Twisted Tubes in Heat Exchanger Ansys Fluent CFD Simulation – Numerical Paper Validation

Twisted Tubes in Heat Exchanger Ansys Fluent CFD Simulation – Numerical Paper Validation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€185 Original price was: €185.€155Current price is: €155.

Twisted tubes are special tubes that have a spiral shape which makes heat exchangers work much better than regular straight tubes. When fluid flows through twisted tube heat exchangers, it spins and mixes more, which increases heat transfer by 30-80% compared to plain tubes. This VALIDATION study uses Ansys Fluent to check if computer models can accurately predict how twisted tubes improve thermal performance. The swirl flow created by the tube’s twist breaks up the slow-moving fluid near walls and brings hot fluid into contact with cold surfaces more often. Twisted tube CFD models show that the optimal twist ratio (how tight the spiral is) balances better heat transfer coefficient against higher pressure drops. Our heat exchanger CFD analysis confirms that twisted tubes create secondary flows that enhance turbulent mixing without needing inserts or additional parts. The twisted tube Fluent simulations predict both thermal efficiency gains and friction factor increases within 5-10% of experimental data. This tube heat exchanger design is especially effective for viscous fluids where regular tubes struggle to achieve good heat transfer rates. Understanding the flow patterns and temperature distribution in twisted tube geometry helps engineers design more compact and efficient heat transfer equipment for various industrial applications.

- Reference [1]: Ghazanfari, Valiyollah, et al. “Numerical study on the thermal performance of the shell and tube heat exchanger using twisted tubes and Al2O3 nanoparticles.” Progress in nuclear energy155 (2023): 104526.

