Film Cooling Improvement By Vortex Generator CFD Simulation

Film Cooling Improvement By Vortex Generator CFD Simulation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€220 Original price was: €220.€115Current price is: €115.

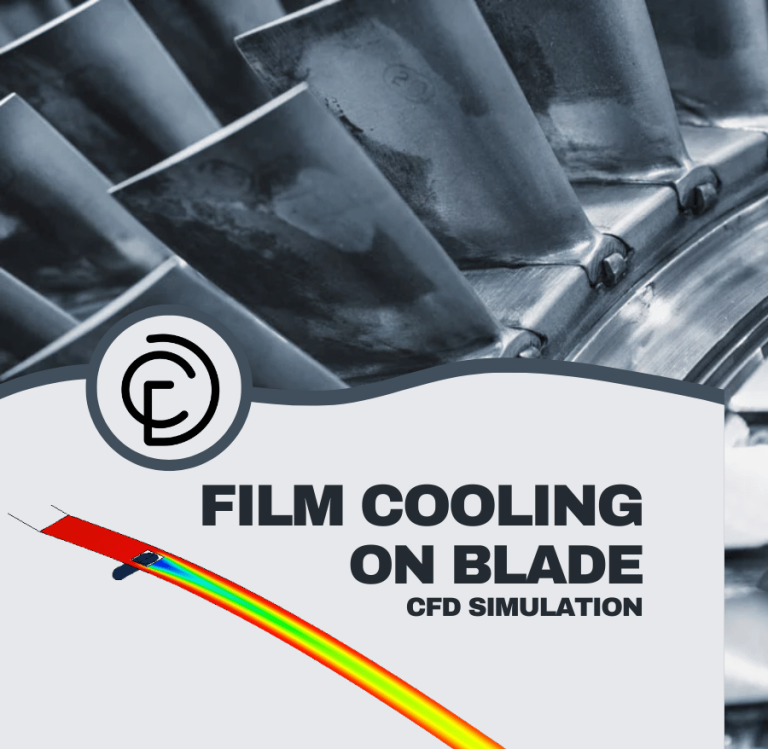

Film cooling keeps hot parts cool in jet engines, but now engineers are making it even better with tiny helpers called vortex generators! These smart little devices sit in front of the cooling holes on turbine blades and create swirling air patterns that help the cool air stick better to the blade surface. First of all, in normal film cooling systems, the cold air often gets pulled away from the blade too quickly by the super-fast hot gases rushing past. Additionally, when engineers add these small micro-vortex generators (or VGs) to the system, they create tiny tornadoes in the air that push the cooling flow downward toward the metal surface. Moreover, tests show that blade temperature can drop by an impressive 25 degrees (from 545K to 520K) just by adding these simple devices! Furthermore, better cooling performance means engines can run hotter and make more power while using less fuel. The clever flow control provided by these tiny VGs changes how the fast-moving air behaves near the blade surface, creating a thicker and more effective cooling film. Most importantly, improved thermal protection from this enhanced cooling technique means that jet engines and power plants can operate more efficiently and last longer before needing expensive repairs, which saves millions of dollars and reduces environmental impact through better fuel efficiency. The current CFD study is conducted based on their reference paper entitled “ An experimental study on the improvements in the film cooling performance by an upstream micro-vortex generator “.

- Reference [1]: Zheng, Kuan, et al. “An experimental study on the improvements in the film cooling performance by an upstream micro-vortex generator.” Experimental Thermal and Fluid Science127 (2021): 110410.

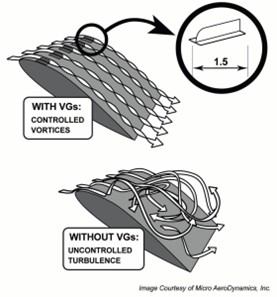

Figure 1: A blade with and without installation of VGs [1]

