Casting CFD Simulation, ANSYS Fluent Training

Casting CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€195.00 Original price was: €195.00.€115.00Current price is: €115.00.

Metal casting creates amazing parts by pouring hot liquid metal into special molds where it cools down and hardens! First of all, the casting process needs careful control to avoid problems like bubbles or cracks in the final product. Additionally, aluminum casting is super popular in car and airplane factories because it makes lightweight but strong parts. Most importantly, engineers use casting simulation to predict how the metal will flow and cool, which helps them fix problems before making real parts. Furthermore, die casting and sand casting are different ways to make metal shapes, each with its own special benefits for different types of products. The mold filling stage is especially important because it determines if the metal parts will have good quality or many defects! Filling simulation is still one of the most popular areas of casting numerical simulation. However, thanks to the reference paper titled “ Numerical Simulation of Casting Filling Process Based on FLUENT,” we conducted a CFD study.

Figure 1: Casting process of aluminum

Simulation Process

The base model was initially designed using Design Modeler, followed by grid generation via proper blocking and the power of ICEM software that resulted in structured mesh. The simulation necessitates the combination of the Volume Of Fluid (VOF) multiphase model and Solidification and Melting modules. Then, the unsteady process of casting pure aluminum is executed.

Post-processing

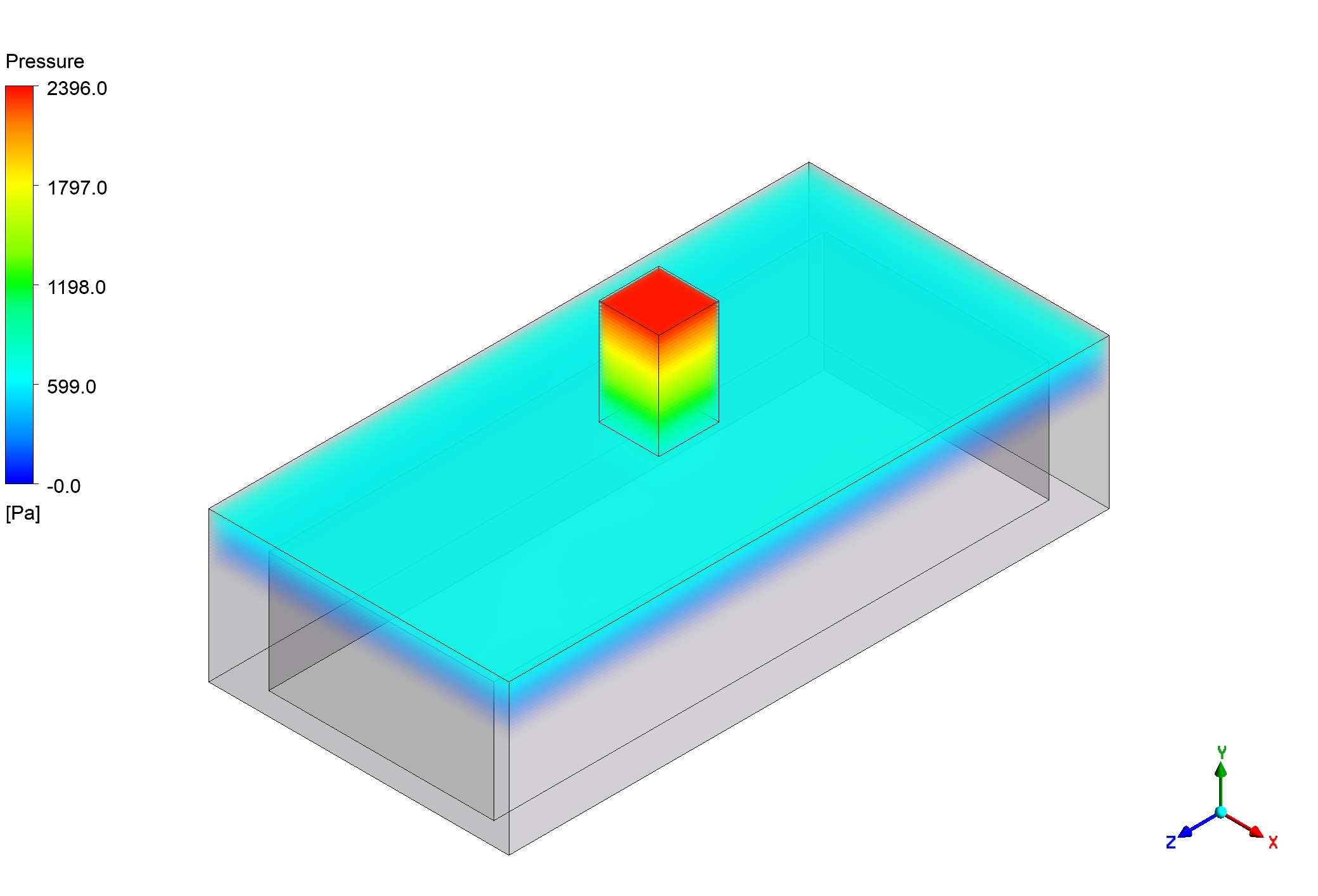

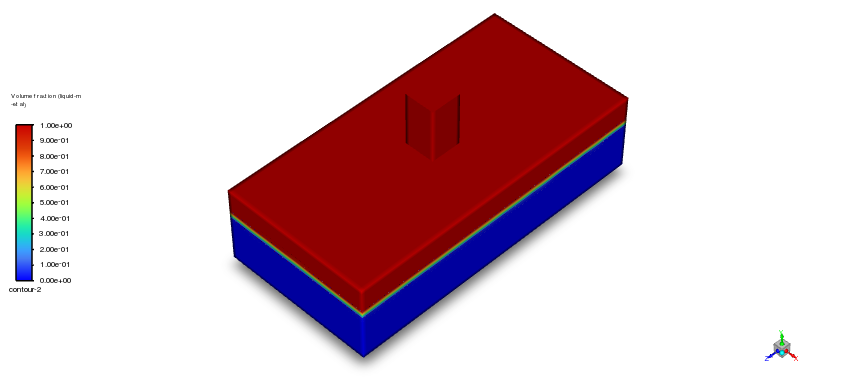

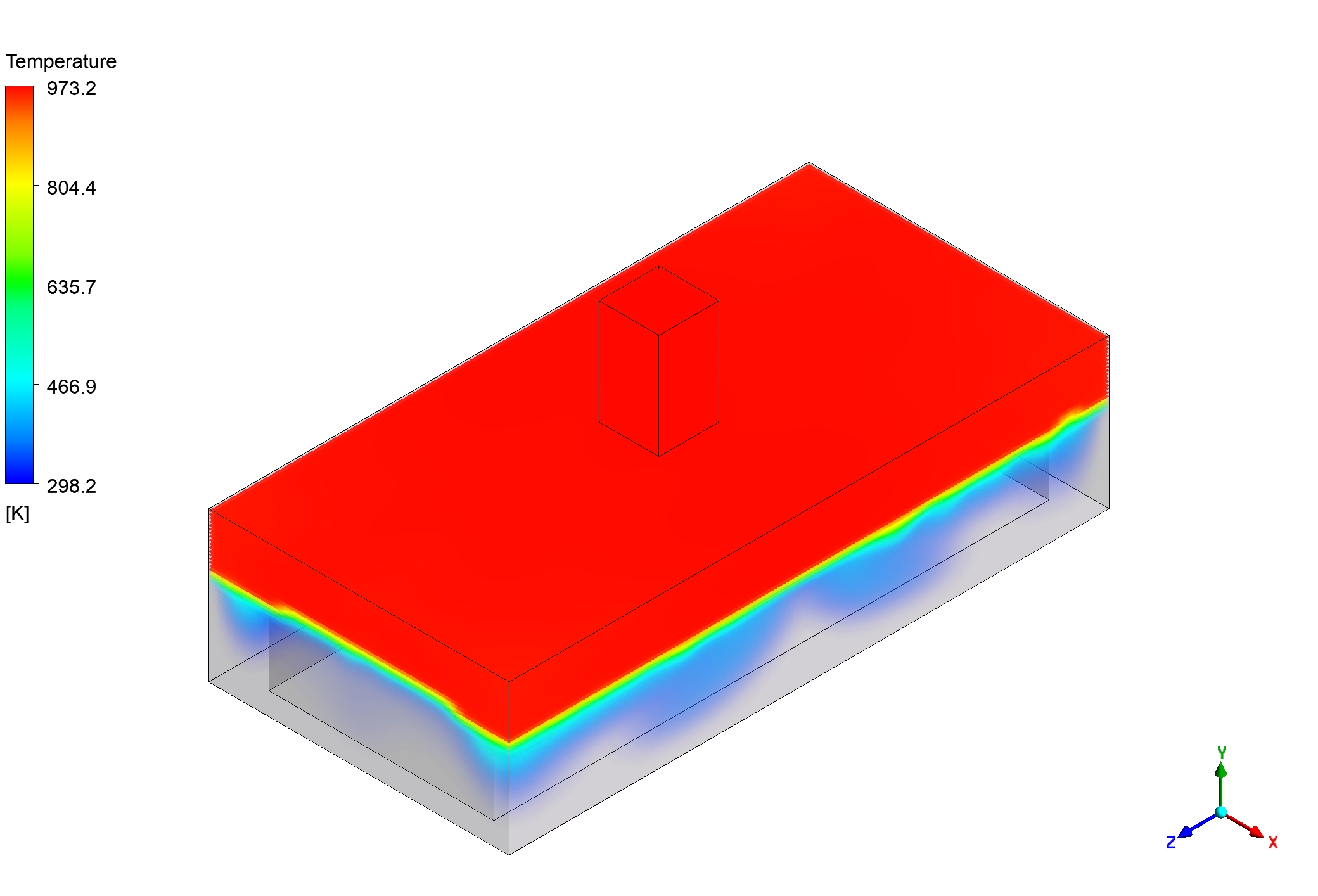

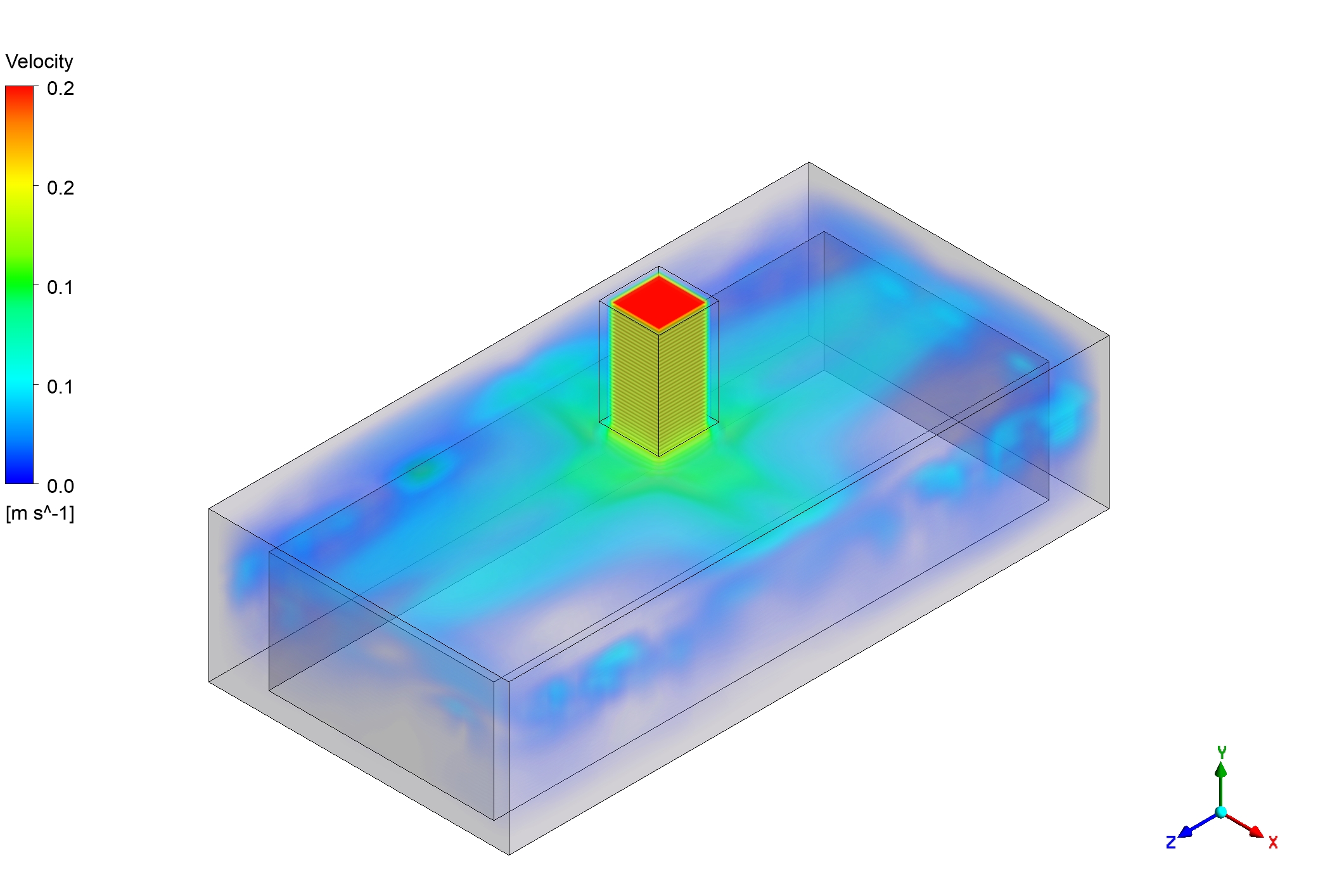

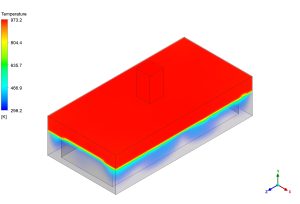

The casting process shows how hot molten aluminum flows into the mold and then slowly cools down! First of all, we can see the liquid metal starts at the top and fills the mold completely with a 100% filling rate, which means no empty spots or bubbles. Additionally, during