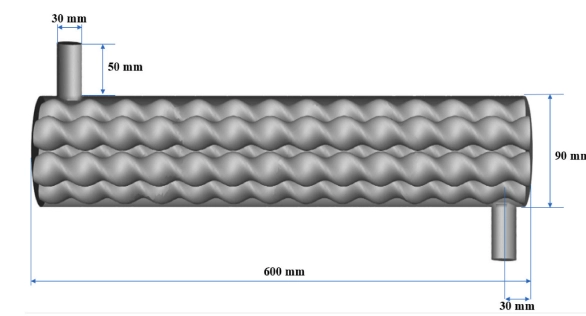

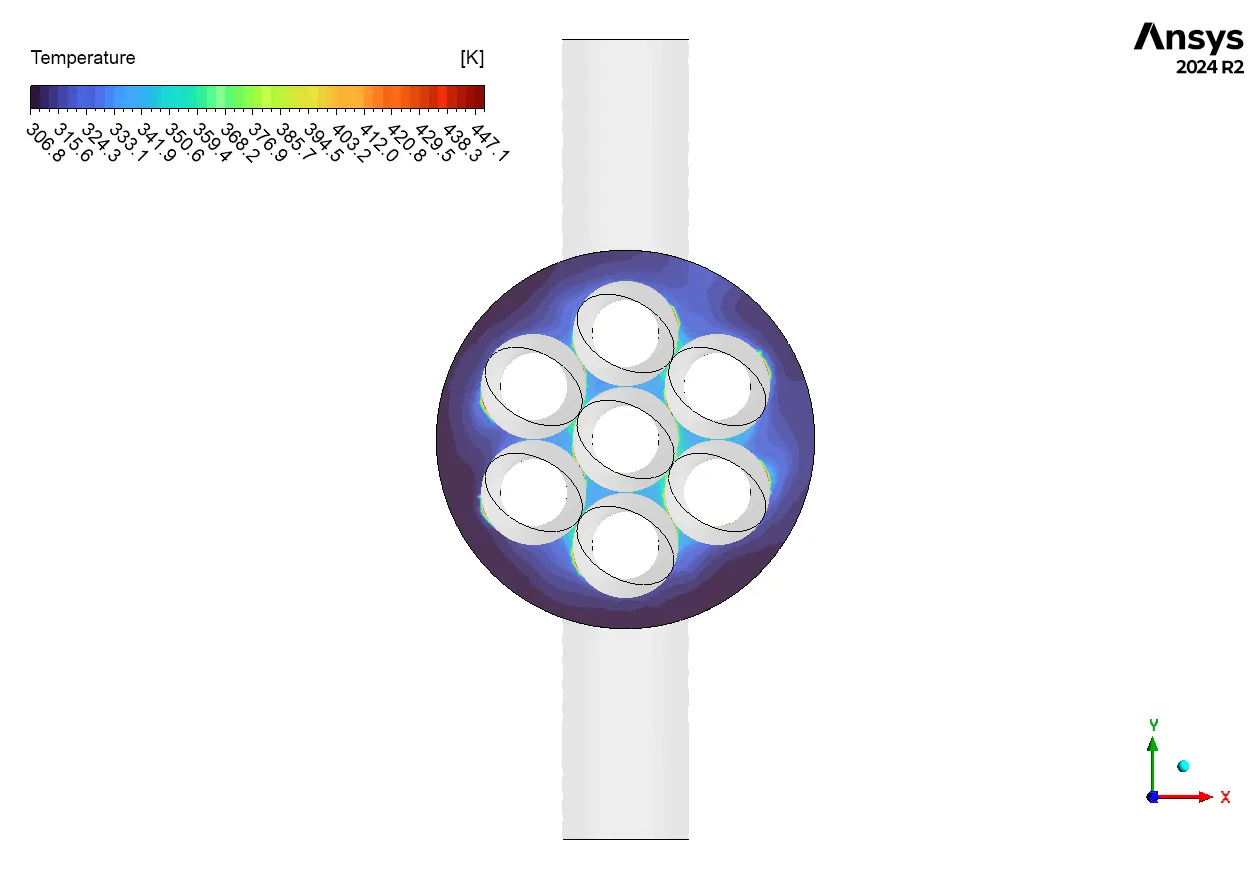

