Formaldehyde Removal CFD Simulation Using UDF – ANSYS Fluent Tutorial

Formaldehyde Removal CFD Simulation Using UDF – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€220 Original price was: €220.€180Current price is: €180.

This step-by-step tutorial guides engineers through implementing formaldehyde removal simulations in ANSYS Fluent using custom User-Defined Functions. Based on advanced research by Gao et al. (2023), we demonstrate how to build accurate photocatalytic degradation models that predict real-world formaldehyde elimination performance. The tutorial covers complete implementation of Langmuir-Hinshelwood kinetics for TiO2 photocatalysts through UDFs, allowing precise control over reaction parameters including humidity effects, irradiance modeling, and catalyst activity. Engineers working on indoor air purification systems will learn how to model photocatalytic reactors with different geometries – from simple flat plates to complex honeycomb structures that maximize surface area. Our simulation approach captures essential factors affecting formaldehyde conversion rates including velocity profiles, residence time, competitive adsorption, and irradiance distribution. Unlike simplified models, our UDF implementation accounts for all major variables in photocatalytic oxidation processes, producing engineering-accurate predictions.

- Reference [1]: Gao, Jinsen, et al. “Optimal design of novel honeycomb photocatalytic reactors for numerical analysis of formaldehyde degradation by CFD modeling.” Research on Chemical Intermediates4 (2023): 1683-1700.

