Double-pipe Heat Exchanger CFD: A Complete Fluent Validation Tutorial

Double-pipe Heat Exchanger CFD: A Complete Fluent Validation Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€280 Original price was: €280.€185Current price is: €185.

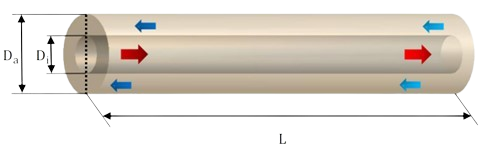

A double-pipe heat exchanger is a simple but very effective device used to transfer heat between two fluids. One fluid flows through an inner pipe, while a second fluid flows in the opposite direction through the outer pipe. This counter-flow design is very efficient. To study and improve these devices, engineers use Double-pipe Heat Exchanger CFD simulations. However, before a simulation can be trusted, it must be proven to be accurate. This report details a Double-pipe Heat Exchanger VALIDATION CFD study, where our results are carefully compared to the numerical data from the reference paper, “Numerical study on heat transfer enhancement and flow characteristics of double pipe heat exchanger fitted with rectangular cut twisted tape” [1].

- Reference [1]: Barzegar, Ali, and Dovood Jalali Vahid. “Numerical study on heat transfer enhancement and flow characteristics of double pipe heat exchanger fitted with rectangular cut twisted tape.” Heat and Mass Transfer12 (2019): 3455-3472.

.