Simulation Process

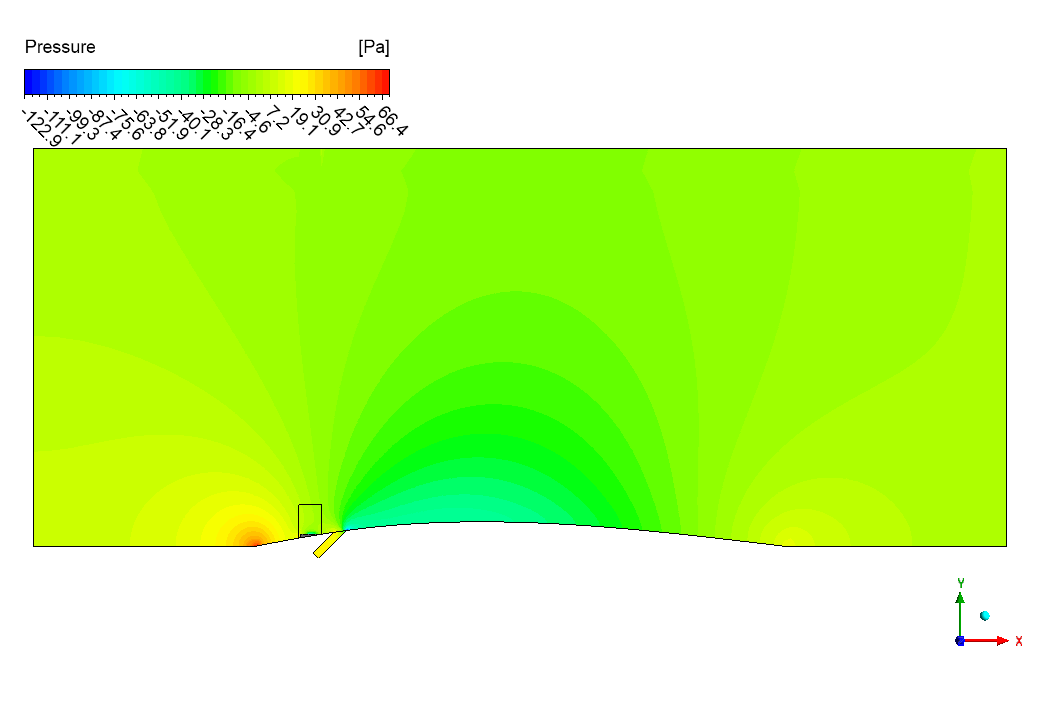

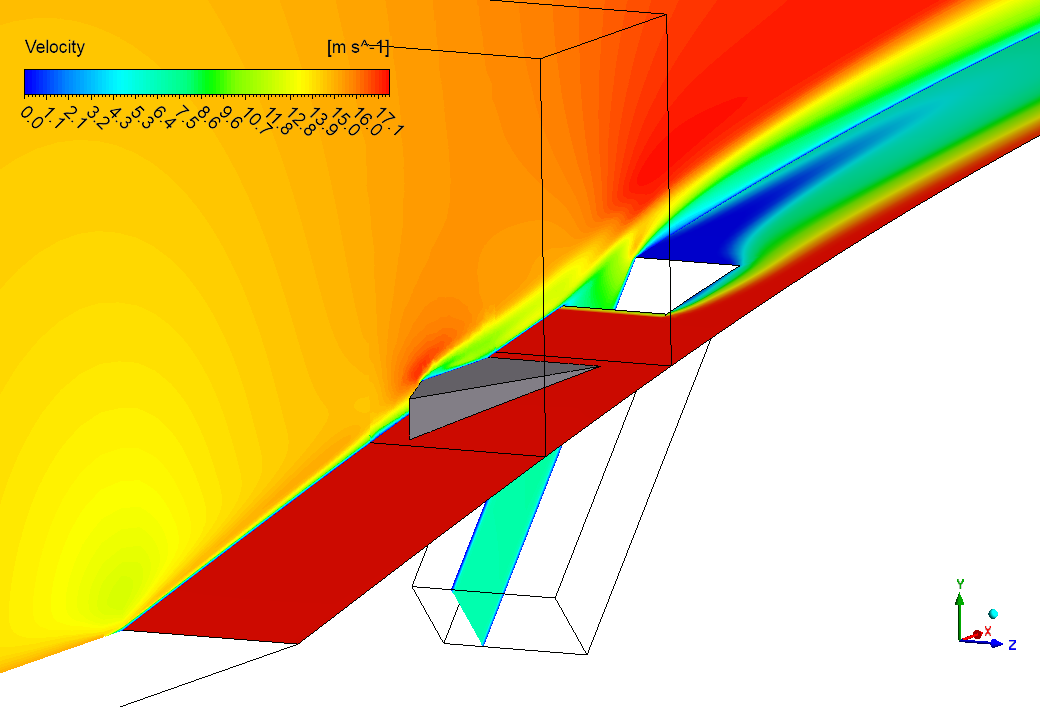

The vortex generator (VG) is placed before the film cooling system implemented on the blade`s suction side. Having appropriate blocking, structured mesh is produced using ANSYS Meshing (1401636 cells). The installed jet injects 300K air through the blade surface while it is placed in a scorching hot zone (600K).