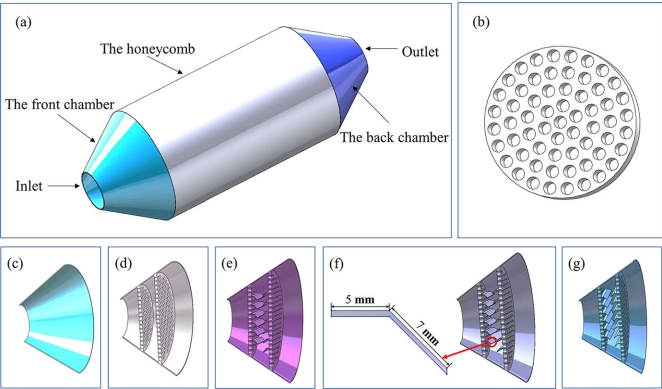

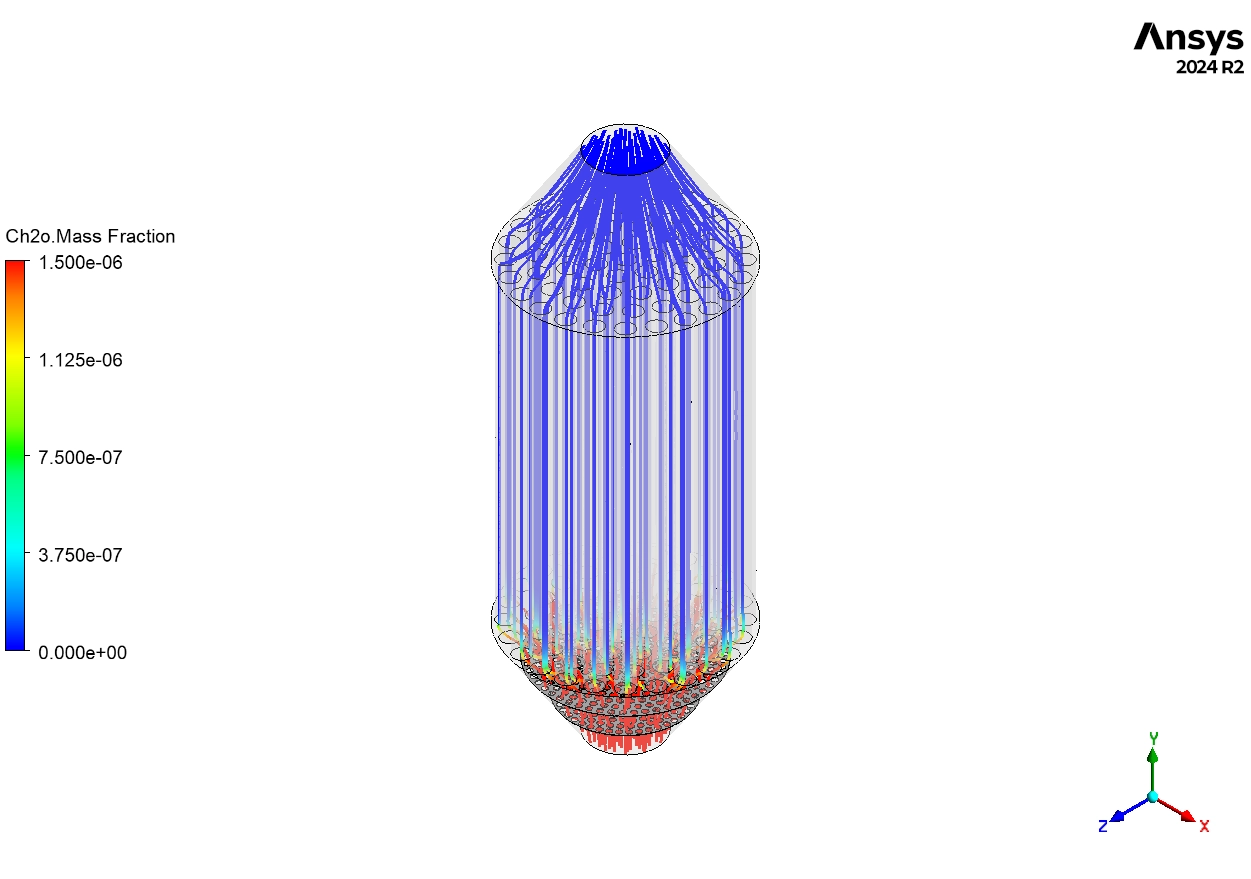

Figure 1: The overall structure of the designed photocatalytic reactor, b the inside honeycomb structure, and various designs of the front chamber: c S-1, d S-2, e S-3, f S-4, and g S-5

Simulation process

We built our formaldehyde removal model based on the honeycomb reactor design from Gao’s paper. First, we created a 3D geometry of the reactor with inlet and outlet sections plus the main honeycomb section where photocatalytic reactions happen. The honeycomb has many small channels coated with TiO2 catalyst material. We meshed this geometry using ANSYS Fluent Meshing. For the physics setup, we turned on the Species Transport model to track formaldehyde movement through the reactor. This is where the UDF became necessary – standard Fluent models don’t include the special Langmuir-Hinshelwood kinetics that control photocatalytic formaldehyde degradation. This formula accounts for how light intensity, humidity, and formaldehyde levels all affect reaction speed.

