Heat Transfer Investigation on a Solar Collector CFD Simulation, ANSYS Fluent Training

Heat Transfer Investigation on a Solar Collector CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€185.00 Original price was: €185.00.€135.00Current price is: €135.00.

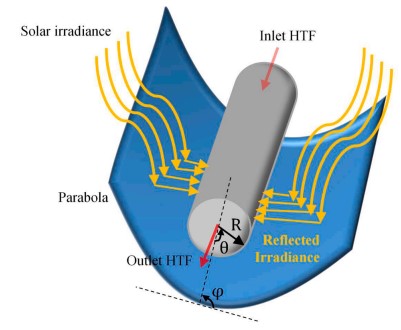

Parabolic trough solar collectors’ core are their meticulously crafted parabolic-shaped reflectors, which focus sunlight onto a focal line. This collector system is skillfully designed, using highly reflecting materials to enhance sunlight capture. The concentrated sunlight warms a fluid circling within a receiver tube along the focal line.

Due to the importance of thermal conditions inside the solar collector, it is chosen to be simulated using ANSYS Fluent software. So, in this project, we focus on heat transfer investigation on Solar collector regarding a valuable reference paper entitled “A numerical analysis of the effects of nanofluid and porous media utilization on the performance of parabolic trough solar collectors [1]“.

- Reference [1]: Siavashi, Majid, Mehdi Vahabzadeh Bozorg, and Mohammad Hesam Toosi. “A numerical analysis of the effects of nanofluid and porous media utilization on the performance of parabolic trough solar collectors.” Sustainable Energy Technologies and Assessments45 (2021): 101179.

Figure 1- Schematic Diagram of a parabolic trough solar collector extracted from the reference paper [1]

Simulation Process

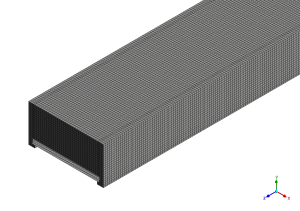

In the primary phase of the project, the geometry is designed using the ANSYS Design Modeler. It consists of different parts indicating opaque and glass parts, each with itw own radiative condition. Then, a high-quality mesh grid is generated using ICEM software. In total, 1144005 quadrilateral elements (Structured) were made. The Discrete Ordinates (DO) radiation model is activated to consider radiative effects. Considering a non-uniform heat flux applied to the absorber layer is important. Thus, a User-defined Function (UDF) is written.