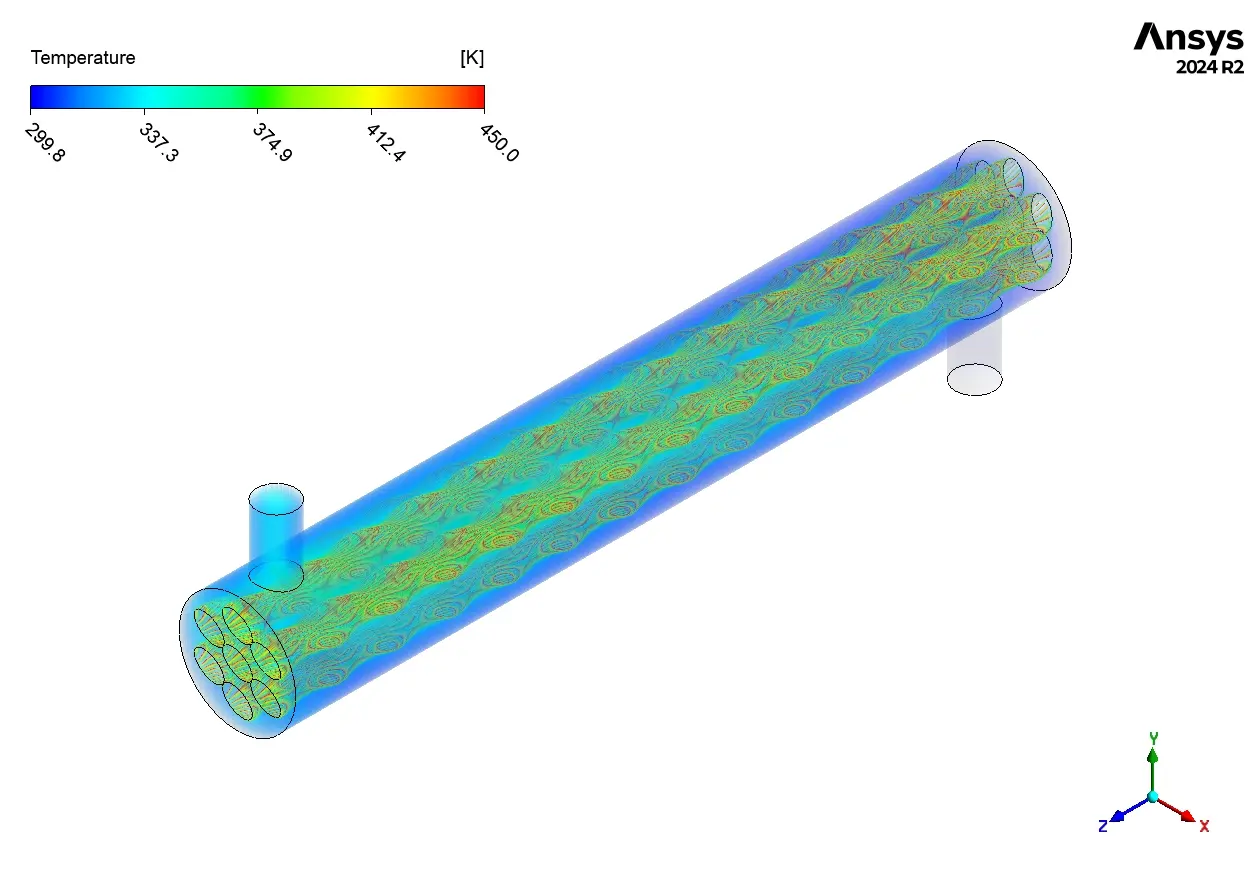

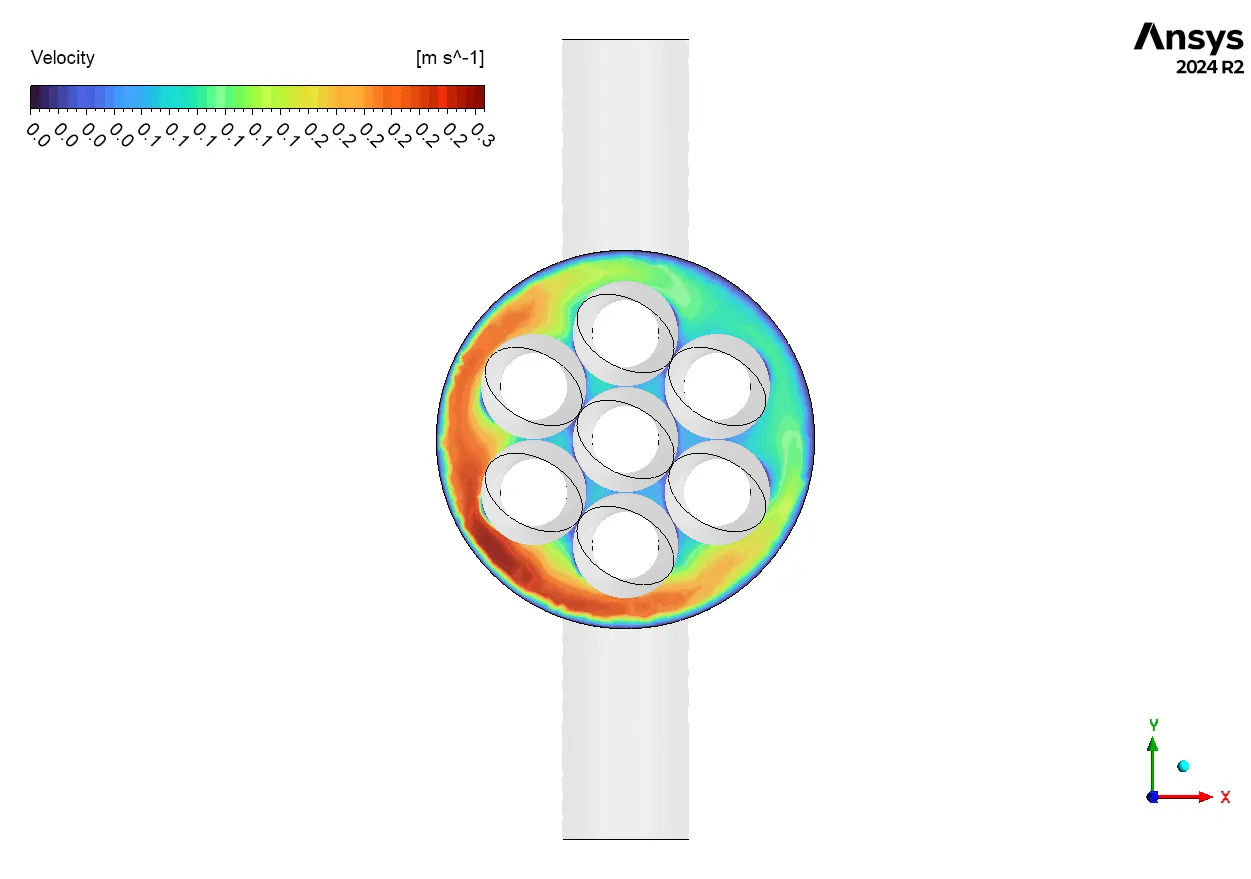

