Two-phase Oil-water Separator CFD Simulation: A Fluent Tutorial

Two-phase Oil-water Separator CFD Simulation: A Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€175 Original price was: €175.€125Current price is: €125.

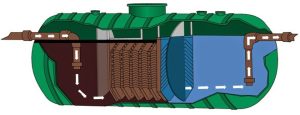

A Two-phase Oil-water Separator is a critical piece of equipment used in industries like oil and gas and wastewater treatment. Its main job is to separate oil droplets from water to prevent environmental pollution. These separators rely on gravity and special internal structures called coalescing plates to work effectively. By forcing the mixture to flow through a specific path, the device allows the lighter oil to float to the top while the heavier water sinks to the bottom.

Performing a Two-phase separator CFD simulation helps engineers understand the complex flow behavior inside these devices without building expensive prototypes. This project is a CFD simulation. We will use ANSYS Fluent to visualize how the internal plates improve separation efficiency. For more in-depth tutorials and resources on this topic, please visit our Separators tutorials.

Figure 1: The geometry of the oil-water separator showing the arrangement of internal baffles.

Simulation Process: Modeling Multiphase Flow in Fluent

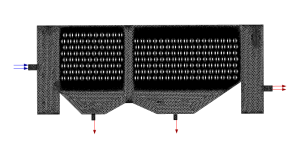

To start this Two phase separator fluent tutorial, we first designed a 2D separator geometry. We then created a mesh consisting of 90,948 triangular cells. Using triangular cells allows us to fit the mesh perfectly around the complex shapes of the internal plates. This mesh density is sufficient to capture the flow gradients between the oil and water layers.

For the physics setup in ANSYS Fluent, we selected the Eulerian multiphase model. This model is the best choice for this type of oil-water separator simulation because it treats both the oil and the water as interpenetrating continuous fluids (phases). This allows the software to calculate how much oil and water is present in every single cell of the mesh. Since the separation process changes as time passes, we configured the solver for a Transient (unsteady) simulation. This lets us watch the separation evolve from a mixed state to a fully separated state.

Figure 2: The unstructured mesh of 90,948 elements used for the simulation.

