Particle Mixing CFD, A DDPM Fluent Tutorial for Mixer Tank Simulation

Particle Mixing CFD, A DDPM Fluent Tutorial for Mixer Tank Simulation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€235 Original price was: €235.€165Current price is: €165.

Particle mixing is a fundamental operation at the heart of countless industries, including pharmaceuticals, chemicals, and food processing. The engineering goal is to achieve a perfectly uniform blend of powders, granules, or other solid particles to guarantee the final product’s quality, safety, and performance. However, achieving this is a significant challenge due to complex phenomena like particle segregation, agglomeration, and the formation of stagnant “dead zones” within the equipment. A Particle Mixing CFD simulation is the most powerful tool engineers have to overcome these issues. For highly concentrated flows, traditional models are insufficient. This is where the Dense Discrete Phase Model (DDPM) becomes essential. This advanced DDPM Fluent tutorial demonstrates the simulation of a complex, three-phase (air, water, solid particles) system inside an industrial Mixer CFD model, providing unparalleled insight into the mixing dynamics.

Figure 1: An industrial particle mixer, the subject of this advanced Particle Mixing Fluent simulation

Simulation Process: Modeling Multiphase Dynamics in a Mixer Tank with DDPM Fluent

To accurately simulate the complex dynamics inside the Mixing Tank CFD, a multi-faceted modeling approach was required in ANSYS Fluent. The simulation’s core is the Sliding Mesh technique, which allows the mesh zone around the rotating blades to move independently of the stationary mixer walls, perfectly replicating the mechanical action of the impeller. The physics is governed by a complex three-phase model: air as the primary Eulerian phase, water as a secondary Eulerian phase, and the solid particles modeled using the advanced Dense Discrete Phase Model (DDPM).

This DPM Particle Mixing CFD setup is crucial because it accounts for two-way coupling, where the fluid pushes the particles and the particles displace and affect the fluid. Critically, DDPM also calculates the granular pressure and viscosity of the particle phase, allowing it to accurately simulate particle-particle collisions and friction in dense concentrations. The particles were introduced into the simulation using a volume injection with a Rosin-Rammler distribution to represent a realistic range of particle sizes.