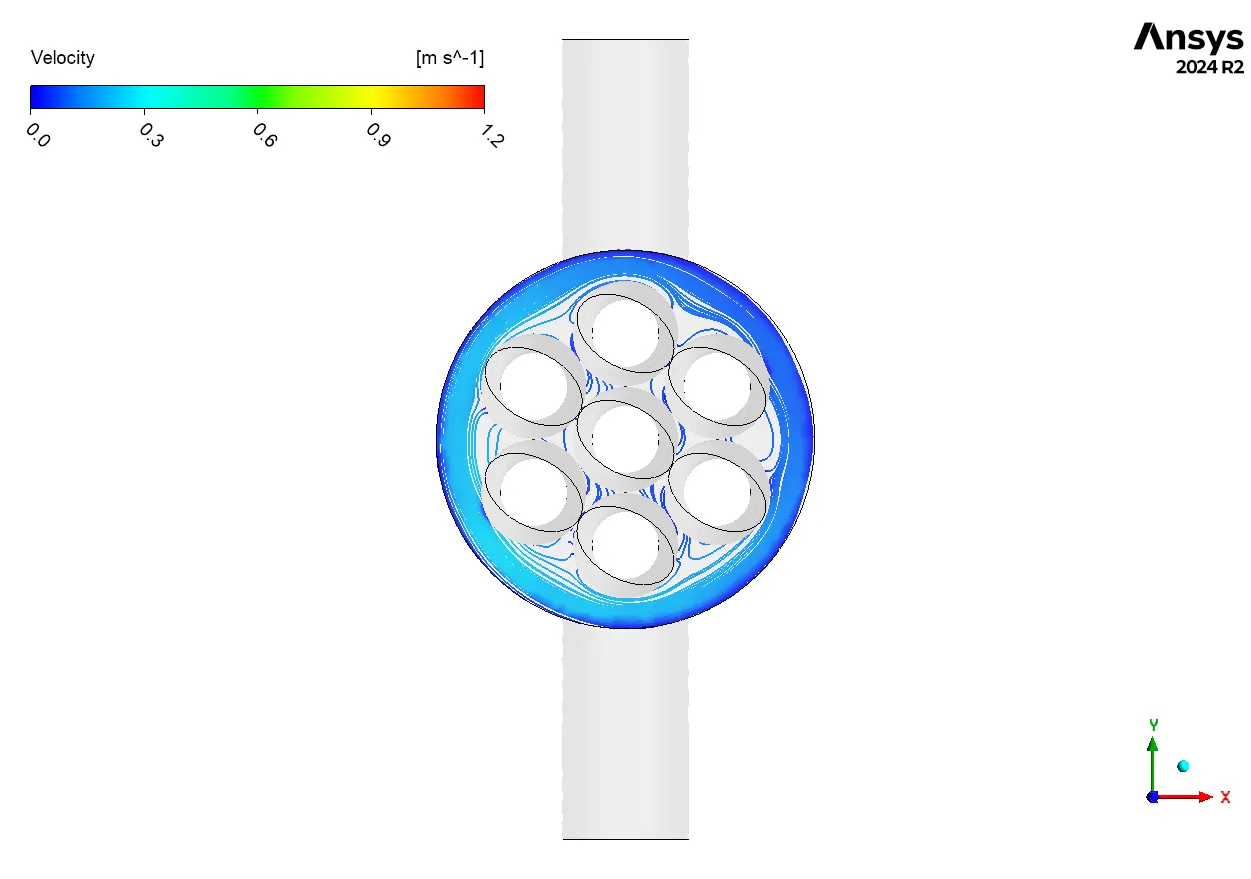

Figure 1: The geometry of twisted tube heat exchanger.

