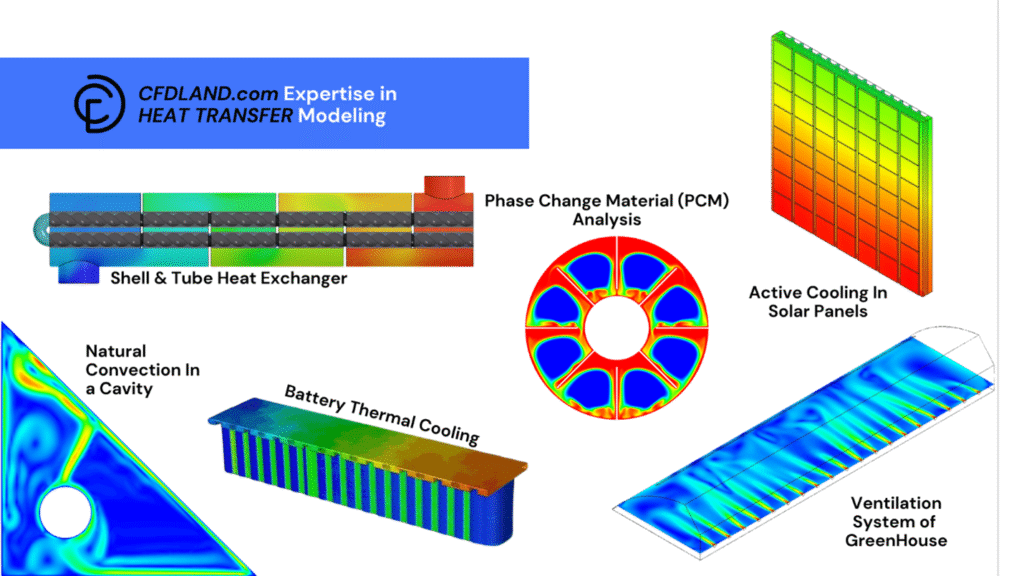

In engineering, convective heat transfer is everywhere. From cooling computer chips to designing better car radiators, engineers must understand how fluids carry heat. Modern tools like CFD simulations help us predict and optimize these heat transfer processes. If you want to explore advanced heat transfer CFD simulations, visit our comprehensive collection at CFDLand’s Heat Transfer Simulation Products. The convective heat transfer coefficient is the key number that tells us how well heat moves between a surface and a fluid. We will explore this important parameter in the next sections.

Contents

Toggle

Figure 1: Various applications of convective heat transfer in engineering systems including natural convection in cavities, battery thermal management, heat exchangers, and ventilation systems – showcasing CFDLand’s expertise in heat transfer modeling

What is convective heat transfer?

Convective heat transfer is one of the main types of heat transfer, along with conduction and radiation. It happens when heat moves because of the bulk movement of fluids, like liquids and gases. When a fluid, such as air or water, flows over a surface that has a different temperature, the fluid carries heat with it. This physical movement of the fluid is the key part of convection.

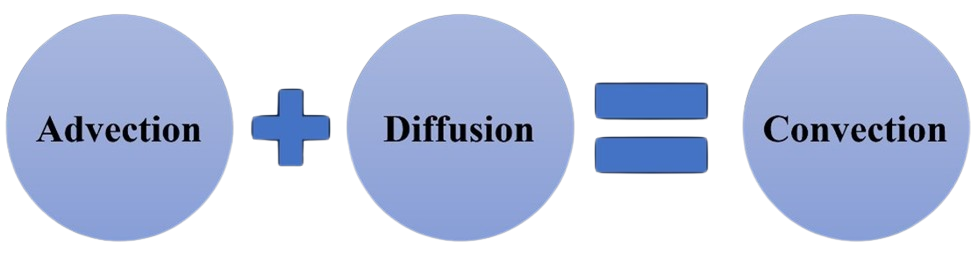

This process actually combines two mechanisms working together: advection and diffusion. Advection is the heat transported by the large-scale motion of the fluid. Diffusion is the heat transfer from random molecular motion, which is most important right at the surface. Together, these two actions create what we know as convection.

Figure 2: The mechanism of convective heat transfer, showing it combines bulk fluid motion (advection) and molecular heat transfer (diffusion).