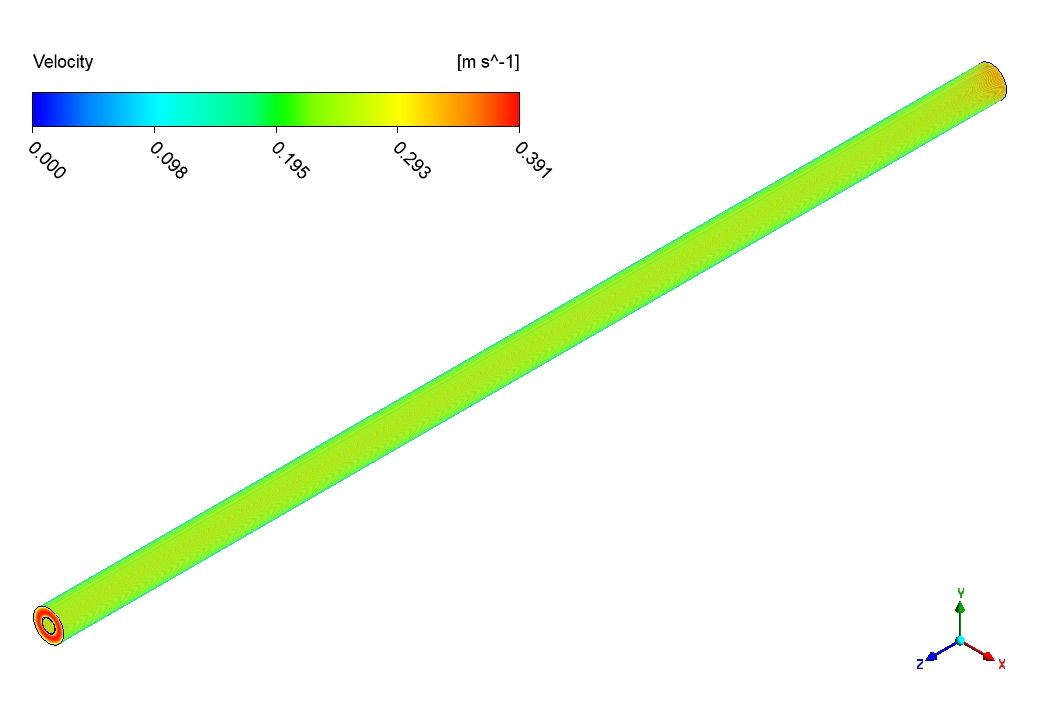

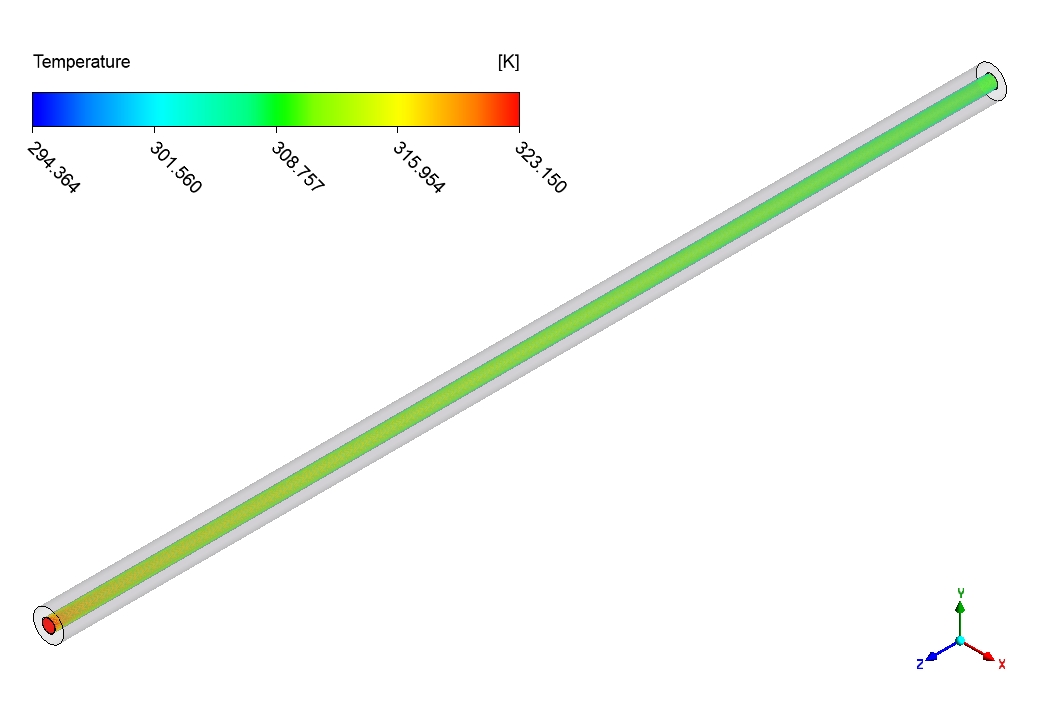

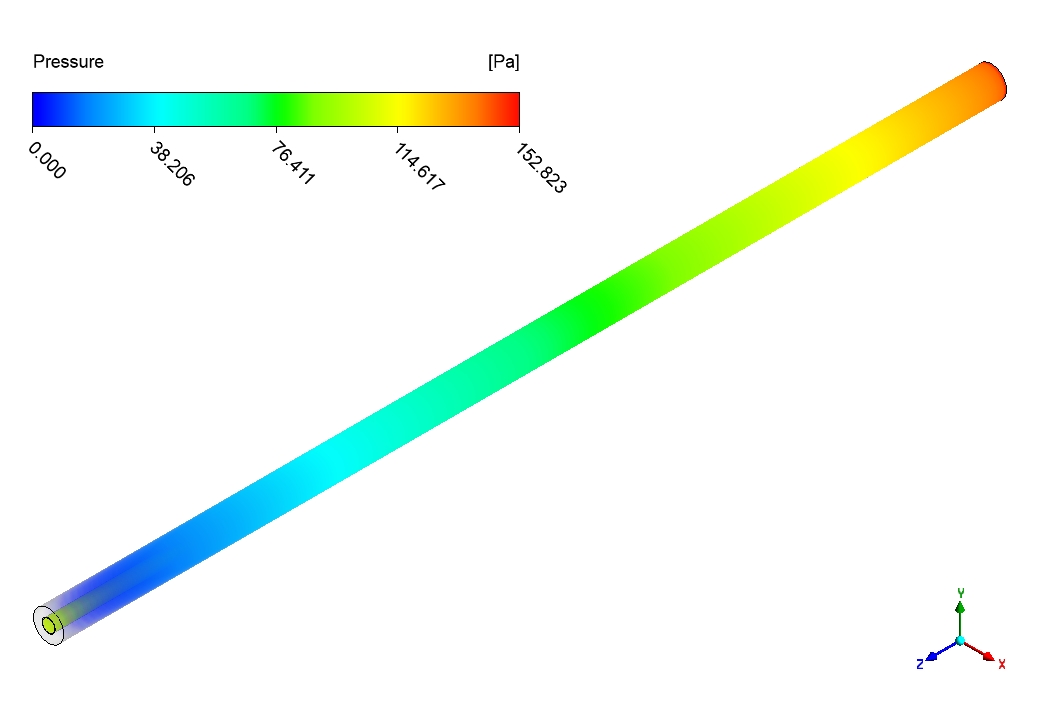

Figure 1: A schematic showing the counter-flow principle in a Double-pipe CFD model.