Post-processing: Analyzing Coalescence and Separation Efficiency

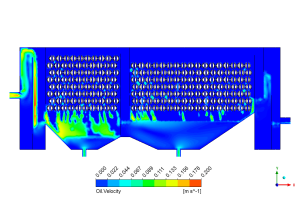

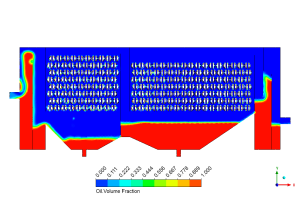

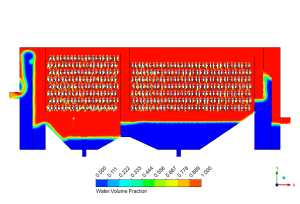

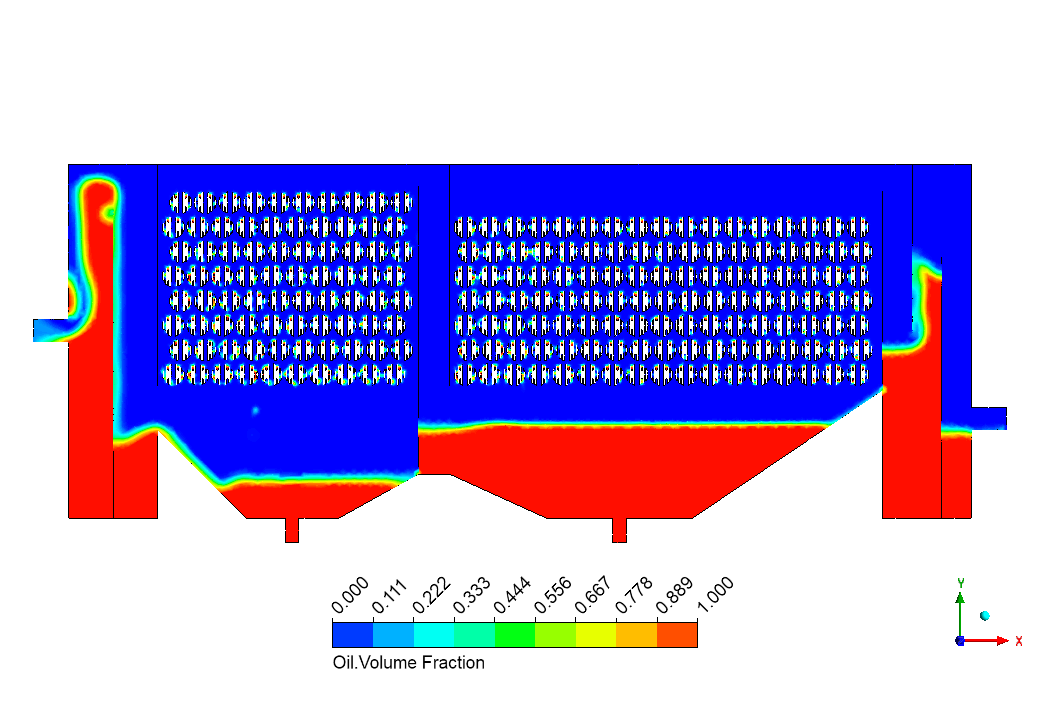

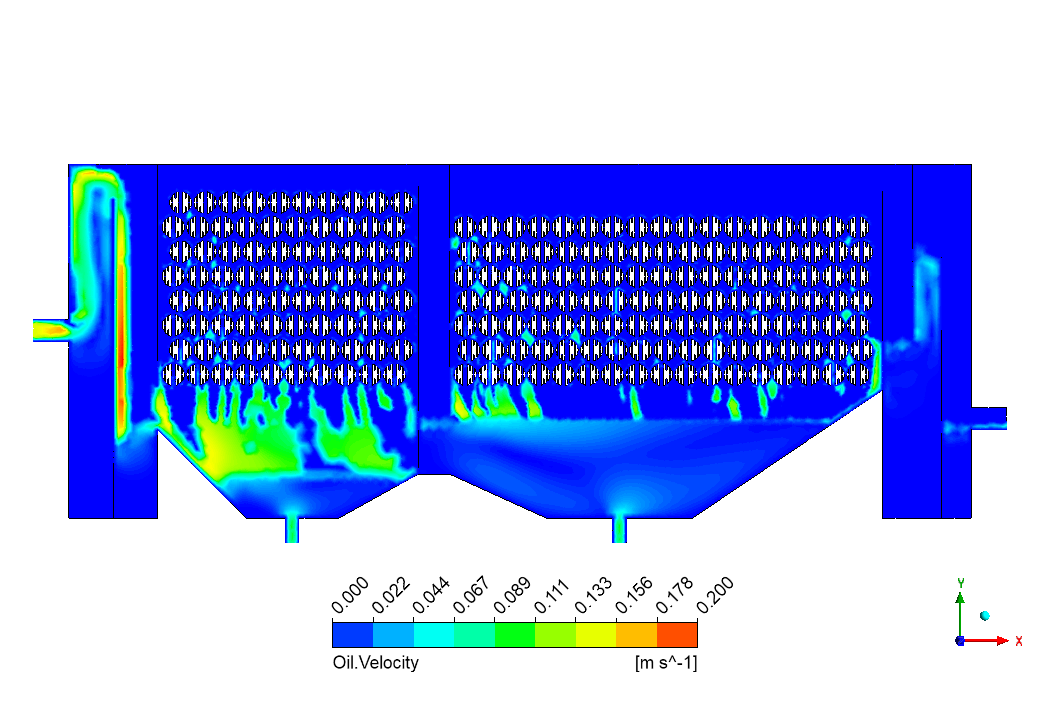

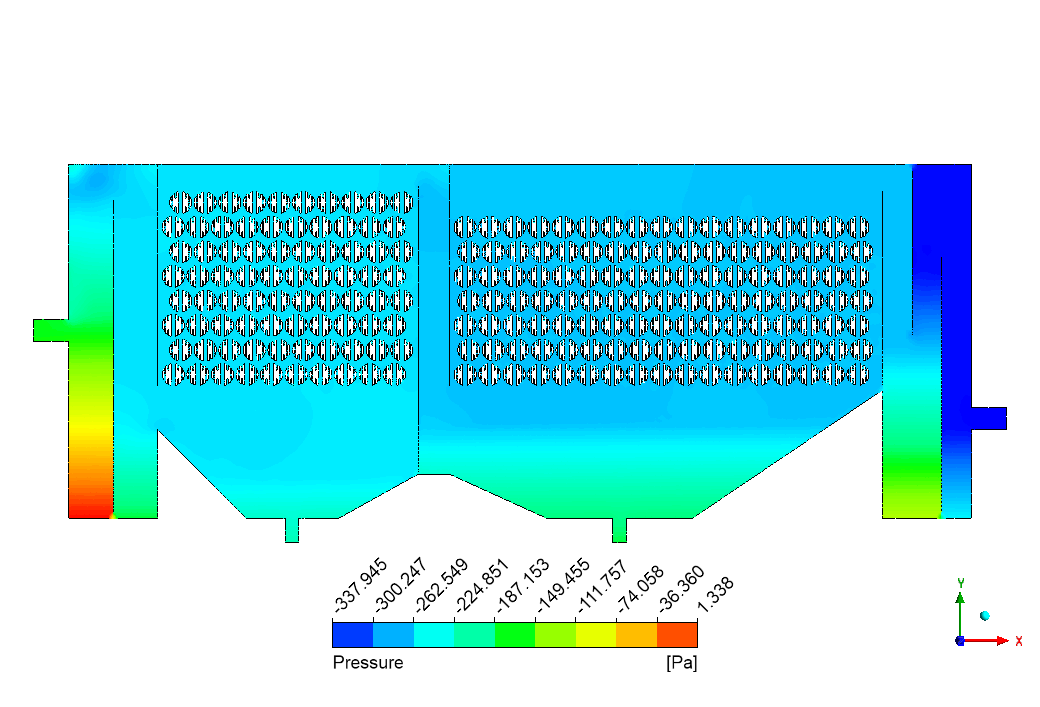

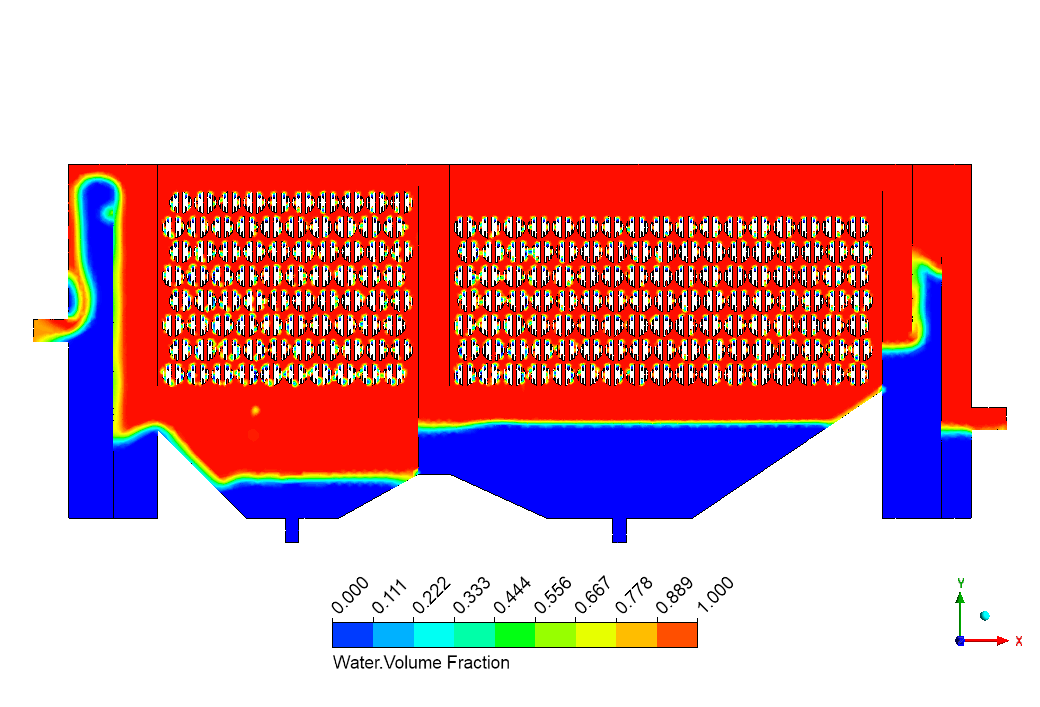

A real analysis of the simulation results provides a deep understanding of how the separator design achieves such high efficiency. The volume fraction contours are the primary indicator of success. They clearly show a distinct stratification: the lighter oil phase (shown in red in the oil contour) accumulates at the very top of the vessel, while the denser water phase settles at the bottom. This sharp interface proves that the gravity separation is working perfectly. However, the most interesting physics is revealed by the velocity contour. The internal plates create a winding, “serpentine” path for the fluid. This design is intentional. By forcing the fluid to travel a longer distance up and down through the baffles, the design significantly increases the “residence time,” which is the amount of time the fluid stays inside the separator.