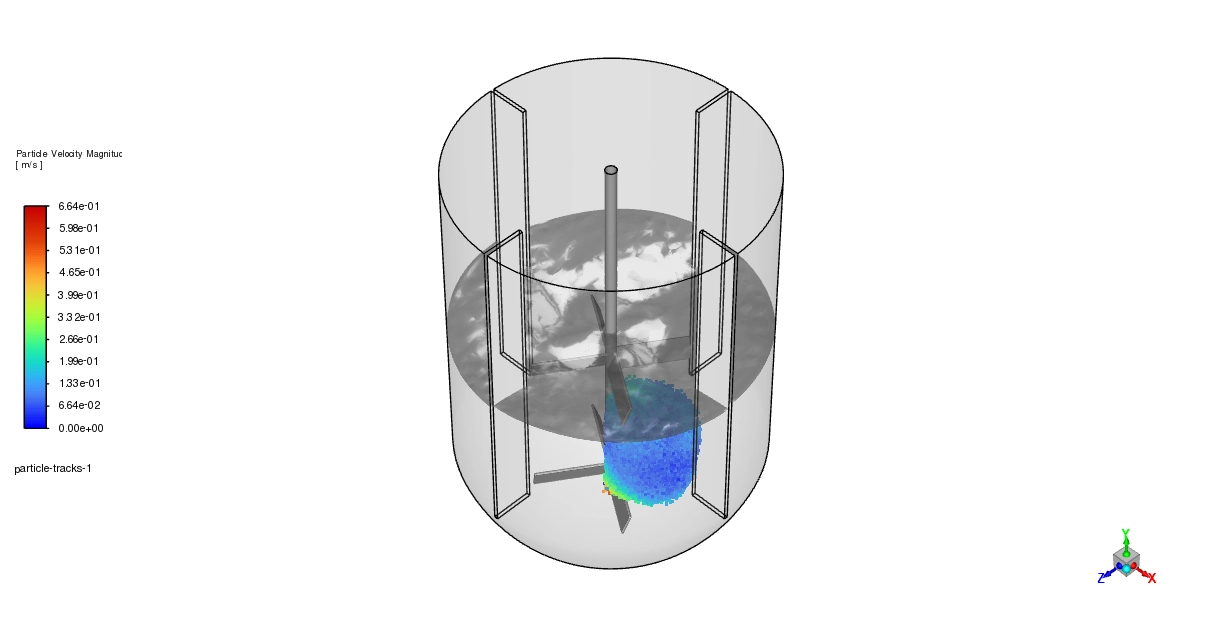

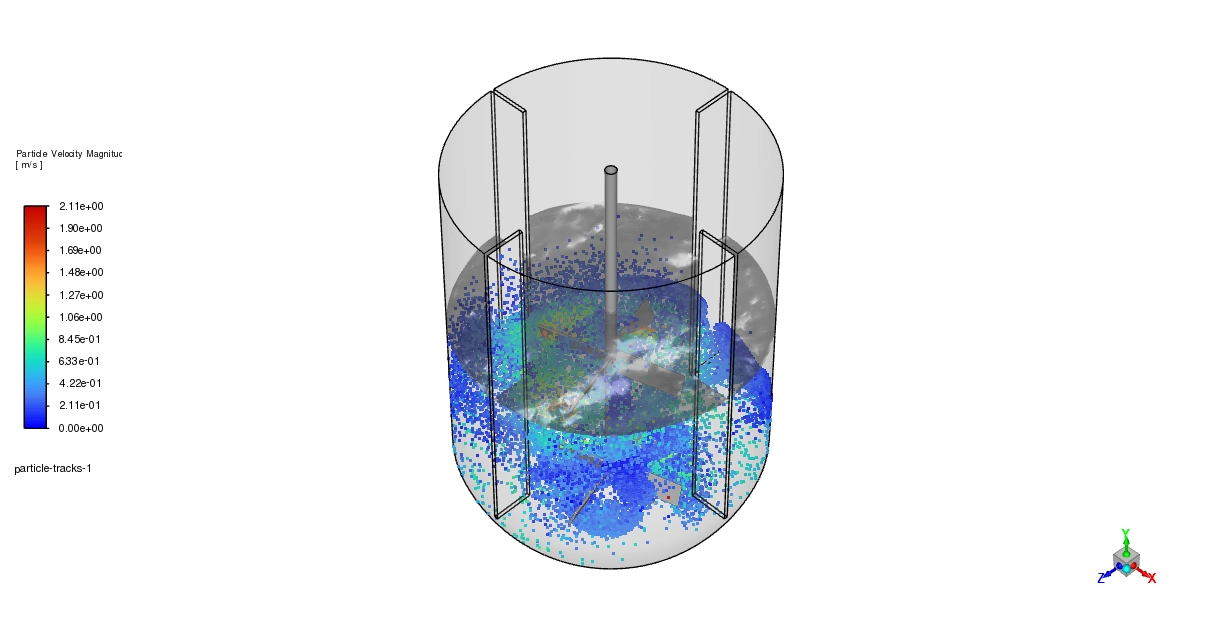

Post-processing: CFD Analysis of Mixing Mechanism From Fluid Dynamics to Particle Dispersion