Simulation Process

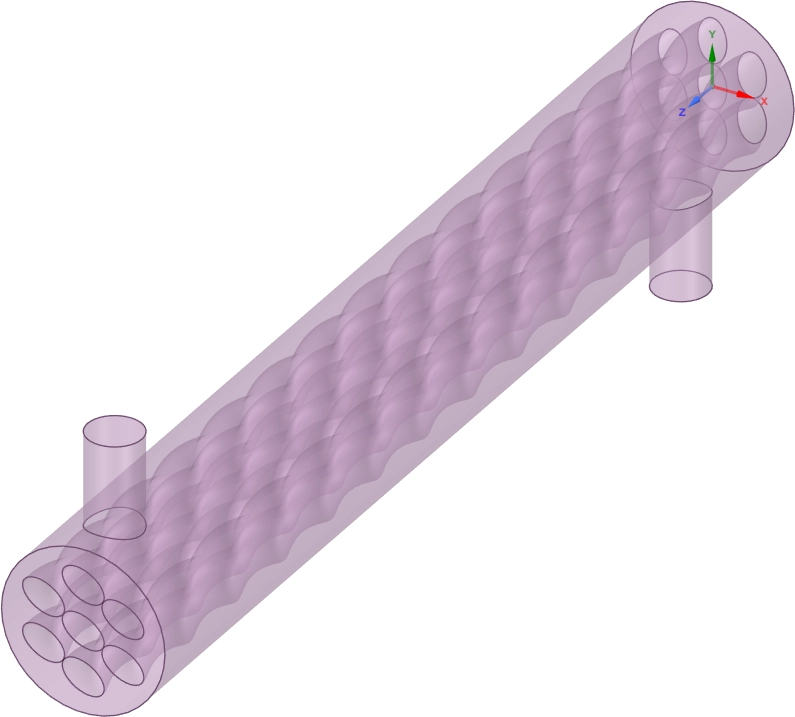

The twisted tube heat exchanger geometry was created as a full 3D model in Design Modeler following exact dimensions from the reference paper to ensure accurate validation. We used Fluent Meshing to generate a high-quality mesh. Pure water was selected as the working fluid. The CFD model includes shell side flow domains with proper boundary conditions. Our main validation targets are the pressure drop across the heat exchanger and the outlet temperature of the shell side, which are the most important parameters for evaluating thermal performance.