Figure 3: Velocity contours showing the low-speed serpentine flow path.

The velocity data confirms that this design strategy works. The contours show that the flow speed is controlled and kept generally below 0.2 m/s throughout the main body of the separator. This low velocity is absolutely critical. If the fluid moved too fast, the turbulence would mix the oil and water back together. Instead, the slow, calm motion allows the tiny oil droplets to collide with the plates and with each other. This process, called coalescence, creates larger oil droplets that are much more buoyant and rise to the surface faster. The combination of the extended flow path and the low velocity creates the perfect conditions for gravity to pull the water down and push the oil up. This Two phase separator ANSYS fluent simulation effectively demonstrates that it is not just gravity, but the intelligent control of fluid velocity by the plates, that guarantees clean water at the outlet.

Figure 4: Volume fraction contours of oil and water showing clear phase separation.

Key Takeaways & FAQ

- Q: Why use the Eulerian model for this simulation?

- A: The Eulerian multiphase model is used in Two phase separator CFD simulation because it is excellent at simulating two continuous fluid phases (like oil and water) that are mixing and separating on a macroscopic scale. It accurately predicts the volume fraction of each phase in every cell.

- Q: What is the function of the internal plates (baffles)?

- A: The plates serve two purposes: they extend the flow path to increase residence time, and they provide a surface for oil droplets to coalesce. As shown in the CFD analysis, they also help keep the velocity low (under 0.2 m/s), which prevents re-mixing.

- Q: Why is this simulation transient?

- A: Separation is a time-dependent process. A Transient simulation allows us to see how long it takes for the oil and water to separate fully and reach a steady state, which is crucial for determining the real-world efficiency of the oil-water separator.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€170 Original price was: €170.€155Current price is: €155.

€180 Original price was: €180.€165Current price is: €165.

€220 Original price was: €220.€155Current price is: €155.

€240 Original price was: €240.€155Current price is: €155.

€210 Original price was: €210.€155Current price is: €155.

Reviews

There are no reviews yet.