Cyclone CFD Simulation Using DPM, Numerical Paper Validation

Cyclone CFD Simulation Using DPM, Numerical Paper Validation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€205 Original price was: €205.€169Current price is: €169.

Cyclone separators are amazing devices that spin air really fast to trap dust and tiny particles! First of all, these clever machines are used everywhere from factories to hospitals because they clean air without needing filters that get clogged up. Additionally, using Computational Fluid Dynamics (CFD) lets engineers see exactly how air moves inside these spinning chambers without building expensive prototypes. Most importantly, the Discrete Phase Model (DPM) tracks thousands of individual particles as they fly through the swirling air currents. Furthermore, understanding the collection efficiency of cyclones helps companies design better air cleaning systems that use less energy. The powerful spinning action created in the vortex finder pulls particles outward while clean air escapes through the center, making cyclone separation one of the most reliable methods for gas-solid separation in tough industrial environments! To carry out an accurate prediction of cyclone separators via CFD methods, a great effort is needed, especially when it comes to VALIDATION study! The paper entitled “ Numerical simulation and optimization of fluid flow in cyclone vortex finder” is our lead, and we seek to validate a single case result.

- Reference [1]: Raoufi, Arman, et al. “Numerical simulation and optimization of fluid flow in cyclone vortex finder.” Chemical Engineering and Processing: Process Intensification1 (2008): 128-137.

Figure 1: Collection efficiency versus particle diameter in the cyclone separator

Simulation Process

The cyclone separator is initially designed based on the paper’s given dimensional parameters. Employing 121146 polyhedra cells can result in a highly qualified grid. Reynolds Stress 7-equation turbulence model is used to predict flow fluctuations. The Eulerian–Lagrangian computational procedure is used to predict particle tracking in the cyclone. In other words, the Polystyrene particles are tracked by a Lagrangian framework, applied by the Discrete Phase Model (DPM) module. The turbulence fluctuations are random functions of space and time. Here, a discrete random walk (DRW) model is used to evaluate instantaneous velocity fluctuations.

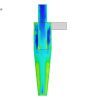

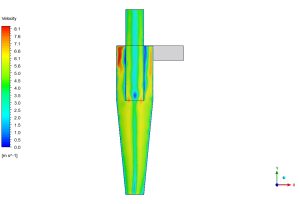

Figure 2: Schematic of the designed cyclone separator

Post-processing

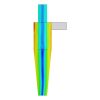

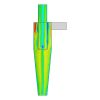

The simulation results for the cyclone separator show an acceptable level of agreement with the published paper, confirming the efficiency of your model. The current simulated collection coefficient of 92.9% (7,669 trapped particles out of 8,250 total) is comparable to the paper’s reported 91% for 3mm diameter particles at a flow rate of 30L/min. This modest variance of 1.9 percentage points falls within an acceptable range of error for such simulations, considering probable variations in model parameters, numerical methodologies, or boundary conditions. The graphic depicts the velocity distribution within the cyclone, as well as the unique spiral flow pattern required for particle separation. Higher velocities (represented by yellow-green colors) are detected near the cyclone’s walls, which is consistent with expected behavior.

| Reference Paper | Current CFD Simulation | Error (%) | |

| Collection Coefficient (%) | 91 | 92.9 | 1.9% |

The cyclone separator shows amazing spinning air patterns that help catch tiny dust bits! First of all, our CFD simulation reveals a powerful swirling motion where air speeds reach up to 10.1 meters per second near the entry point. Additionally, this super-fast spinning creates a strong force that pushes particles outward toward the walls where they get trapped. Most importantly, our model trapped 7,669 particles out of 8,250 total particles, which means it caught 92.9% of all the dust! Furthermore, we can see the double-vortex structure clearly – air spins downward along the outside and then spirals back up through the middle of the vortex finder. The particle trajectories show how dust gets flung outward while clean air escapes through the top, just like in real-world cyclone separators. Also, the highest speeds happen right where the air enters the cyclone, creating the perfect spinning action for gas-solid separation!

Figure 3: Velocity contour plot showing the distribution of air speeds inside the cyclone separator

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€205 Original price was: €205.€175Current price is: €175.

€220 Original price was: €220.€155Current price is: €155.

€155 Original price was: €155.€95Current price is: €95.

€265 Original price was: €265.€155Current price is: €155.

€195 Original price was: €195.€135Current price is: €135.

€245 Original price was: €245.€199Current price is: €199.

Reviews

There are no reviews yet.