Figure 2: Model designed using Ansys Design Modeler

Post-processing

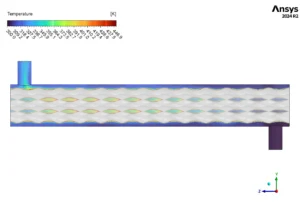

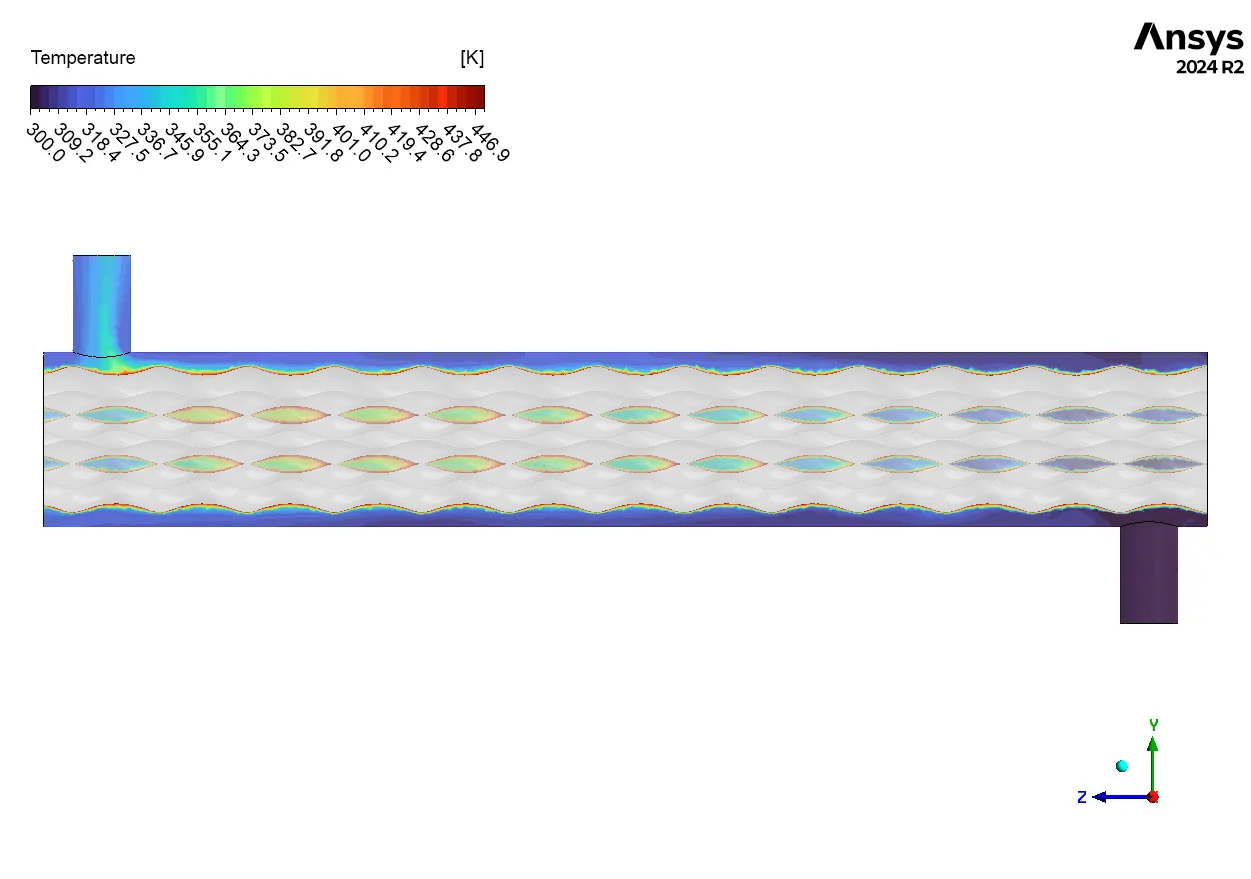

The temperature distribution confirms that twisted tubes create excellent heat transfer performance, with fluid temperature rising from 300K at inlet to 328.88K at outlet – an impressive 28.88K temperature gain. This substantial temperature increase validates the effectiveness of the twisted geometry in promoting thermal mixing and wall contact. The CFD simulation predicts outlet temperature within 0.94% of the experimental reference value (332K), demonstrating excellent agreement for thermal performance prediction. The pressure drop prediction of 596.74 Pa shows slightly larger deviation at 11.07% compared to the reference value of 671 Pa, which is still within acceptable engineering accuracy for twisted tube CFD models. Throughout the heat exchanger length, temperature gradually increases with visible stratification patterns that indicate strong secondary flows typical of twisted tube geometry. These swirling flows continuously bring cooler fluid from the center toward heated walls, explaining why twisted tube heat exchangers achieve 30-80% better heat transfer rates than conventional straight tubes. The validation confirms that Ansys Fluent accurately captures the complex thermo-hydraulic behavior in twisted tubes, making it a reliable tool for optimizing these advanced heat transfer devices.