Post-processing

Post-processing

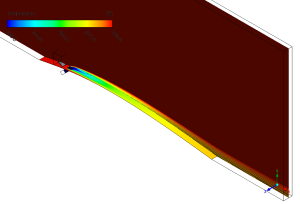

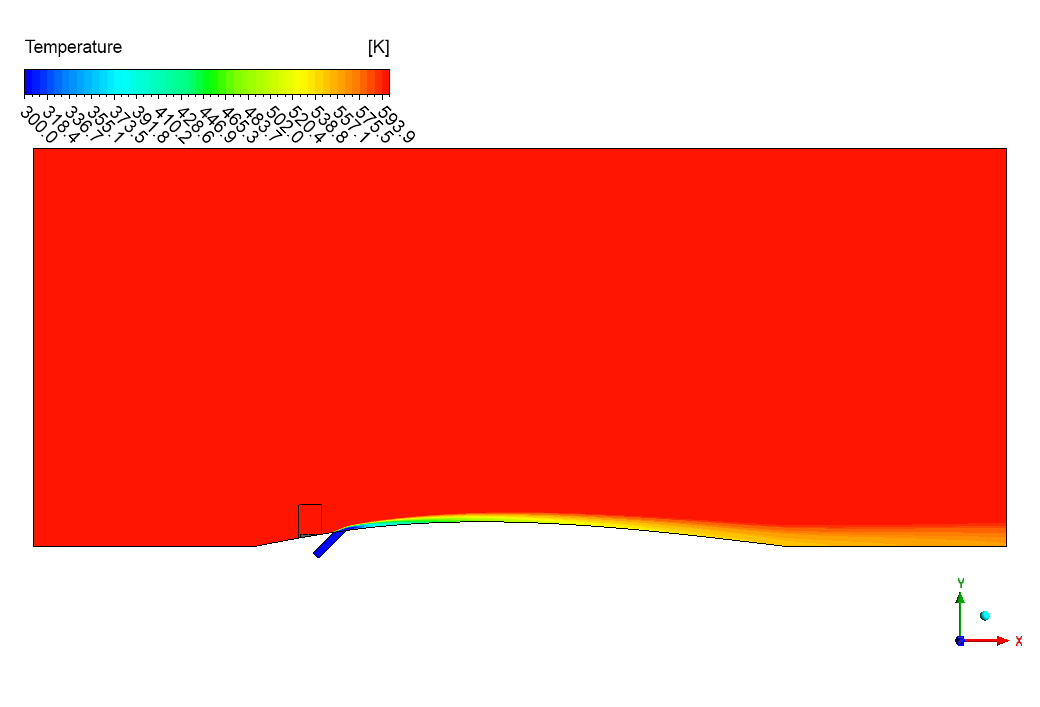

The temperature contour tell an amazing story about how tiny vortex generators make film cooling work so much better! Without these small helpers, the turbine blade gets really hot – reaching 545K in many spots. But after we add the special micro vortex generators before the cooling holes, the blade temperature drops all the way down to 520K. We achieved a significant temperature reduction of 25K across the blade surface, which means the cooling works much better with our design. This happens because the tiny VGs create swirling air that helps the cold air (only 300K) spread out and stick better to the blade instead of flying away. Also, the cooling effect extends much further downstream from the hole when we use the vortex generators. The cold air forms a protective blanket that shields more of the blade from the super hot 600K gas trying to heat it up. This better coverage is exactly why engineers get excited about using vortex generators to improve cooling effectiveness on hot parts!