the metal solidification, the temperature ranges from 298.2 Kelvin (25°C) to 973.2 Kelvin (700°C) – that’s hotter than your home oven! Most importantly, the heat transfer happens most quickly at the bottom and sides of the mold where the hot metal touches the cooler walls. Furthermore, this creates a thermal gradient that moves from the middle outward, just like when you drop an ice cube in hot water and watch the cold spread. The metal stays super hot in the middle section at nearly 700°C while the edges cool much faster!

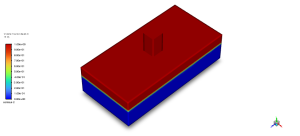

Figure 2: Volume fraction distribution showing 100% filling of the mold cavity with molten aluminum

The solidification process doesn’t happen all at once – it starts at the edges and moves inward like ice forming on a pond! First of all, the bottom part of the casting cools fastest because it touches the mold first, dropping to around 466.9 Kelvin (193.9°C) while the top stays much hotter. Additionally, this different cooling rate is really important because it affects how strong the final metal part will be. Most importantly, the top section with the small cube shape stays at the highest temperature (973.2K) for the longest time because it’s the thickest part. Furthermore, this matches exactly what happens in real aluminum casting factories and confirms our computer model works correctly! The solidification time follows the pattern that professional metalworkers expect, with thin sections cooling in seconds and thicker parts taking much longer.

Figure 3: Temperature distribution during the solidification process

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160.00 Original price was: €160.00.€75.00Current price is: €75.00.

€190.00 Original price was: €190.00.€95.00Current price is: €95.00.

€240.00 Original price was: €240.00.€175.00Current price is: €175.00.

€200.00 Original price was: €200.00.€115.00Current price is: €115.00.

€240.00 Original price was: €240.00.€115.00Current price is: €115.00.

€240.00 Original price was: €240.00.€135.00Current price is: €135.00.

Reviews

There are no reviews yet.