Bank of Tubes Analysis Using Periodic Boundary CFD Simulation | ANSYS Fluent Tutorial

Bank of Tubes Analysis Using Periodic Boundary CFD Simulation | ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€0.00

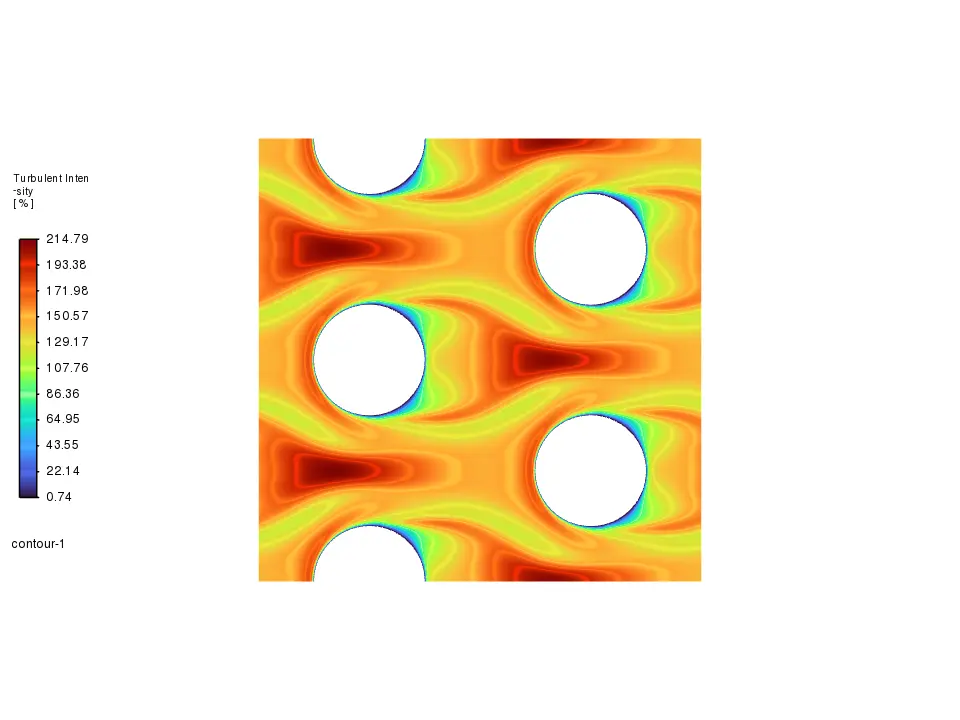

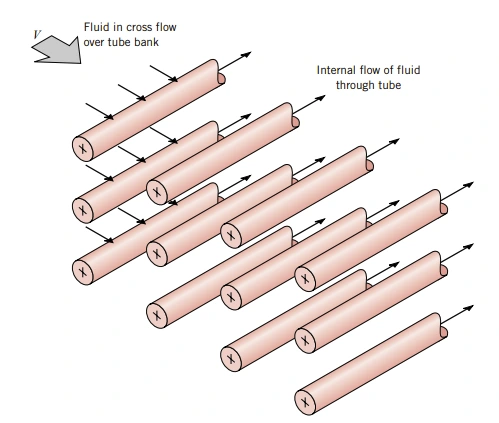

Using periodic boundary conditions, our Bank of Tubes Analysis lesson shows how to efficiently simulate fluid flow and heat transfer across tube banks in ANSYS Fluent. By simulating a subset of the tube bank instead of the whole array, this method significantly cuts down on computing resources without sacrificing accuracy in describing the flow and thermal performance. The tutorial explains how to simplify the geometry, refine the mesh around the surfaces of the tubes, and use periodic bounds correctly so that they mimic the tubes’ pattern. In order to build effective heat exchangers, cooling systems, and process equipment, you will learn to evaluate critical performance indicators including pressure drop, heat transfer coefficients, and flow distribution patterns. Engineers optimizing thermal performance in power generation, HVAC systems, or chemical processing applications can greatly benefit from this modeling technique since it helps them grasp the complicated interactions between many tubes. If you’re looking to improve your CFD simulation abilities, we recommend checking out CFDland’s other free resources, such as the “Aerodynamic Analysis of Hatchback & Sedan Cars” and “Erosion in a Bent Pipe” courses, which are also available as FREE PRODUCTS.