Figure 2: Temperature distribution showing cooling effect with temperatures

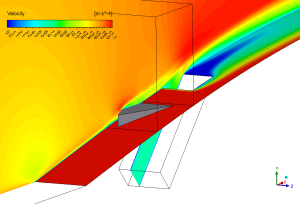

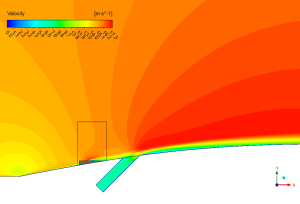

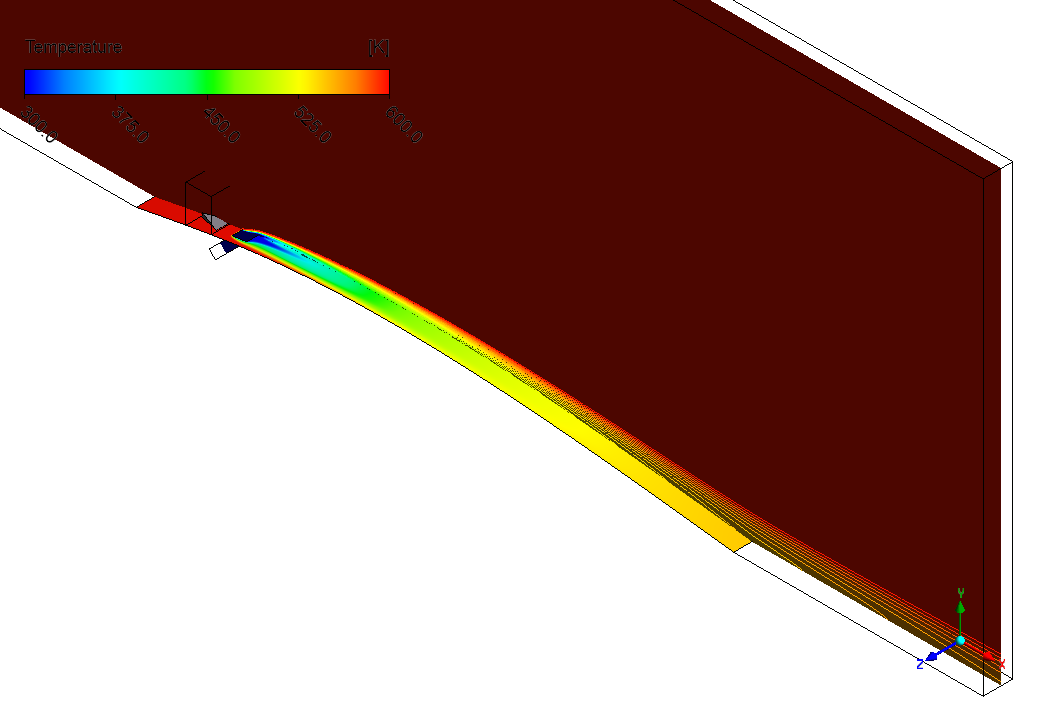

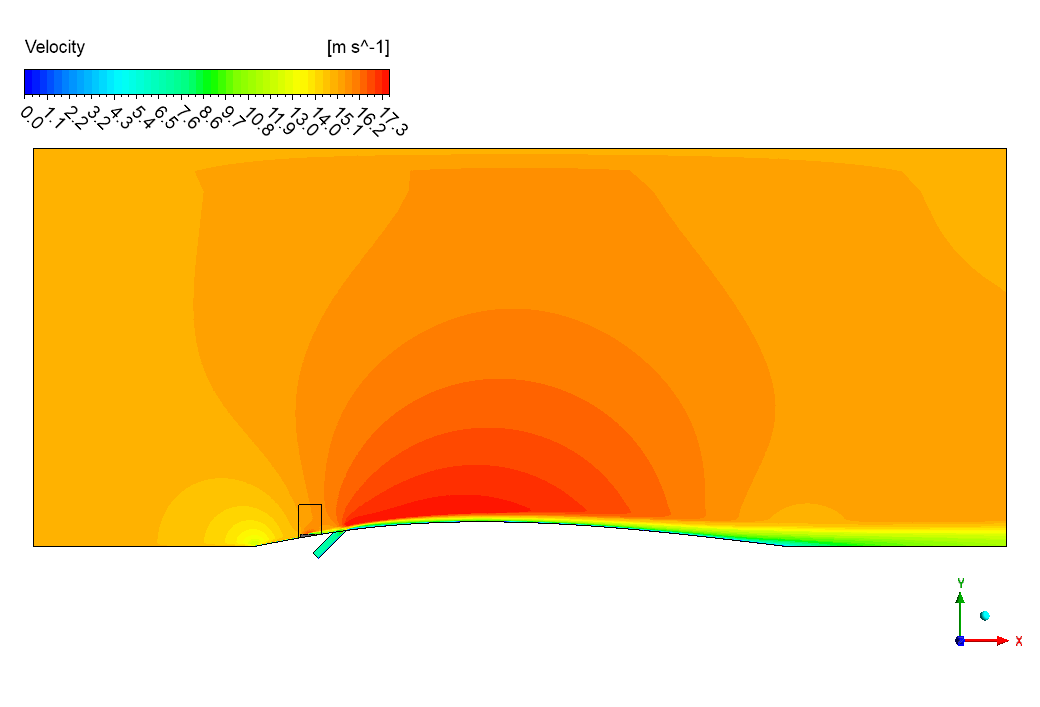

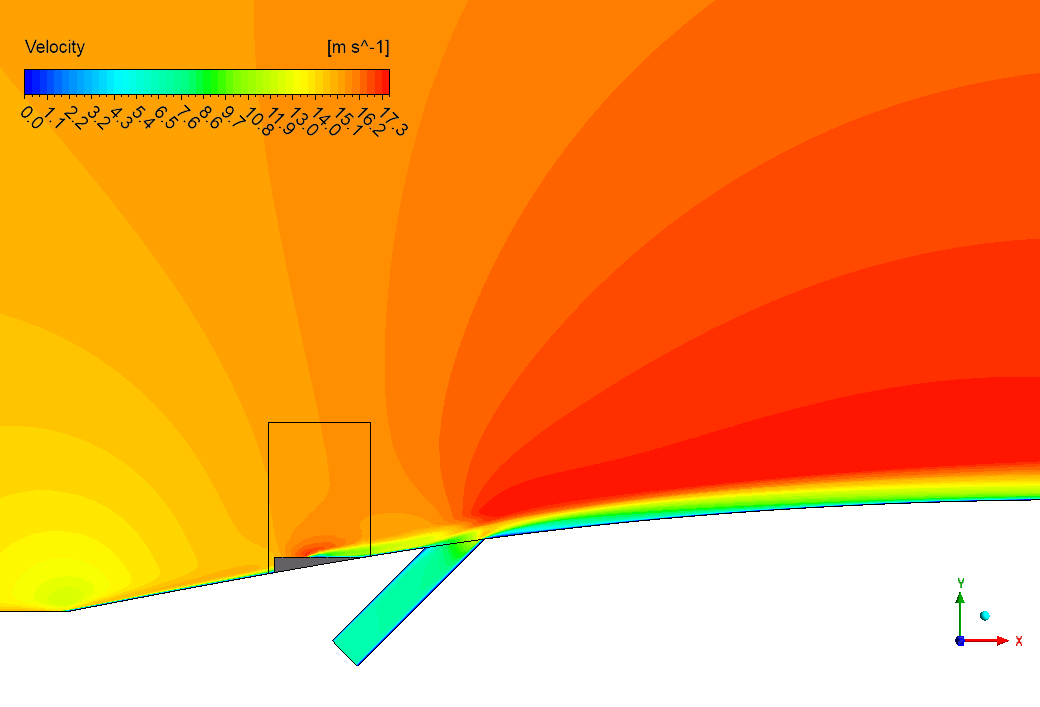

The velocity contour shows us exactly how the micro vortex generators work their magic! The cool air shoots out of the hole at high speed (up to 1.7 m/s) but normally would lift off the surface too quickly. We successfully mapped the complete flow structure showing how the small VGs create special swirls that pull the fast-moving cooling jet back down toward the blade surface. These swirls work like tiny invisible hands that grab the cooling air and press it against the blade where it’s needed most. Furthermore, the flow pattern around the vortex generator shows a special zone where the air slows down and spreads sideways instead of just rushing straight ahead. This spreading helps the cooling air cover more of the blade surface with the same amount of air! Additionally, the improved flow attachment means less cooling air gets wasted by flying away from the blade. This is super important for jet engines and power plants because every bit of air used for cooling instead of making power costs money and efficiency. Thanks to these tiny vortex generators, the film cooling system works much better while using the same amount of precious cooling air!

Figure 3: Velocity distribution showing flow speeds from 0 to 1.7 m/s around cooling hole with micro vortex generator,

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€195 Original price was: €195.€155Current price is: €155.

€215 Original price was: €215.€165Current price is: €165.

€155 Original price was: €155.€95Current price is: €95.

€380 Original price was: €380.€185Current price is: €185.

Reviews

There are no reviews yet.