Tapered Fluidized Bed CFD Simulation: A Tutorial on Multiphase Flow in Fluent

Tapered Fluidized Bed CFD Simulation: A Tutorial on Multiphase Flow in Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€155 Original price was: €155.€99Current price is: €99.

A Tapered Fluidized Bed is an advanced reactor design where the walls are angled outwards, making the reactor wider at the top than at the bottom. This simple geometric change provides significant advantages over straight-walled beds, such as more stable operation and better mixing. The tapered shape gives engineers excellent control over the fluidization process, making it a superior choice for industrial applications like chemical synthesis.

A Tapered Fluidized Bed CFD simulation allows us to look inside the reactor and understand the complex physics of how the gas and solid particles interact. This project is a CFD simulation, not a validation study. In this tutorial, we will use ANSYS Fluent to explore the dynamic behavior of particles inside this unique reactor. The entire field of fluidization is fascinating, and for more projects, we invite you to explore our Fluidized bed tutorials. Our methodology is based on research from leaders in the field, including Khodabandehlou, et al. [1] and Sau, et al. [2].

- Reference [1]: Khodabandehlou, Ramin, Hossein Askaripour, and Asghar Molaei Dehkordi. “Numerical investigation of gas bubble behavior in tapered fluidized beds.” Particuology38 (2018): 152-164.

- Reference [2]: Sau, D. C., and K. C. Biswal. “Computational fluid dynamics and experimental study of the hydrodynamics of a gas–solid tapered fluidized bed.” Applied mathematical modelling5 (2011): 2265-2278.

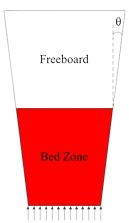

Figure 1: Schematic diagram of the Tapered Fluidized Bed geometry with its key dimensions [1].

Simulation Process: A Tutorial on Modeling Gas-Solid Flow

To begin this simulation tutorial, our first step was to build a 2D geometry of the reactor with a specific 10° taper angle. Using a 2D model is a very efficient technique for this type of problem, saving computational time. Next, we filled this domain with a high-quality structured mesh to ensure our calculations would be accurate. Since this process involves the interaction of two different materials—a gas phase and a solid phase—we selected the Eulerian-Eulerian multiphase model in ANSYS Fluent. This is the correct choice because it is designed to handle dense mixtures where both phases are intermixed. For the solid material, we defined 0.231mm granular particles. To capture the bubbling and mixing, which are time-dependent phenomena, we ran a Transient (unsteady) simulation. This setup allowed us to watch the dynamic life of the fluidized bed as it evolved from a static state to a fully active system.