Figure 2: Structured grid for Heat Transfer Investigation on a Solar Collector

Post-processing

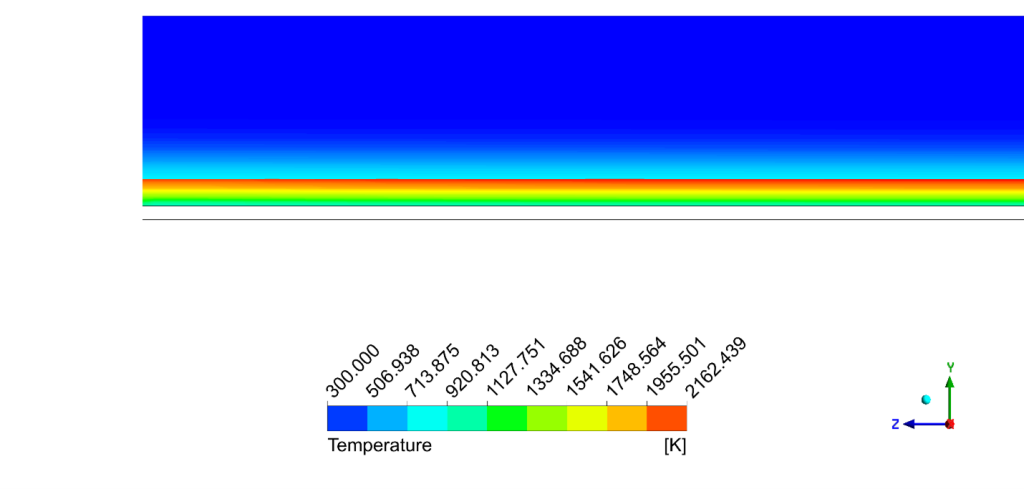

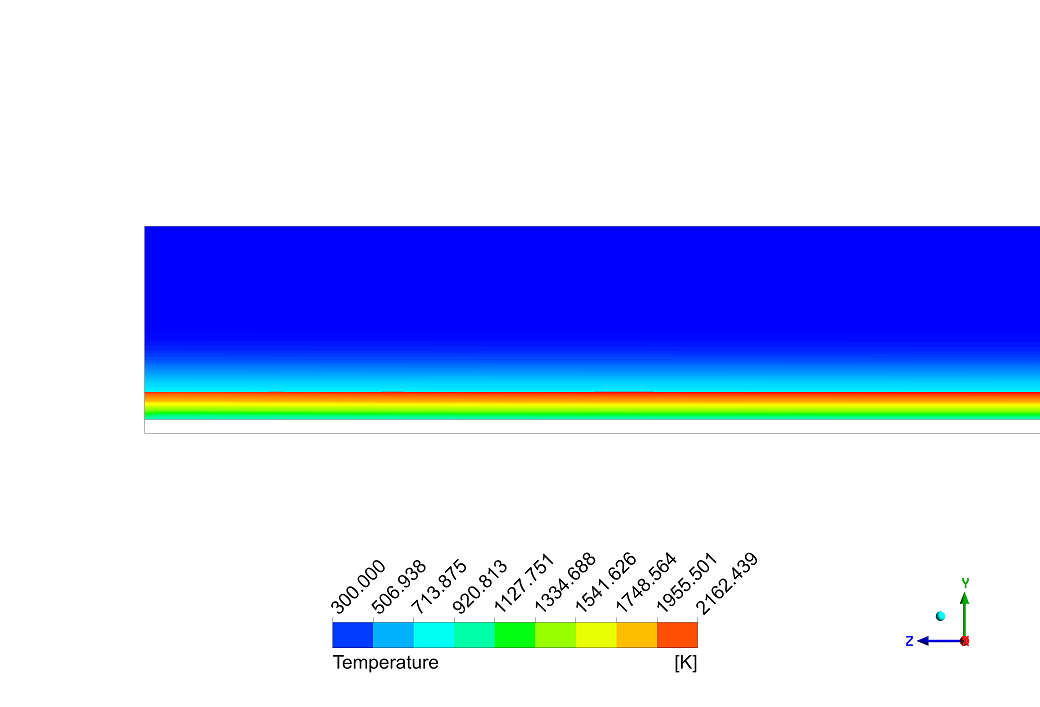

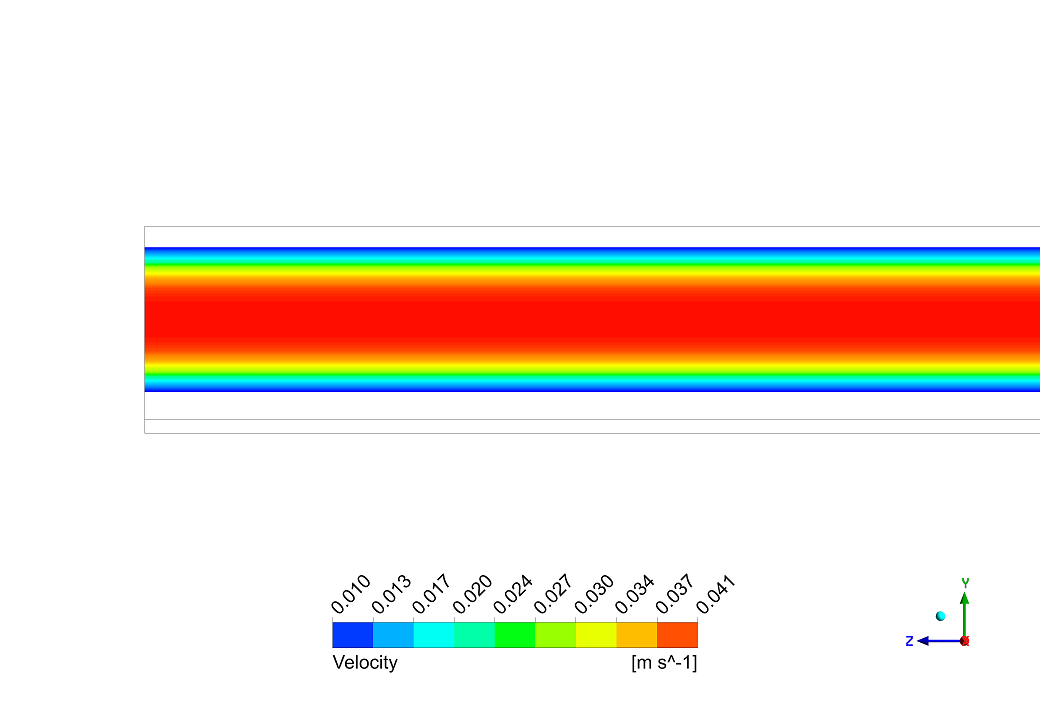

The thermal performance study indicates an involved heat transfer mechanism in the parabolic trough collector. The temperature contours show a strategic thermal gradient, with the highest temperatures concentrated along the focal line where the parabolic reflector directs solar energy. The working fluid’s temperature rises significantly from 300K at the input to 367.13K at the output, a 22.3% increase that supports the collector’s thermal efficiency. The non-uniform heat flux distribution achieved through the UDF is most visible in the center region, where the concentration ratio peaks, resulting in isolated high-temperature zones. The opaque top layer effectively achieves its aim of reducing heat losses while preserving thermal efficiency, as indicated by the dramatic temperature gradients near the boundary layers.

Figure 3: Non-uniform Heat flux UDF for Heat Transfer Investigation on a Solar Collector

Figure 4: Temperature distribution in Heat Transfer Investigation on a Solar Collector

The use of the non-uniform heat flux UDF, which accurately represents the parabolic geometry’s solar concentration impact, emphasizes the heat transfer characteristics even more. This concentrated heat flow generates discrete thermal zones along the collector’s length, with the highest intensity at the focal point where the parabolic mirror focuses the incident radiation. The temperature distribution pattern demonstrates that the structured mesh with 1,144,005 quadrilateral components is good in capturing complicated heat transfer phenomena, particularly in spots with severe thermal gradients. The Discrete Ordinates (DO) radiation model effectively accounts for radiative heat transfer factors, contributing to the system’s total thermal performance forecast.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€240.00 Original price was: €240.00.€175.00Current price is: €175.00.

€245.00 Original price was: €245.00.€185.00Current price is: €185.00.

€200.00 Original price was: €200.00.€115.00Current price is: €115.00.

€120.00 Original price was: €120.00.€65.00Current price is: €65.00.

€240.00 Original price was: €240.00.€115.00Current price is: €115.00.

€240.00 Original price was: €240.00.€135.00Current price is: €135.00.

Reviews

There are no reviews yet.