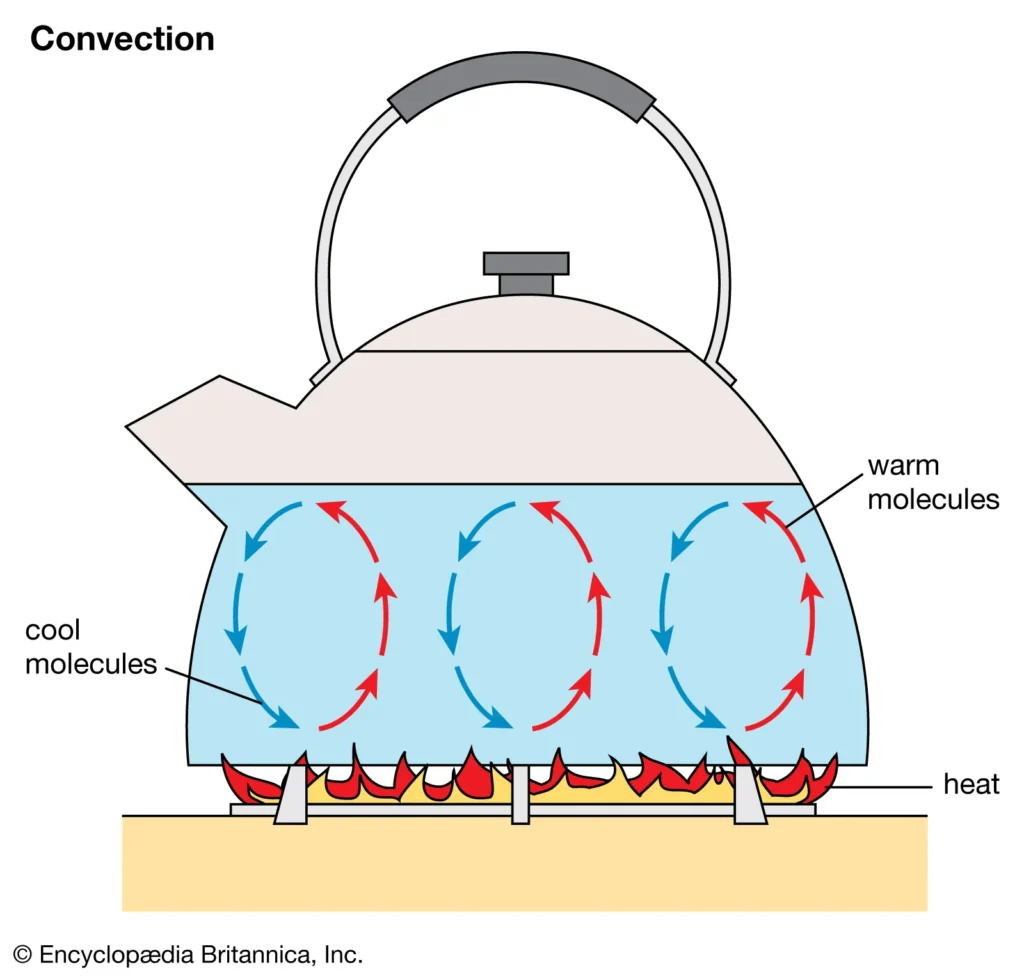

This process is very common in our daily lives. For example, when you boil water in a pot, the hot water at the bottom becomes less dense and rises. The cooler, denser water from the top sinks to take its place. This creates a circular flow, or current, that transfers heat efficiently. Another great example is a cool sea breeze, which is a type of natural convection that carries heat away from your warm skin. The main idea behind convective heat transfer is perfectly explained by Newton’s law of cooling. This law states that the rate of heat transfer is proportional to the temperature difference between the surface and the surrounding fluid. A bigger temperature difference always means a faster rate of heat transfer.

In engineering, understanding and controlling convection is critical for countless applications. These include designing efficient heat exchangers, developing battery thermal management systems, and ensuring proper building ventilation.

Figure 3: A daily example of convective heat transfer

What is the formula of convection heat transfer?

The main convective heat transfer formula is known as Newton’s Law of Cooling. This is a very important convection heat transfer equation used in many engineering and physics problems. It helps us calculate how much heat moves from a surface to a moving fluid. The formula is:

![]()

Let’s look at what each part of this formula means:

- Q is the heat transfer rate. This tells us how much heat is transferred every second. We measure it in Watts (W).* h is the convective heat transfer coefficient. This is a key value that shows how effective the heat transfer is. A high ‘h’ value means heat transfers very easily. We will discuss this more in the next sections. Its unit is Watts per square meter per Kelvin (W/m²K).

