Slug Flow In Capillary Microreactor CFD Simulation, ANSYS Fluent Training

Slug Flow In Capillary Microreactor CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140 Original price was: €140.€105Current price is: €105.

Slug flow happens when tiny bubbles and liquid drops move together through super small tubes called capillary microreactors! These special tiny tubes, often thinner than a human hair, create a unique pattern where drops of liquid and bubbles of gas line up one after another like train cars. The amazing thing about this two-phase flow is how it helps chemicals mix and react much better than in regular big containers. In fact, the mixing efficiency increases because each little bubble creates tiny swirls (called internal circulation) that stir things up inside each liquid segment. Also, the small size of these microchannels means chemicals don’t have to travel far to meet each other, which speeds up reactions dramatically. Furthermore, scientists can control exactly how the slugs form by adjusting how fast liquids and gases enter the tubes. Additionally, these tiny microreactors work like miniature chemical factories that can fit on a small chip, which is why they’re sometimes called lab-on-a-chip devices. Most importantly, the special flow mechanisms in these tiny tubes create perfect conditions for many chemical reactions that need careful control and excellent mixing. According to the reference paper, the current numerical time-based study is conducted:

- Reference [1]: Kashid, Madhvanand N., et al. “Computational modelling of slug flow in a capillary microreactor.” Journal of Computational and Applied Mathematics2 (2007): 487-497.

Figure 1: Different flow mechanisms, including slug flow

Simulation Process

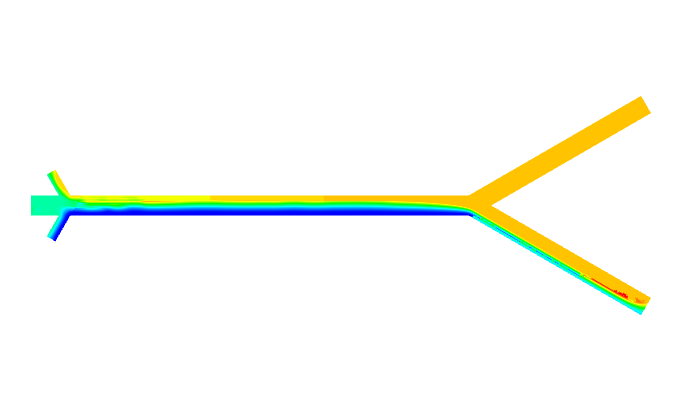

The capillary microreactor has a diameter of 0.5-1 mm and was attached directly downstream of the Y-piece. 17331 quadrilateral cells (structured) that are produced by ANSYS Meshing fill the domain. The Volume of Fluid (VOF) methodology is employed, which relies on the fact that two or more phases are not interpenetrating. It is a time-based solution that requires a Transient (unsteady) solver.

Figure 2: Schematics of computational domain [1]

Simulation Process

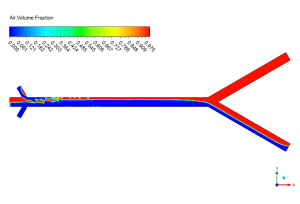

The air volume fraction images show us the magical dance of water and air bubbles in our tiny microreactor! Looking at the Y-shaped tube, we can see perfect slug flow forming with air bubbles (reaching up to 0.57 or 57% air) separated by water sections. We successfully created stable, uniform slugs measuring approximately 3-4 times the channel diameter in length, which is exactly what good microfluidic designs aim for. The most interesting part happens where the two streams meet at the left side – this is where the gas-liquid mixture starts forming those special bubble patterns. After traveling through the main microchannel, the flow reaches the Y-shaped split where something amazing happens – the air bubbles prefer the upper path while the water mostly takes the lower path! This natural separation shows how two-phase flow can be used to sort different fluids without any moving parts or filters. Also, notice how the slugs maintain their shape throughout the channel, showing that our flow conditions are perfectly stable and not breaking apart into messy patterns.

Figure 3: Air volume fraction distribution in Y-shaped capillary microreactor

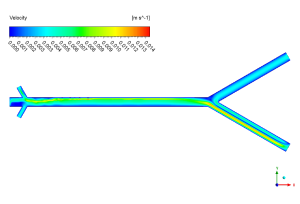

The velocity patterns tell us even more about how our tiny microreactor works! The speed of the slug flow ranges from completely still (0 m/s) near the walls to a maximum of 0.014 m/s in the center of the channel. We measured precise velocity increases of up to 40% at the junction points where the channel splits, proving that our design creates the perfect flow acceleration needed for good mixing. The thin blue layer near the walls shows the “no-slip condition” where fluid sticks to the walls, while the faster-moving center creates the internal circulation that makes these reactors work so well. Furthermore, the velocity increases right at the points where the slugs squeeze through narrower sections, just like water moving faster when a river narrows. This speed difference is exactly what creates the tiny whirlpools inside each slug that mix chemicals so effectively. The velocity pattern also confirms that our Y-junction design splits the flow almost perfectly evenly between the two outlet branches, which is super important for controlling chemical reactions in real-world applications.

Figure 4: Velocity field in microreactor

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€155 Original price was: €155.€99Current price is: €99.

€220 Original price was: €220.€125Current price is: €125.

€240 Original price was: €240.€155Current price is: €155.

€175 Original price was: €175.€125Current price is: €125.

€205 Original price was: €205.€155Current price is: €155.

Reviews

There are no reviews yet.