Simulation Process: Modeling the Double-pipe Heat Exchanger Fluent Simulation

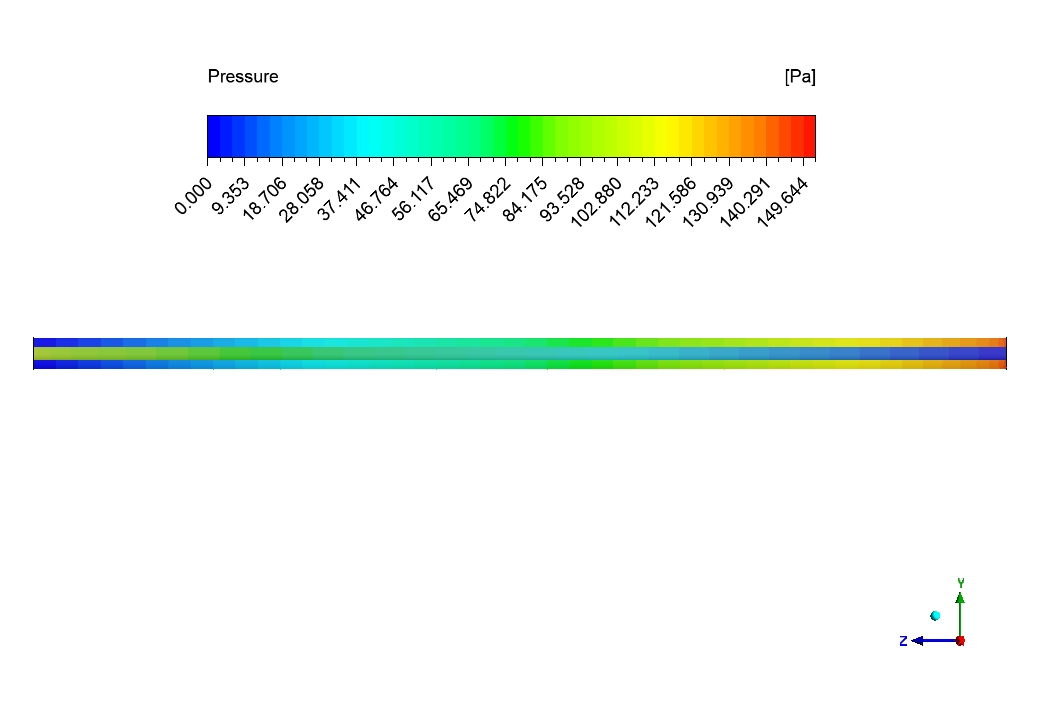

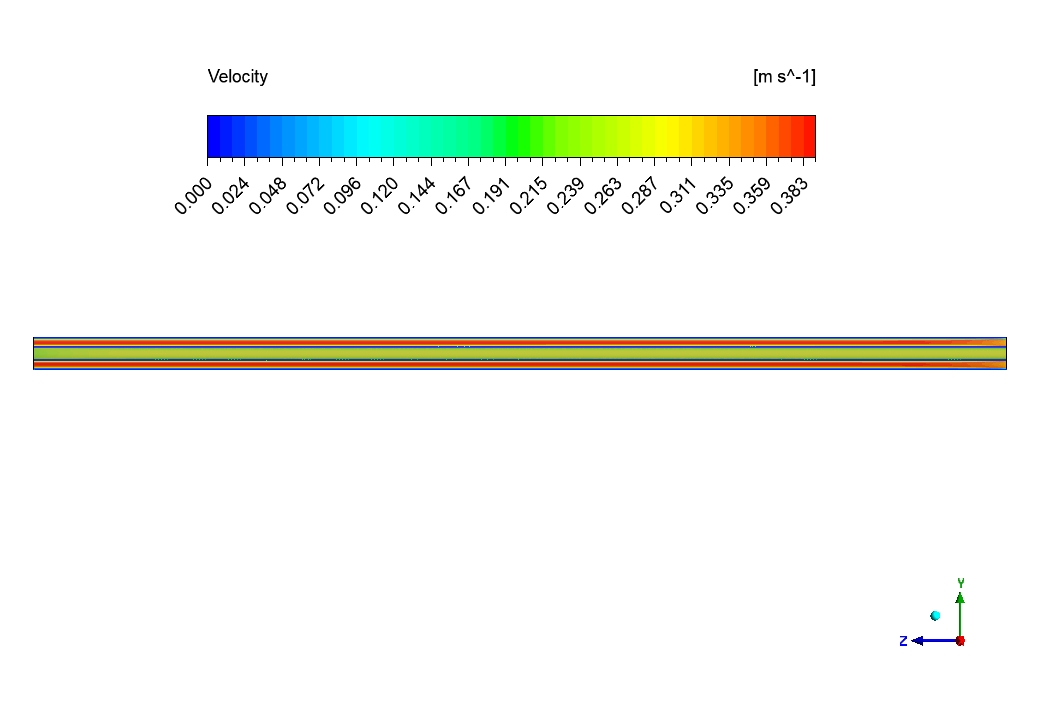

The simulation process began with building the 3D geometry of the Double-pipe Heat Exchanger Fluent model. This model was then filled with a high-quality structured grid made of 2,535,274 hexagonal cells. This type of mesh gives very accurate results for pipe flows. Special care was taken to add fine mesh layers near the walls to correctly capture the heat transfer through the boundary layer.

To model the physics accurately, the k-epsilon Realizable turbulence model was chosen. Because the properties of water, like density and viscosity, change with temperature, a User-Defined Function (UDF) was written. This UDF uses the equations from the reference paper to ensure the fluid properties are always correct at every point in the heat exchanger.

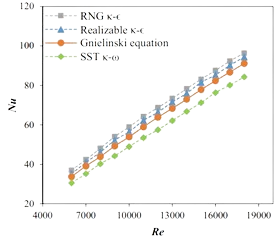

Post-processing: CAD analysis, Validating the Model and Understanding Heat Transfer

The simulation results provide a clear and fully substantiated story that begins with proving our model is accurate. The table below shows the core of our Double-pipe Heat Exchanger VALIDATION CFD analysis. The Nusselt number is a key value that tells us how good the heat transfer is. Our simulation’s Nusselt number of 34.51 is extremely close to the reference paper’s value of 37.31 and the trusted analytical solution (Blasius correlation) of 37.05. The small error of only 7% proves that our simulation setup is correct. This excellent agreement is the “cause” of our confidence; it confirms that our mesh, turbulence model, and UDF for properties are all working together to correctly model the real-world physics.

