Hydrogen-air Combustion CFD, A Fluent Tutorial with Radiation and NOx Formation

Hydrogen-air Combustion CFD, A Fluent Tutorial with Radiation and NOx Formation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€240 Original price was: €240.€135Current price is: €135.

Hydrogen is a clean fuel because when it burns with air, it mainly produces water. However, this Hydrogen-air Combustion process happens at very high temperatures. This intense heat creates two major challenges for engineers. First, a significant amount of energy is transferred by Radiation in Combustion, which can affect the performance and durability of the burner. Second, the high temperatures can cause nitrogen from the air to react, leading to NoX formation, which is a harmful pollutant.

This project presents a 3D combustion CFD simulation of a micro-cylindrical combustor. The goal is to accurately model the complex interactions between the fluid flow, chemical reactions, and heat transfer. We will use the study by Pashchenko [1] as a reference to guide our understanding of the physics involved in this Hydrogen Flame Simulation.

- Reference [1]: Pashchenko, Dmitry. “Comparative analysis of hydrogen/air combustion CFD-modeling for 3D and 2D computational domain of micro-cylindrical combustor.” International Journal of Hydrogen Energy49 (2017): 29545-29556.

- Reference [2]: Jiaqiang, E., et al. “Effects of inlet pressure on wall temperature and exergy efficiency of the micro-cylindrical combustor with a step.” Applied Energy175 (2016): 337-345.

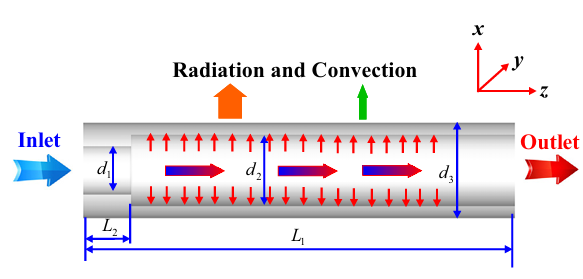

Figure 1: A schematic diagram showing the design of the micro-cylindrical combustor [2].

Simulation Process: CFD Modeling: Using Fluent for a 3D Combustion Simulation

The simulation’s accuracy began with a careful geometry and mesh setup. The 3D model of the micro-combustor was built in Design Modeler using 26 separate bodies. This multi-body approach allowed for the creation of a high-quality, fully structured mesh containing 164,160 cells. A structured mesh is ideal for providing a stable and accurate solution, especially for complex flow and reaction phenomena.

The physics of the simulation were configured in ANSYS Fluent. The Species Transport model was activated to manage the complex chemistry, which involved a detailed 19-step reaction mechanism. To account for the intense heat transfer from the flame, the P1 radiation model was enabled. This step is essential because neglecting radiation would lead to incorrect temperature predictions and, consequently, an inaccurate simulation of the NoX formation. Finally, the dedicated Nox Model in Fluent was used to simulate the formation of thermal NOx, providing a complete picture of the combustion process and its environmental impact.

Figure 2: The 3D geometry of the combustion chamber, composed of multiple parts to allow for a structured mesh.

Figure 3: The high-quality structured mesh used for the 3D Combustion Chamber Simulation.

Post-processing: CFD Analysis of Flame Structure, Radiation, and NOx Formation

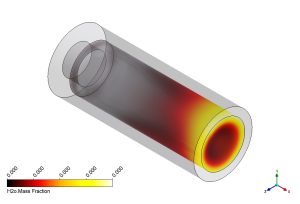

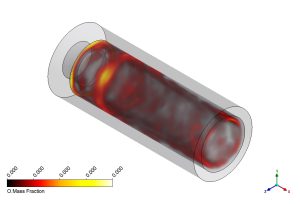

A thorough examination of the results provides a clear understanding of the entire combustion process. The contour plots in Figure 4 show the distribution of Hydrogen Combustion Products and key chemical species. The mass fraction of water vapor (H2O) is highest in the downstream part of the chamber, showing where the reaction is most complete. In contrast, the atomic oxygen (O) contour highlights the hottest parts of the flame where dissociation occurs. Atomic oxygen is a highly reactive radical, and its presence pinpoints the active zones of the Hydrogen Flame CFD, confirming that our Species Transport model is correctly capturing the complex, multi-step chemistry.

Figure 4: Mass fraction contours of a) H2O and b) Atomic O from the Hydrogen-air Combustion CFD simulation.

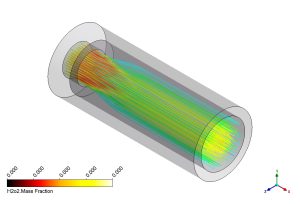

Figure 5 reveals the critical connection between the flow path, temperature, and pollutant formation. The streamlines, colored by the mass fraction of hydrogen peroxide (H2O2), show a smooth flow through the combustor, which gives the chemicals enough time to react. The presence of H2O2, an important intermediate species, is a direct result of the complex reaction mechanism. The accuracy of this chemical prediction is only possible because the P1 radiation model provides a correct temperature field. This is the key insight: an accurate temperature field is essential for a reliable NoX formation Fluent simulation. The high-temperature zones predicted by our model are precisely where thermal NoX Formation happens, as nitrogen and oxygen from the air break apart and recombine. This demonstrates that our Pollutant Formation Simulation is built on a solid thermal and chemical foundation.

Figure 5: Streamlines colored by H2O2 mass fraction, illustrating the flow path and intermediate species in the 3D combustion CFD simulation.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€190 Original price was: €190.€99Current price is: €99.

€160 Original price was: €160.€80Current price is: €80.

€130 Original price was: €130.€85Current price is: €85.

€190 Original price was: €190.€95Current price is: €95.

€120 Original price was: €120.€65Current price is: €65.

€360 Original price was: €360.€180Current price is: €180.

Reviews

There are no reviews yet.