Persian Windmill Performance CFD Study Using MRF – ANSYS Fluent Tutorial

Persian Windmill Performance CFD Study Using MRF – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140 Original price was: €140.€125Current price is: €125.

This tutorial explores the unique design and performance characteristics of Persian windmills (known as Asbad), one of the oldest vertical-axis wind energy systems in the world. Dating back over 1,000 years, these remarkable windmill structures found primarily in eastern Iran and Afghanistan represent a significant achievement in historical wind power technology. Unlike European horizontal-axis designs, the Asbad windmill features distinctive vertical blades arranged around a central shaft, capturing wind energy from multiple directions without requiring reorientation. The traditional Persian windmill design typically includes 6-12 rectangular wooden blades with fixed pitch angles that automatically generate rotation from the region’s persistent “120-day winds.” These ingenious wind energy converters continue to inspire contemporary vertical-axis wind turbine (VAWT) research due to their self-starting capability at low wind speeds and simple. Our focus on the current study is on the effect of wooden blades number on the turbine performance by means of ANSYS Fluent.

Figure 1: Ancient Persian windmill

Simulation process

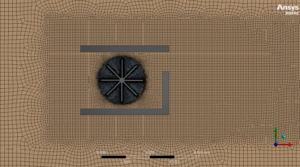

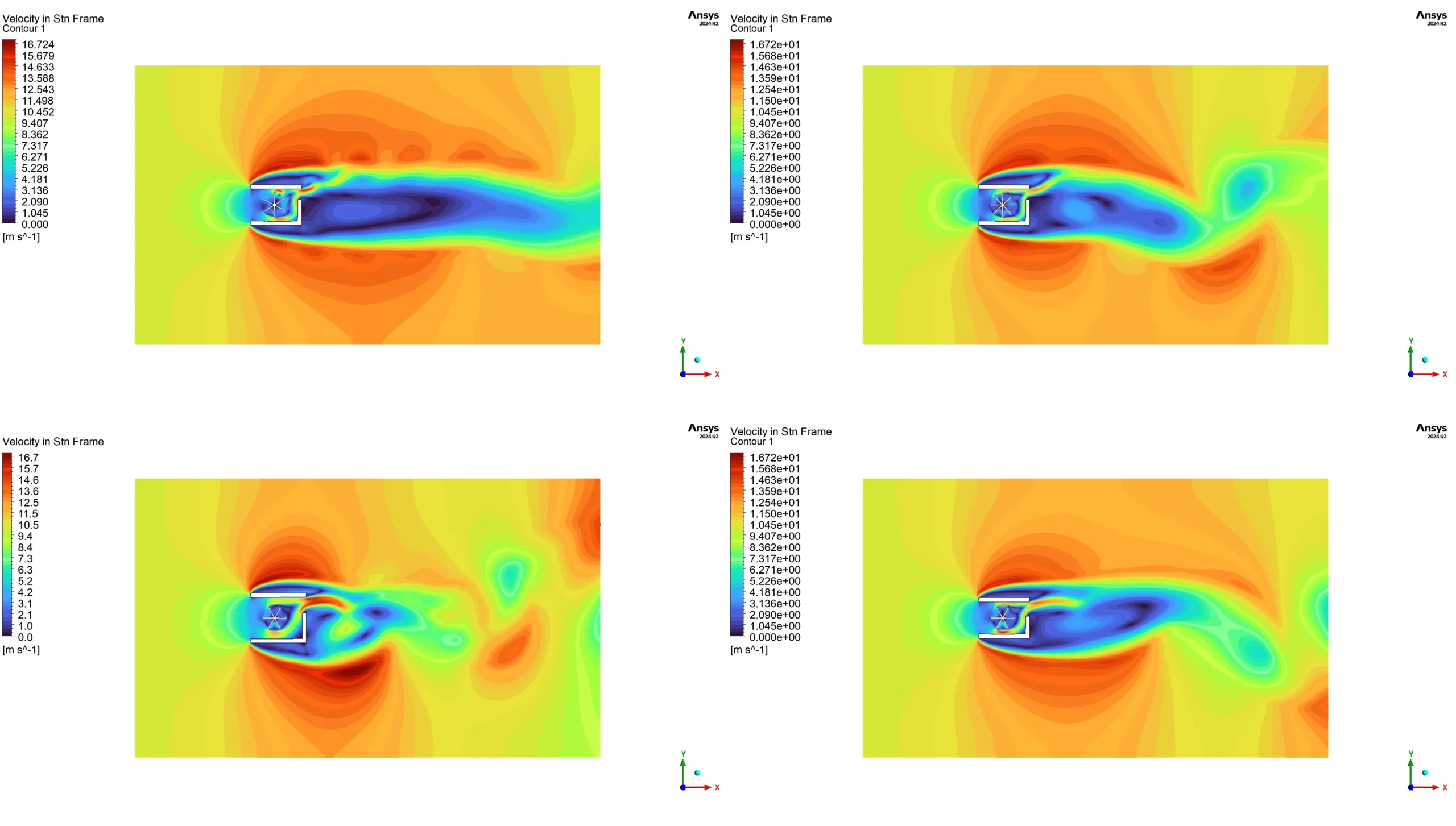

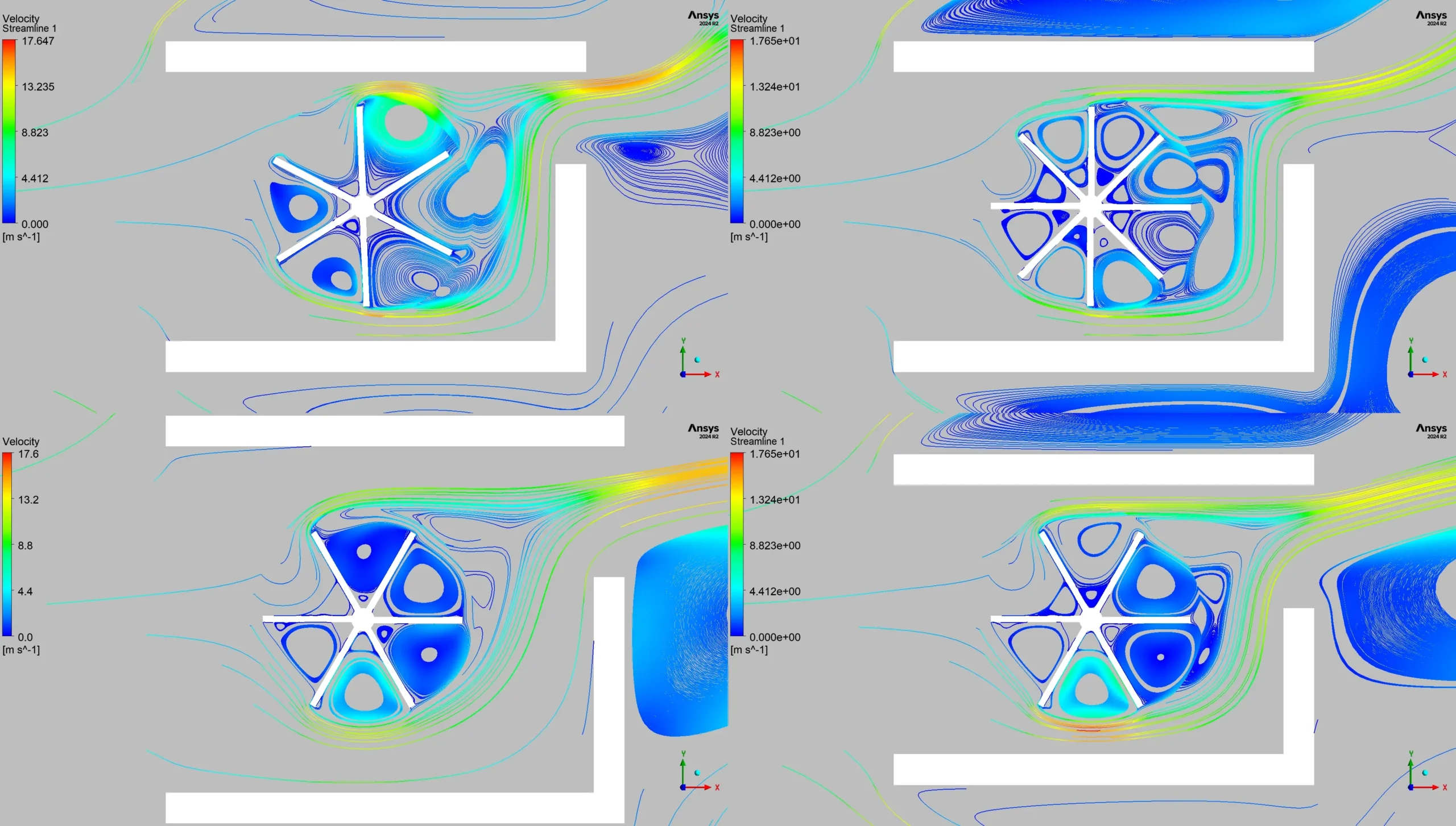

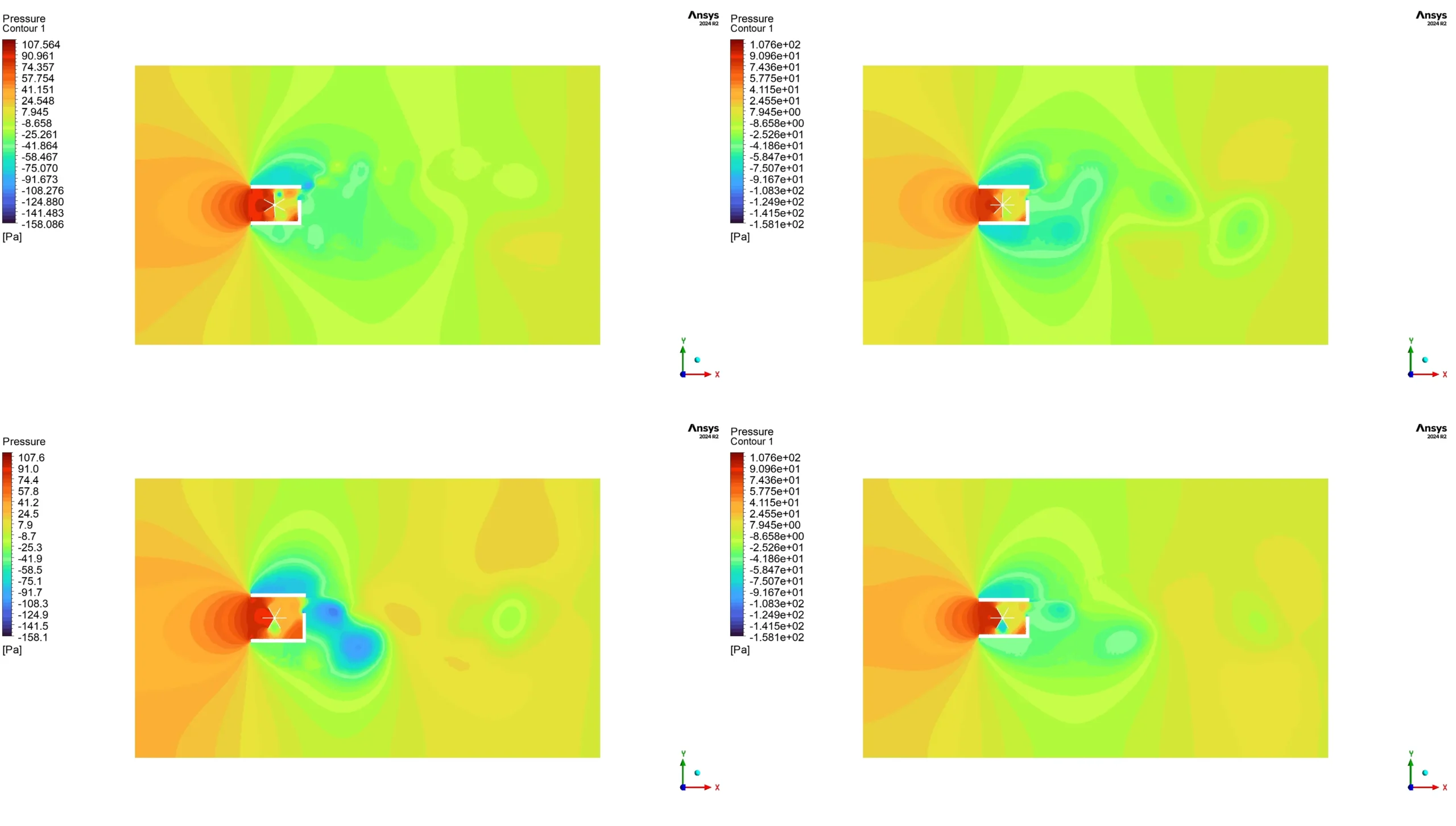

Our study compares two traditional Persian windmill designs – one with 6 vertical blades and another with 8 blades – to assess how blade configuration affects windmill performance. We modeled different room spaces around each Asbad windmill to investigate how confinement influences air flow patterns and energy capture. The computational domain uses a hybrid grid combining structured elements in free-stream regions with unstructured mesh near the complex blade geometry. For modeling rotation, we applied the Multiple Reference Frame (MRF) technique, creating a rotating zone around the windmill structure while keeping the mesh stationary. This approach efficiently simulates the rotor assembly spinning at its operational speed of 18 rpm.

