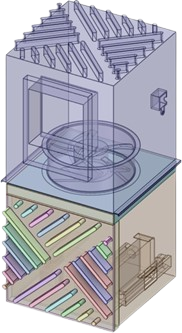

Figure 1: Schematic of Air purifier fan and filters

Simulation Process

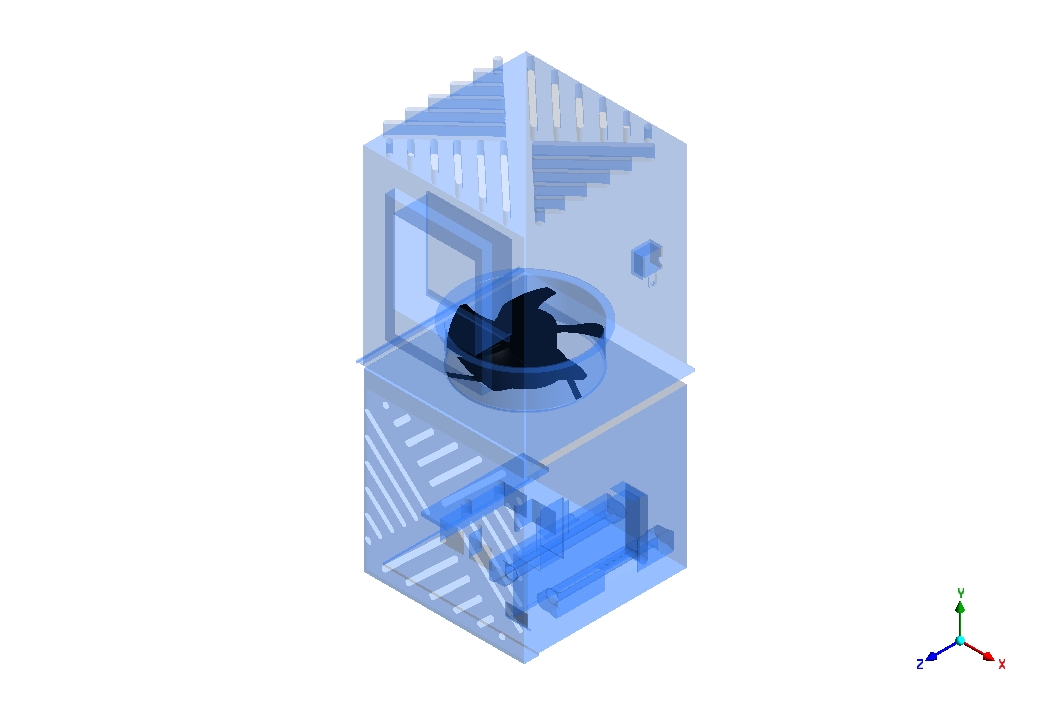

The complex model is designed with the powerful tool Solidworks. Several filtrations are implemented by means of Porous modules to absorb various pollutants of different sizes. However, the main focus of the project is on fan performance and role; the filtration effect on flow is taken into account. The fan itself rotates at 3200 rpm to actively enhance air circulation.

