Conical Mixers in Double-pipe Heat Exchanger CFD: A Fluent Tutorial

Conical Mixers in Double-pipe Heat Exchanger CFD: A Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€170 Original price was: €170.€125Current price is: €125.

The conical elements inside a double-pipe heat exchanger work like tiny mixing helpers. They make hot and cold fluids share heat much better. These special cone-shaped pieces sit inside the pipes and create swirls in the fluid. This motion breaks up the slow-moving fluid layer that normally sticks to the pipe walls and acts like an insulation blanket. This simple change allows the heat exchanger to be smaller and more efficient, saving space and materials. Our Conical Mixers In Double-pipe Heat Exchanger CFD study uses computer simulation to see exactly how well these inserts work.

Figure 1: Schematic of the Conical Mixer CFD setup within a double-pipe heat exchanger.

Simulation Process: Fluent Setup, the Heat Exchanger with Conical Inserts

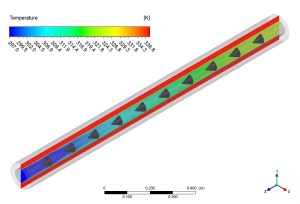

To begin our simulation, we first built the 3D geometry of the heat exchanger. The model includes the inner pipe for cold air and the outer pipe for hot water. To create a very neat and accurate grid, we used a multizone meshing method. This allowed us to have a structured grid inside the pipes and around the 12 conical elements. The final high-quality mesh had 1,245,600 cells. In the Fluent solver, we set up a cross-flow design. Cold air enters the inner pipe at a temperature of 297K, while hot water flows through the outer pipe at 338K.

Figure 2: The multizone structured grid used for the Double-pipe Heat Exchanger CFD analysis.

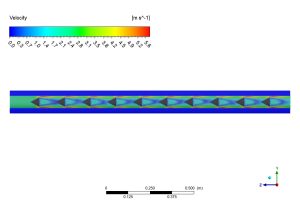

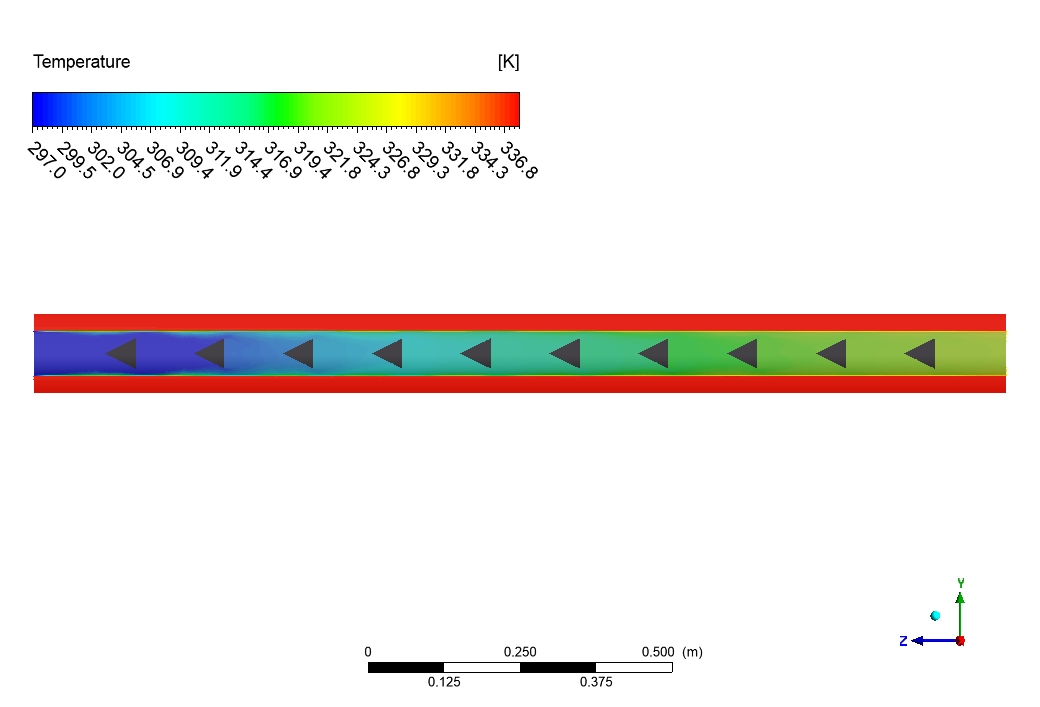

Post-processing: CFD Analysis, Visualizing Thermal and Flow Field Enhancement

The temperature contour provides clear evidence of how well these cones improve heat transfer. As the cold air flows from left to right, it gets much warmer. The contour shows the air temperature increasing by 28.8K, starting at 297K and reaching 325.8K by the time it leaves the pipe. This means a large amount of heat was successfully transferred from the hot water. The hot water in the outer pipe stays very hot (around 337K), showing it has plenty of thermal energy to give. The most important observation is that the temperature changes most rapidly right after each conical mixer, which proves these elements are the direct cause of the enhanced heat exchange.

Figure 3: Temperature distribution from the Conical Mixers In Double-pipe Heat Exchanger Fluent simulation, showing the air heating from 297K to 325.8K.