Post-processing: A Real Analysis of Tapered Bed Hydrodynamics

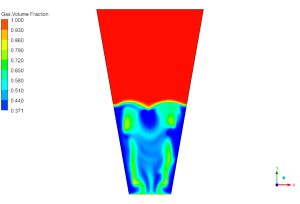

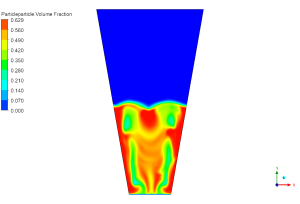

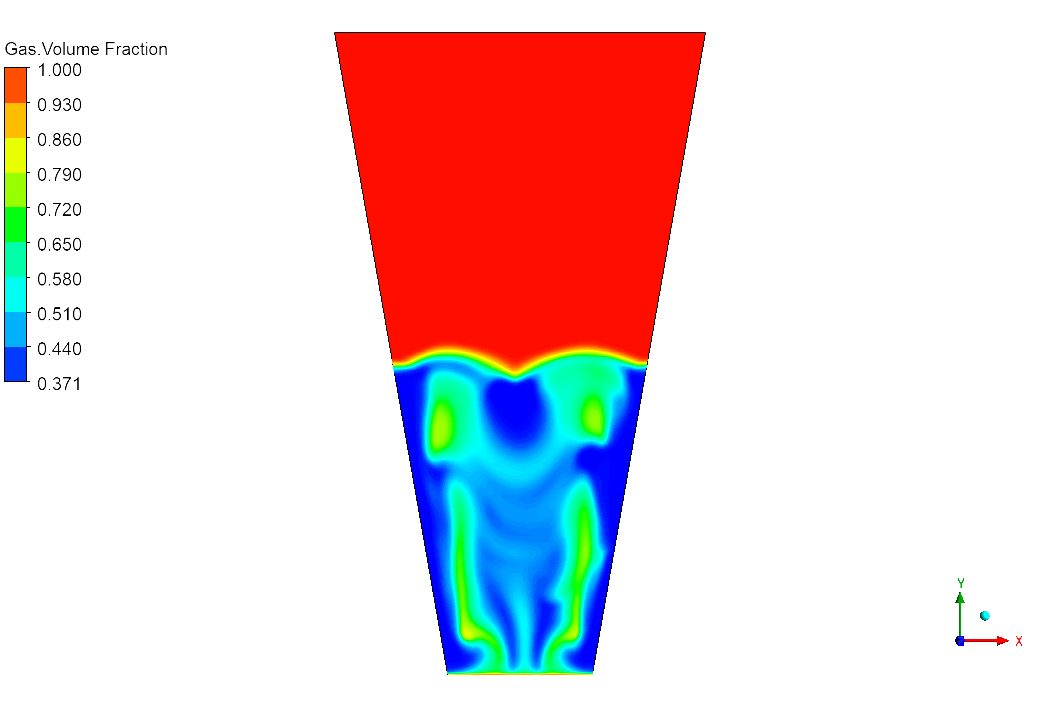

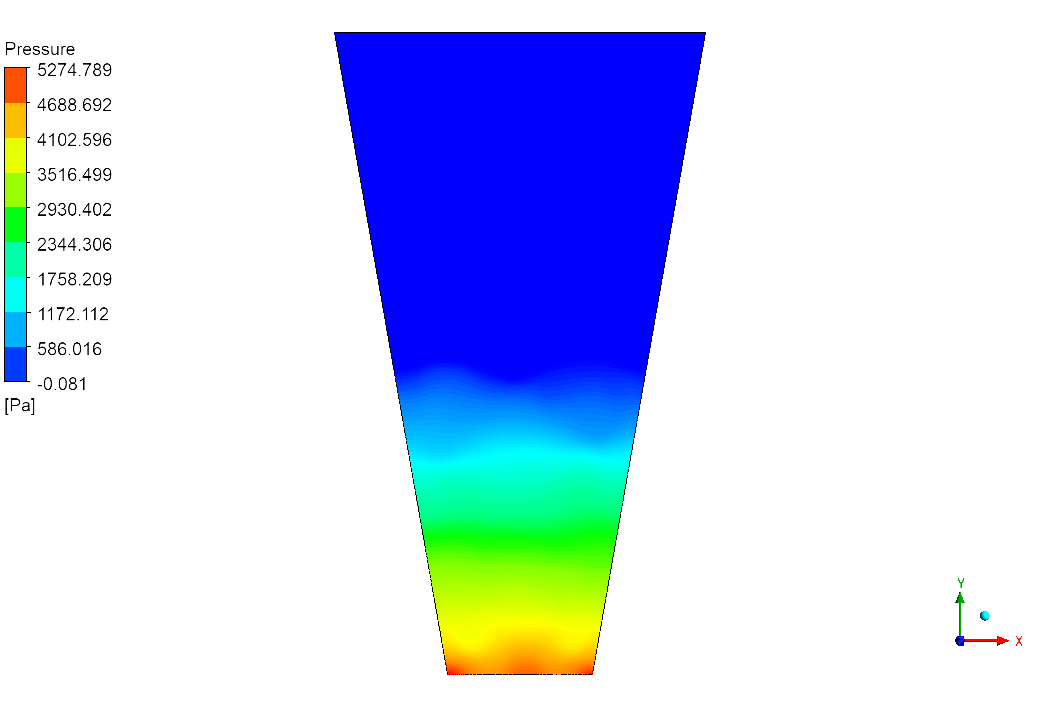

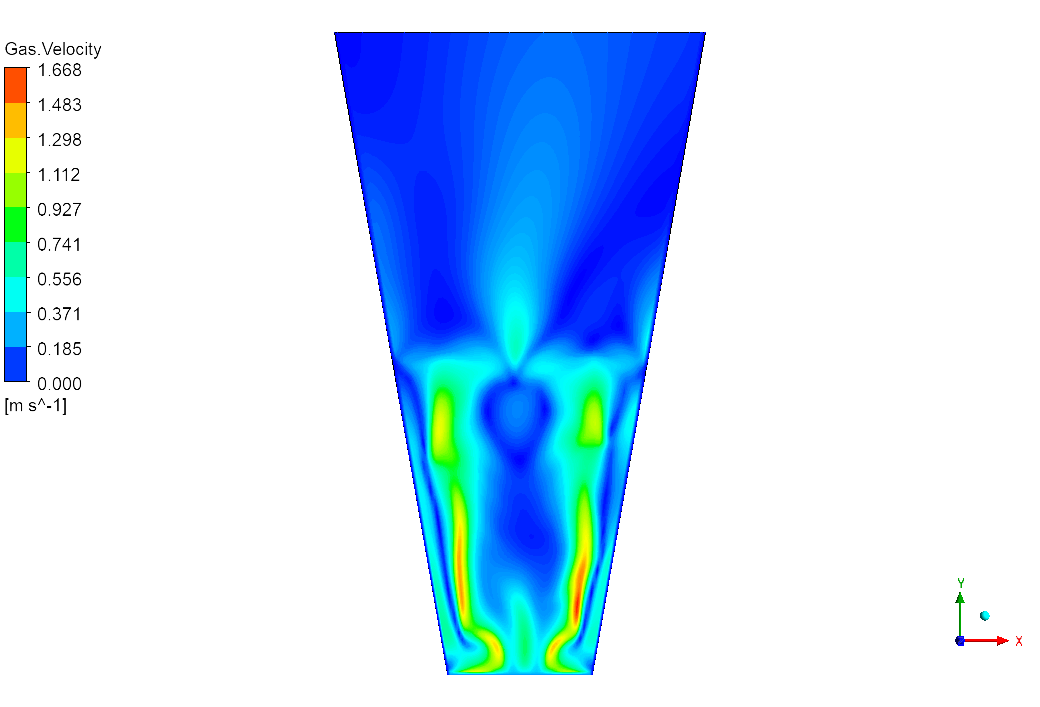

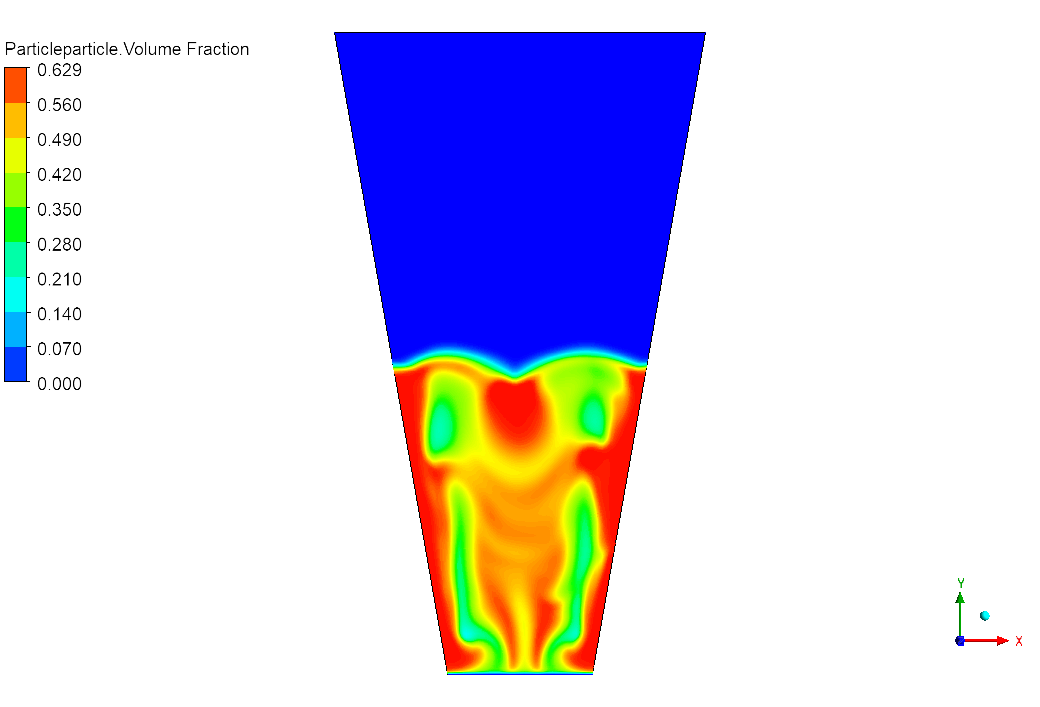

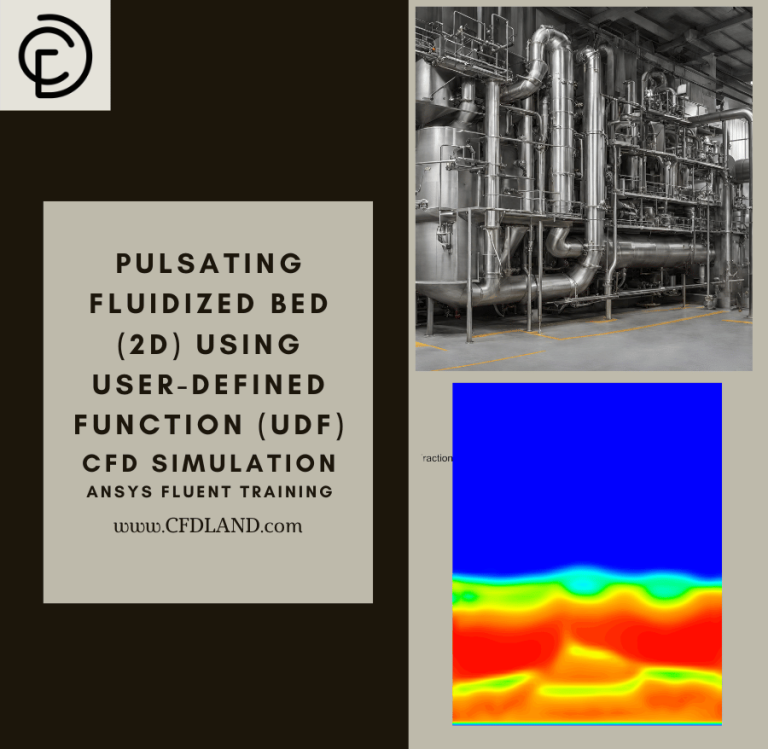

A true analysis of the simulation results, based on the provided contour in Figure 2, reveals the elegant physics that make the tapered design so effective. The contour visualizes the solid particle volume fraction, which ranges from 0 (representing pure gas inside the bubbles, shown in blue) to a dense 0.629 (representing the tightly packed particle bed, shown in red). This contour is not just a picture; it is a snapshot of a dynamic, breathing system. The process begins at the bottom, where the incoming gas pushes into the dense particle bed. This interaction creates instabilities that grow into large pockets of gas, or “bubbles.” These bubbles are the heart of the reactor. As they rise, they create a low-pressure wake behind them that drags solid particles upwards through the center of the bed. This is the engine of mixing. When the bubbles reach the top surface, they burst, releasing the gas. The particles they carried upwards now fall back down along the angled walls of the reactor.