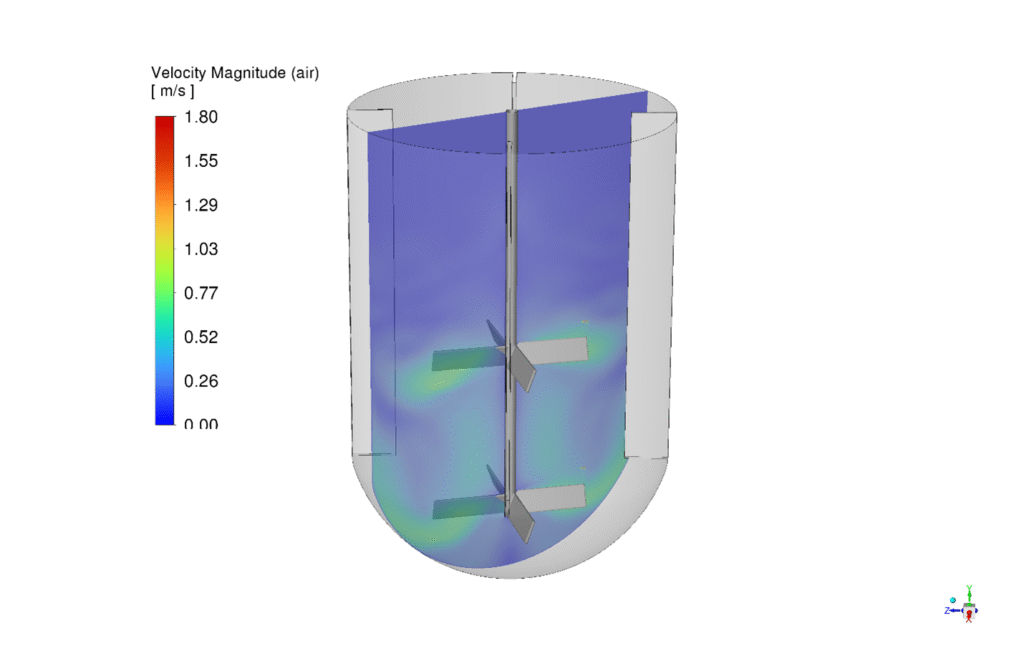

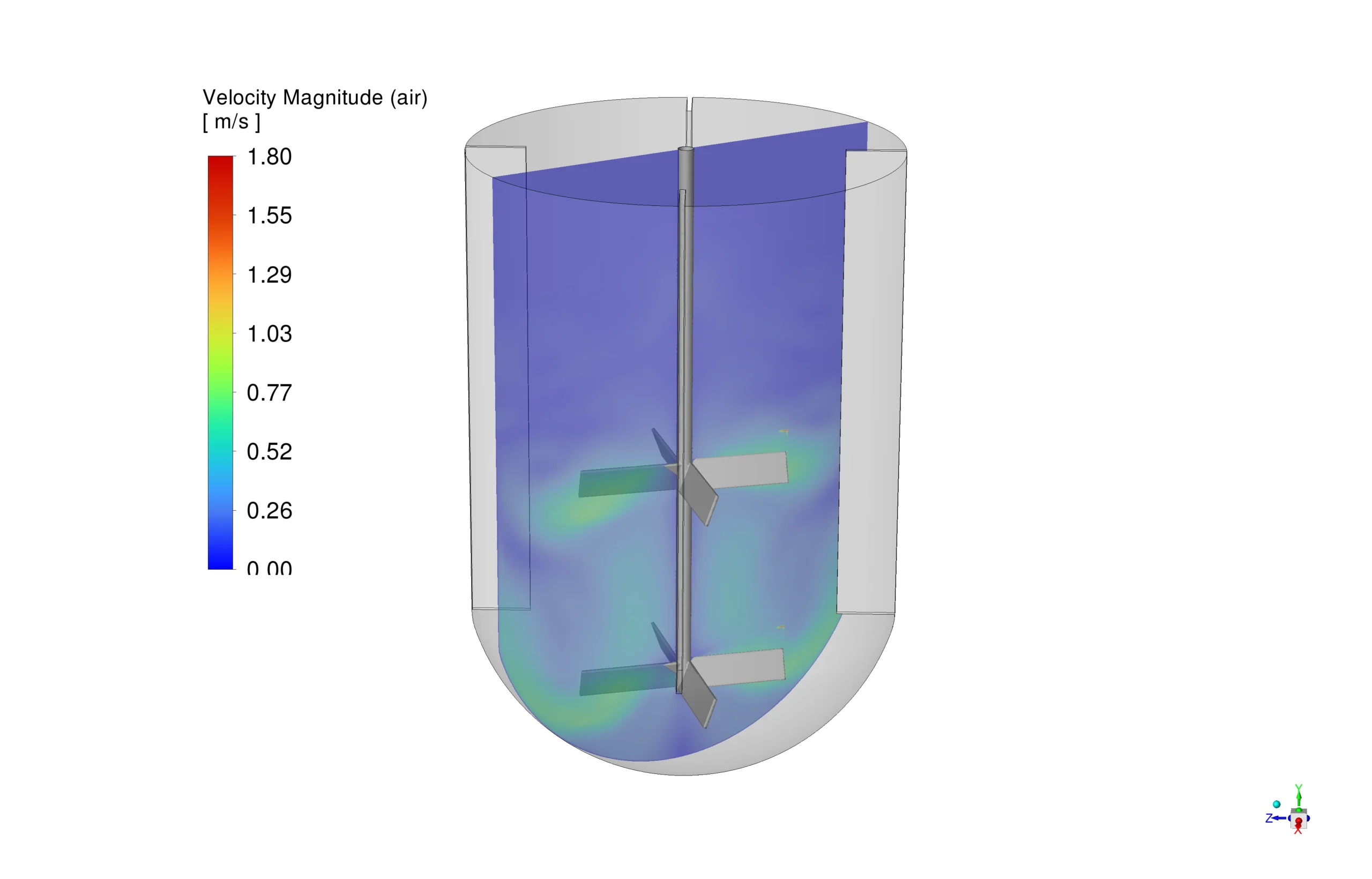

The velocity magnitude field in the particle mixing CFD simulation ranges from 0 m/s in dead zones to 1.80 m/s near rotating blades, creating circulation patterns that drive particle movement and mixing efficiency in the mixer. Air flow velocity is highest around blade tips where shear forces are strongest, generating turbulence that helps disperse particles throughout the mixer volume. ANSYS Fluent results capture flow recirculation zones behind blades where particles can get trapped, affecting mixing uniformity and creating potential segregation areas. CFD analysis predicts velocity gradients that control particle entrainment, with higher velocities near blades providing better particle suspension and mixing action. Fluent CFD simulation shows that blade rotation creates strong radial and axial flow components that promote particle circulation and prevent settling at mixer bottom, essential for effective powder mixing operations.

Figure 2: velocity distribution within the Mixer CFD model, clearly showing the high-energy zones at the blade tips that drive the entire mixing process.

