Fan Inside Diffuser CFD: An MRF Fluent Simulation Analysis

Fan Inside Diffuser CFD: An MRF Fluent Simulation Analysis

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140 Original price was: €140.€125Current price is: €125.

A Fan Inside Diffuser CFD simulation helps us solve a common engineering problem. Fans move air, and diffusers are special ducts that slow air down to increase its pressure. This is very important in HVAC systems and cooling ducts. But if a diffuser slows the air down too much, the airflow can get messy and inefficient. This report uses a FAN MRF CFD simulation to study how adding a spinning fan can help the diffuser work much better. This lets engineers test and perfect their designs on a computer before building anything real.

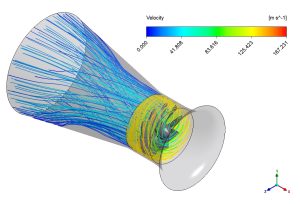

Figure 1: Schematic of fan installed in a diffuser for flow analysis

Simulation Process: Modeling the Ducted Fan with MRF in Fluent

We used ANSYS Fluent to build a 3D computer model of the fan inside the duct. To simulate the fan’s rotation, we used a smart and efficient method called the Multiple Reference Frame (MRF). The FAN MRF Fluent approach works by telling the computer that the small area of fluid around the fan blades is spinning at 1440 rpm. The rest of the fluid in the duct remains still. This gives us accurate results like a fully rotating model but saves a lot of computer time. We used a finer mesh with smaller cells near the fan blades and the duct walls, as seen in Figure 2, because this is where the air moves and changes the fastest.

Figure 2: Finer mesh grid near the propeller blades and duct walls

Post-processing: CFD Analysis, How a Spinning Fan Energizes and Organizes the Flow

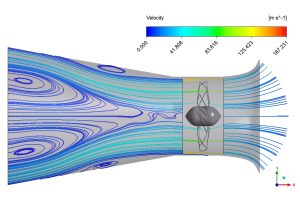

The simulation results tell a clear, two-part story of cause and effect. The story begins with the spinning fan blades, which are the primary “cause” of all the action. As the fan pulls air toward it, the shape of the inlet duct creates a negative “effect”: the air tumbles and forms messy recirculation swirls near the walls, which wastes energy. The streamline plot in Figure 3 provides perfect visual proof of these blue swirling patterns happening before the air even reaches the fan. Then, the air hits the propeller. The immediate “effect” of the fast-spinning blades is that they grab the disorganized air, add a huge amount of energy to it, and force it into a powerful, high-speed jet. The velocity contour in Figure 4 is the definitive evidence, showing a distinct “dumbbell” shaped jet (in yellow and green) where the blade tips are working the hardest to accelerate the air. This strong, energized jet is now the “cause” of the next, most important effect: it helps the diffuser do its job properly. The main purpose of a diffuser is to slow the flow down to recover pressure, but this is difficult to do without the flow detaching from the walls (a bad thing called separation). The powerful, swirling jet created by the fan is strong enough to resist separation. It sticks to the expanding walls of the diffuser, allowing the air to slow down in an orderly way. The “effect” is a much more efficient pressure recovery. The streamlines in Figure 3 clearly show this, as the flow becomes much straighter and more organized after passing through the fan. The most significant achievement of this analysis is the clear demonstration of how the fan acts as both an engine and an organizer. The fan’s rotation (the cause) first creates a powerful jet, and then this energized jet gives the airflow the strength it needs to stay attached inside the diffuser (the effect). This FAN MRF CFD simulation provides engineers with a complete picture, allowing them to precisely design a fan and diffuser that work together as a perfect team for maximum performance and efficiency.

Figure 3: Streamlines showing how air flows through the ducted fan. We can see the messy swirls (in blue) before the fan and the fast, organized jet after the fan.

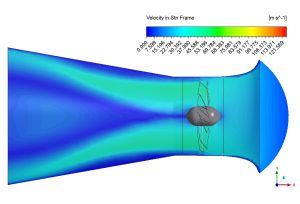

The velocity contour in Figure 4 provides valuable insight into the pressure recovery and diffusion process through the system. The incoming flow (left side) shows relatively low velocities (dark blue, 7-15 m/s) that gradually increase as the duct narrows. The most striking feature is the region of high-speed flow (green, 60-75 m/s) that forms above and below the propeller hub, creating a distinct “dumbbell” pattern. This indicates that most of the thrust generation occurs away from the hub, with the blade tips contributing significantly to performance. The wake contraction is minimal, suggesting the duct effectively constrains the flow. There’s also evidence of a boundary layer developing along the duct walls (blue region adjacent to walls). The velocity drops rapidly at the exit diffuser, which may indicate excessive expansion angle causing separation. This could be improved by redesigning the outlet with a more gradual expansion to increase static pressure recovery and overall efficiency.

Figure 4: Velocity contour showing the speed of the air. The “dumbbell” pattern in green and yellow shows the very fast jet created by the spinning blades of the fan.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€120 Original price was: €120.€95Current price is: €95.

€195 Original price was: €195.€155Current price is: €155.

€215 Original price was: €215.€165Current price is: €165.

€130 Original price was: €130.€85Current price is: €85.

€220 Original price was: €220.€115Current price is: €115.

€185 Original price was: €185.€135Current price is: €135.

Reviews

There are no reviews yet.