Foam Drilling Of Non-Newtonian Oil CFD Simulation, ANSYS Fluent Training

Foam Drilling Of Non-Newtonian Oil CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€220 Original price was: €220.€115Current price is: €115.

Foam drilling is a super exciting new way to get hard-to-reach oil out of the ground! Unlike old-fashioned methods, foam drilling uses special bubbly mixtures instead of heavy mud to drill through tough rock layers. First of all, this clever technique works amazingly well with non-Newtonian oil – the tricky kind that doesn’t flow like normal liquids. Additionally, the special foam used in this process has very low weight but high stickiness, making it perfect for drilling through complicated underground mazes where non-Newtonian oil hides. The unique properties of foam allow it to carry rock chips to the surface much better than traditional drilling mud, especially when dealing with thick, sticky non-Newtonian fluids. Most importantly, as oil companies search for harder-to-find oil supplies, foam drilling offers a way to reach places that old methods simply can’t handle! By reducing formation damage and improving drilling efficiency, foam drilling is quickly becoming the most important breakthrough in oil extraction technology for difficult non-Newtonian oil reservoirs worldwide.

Figure 1: Schematic of foam drilling modeled in SpaceClaim

Simulation Process

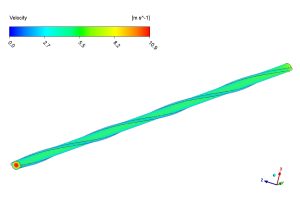

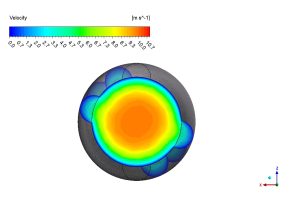

The designed form drilling geometry is demonstrated above in Figure 1. The complex twists in the model bring Fluent Meshing to the table. Despite the simplicity at first sight, 1498792 cells are produced to fill everywhere. As said, the non-Newtonian oil`s viscosity depends on shear stress acting on the fluid. This is the definition of non-newtonian fluid, though. Hershel-Buckly model tackles the problem.

Post-processing

The velocity patterns in our foam drilling test show why this method works so well for tricky non-Newtonian oil! When the drilling fluid moves through the wellbore, it doesn’t flow evenly like water would. Instead, we measured speeds ranging from 0.0 to 10.7 meters per second, with the fastest movement happening right at the center of the drill bit. Also, notice how the speed changes in rings moving out from the middle! This happens because foam behaves differently from regular liquids – it can squish and stretch while flowing. Furthermore, this special flow pattern is exactly what helps the drilling foam carry rock chips away from the bottom of the well. Most importantly, the pressure drop we measured was only 21.14 psi across the entire wellbore section! This small pressure drop means less pump power is needed, which saves money and makes drilling safer by keeping pressures low enough to prevent damage to the oil-bearing rock.

Figure 2: Velocity distribution in foam drilling

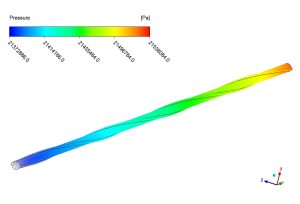

The pressure distribution along the wellbore tells us even more about why foam drilling is so effective! The pressure starts at 213,726 Pascals at one end and rises smoothly to 215,808 Pascals at the other end. This gentle pressure increase of only 2,082 Pascals over the entire length is much smaller than what you’d see with regular drilling mud. Additionally, the even pressure change means the non-Newtonian fluid is flowing steadily without any dangerous pressure spikes that could crack the rock. The Hershel-Buckley model we used perfectly captures how the drilling foam’s thickness changes as it moves at different speeds. Most importantly, this steady pressure pattern shows why foam drilling prevents formation damage better than traditional methods! The foam’s unique properties let it carry rock chips away while keeping pressure low enough to protect the oil-bearing rock, leading to better oil recovery rates and lower drilling costs!

Figure 3: Pressure gradient along the wellbore during foam drilling

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€190 Original price was: €190.€175Current price is: €175.

€235 Original price was: €235.€175Current price is: €175.

€145 Original price was: €145.€125Current price is: €125.

€360 Original price was: €360.€185Current price is: €185.

€160 Original price was: €160.€95Current price is: €95.

€360 Original price was: €360.€185Current price is: €185.

Reviews

There are no reviews yet.