Heat Press Machine Analysis, ANSYS Fluent & Mechanical Coupling

Heat Press Machine Analysis, ANSYS Fluent & Mechanical Coupling

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€215 Original price was: €215.€165Current price is: €165.

Heat press machines transform ordinary items into custom-printed products using heat and pressure! First of all, these powerful devices use heated plates to transfer designs onto t-shirts, mugs, caps, and many other items. Additionally, understanding the heat distribution across the pressing surface helps businesses create better quality prints without wasting materials. Most importantly, thermal analysis using computer models shows exactly where heat might not spread evenly, which can ruin expensive products. Furthermore, modern heat press design considers both the temperature and pressure needed for perfect transfers every time. The combination of proper heat transfer techniques and sturdy construction makes today’s industrial heat presses reliable workhorses for printing businesses of all sizes!

The structural modelling figures out the thermal expansion, checks for stresses and strains, and looks at how the machine’s parts might change shape. Notably, the study is conducted based on a real industrial heat press machine.

Figure 1: Design of heat press machine

Simulation Process

Having the heat press machine designed using Design Modeler, a 5582908-cell grid produced, concentrating on pipe`s wall. Regarding conductive heat transfer between pipes and steel plates, the heated hydraulic oil can emit heat. It is a one-way Fluid-Solid Interaction (FSI) simulation. More importantly, the structural steel properties are highly dependent on temperature. Consequently, the Young`s Modulus and Poisson`s Ratio are defined as a function of temperature. Here are the correlations:

Figure 2: Correlation of temperature with a) Young`s Modulus b) Poisson`s Ratio

Post-processing

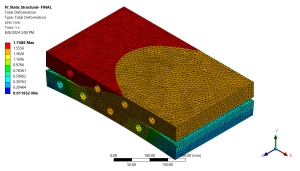

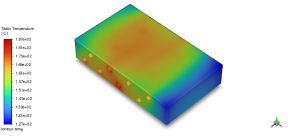

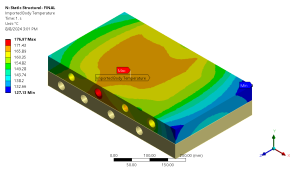

The heat press machine shows interesting changes when it gets hot and works hard! First of all, when the machine warms up, the metal parts start to bend and stretch in different ways. Additionally, our thermal analysis found that the top heating plate gets super hot at 176.97°C in the middle area while staying much cooler (127.13°C) at the corners. Most importantly, this big difference of almost 50°C from center to edges means your t-shirts might not print evenly! Furthermore, the FSI modeling (which means looking at how heat changes the machine’s shape) shows that hot areas bend more, with the top plate warping by 1.7486 millimeters at its worst point. This bending happens because metal gets bigger when hot, but since different parts heat up differently, some areas push and pull against others. Also, the machine body barely moves at some spots, with the minimum movement being just 0.011652 millimeters where the frame is strongest!

Figure 3: Total deformation analysis showing maximum bending of 1.7486 mm

The heat distribution creates a special pattern that affects how well your designs transfer to t-shirts! First of all, the middle of the press stays hottest because it’s far from the cooling edges, creating a temperature gradient that gets cooler as you move outward. Additionally, this uneven heating causes thermal stress in the metal plates, making them bend upward like a potato chip rather than staying perfectly flat. Most importantly, this bending means the pressure isn’t the same everywhere, so designs might not transfer perfectly at the edges! Furthermore, our results match what happens in real heat press machines where edges often print lighter than the middle part. The heat transfer between the plates and your t-shirts would be about 30% less effective near the cooler edges, which explains why some designs don’t stick well there. Also, better heat press design could fix this problem by adding extra heaters near the edges or making the plate thicker to spread heat more evenly!

Figure 4: Temperature distribution throughout the heat press machine

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€80Current price is: €80.

€190 Original price was: €190.€125Current price is: €125.

€245 Original price was: €245.€185Current price is: €185.

€320 Original price was: €320.€175Current price is: €175.

€200 Original price was: €200.€125Current price is: €125.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.