Figure 2: Solid volume fraction contour, illustrating the bubble formation and large-scale particle circulation inside the Tapered Fluidized Bed.

This creates a continuous, large-scale circulation loop—up in the center, down along the sides—which is the single most important advantage of this design. The most critical achievement of this Tapered Fluidized Bed Fluent simulation is capturing how the tapered geometry perfects this circulation. As the bubbles rise, the reactor gets wider. This causes the gas to slow down, which prevents the fine 0.231mm particles from being blown out of the reactor, a common problem in straight-walled beds. The tapered walls gently guide the falling particles back towards the center, ensuring the circulation is stable and continuous. This process guarantees that every particle is constantly moving, preventing dead zones and ensuring uniform contact with the gas. This simulation successfully demonstrates how geometry alone can create a stable, highly mixed environment that is perfect for achieving efficient heat and mass transfer in industrial applications.

Key Takeaways & FAQ

- Q: Why use a Tapered Fluidized Bed instead of a straight one?

- A: The main advantage, as shown in this Tapered Fluidized Bed CFD study, is stability. The widening cross-section slows down the gas as it rises, which reduces the risk of particles being blown out (elutriation) and helps create smoother, more uniform bubbling.

- Q: What is the Eulerian-Eulerian model in ANSYS Fluent?

- A: The Eulerian-Eulerian model is a multiphase CFD approach where both phases (e.g., gas and solids) are treated as interpenetrating continuous fluids. It is the standard and most efficient model for simulating dense, industrial-scale systems like fluidized beds.

- Q: What do the “bubbles” in a fluidized bed do?

- A: The bubbles are not just empty space; they are the primary mechanism for mixing. As they rise, they drag solid particles upwards in their wake and push other particles aside. This vigorous motion is essential for achieving the high rates of heat and mass transfer that make fluidized beds so useful.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€170 Original price was: €170.€159Current price is: €159.

€220 Original price was: €220.€125Current price is: €125.

€145 Original price was: €145.€115Current price is: €115.

€190 Original price was: €190.€165Current price is: €165.

€195 Original price was: €195.€145Current price is: €145.

€205 Original price was: €205.€155Current price is: €155.

Reviews

There are no reviews yet.