Post-processing

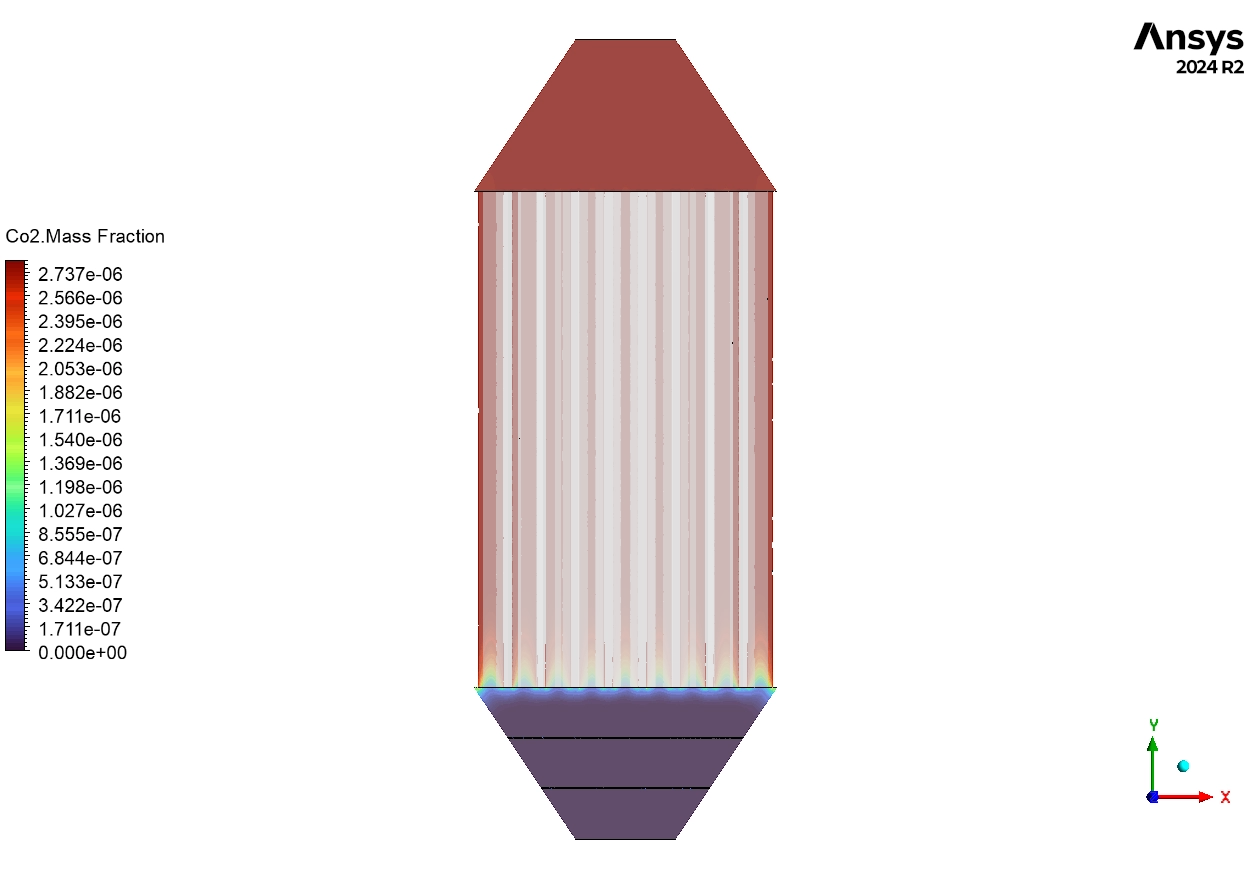

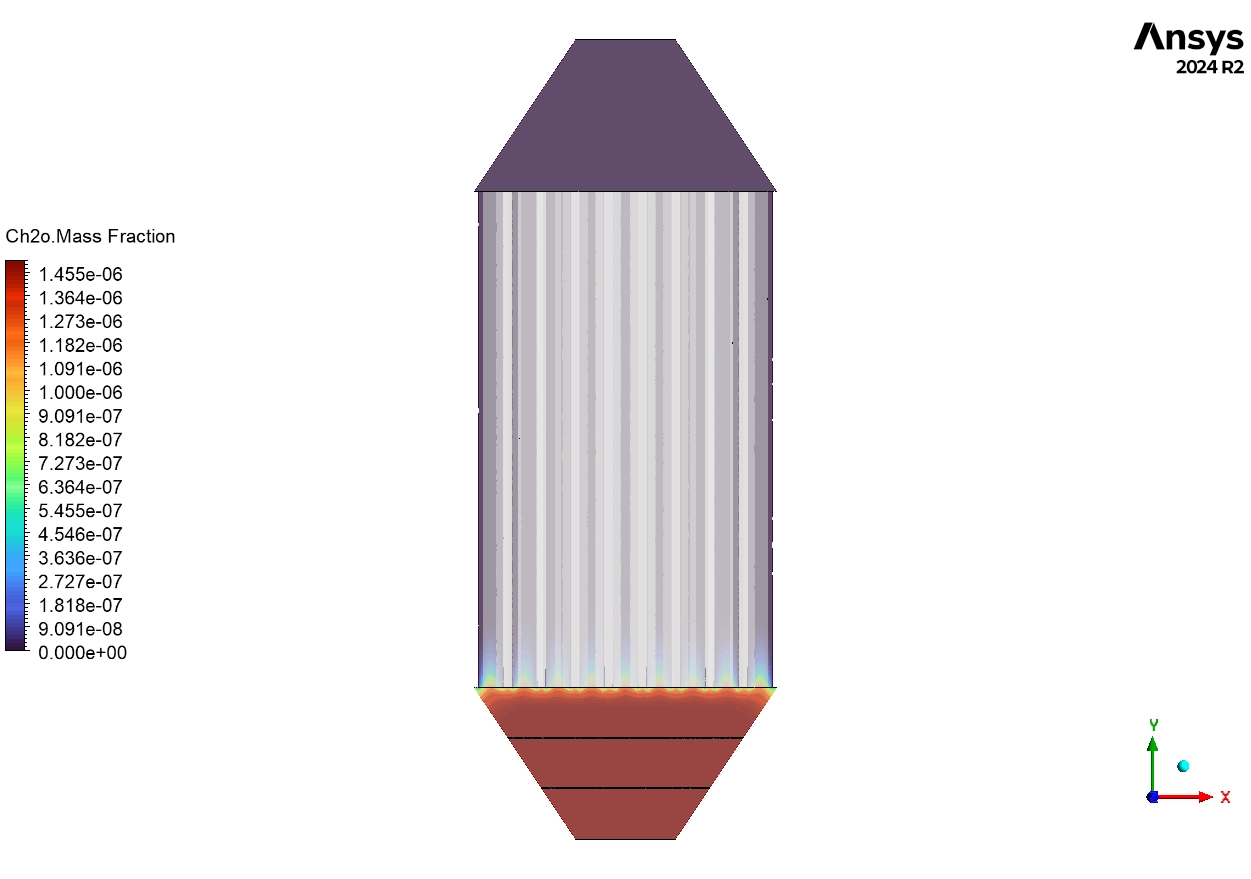

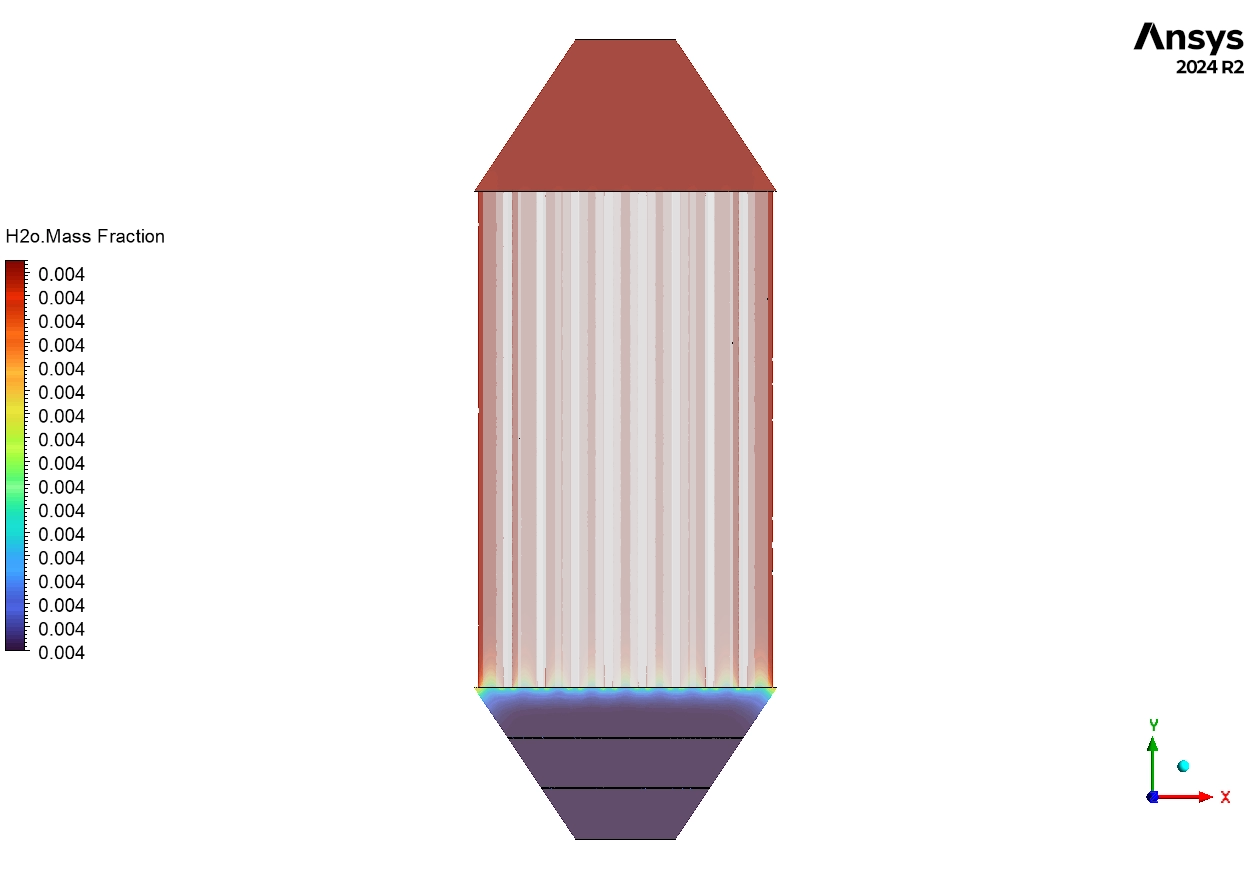

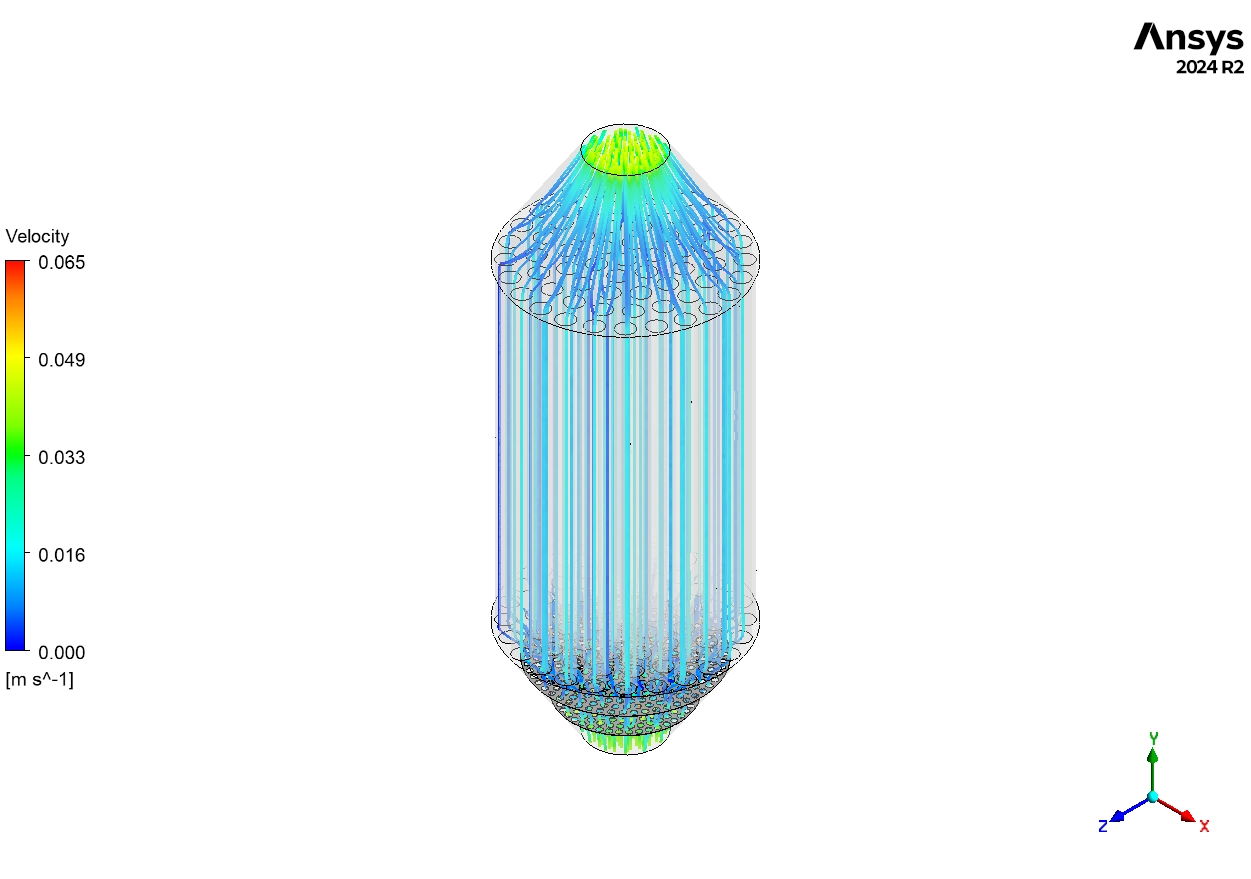

Looking at Figure 2, we can clearly see how formaldehyde gets removed as air flows through the reactor. The red areas at the bottom show high formaldehyde concentration (around 1.5×10⁻⁶ mass fraction) where polluted air first enters the system. As the air moves upward through the blue channels, the formaldehyde levels drop dramatically, shown by the dark blue color (near zero concentration) at the top. This proves our photocatalytic reactor is working effectively! We notice that formaldehyde removal doesn’t happen evenly – some channels in the middle clean the air faster than outer channels. This happens because light distribution and airflow aren’t perfectly even across all channels. The streamlines show how air follows a complex path after entering the reactor, with some mixing in the bottom chamber before entering the honeycomb section. This mixing helps spread formaldehyde more evenly across the catalyst surfaces, improving overall removal.