Figure 2: Hybrid grid generated over Persian Windmill CFD analysis

Post-processing

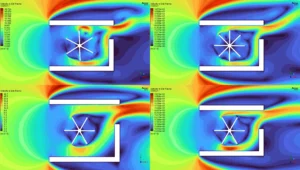

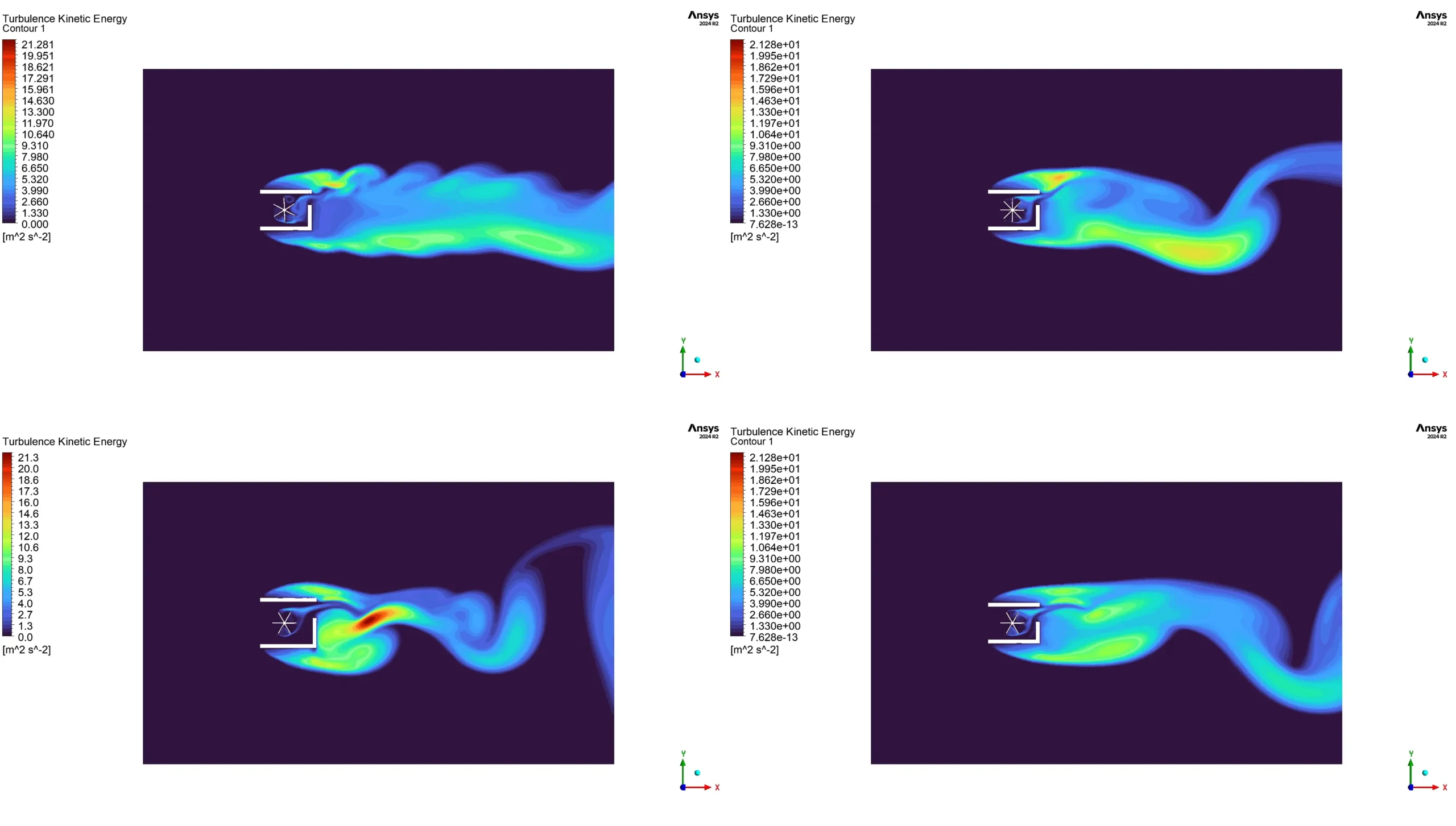

Looking inside the traditional Persian windmills, we can see major differences between designs! The 6-blade Asbad design produces 8.29 N.m torque in the small room setup – a surprising result showing how these ancient wind catchers work best in confined spaces. When tested in a larger room, the same 6-blade windmill structure generates only 5.66 N.m torque, proving that proper room sizing matters greatly for performance optimization. Ancient builders somehow understood this relationship without modern flow analysis tools! The highest wind speeds occur at the entrance channel where the flow gets squeezed, reaching 17.65 m/s from the original 10 m/s input – a 76.5% increase through natural funneling effects. These acceleration zones create pressure differences that drive the rotor assembly more efficiently than open designs. Most interesting is how the small-room 8-blade configuration produces just 2.87 N.m torque – much lower than expected and contrary to modern vertical turbine principles where more blades typically mean more power at low speeds.

| Windmill Configuration | Room Size | Torque (N.m) | Efficiency Rank |

| 6-Blade Persian Design | Small Room | 8.29 | 1st |

| 6-Blade Persian Design | Large Room | 5.66 | 2nd |

| 8-Blade Persian Design | Small Room | 2.87 | 3rd |

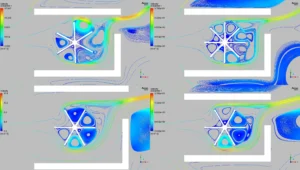

The streamline patterns tell us why these results happen! In the 6-blade Persian windmill with small room, we see perfectly formed vortices between blades that create strong rotational forces. These spinning air pockets act as natural pressure “engines” pushing the wooden blades in proper sequence. The 8-blade design suffers from too much crowding – the air can’t form these helpful vortices because the space between blades is 42% smaller than the 6-blade version. When the room gets bigger with the 6-blade design, the wind energy spreads out too much before hitting the blades, weakening the driving force. A simple table shows the stark differences.

Figure 3: Velocity Distribution in Different Persian Windmill Configurations

Figure 4: Flow Pathways Through Different Windmill Configurations

These findings match historical evidence where most successful Asbad windmills used 6-7 blades in narrow passages rather than more blades or open spaces – our ancestors learned through trial and error what modern CFD analysis now confirms!

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€190 Original price was: €190.€175Current price is: €175.

€180 Original price was: €180.€150Current price is: €150.

€165 Original price was: €165.€105Current price is: €105.

€140 Original price was: €140.€85Current price is: €85.

€120 Original price was: €120.€65Current price is: €65.

€245 Original price was: €245.€185Current price is: €185.

Reviews

There are no reviews yet.