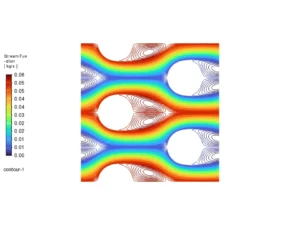

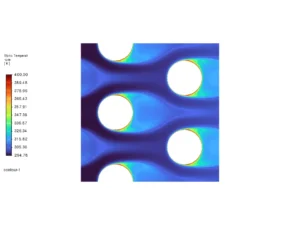

Figure 1: Bank of tube CFD analysis

Simulation Process

Our simulation begins with creating a simplified geometry in ANSYS Design Modeler, modeling just a representative section of the tube bank rather than the entire array. We define the fluid domain around a single tube or a small cluster of tubes, carefully placing periodic boundaries at positions where the flow pattern repeats. The mesh generation employs an unstructured approach with critical boundary layer. In ANSYS Fluent, we establish periodic boundary conditions at the domain sides, which mathematically connects the flow exit from one boundary to the entrance at the corresponding boundary. For thermal conditions, we set the tube walls at a constant temperature of 400K while the water enters at 300K, creating a clear temperature difference to drive heat transfer.

Post-processing

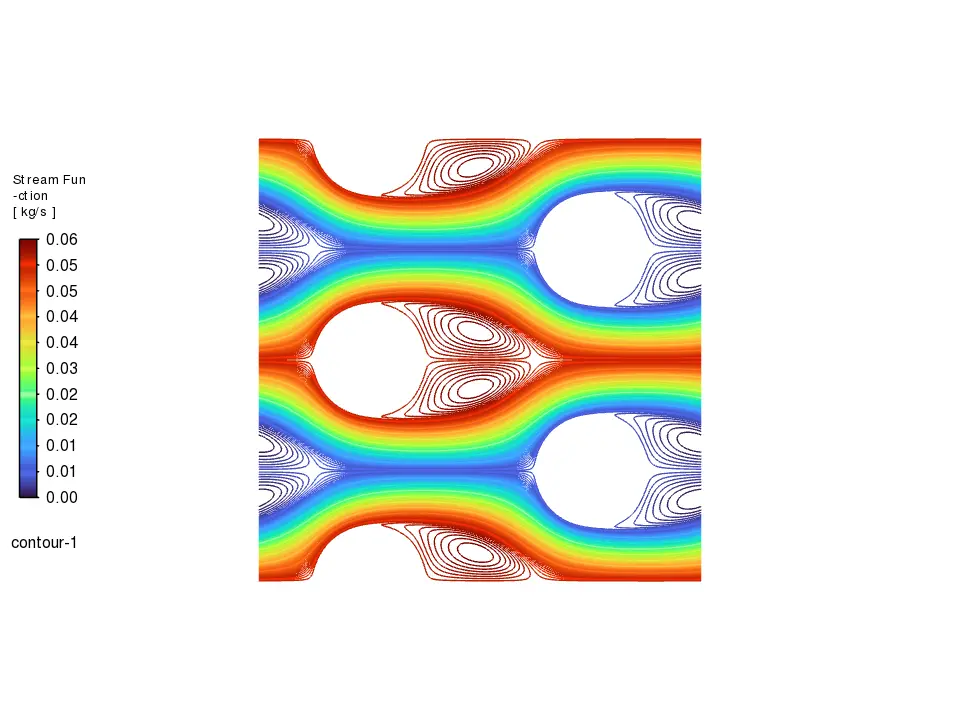

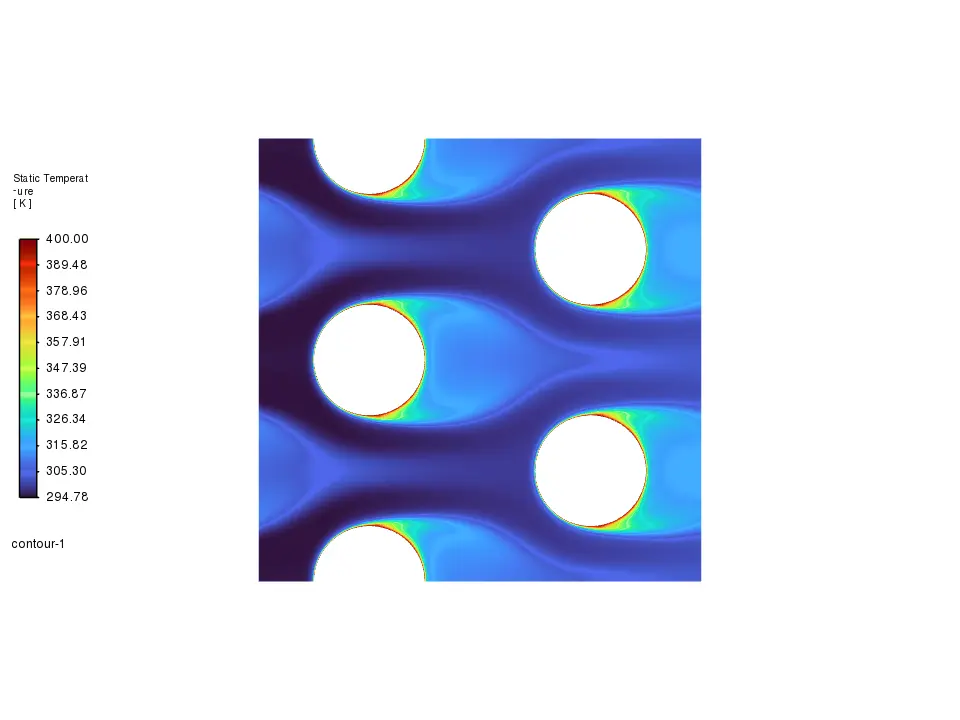

The temperature contour shows an interesting thermal pattern in our tube bank setup. At the tube surfaces, the 400K boundary state is marked by bright orange-red areas. The water around the tubes has a temperature gradient that goes outward. The thermal boundary layer can be seen as a change in color from red to green to blue. It is easy to see that heat is transferred best at the front of each tube, where fresh, cool water comes in direct touch with it. The wake areas behind each tube, on the other hand, have moderate temperatures and little mixing. Our periodic boundary conditions make sure that this pattern of temperature distribution repeats itself across the tube array, which proves that this modeling method works.

