Lift-Drag Optimization On Airfoil Using Mesh Morphing (RBF) – ANSYS Fluent Tutorial

Lift-Drag Optimization On Airfoil Using Mesh Morphing (RBF) – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€150

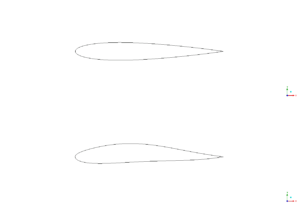

Aerodynamic optimization of airfoils is a critical challenge in aerospace engineering, as minor enhancements in lift-to-drag ratio can substantially increase aircraft efficiency and performance. Conventional optimization methods necessitate iterative cycles of geometric alteration, remeshing, and solution calculation—a protracted procedure that constrains design discovery. Radial Basis Function (RBF) mesh morphing provides a sophisticated method for facilitating dynamic alterations of airfoil shapes without necessitating complete domain remeshing throughout iterations. The combination of RBF morphing with optimization algorithms facilitates the effective study of design alternatives to ascertain airfoil designs that enhance lift while reducing drag under specified flying conditions. What we aim to do over base airfoil is to enhance lift-to-drag ratio using Mesh morphing technique in ANSYS Fluent.

Figure 1: Base airfoil and proposed modification to enhance lift-to-drag ratio by Mesh morphing (RBF) technique

Simulation process

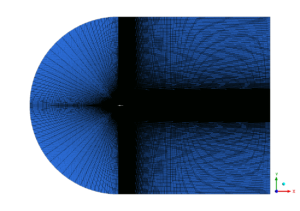

The optimization framework was constructed around a C-shaped computational domain extending in all directions to ensure far-field boundary independence. The baseline airfoil geometry served as the initial configuration, with the domain discretized using a high-quality structured grid featuring quadrilateral elements with appropriate clustering near the airfoil surface to resolve the boundary layer physics accurately. Flow conditions were set to a moderate subsonic regime with Mach number 0.4 (approximately 136 m/s), representing typical cruise conditions where both lift performance and drag reduction become critical design factors. The Spalart-Allmaras turbulence model was selected for its proven reliability in external aerodynamic applications with attached boundary layers and moderate pressure gradients, offering a good balance between computational cost and accuracy for airfoil analysis. Air was modeled as an ideal gas with standard atmospheric properties to properly account for compressibility.

Figure 2: structured grid over airfoil domain for geometrical optimization using RBF mesh morphing