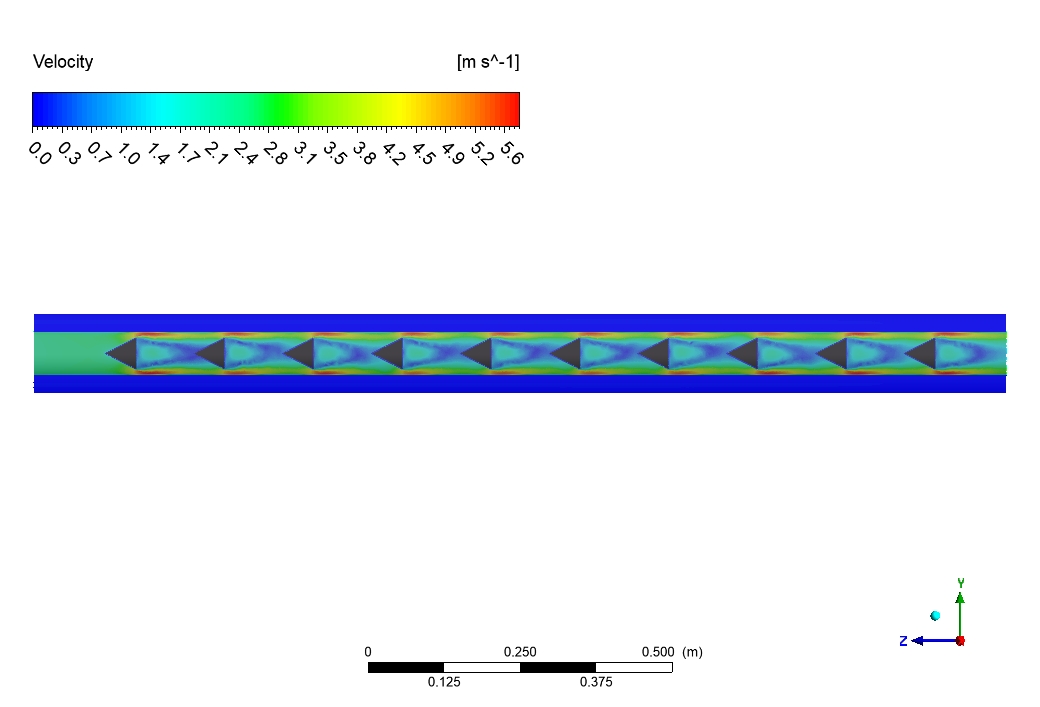

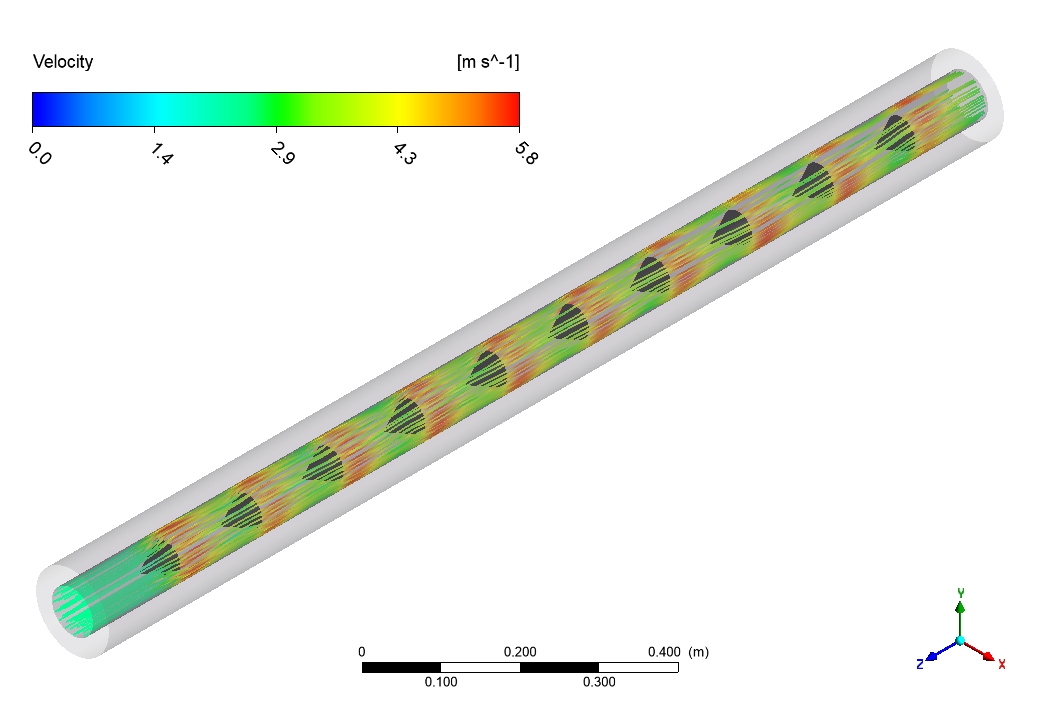

The velocity contour explains why the heat transfer is so much better. Without the cones, the fluid would flow in a straight, lazy line. With the cones, the fluid is forced to move around them, creating small swirls and vortexes that mix everything up. The fluid speeds up as it passes the tips of the cones, reaching speeds up to 0.6 m/s. This repeating pattern of speeding up and slowing down creates turbulence. This turbulence breaks apart the slow-moving fluid layer on the pipe walls that usually stops heat from moving. The most important achievement of this simulation is the clear demonstration that simple, static conical elements can generate significant swirl and turbulence, dramatically improving the convective heat transfer coefficient and overall thermal performance of the heat exchanger.

Figure 4: Velocity field from the Conical Mixers Fluent analysis, showing how the elements create turbulence and increase flow velocity.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€145Current price is: €145.

€170 Original price was: €170.€145Current price is: €145.

€160 Original price was: €160.€110Current price is: €110.

€160 Original price was: €160.€80Current price is: €80.

€160 Original price was: €160.€75Current price is: €75.

Reviews

There are no reviews yet.