Phase Change Materials (PCMs) Course – ANSYS Fluent

Master PCM Simulation: Comprehensive Phase Change Material Modeling in ANSYS Fluent

Transform your thermal engineering capabilities with this specialized course on Phase Change Material simulation. Learn to accurately model complex melting and solidification phenomena through research-validated techniques applied to real-world challenges. From heat exchangers and thermal storage to solar panel cooling, this comprehensive training provides the complete workflow for implementing enthalpy-porosity approaches and capturing natural convection in phase change processes. Whether you’re optimizing renewable energy systems or designing advanced thermal management solutions, these industry-relevant skills will distinguish you as a specialist in one of today’s most valuable simulation domains. Includes hands-on validation with experimental data across multiple applications, giving you confidence to tackle your own PCM implementation projects.

€640.00 Original price was: €640.00.€299.00Current price is: €299.00.

Course details

Course Type : Offline

Course Duration : +4 Hours

Syllabus : 4 Sessions

What You'll Learn

- Master the fundamental principles of Phase Change Materials including thermodynamic properties, classifications, and computational modeling approaches using ANSYS Fluent.

- Apply simulation techniques to VALIDATE heat transfer enhancement in triplex tube heat exchangers with different fin configurations and heating methods.

- Analyze how container materials and thermal diffusivity influence PCM melting behavior in spherical geometries through comparative visual validation techniques.

- Optimize solar panel efficiency by implementing PCM-based thermal management systems that maintain optimal operating temperatures under intense solar radiation.

Syllabus for Phase Change Materials (PCMs) Course Using ANSYS Fluent

Objectives: By the end of this session, participants will:

- Understand the fundamental principles of thermal energy storage and phase change phenomena

- Identify different types of PCMs and their thermodynamic properties

- Recognize various industrial and commercial applications of PCMs

- Gain foundational knowledge for computational modeling of PCMs in ANSYS Fluent

- Develop the ability to distinguish between sensible and latent heat storage mechanisms

- Comprehend how PCMs function at the molecular level during phase transitions

Key Concepts:

- Energy Storage Methods

- Latent Heat vs. Sensible Heat

- Phase Change Mechanisms

- Molecular Behavior During Phase Transition

- PCM Classifications (Organic, Inorganic, Eutectics)

- Material Properties and Selection Criteria

- Industrial Applications

- Computational Modeling Fundamentals

- Enthalpy-Porosity Approach

- Solidus and Liquidus Temperatures

- Liquid Fraction Concept

- Conservation Equations

- ANSYS Fluent Capabilities and Limitations

Description:

Session 1 provides a comprehensive introduction to Phase Change Materials (PCMs) and their thermodynamic principles, establishing the foundation for advanced modeling in ANSYS Fluent. In an era of increasing energy demands and environmental concerns, PCMs offer innovative solutions for efficient thermal energy storage. This session begins by contrasting traditional sensible heat storage with latent thermal energy storage, demonstrating how PCMs leverage phase transitions to store significantly more energy while maintaining near-constant temperatures. Participants will explore the molecular mechanisms behind melting and freezing processes, gaining insights into how PCMs absorb, store, and release thermal energy at the microscopic level.

The session delves into PCM classifications—covering organic materials like paraffins with their high fusion heat, inorganic compounds such as hydrated salts, and specialized eutectic mixtures—while analyzing their respective advantages and limitations. Through examination of diverse real-world applications across industries—from renewable energy and construction to aerospace, textiles, and medicine—participants will appreciate PCMs’ versatility and potential. The session culminates with an introduction to computational modeling concepts essential for ANSYS Fluent simulation, including the enthalpy-porosity formulation, liquid fraction calculations, and conservation equations that govern phase change phenomena. By understanding both theoretical foundations and practical modeling approaches, participants will be prepared to tackle the validation cases in subsequent sessions with confidence and clarity.

