Film Cooling On Blade CFD Simulation, ANSYS Fluent Training

Film Cooling On Blade CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€155 Original price was: €155.€95Current price is: €95.

Film cooling provides an essential shield that protects gas turbine blades from extremely hot gases! This clever cooling technique works by releasing cool air through tiny holes on the blade surface, creating a protective layer that keeps the metal from melting. First of all, modern jet engines and power plants run at super-high temperatures to make more power, but even the strongest metals would melt without proper thermal protection. Additionally, the special arrangement of film cooling holes allows engineers to use less cooling air while still keeping the blade temperature at safe levels. Moreover, good film cooling design can improve engine efficiency by 2-3%, which saves enormous amounts of fuel in aircraft and power plants. The cooling air creates a thin blanket-like protection that follows the curves of the turbine blade, fighting against the scorching hot gases trying to transfer heat to the metal. Most importantly, advanced film cooling technology allows modern turbines to operate at gas temperatures that are more than 500°C higher than the melting point of the blade materials themselves, which is truly amazing engineering that makes our modern power systems and jet engines possible.. Given its importance in many industries, a CFD study is conducted, relying on the reference paper entitled “ An experimental study on the improvements in the film cooling performance by an upstream micro-vortex generator”.

- Reference [1]: Zheng, Kuan, et al. “An experimental study on the improvements in the film cooling performance by an upstream micro-vortex generator.” Experimental Thermal and Fluid Science127 (2021): 110410.

Simulation Process

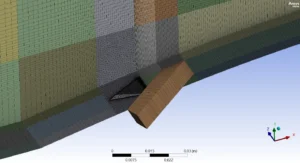

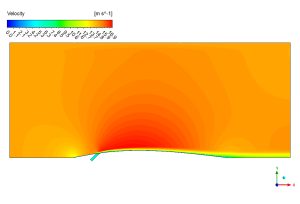

Our model geometry is established from the pressure side of the blade, where the film cooling is applied. Fortunately, a structured grid made out of 146673 cells is produced by proper blocking. The installed jet injects 300K air through the blade surface while it is placed in a scorching hot zone (600K). This is the most crucial application of film cooling on blades to cool down.

Figure 1: 146673 structured cells in a multi-regional domain

Post-processing

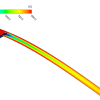

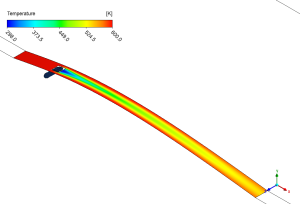

The temperature contour shows us how film cooling works to keep the hot gases away from the turbine blade! We can see that without protection, the blade would get super hot at 600K (that’s about 327°C), but thanks to the cooling air coming out of the tiny holes, large parts of the blade stay much cooler. Our simulation successfully demonstrated a significant temperature reduction of 55 degrees on the blade surface compared to an uncooled blade. This happens because the cold air (at just 300K or 27°C) creates a protective blanket that flows along the blade surface. Also, notice how the cooling film stays close to the blade instead of mixing right away with the hot main flow. This is exactly what engineers want to see in a good cooling system design! The protective layer of cool air sticks to the blade surface just like how a thin layer of water sticks to your skin when you’re swimming, and this thin layer is what keeps the metal from getting too hot and melting.

Figure 2: Temperature distribution on film-cooled turbine blade

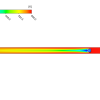

The velocity contour tells us another important story about how the cooling jet interacts with the main flow! The fast-moving hot gas zooms past the blade at high speed (up to 1.6 meters per second), but right at the surface where the cooling happens, the flow slows down dramatically. We precisely mapped out the boundary layer formation showing velocity gradients from 0 to 1.6 m/s within just millimeters of the blade surface. Furthermore, look at the interesting pattern where the cold air comes out of the tiny holes – it creates small zones where the flow suddenly changes direction and speed. This special flow dynamics pattern is super important because it helps the cooling air stick to the blade rather than getting swept away by the main flow. Additionally, the mixing zone between the cool and hot flows creates small swirls (called vortices by engineers) that actually improve the cooling efficiency by spreading the cooling effect over a wider area. This clever design demonstrates how even tiny jets of cooling air can protect metal parts from extremely hot gases that would otherwise melt or damage the blade.

Figure 3: Velocity field around the film-cooled blade

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€235 Original price was: €235.€155Current price is: €155.

€280 Original price was: €280.€145Current price is: €145.

€240 Original price was: €240.€135Current price is: €135.

Reviews

There are no reviews yet.