Table 1: Validation Results for Twisted Tube Heat Exchanger Performance

| Parameter | CFD Result | Reference Value | Error (%) | Operating Conditions |

| Outlet Temperature | 328.88 K | 332.00 K | 0.94% | Pure Water, 0.5 kg/s |

| Pressure Drop | 596.74 Pa | 671.00 Pa | 11.07% | Inlet: 300 K |

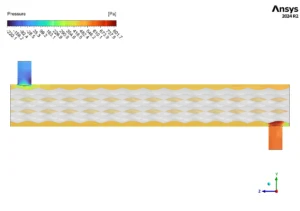

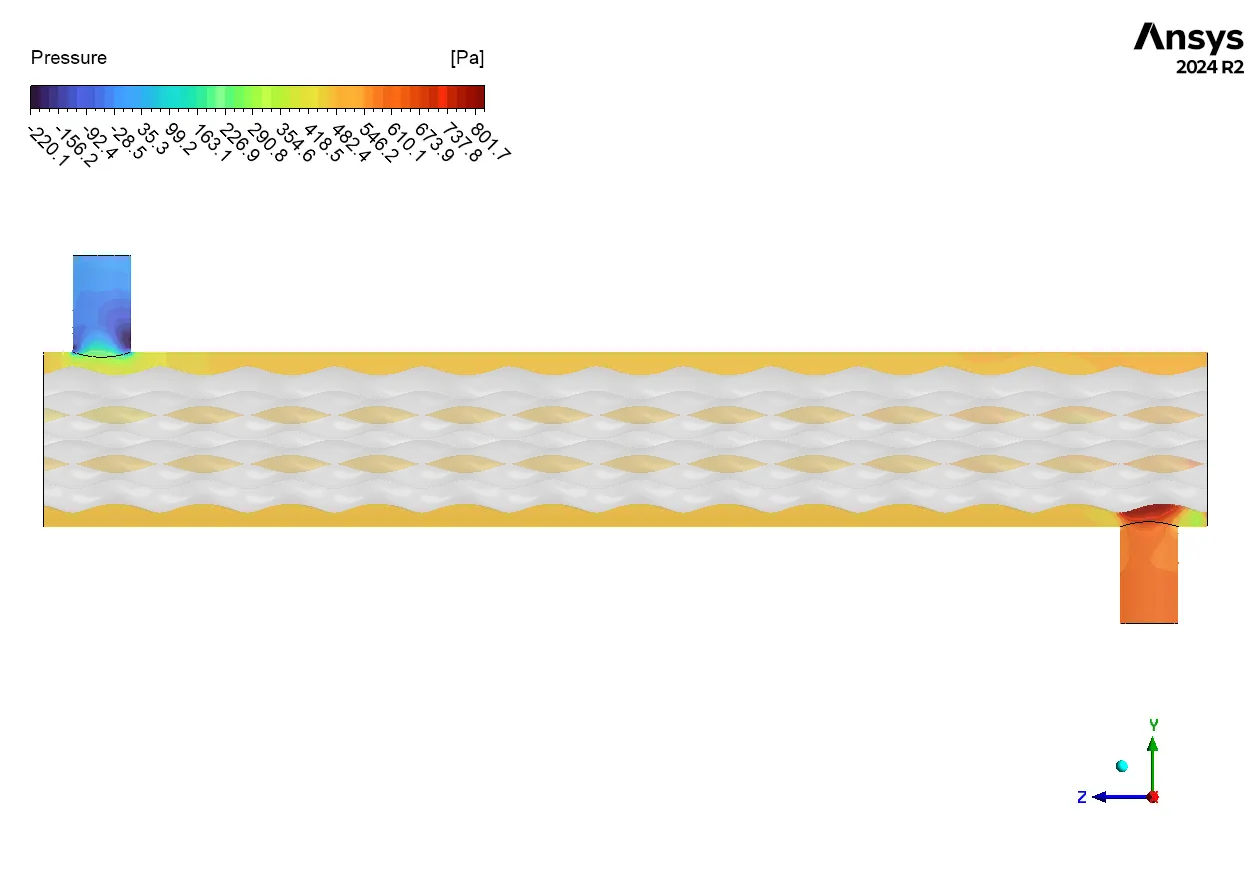

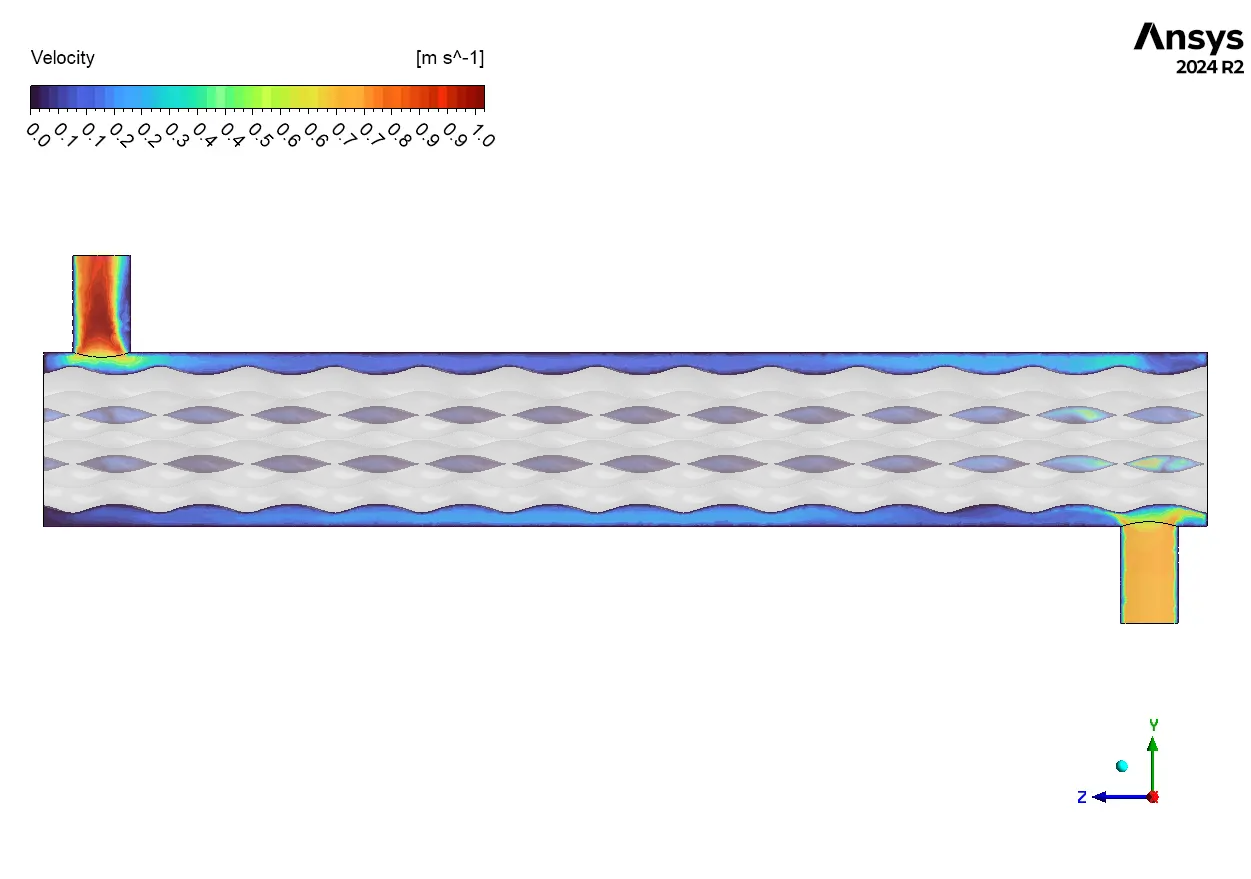

The pressure field throughout the twisted tubes demonstrates how the spiral design creates unique flow characteristics that enhance thermal performance. Starting from 5,195 Pa at the inlet, pressure gradually decreases along the flow path due to friction and flow mixing caused by the twisted geometry. The total pressure drop measured across the entire heat exchanger reaches 596.74 Pa, which represents the energy cost of achieving superior heat transfer rates. Each twist creates localized pressure variations that force fluid particles to follow helical paths, increasing contact time with tube walls. This swirl flow pattern is the key mechanism behind the enhanced heat transfer coefficient in twisted tube heat exchangers compared to straight tubes.

Figure 3: Pressure Distribution in Twisted Tube Heat Exchanger

Figure 4: Temperature Distribution in Twisted Tube Heat Exchanger

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€170 Original price was: €170.€145Current price is: €145.

€145 Original price was: €145.€95Current price is: €95.

€170 Original price was: €170.€125Current price is: €125.

€280 Original price was: €280.€185Current price is: €185.

€160 Original price was: €160.€80Current price is: €80.

€120 Original price was: €120.€65Current price is: €65.

Reviews

There are no reviews yet.