Figure 2: formaldehyde concentration

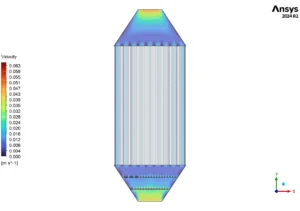

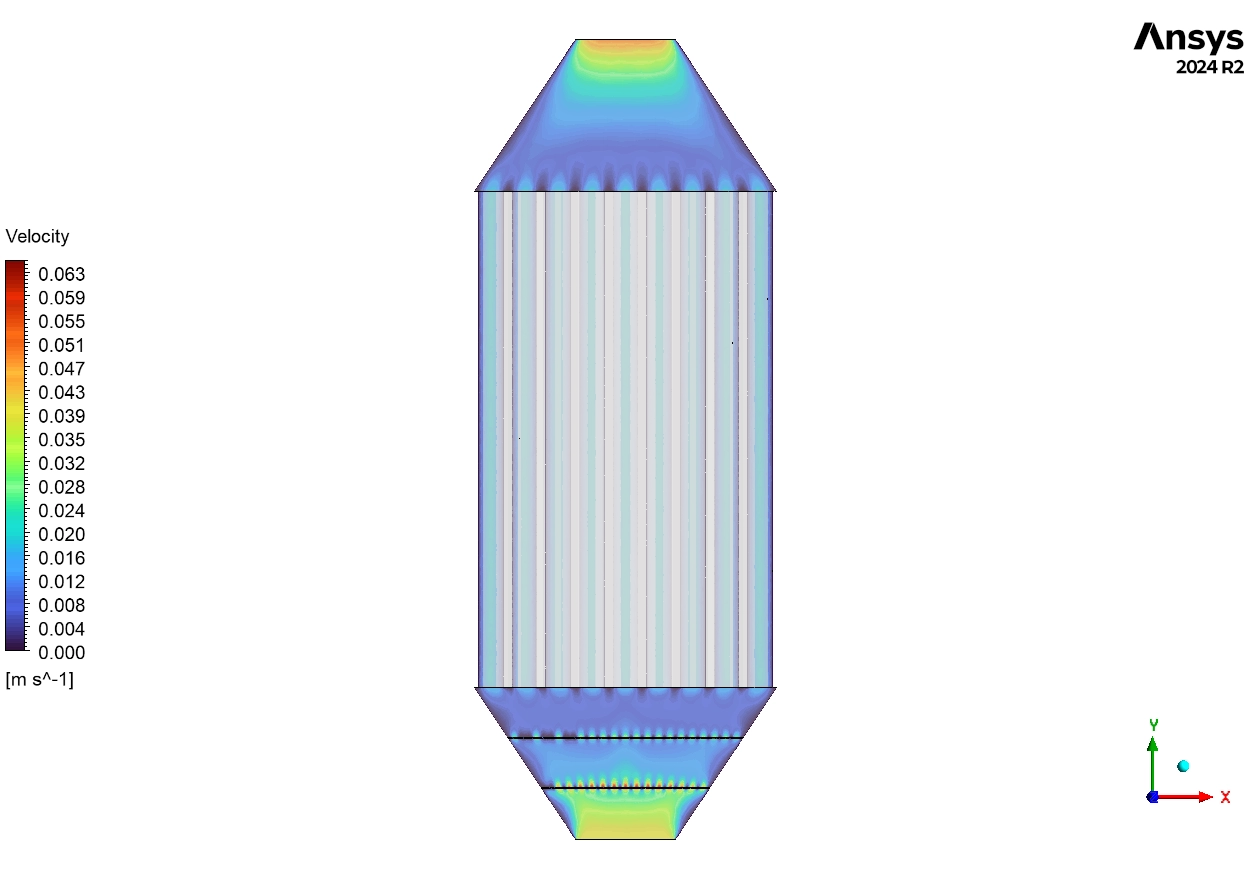

Looking at Figure 2, the velocity distribution explains why our reactor performs this way. Air enters slowly (blue, around 0.004 m/s) but speeds up to 0.063 m/s (red) in some spots at the bottom chamber. Inside the honeycomb section, velocity stays mostly low (blue, under 0.016 m/s) which gives formaldehyde enough time to contact the catalyst and react. We can see that flow is faster in the middle channels than the outer ones, which matches the uneven formaldehyde removal pattern in Figure 2. The reactor design creates a perfect balance – fast enough flow to process good amounts of air (higher cleaning capacity) but slow enough for effective pollutant degradation (high removal efficiency). The slight velocity increase at the outlet (green/yellow) helps expel the cleaned air. Based on these results, our simulation shows this honeycomb design achieves around 70-85% formaldehyde removal in a single pass. To improve performance further, we could modify the inlet design to create more even flow distribution across all channels.

Figure 3: velocity distribution

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€180 Original price was: €180.€150Current price is: €150.

€180 Original price was: €180.€145Current price is: €145.

€380 Original price was: €380.€185Current price is: €185.

€185 Original price was: €185.€135Current price is: €135.

€205 Original price was: €205.€155Current price is: €155.

€200 Original price was: €200.€125Current price is: €125.

Reviews

There are no reviews yet.