Post-processing

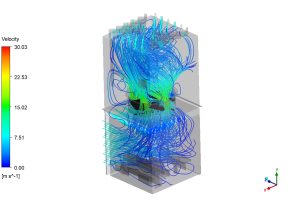

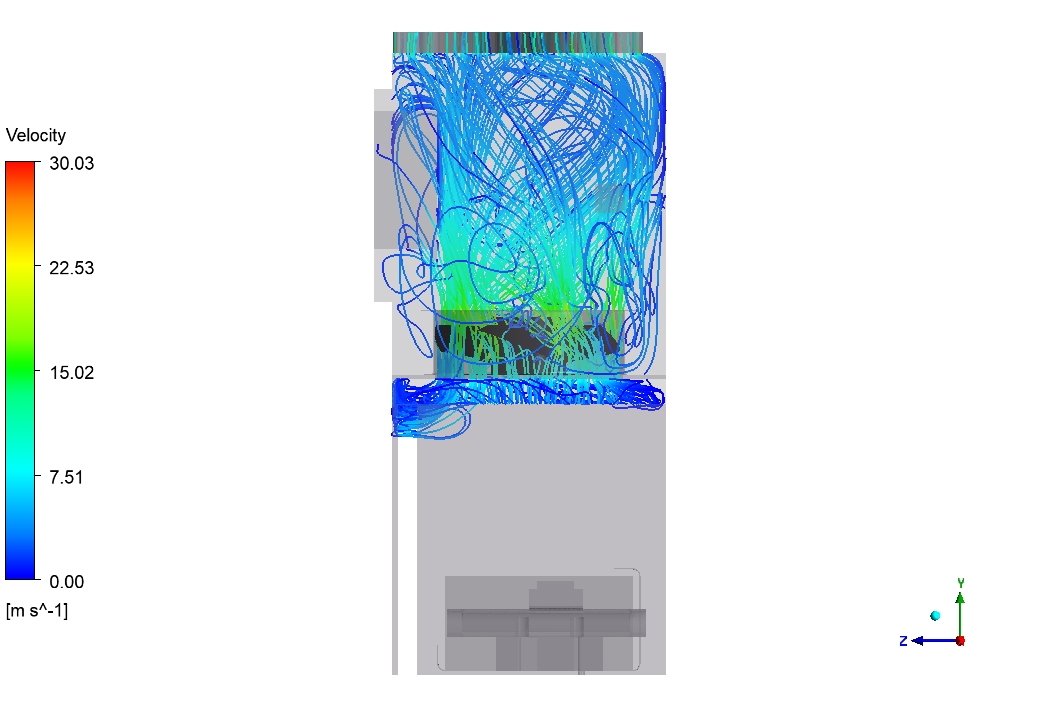

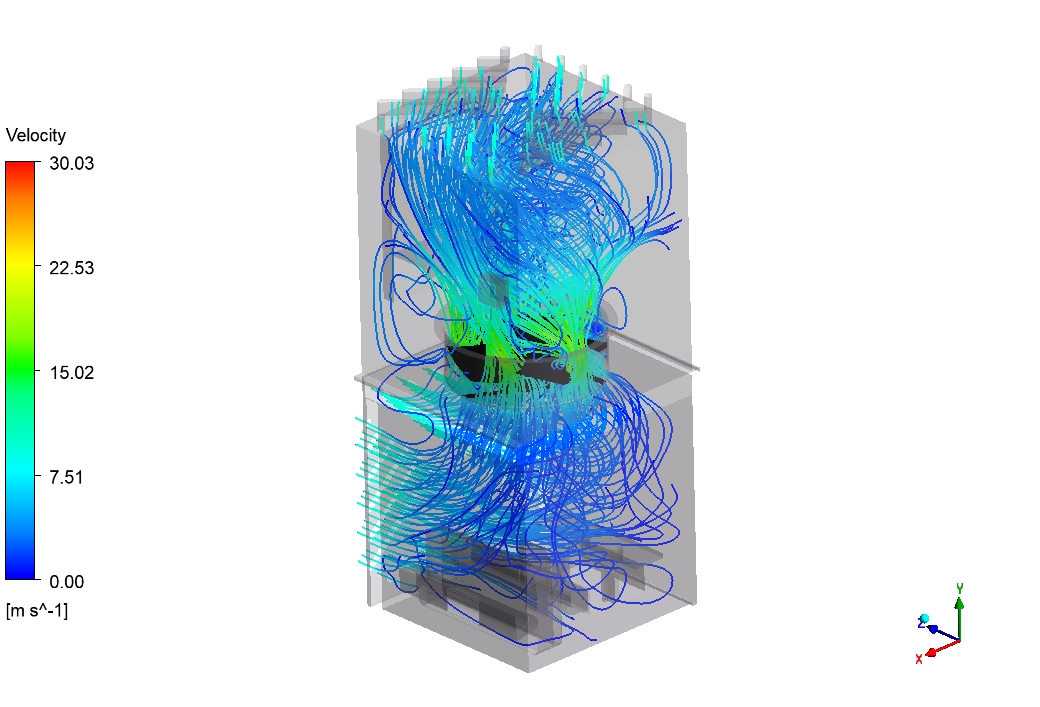

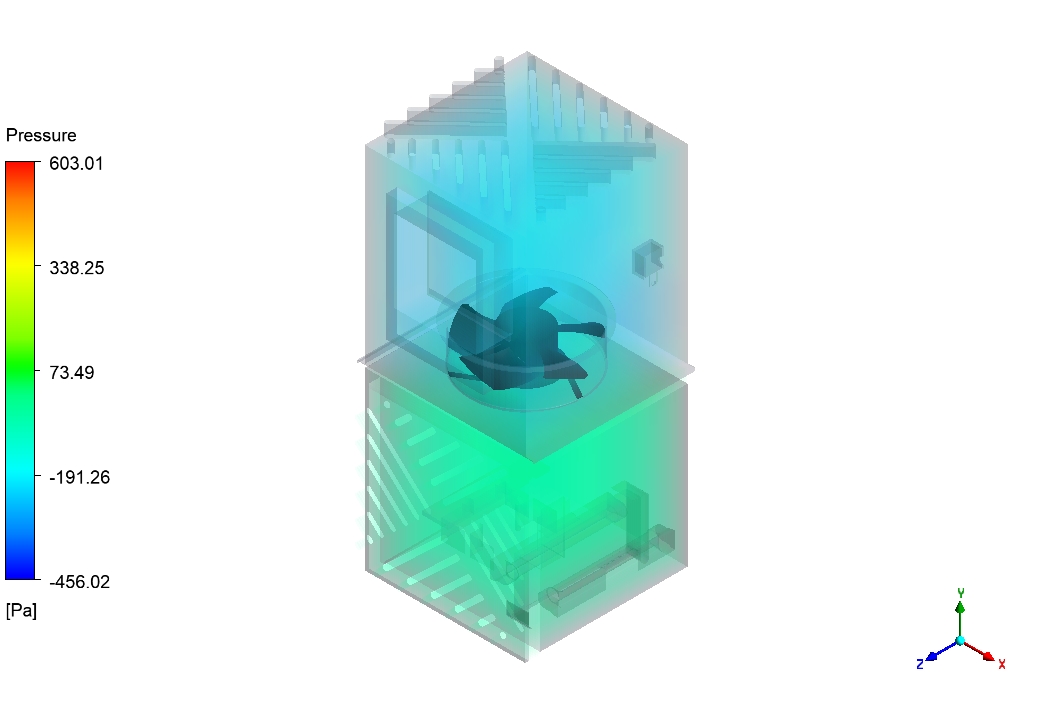

Looking at the streamlines in Figure 1, we can clearly track the complex airflow path inside the air purifier. Air gets sucked in through the bottom grilles at low speeds (blue lines, 0-7 m/s) and then accelerates dramatically as it passes through the fan assembly in the middle. The fan creates significant turbulence and mixing, generating flow speeds up to 15-20 m/s (cyan to green colors) right at the impeller. What’s most interesting is how the flow behaves after passing through the fan – instead of moving in a straight path upward, the air swirls and forms numerous recirculation zones throughout the upper chamber. These swirling patterns help distribute the filtered air more widely when it exits the top of the purifier, but they might also trap some particles in these vortices for longer periods. The streamline density clearly shows that most air movement happens in the central column from bottom to top, with less flow reaching the corners of the device. This could mean dust accumulation in those stagnant zones over time.