Post-processing

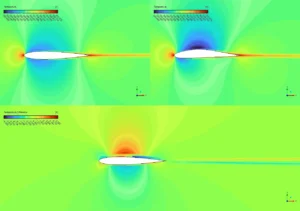

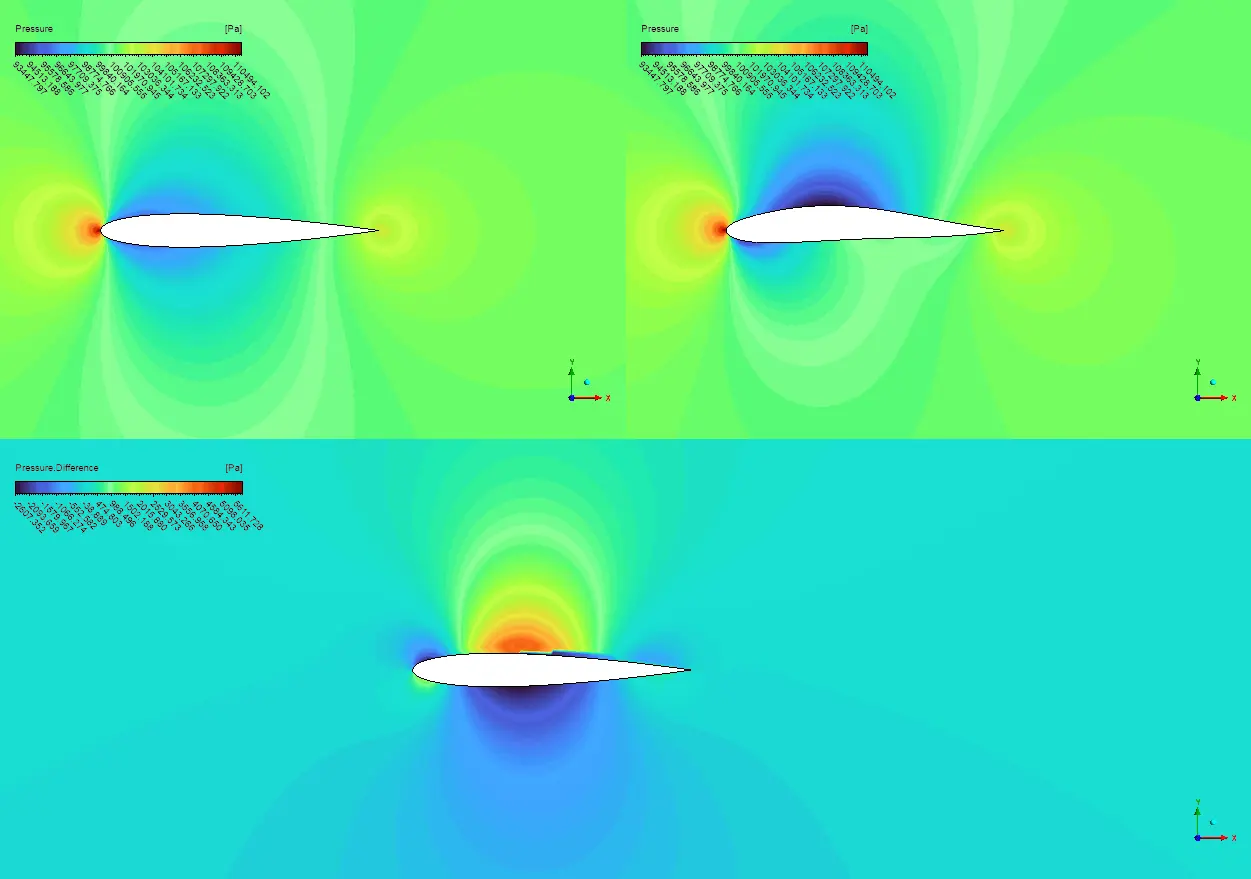

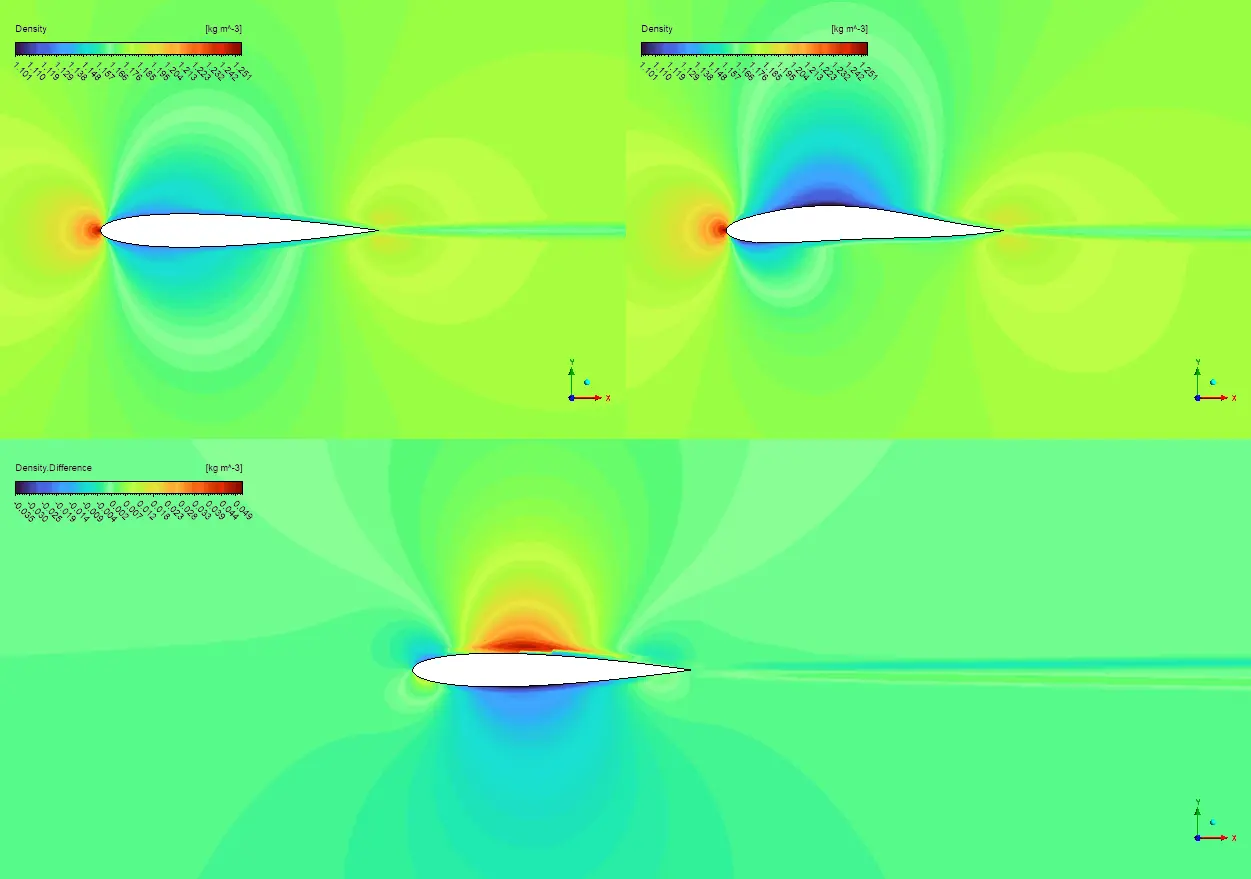

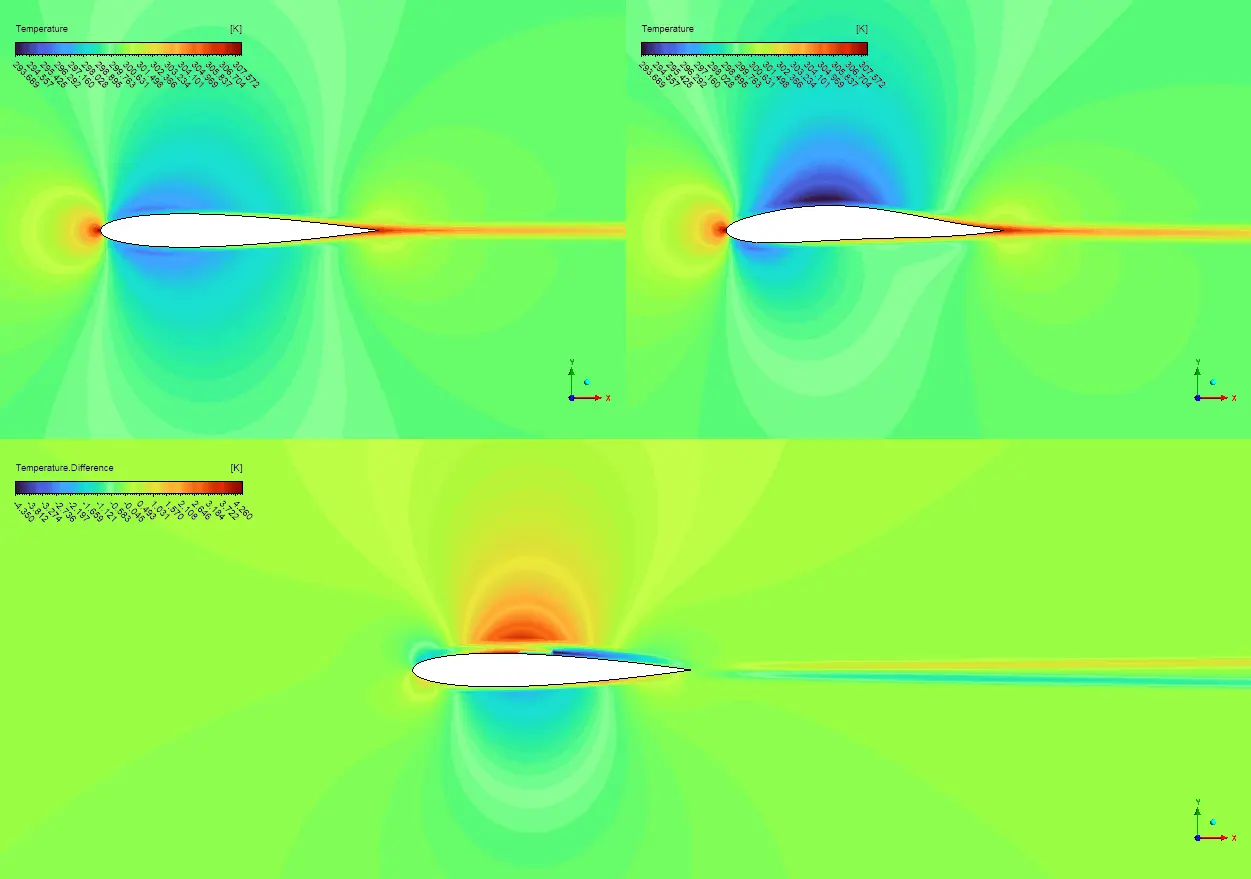

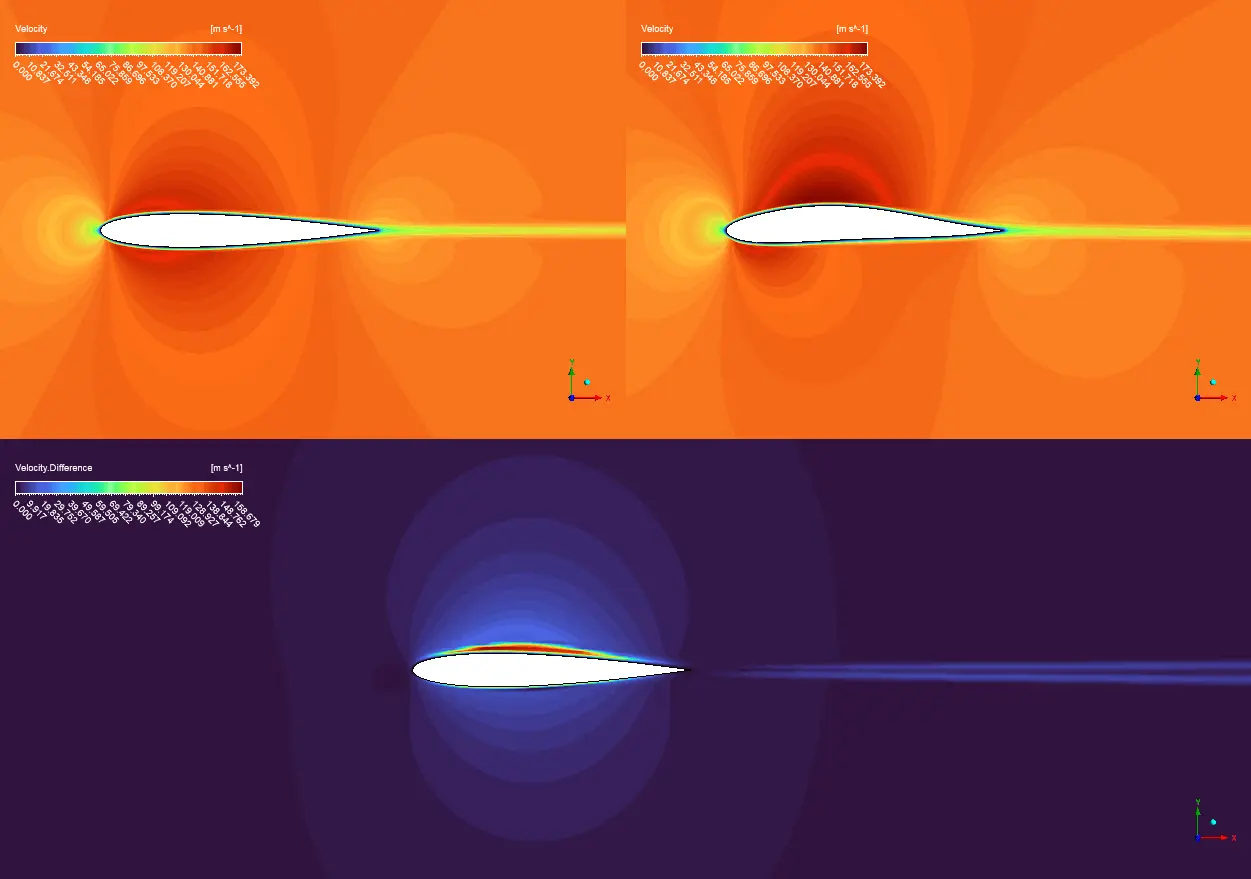

The optimization results proves a remarkable transformation in airfoil performance, with the lift coefficient increasing by over 400 times from virtually zero (CL = 0.00042) to a substantial value (CL = 0.17548) while incurring only a minimal 4.5% penalty in drag (CD increasing from 0.01139 to 0.01190). This dramatic improvement in lift-to-drag ratio is clearly visualized in the temperature contour plots, where the optimized airfoil exhibits a pronounced asymmetric temperature distribution with significantly higher temperatures above the airfoil (red-orange region) and lower temperatures below (blue-green region)—the classic signature of effective lift generation. The temperature difference plot further highlights this asymmetry, showing the concentrated high-temperature region above the airfoil that corresponds to the lower pressure zone responsible for lift production. The velocity contours provide additional insight into the optimization’s effectiveness, revealing substantially accelerated flow over the upper surface of the optimized airfoil (darker red region) compared to the more uniform flow field around the baseline geometry. This accelerated flow is directly responsible for generating the pressure differential that produces lift, according to Bernoulli’s principle. The velocity difference plot confirms these observations, showing the greatest flow modifications occurring near the leading edge and upper surface where the RBF morphing technique subtly adjusted the airfoil curvature to optimize pressure distribution.

Figure 3: Lift-to-drag enhancement due to RBF mesh morphing implementation on subsonic flow over airfoil

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€195 Original price was: €195.€155Current price is: €155.

€180 Original price was: €180.€150Current price is: €150.

€235 Original price was: €235.€155Current price is: €155.

€155 Original price was: €155.€95Current price is: €95.

€240 Original price was: €240.€135Current price is: €135.

Reviews

There are no reviews yet.