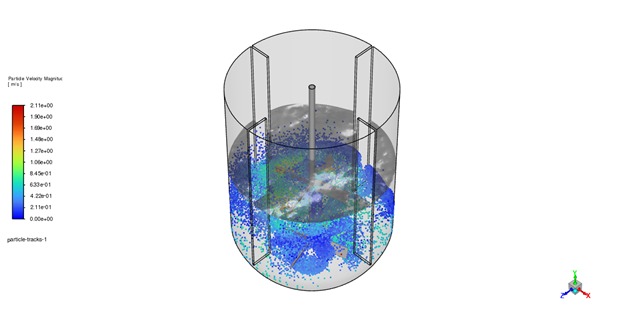

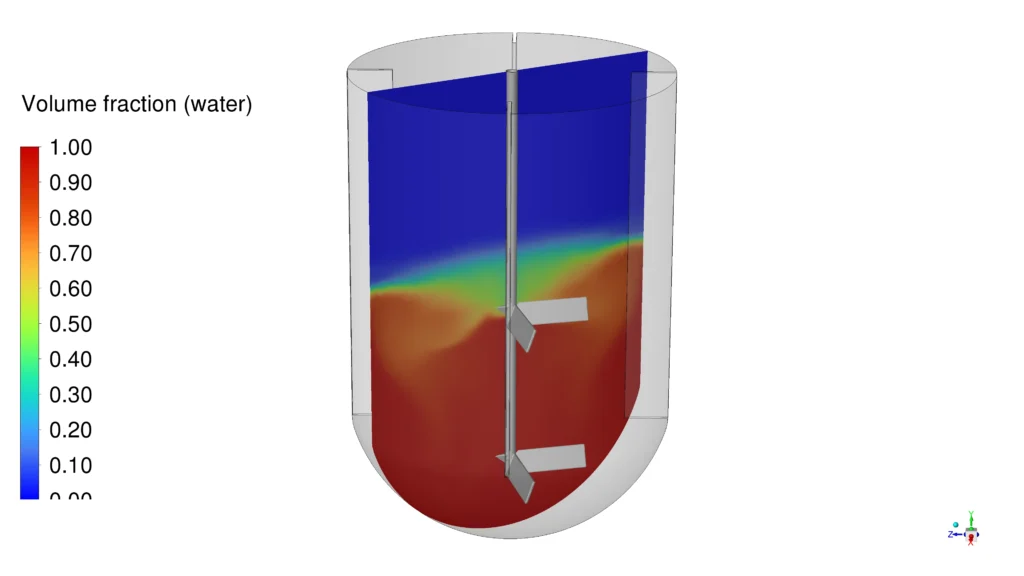

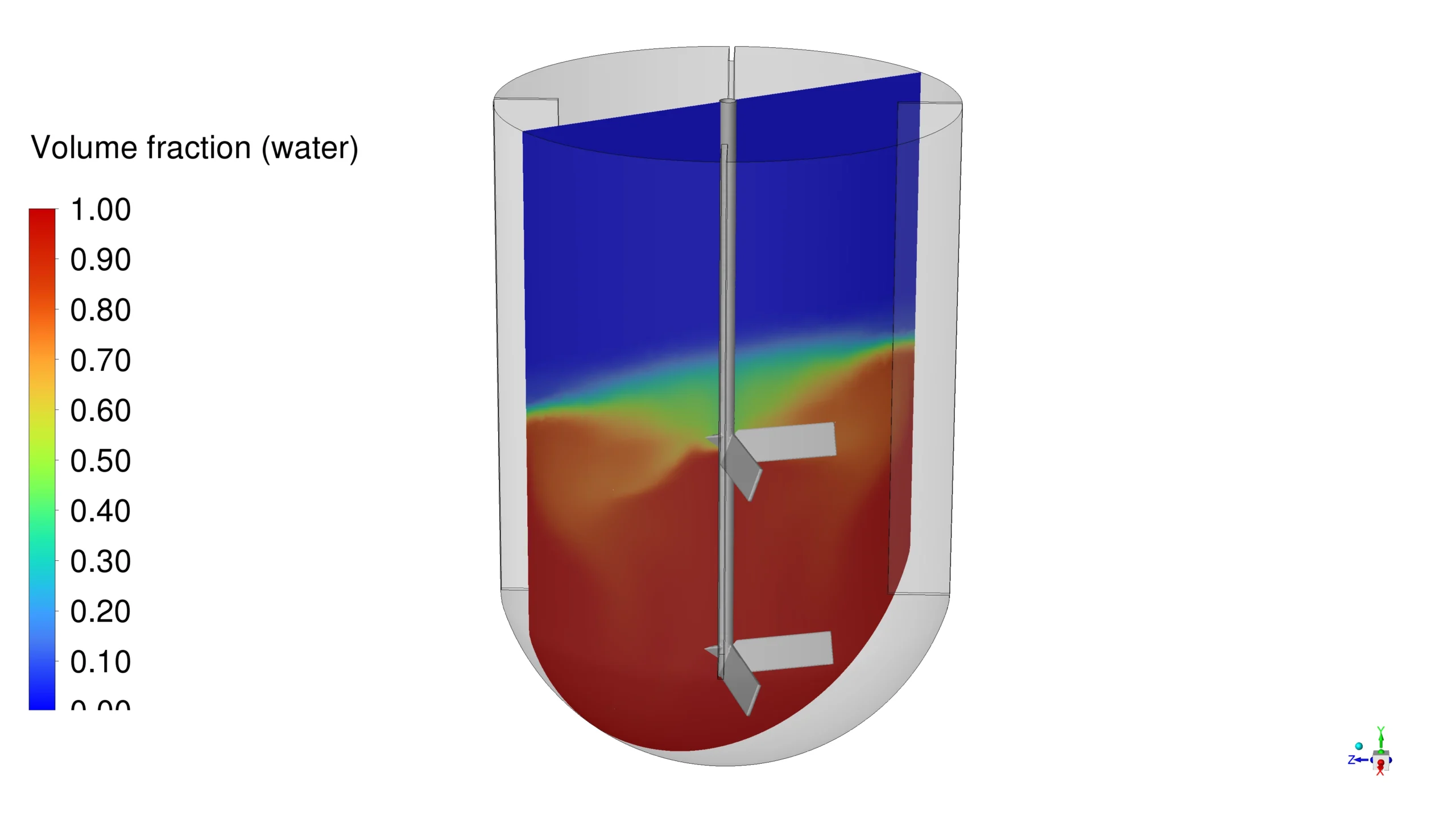

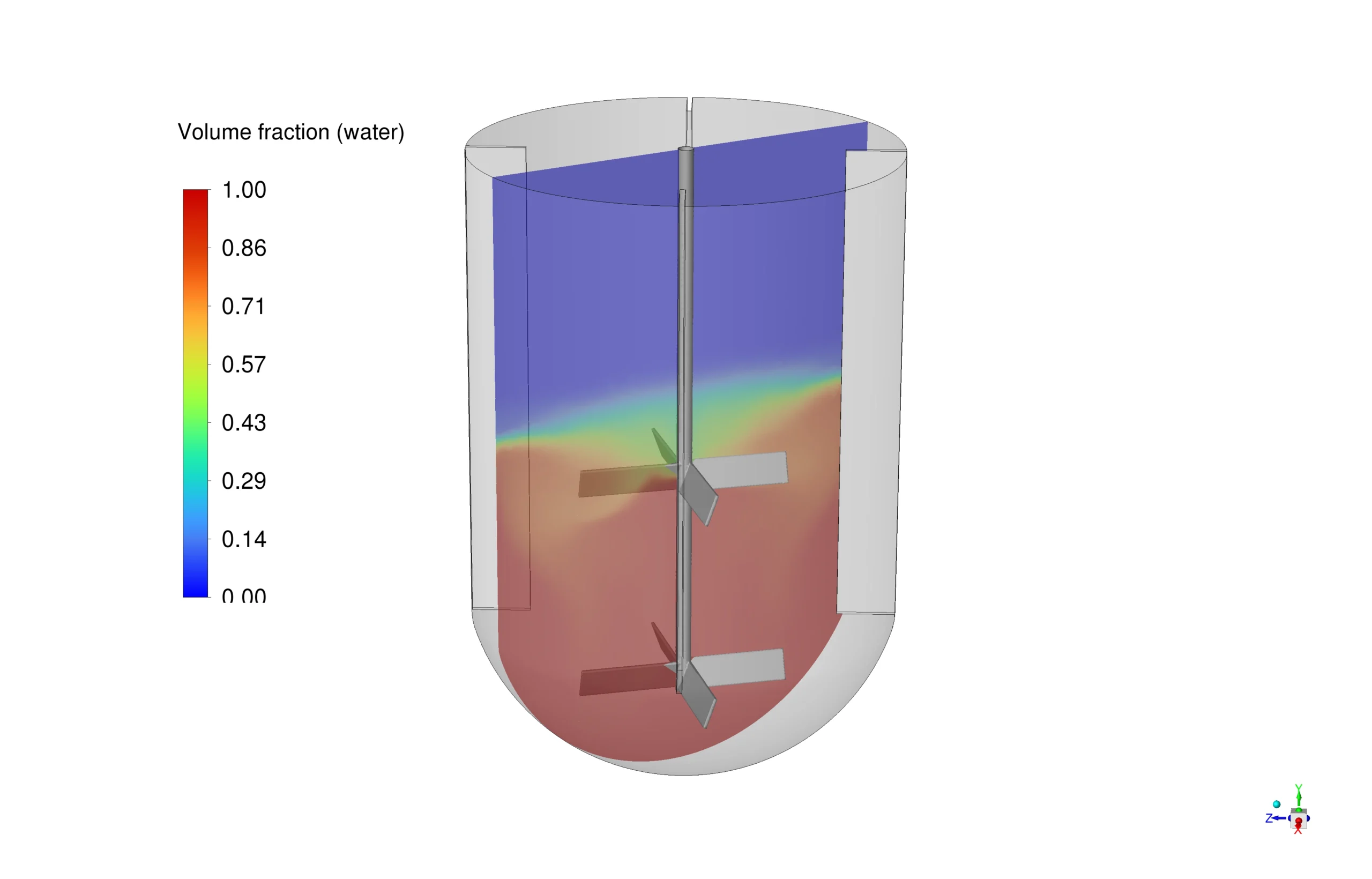

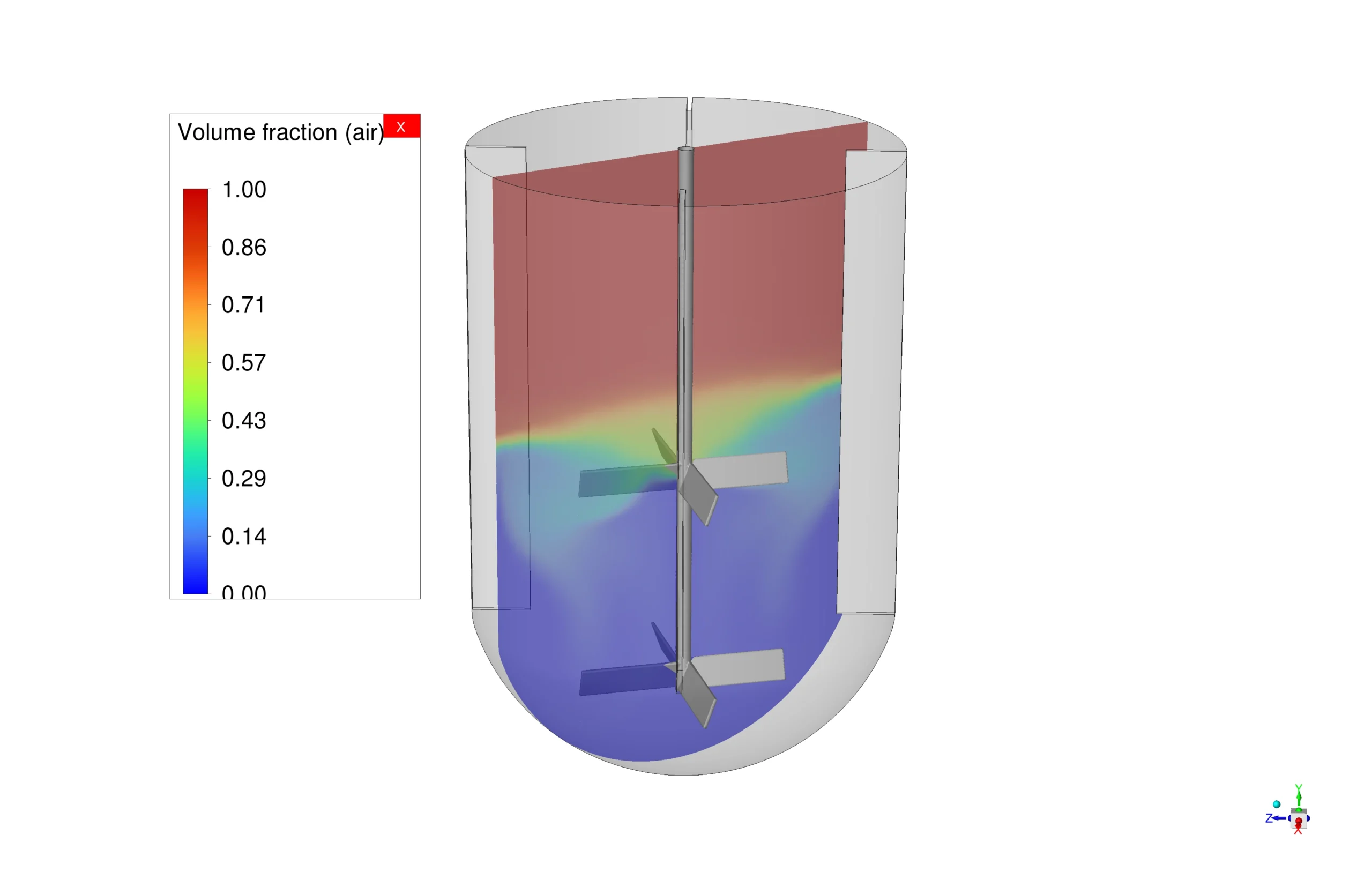

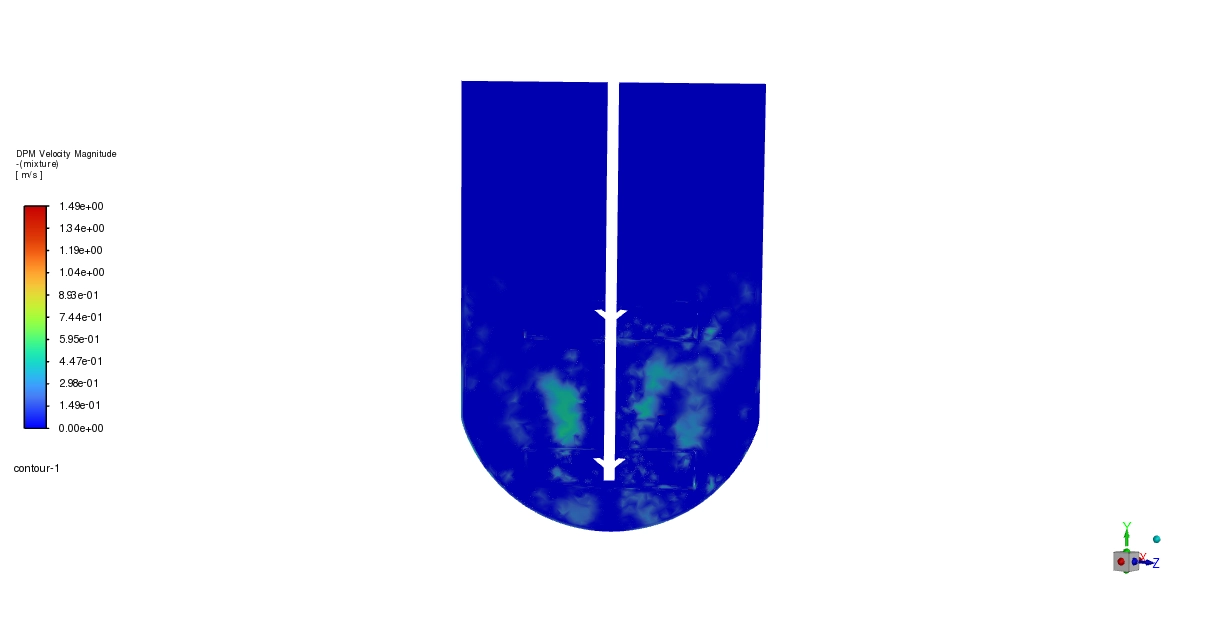

This powerful fluid motion directly drives the behavior of the other phases, as shown in Figure 2. The water phase (shown in red) is violently churned by the blades, creating a sloshing wave that splashes upwards and wets the solid particles. This wetting action is the first step in creating a homogeneous slurry. The DDPM particles, colored by their velocity, are then captured by this three-phase flow. They are lifted from the bottom of the tank and thrown outwards and upwards, following the fluid streamlines, with individual particle velocities reaching 2.11 m/s. The most significant achievement of this Particle Mixing CFD simulation is the visualization of this complete, coupled mechanism: the impeller energizes the air, the air drives the water wave, and the wave wets and transports the particles, while the particle-to-particle collisions modeled by DDPM Fluent ensure localized, micro-scale mixing. This detailed, multi-layered analysis provides a complete engineering understanding of the mixing process, far beyond what could be observed through physical experiments alone.

Figure 3: Distribution of the Water Volume Fraction and the corresponding particle movement tracked by the DDPM Fluent model, showing the interaction between the liquid and solid phases

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€180 Original price was: €180.€155Current price is: €155.

€145 Original price was: €145.€115Current price is: €115.

€270 Original price was: €270.€165Current price is: €165.

€190 Original price was: €190.€165Current price is: €165.

€240 Original price was: €240.€155Current price is: €155.

€155 Original price was: €155.€99Current price is: €99.

Reviews

There are no reviews yet.