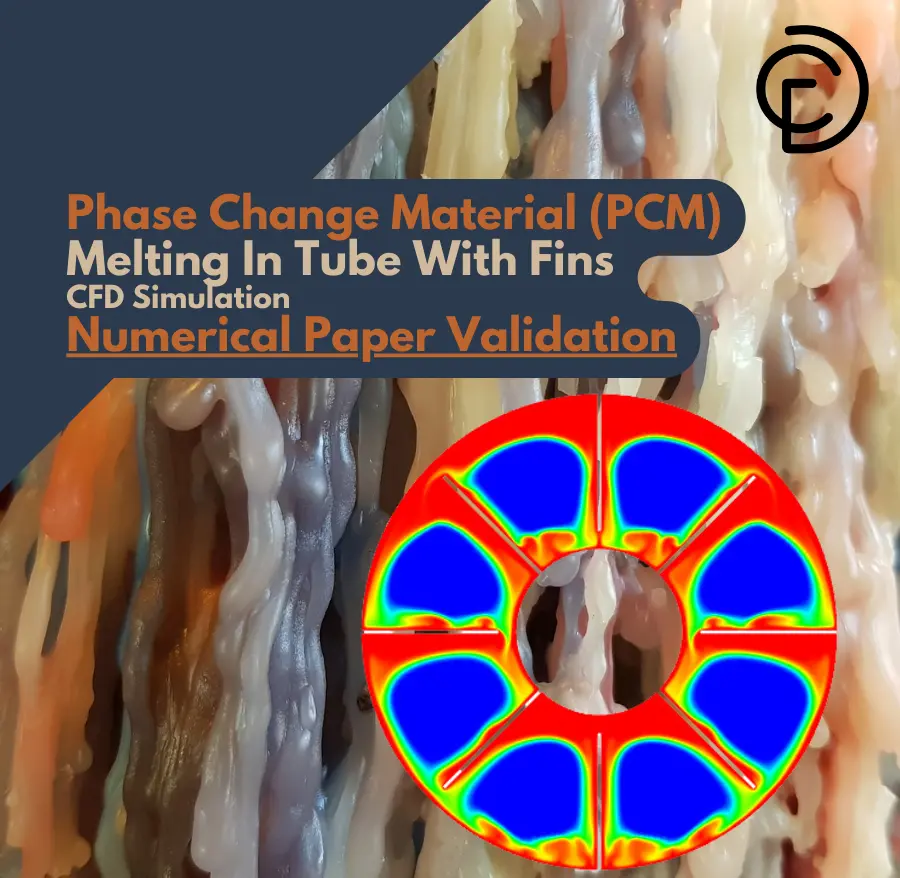

Objective: Apply ANSYS Fluent to validate numerical models against experimental data in triplex tube heat exchangers

Key Concepts:

Triplex Tube Heat Exchanger (TTHX) Configurations

Numerical Model Development

- Mesh generation strategies

- Enthalpy-porosity formulation

- Boundary conditions setup

- Experimental Validation Process

- Temperature measurement techniques

- Liquid fraction calculation

- Error analysis methods

- Performance Comparison

Description:

In Session 2, participants will learn to VALIDATE a research paper that investigates heat transfer enhancement in a triplex tube heat exchanger using phase change materials. The session focuses on replicating the numerical model from the paper using ANSYS Fluent to simulate the melting process of RT82 PCM under different heating conditions. Students will set up the simulation parameters, generate appropriate meshes, and implement the enthalpy-porosity model to accurately capture phase change phenomena. Through step-by-step guidance, participants will understand how to compare temperature plots and liquid fraction data between numerical predictions and experimental results.

By validating both temperature plots and liquid fraction curves, participants will gain practical skills in computational modeling while understanding the physics behind heat transfer enhancement techniques. This hands-on approach will enable students to critically evaluate research findings and develop confidence in using ANSYS Fluent for their own PCM applications and research. Read More

Objective: Validate numerical simulations of paraffin wax melting in a spherical cavity using ANSYS Fluent against Experimental data

Key Concepts:

- Spherical Cavity Design and Setup

- Experimental Visualization Techniques

- Volume of Fluid (VOF) Approach

- Heat Flux and Temperature Profiles

- Model Validation Through Visual Comparison)

Description:

Session 3 focuses on validating a published study examining paraffin wax melting in spherical cavities made from different materials. Using ANSYS Fluent’s enthalpy-porosity model and Volume of Fluid (VOF) method, participants will simulate unconstrained melting processes and compare results with experimental visualization data. The session demonstrates how cavity materials with higher thermal diffusivity (aluminum, copper) significantly enhance melting rates compared to materials with lower diffusivity (glass) due to increased natural convection effects.

Participants will learn practical validation techniques using image comparison and digital analysis to verify simulation accuracy. The session also explores how different Stefan numbers affect melting time, heat flux patterns, and natural convection strength. By the end of this session, students will understand how to properly set up and validate PCM simulations involving spherical geometries and free surface melting, with direct applications in thermal energy storage system design and material selection.