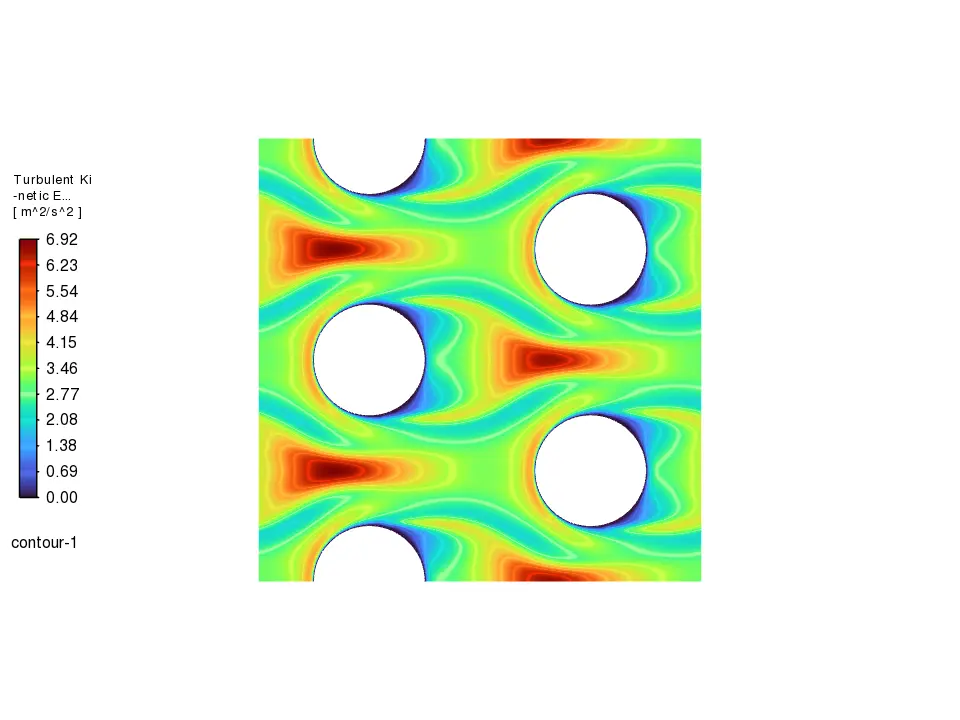

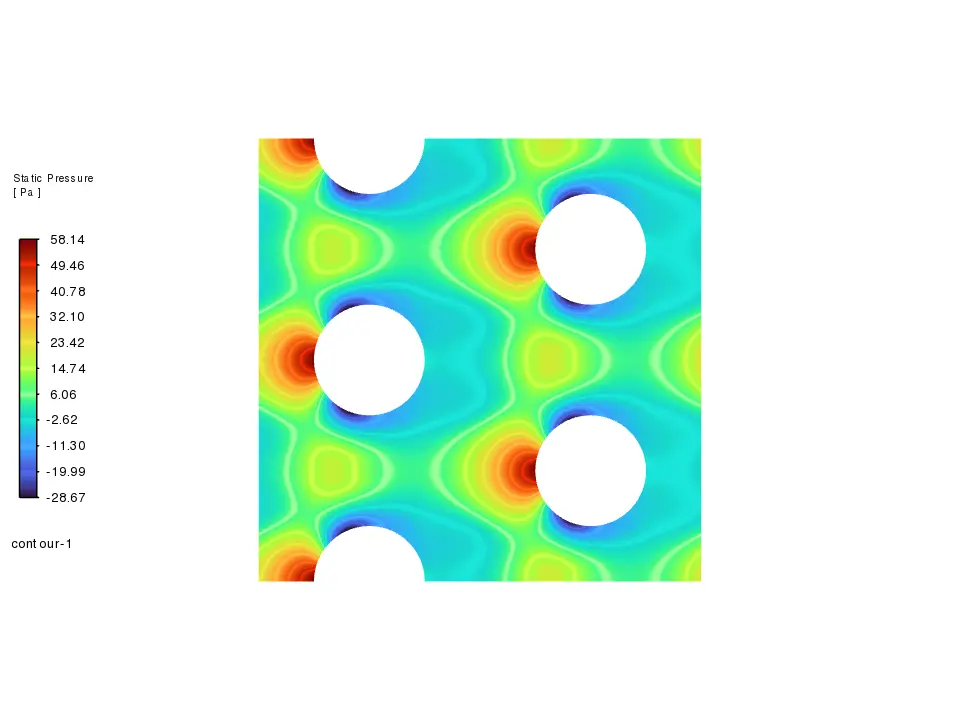

Figure 2: Flow around bank of tubes – CFD Simulation

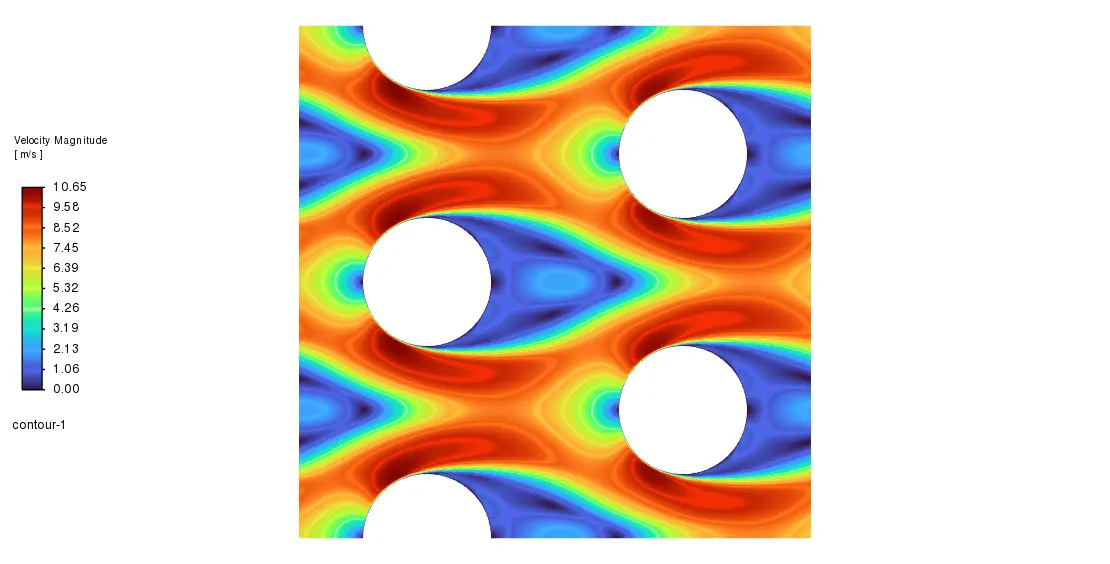

The flow behavior illustrated by the velocity and stream function contours demonstrates the complex fluid dynamics at work. The velocity contour reveals maximum speeds of approximately 10.65 m/s (red regions) occurring in the narrow passages between adjacent tubes where the flow area constricts. Behind each tube, distinctive blue regions indicate low-velocity recirculation zones where the flow separates from the tube surface. The stream function visualization further confirms this pattern, showing streamlines that wrap around the tubes and form closed recirculation bubbles in the wake regions. These flow patterns directly impact heat transfer performance – notice how areas with higher velocities (between tubes) correspond to regions with enhanced temperature gradients in the thermal contour, highlighting the important relationship between fluid flow and heat transfer in tube bank arrangements.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€130.00 Original price was: €130.00.€85.00Current price is: €85.00.

€295.00 Original price was: €295.00.€175.00Current price is: €175.00.

€320.00 Original price was: €320.00.€175.00Current price is: €175.00.

€120.00 Original price was: €120.00.€65.00Current price is: €65.00.

€245.00 Original price was: €245.00.€185.00Current price is: €185.00.

€280.00 Original price was: €280.00.€145.00Current price is: €145.00.

Reviews

There are no reviews yet.