Figure 2: Air after the suction and passing through the fan

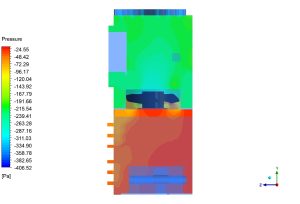

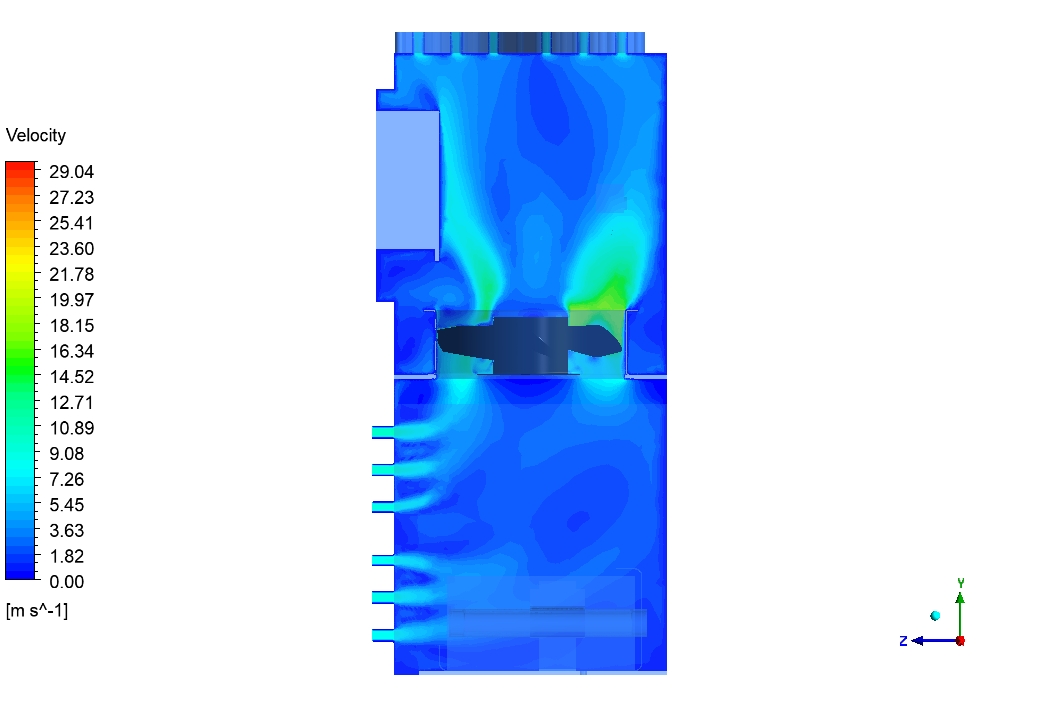

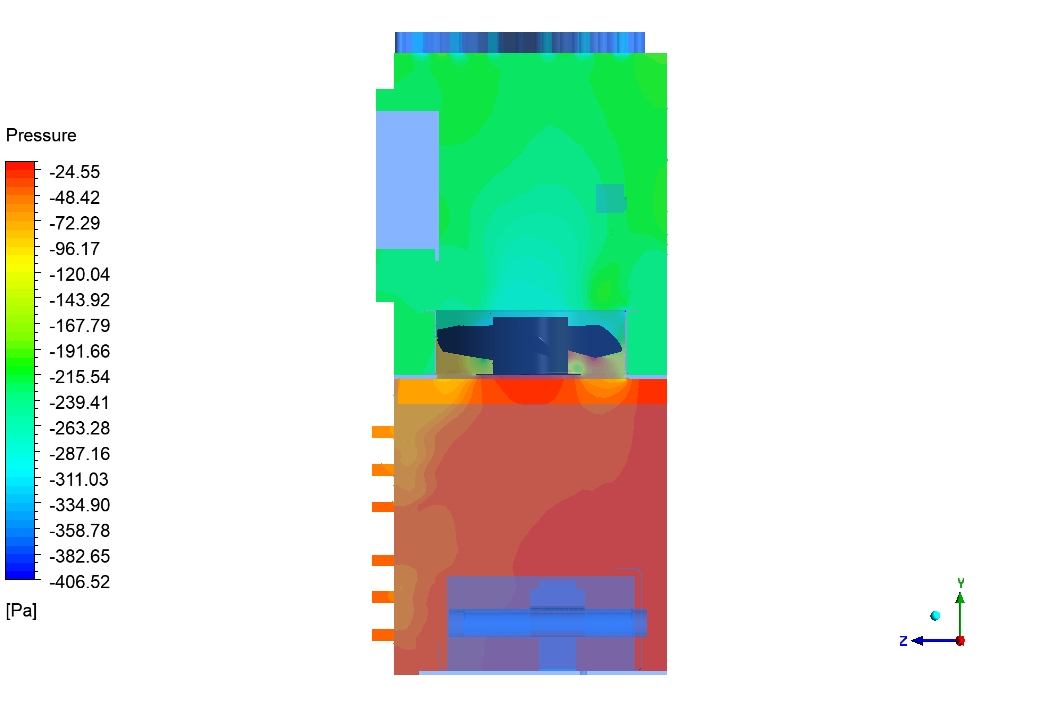

The velocity and pressure fields tell us more about the purifier’s performance. The velocity contour shows the highest speeds concentrated tightly around the fan blades (green region, 15 m/s), quickly dropping off to around 7.5 m/s (light blue) just above and below the fan. This rapid velocity drop indicates significant energy dissipation, probably due to the filter media creating resistance. The pressure contour confirms this with a dramatic pressure gradient across the entire unit. The bottom section shows very negative pressure (red, -24 to -48 Pa) where the fan is actively pulling air in. The fan itself sits in an area of extremely low pressure (dark blue, -382 to -406 Pa), which drives the whole flow system. The top section shows a moderate negative pressure (green, -143 to -167 Pa). This overall pressure difference of about 350-380 Pa between inlet and outlet seems reasonable for a small purifier but means the fan must work quite hard against the filter resistance. The sharp pressure boundary (orange band) in the middle indicates where the main pressure recovery happens and suggests this might be the location of the primary filtration element.

Figure 3: Pressure drop by filters

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€130 Original price was: €130.€85Current price is: €85.

€105 Original price was: €105.€85Current price is: €85.

€140 Original price was: €140.€65Current price is: €65.

€240 Original price was: €240.€125Current price is: €125.

€120 Original price was: €120.€65Current price is: €65.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.