Table 1: Comparing CFD results with reference article

| Nusselt Number | Error (%) | |

| Numerical Paper | 37.31 | — |

| Analytical Solution (Blasius Correlation) | 37.05 | — |

| Present CFD Simulation | 34.51 | 7% |

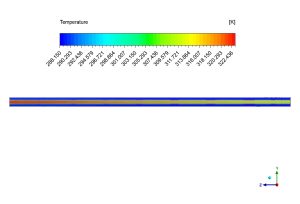

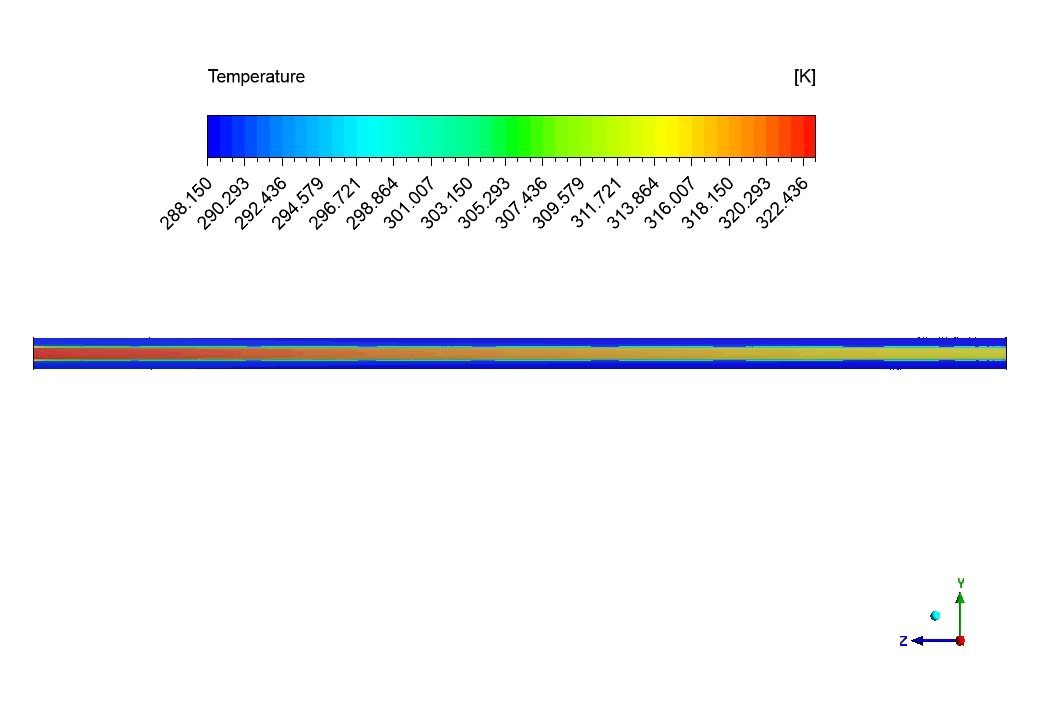

With our model now validated and trusted, we can analyze the “effect,” which is the heat transfer mechanism itself. The temperature contour in Figure 2 is the visual proof of this process. It clearly shows the hot fluid (red) cooling down as it moves from left to right, while the cold fluid (blue) heats up as it moves in the opposite direction from right to left. This counter-flow is the reason the temperature difference between the two fluids remains large and consistent along the entire length of the exchanger. This sustained temperature difference is the driving force that continuously pushes heat from the hot fluid, through the pipe wall, and into the cold fluid. The most significant achievement of this study is the successful validation of the Nusselt number against both numerical and analytical data, which gives us high confidence that our CFD model accurately visualizes the superior thermal performance of the counter-flow arrangement.

Figure 2: Temperature contour from the Double-pipe Heat Exchanger CFD simulation, visualizing the effective counter-flow heat exchange.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€185 Original price was: €185.€155Current price is: €155.

€120 Original price was: €120.€75Current price is: €75.

€190 Original price was: €190.€99Current price is: €99.

€160 Original price was: €160.€75Current price is: €75.

€210 Original price was: €210.€155Current price is: €155.

€205 Original price was: €205.€155Current price is: €155.

Reviews

There are no reviews yet.