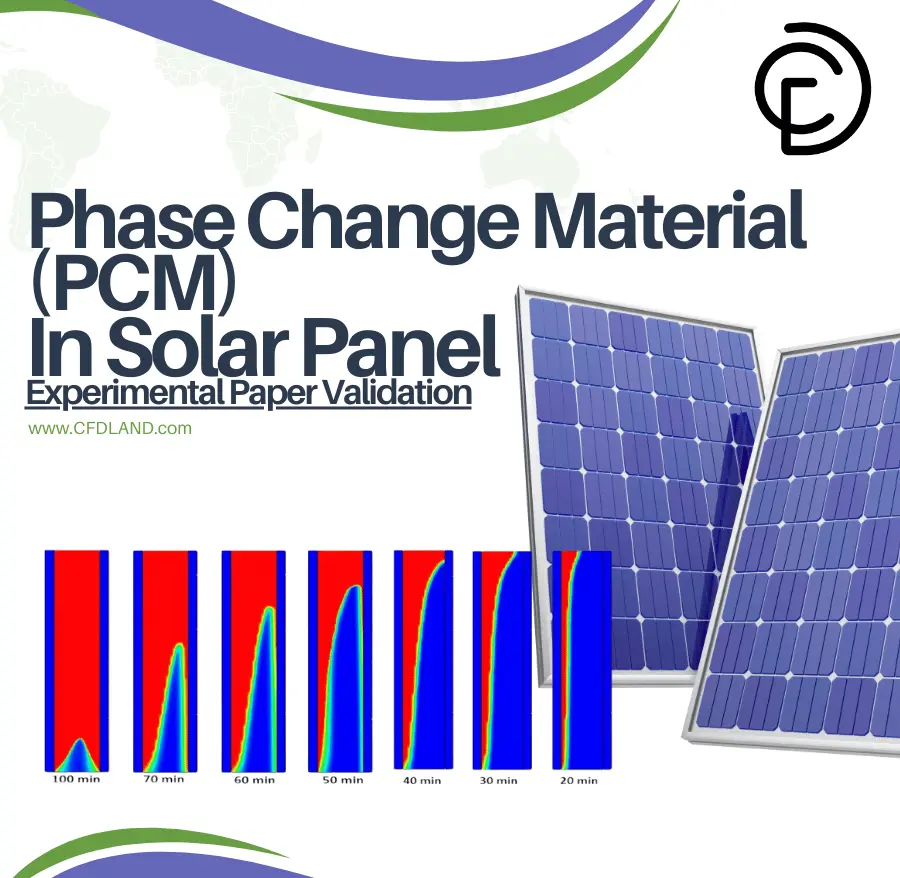

Objective: Learn how to validate CFD models for solar panel-PCM systems

Key Concepts:

- Solar Panel Efficiency Challenges

- PCM Integration with Solar Panels

- Buoyancy-Driven Flow Simulation

- Solid-Liquid Interface Tracking

- Natural Convection in Melting Process

- Validation Using Experimental Data

- Performance Metrics and Comparison

Description:

Session 3 focuses on validating a research paper that investigates the use of phase change materials to maintain optimal operating temperatures in solar panels. This practical application addresses a significant challenge in solar energy: the efficiency loss that occurs when panels operate at high temperatures—typically a 0.5% efficiency drop for each degree above the nominal 25°C operating temperature.

Participants will learn how to model a coupled solar panel-PCM system using computational fluid dynamics in ANSYS Fluent. The session covers the enthalpy-porosity approach for simulating phase transitions, with special emphasis on capturing natural convection within the melting PCM. Through step-by-step modeling and validation against experimental data, students will evaluate how PCM systems can maintain panel temperatures below 40°C for extended periods under intense solar radiation (1000W/m²). Read More

Why Choose This Course?

- All Skill Levels Welcome – Labeled “Beginners” but packed with advanced PCM modeling concepts for experienced ANSYS Fluent users.

- Validation-Focused – Three comprehensive research-grade validation studies comparing simulation results to experimental data from peer-reviewed publications.

- Structured Methodology – Each session builds from thermodynamic fundamentals to practical implementation of PCM models in ANSYS Fluent.

- Official Certification – Receive CFDLAND Certificate upon completion verifying your PCM modeling expertise (contact us for details).

- Exceptional Value – Purchasing these three validation studies individually would cost 2-3 times more than this comprehensive course package.

- Real-World Applications – Practical industry cases including heat exchangers, thermal storage, and solar panel cooling rather than simplified academic examples.

Frequently Asked Questions

-

Do I need prior CFD experience to take this course? Basic ANSYS Fluent familiarity is recommended but not required. We cover essential navigation and setup steps, though having some CFD fundamentals will help you progress faster through the material.

-

Which engineering disciplines is this course suitable for? This course is ideal for mechanical, chemical, energy, and thermal engineers working in fields like renewable energy, HVAC, building design, electronics cooling, and thermal energy storage applications.

-

What makes this course different from other CFD courses? Our unique focus on Phase Change Materials with multiple research-grade validation studies sets us apart. Rather than generic CFD tutorials, we teach specialized techniques for accurately simulating complex melting and solidification processes.

-

How long will I have access to the course materials? The course tutorial videos will be available to you permanently after purchase. You can review and revisit any session at your own pace.

-

How is the course structured? Each session follows a complete workflow: geometry creation, mesh generation, physics setup, solver configuration, post-processing, and validation against experimental data, with progressive complexity across different PCM applications.

-

Can I receive a certificate after completing the course? Yes! Upon finishing all sessions and associated exercises, you’ll receive an official CFDLAND Certificate verifying your specialized skills in PCM simulation. This can be added to your professional portfolio and LinkedIn profile.

This course is ideal for engineers, researchers, and professionals seeking to deepen their understanding of PCM technology and its real-world applications. Whether you’re involved in energy management, thermal engineering, or product design, this course provides valuable insights and practical skills to drive innovation in your field.

- In-depth understanding of Phase Change Materials and their thermodynamic properties

- Proficiency in simulating and analyzing PCM systems using industry-standard tools

- Practical insights into applying PCM technology for heat transfer enhancement, energy storage, and renewable energy solutions

Related products

-

TrainingCourse

ANSYS FLUENT COURSE For BEGINNERS

Rated 5.00 out of 5€1,500.00Original price was: €1,500.00.€299.00Current price is: €299.00. Add to cart

Reviews

There are no reviews yet.