- A is the heat transfer surface area. This is the total area of the object that is in contact with the fluid. A larger area means more space for heat to move. We measure it in square meters (m²).

- (Ts – T∞) is the temperature difference.

- Ts is the surface temperature of the object.

- T∞ (T-infinity) is the bulk fluid temperature far away from the surface.

- The entire rate of heat transfer depends directly on this temperature difference. If there is no difference in temperature, there is no heat transfer.

This formula clearly shows that the heat transfer rate (Q) increases if the heat transfer coefficient (h), the surface area (A), or the temperature difference increases. Understanding this relationship is fundamental for controlling heating and cooling processes.

Convective heat transfer coefficient units

Understanding the convective heat transfer coefficient units is very important for correct calculations. The units tell us how much heat power is transferred over a certain area for each degree of temperature difference. In the International System of Units (SI units), which is used most often in science and engineering, the unit for the convective heat transfer coefficient (h) is:

Watts per square meter-Kelvin (W/m²K)

This means the unit measures the rate of heat (Watts) that passes through one square meter of area (m²) when the temperature difference between the surface and the fluid is one Kelvin (K).

In the imperial system, which is sometimes used in the United States, the unit for ‘h’ is British thermal units per hour per square foot per degree Fahrenheit (Btu/hr·ft²·°F).

It is important to remember that the value of ‘h’ is not a fixed number. It changes based on many factors. These include the properties of the fluid (like its viscosity and density), the speed of the fluid flow, and the shape and size of the surface. We will explore how to find ‘h’ in the next sections.

How to measure the convective heat transfer coefficient?

The convective heat transfer coefficient (h) is a complex value, so we cannot measure it directly with a single tool. Instead, engineers and scientists use three main methods to find ‘h’.

-

Experimental Measurements: This method uses physical experiments. Scientists set up a real test, measure the heat transfer rate (Q), the surface area (A), and the temperatures (Ts and T∞), and then they calculate ‘h’ using the main formula. This gives very accurate results for a specific setup but can be expensive and time-consuming.

-

Empirical Correlations: This is a very common method in engineering. Correlations are special formulas that were created from many experimental results. These formulas use important dimensionless numbers to help calculate the heat transfer coefficient. Some of these key numbers are:

- The Nusselt number (Nu), which represents the convective heat transfer.

- The Reynolds number (Re), which describes if the flow is smooth or chaotic.

- The Prandtl number (Pr), which relates to the fluid’s properties.

- The Grashof number (Gr), which is used for natural convection.

Once sufficient data is gathered to formulate the appropriate equation for h, dimensionless numbers are employed to derive an equation applicable across different fluid types and surface geometries. The average Nusselt number serves as a crucial parameter in this process and is expressed in equation 2.

![]()

where [W.m-2.K-1] is the averaged convection heat transfer coefficient, L [m] is a characteristic length or characteristic dimension associated with the flow geometry, and k is the thermal conductivity of the fluid [W.m-1.K-1].

For instance, the average Nusselt number for flow over a cylinder is obtained from an equation proposed by Churchill and Bernstein as:

![Rendered by QuickLaTeX.com \[ Nu_D = 0.3+\frac{0.62Re_D^\frac{1}{2}Pr^\frac{1}{3}}{{[1+(0.4/Pr)^\frac{2}{3}]}^\frac{1}{4}} [1+(\frac{Re_D}{282000})^\frac{5}{8}]^\frac{4}{5}} \]](https://cfdland.com/wp-content/ql-cache/quicklatex.com-fa0be0133ed657a96471f70abc325a23_l3.png)

Re and Pr are the Reynolds number and the Prandtl number, respectively. Therefore for flow over a cylinder, average convective heat transfer coefficient is calculated using equations 2 and 3.

In heat transfer handbooks and scientific papers, equations and tables are often provided to determine Nusselt numbers for different surface geometries and fluid flow conditions. These resources offer valuable tools for engineers and researchers to analyze convective heat transfer across various scenarios.

3. Computational Fluid Dynamics (CFD) Simulations: This is a powerful modern method. CFD simulations use computers to solve complex equations that describe how a fluid flows and transfers heat. CFD is extremely useful because it can find the convective heat transfer coefficient for very complex shapes and situations where simple formulas do not work. It can show you how ‘h’ changes over the entire surface, giving a very detailed picture.

Convective heat transfer coefficient table

The convective heat transfer coefficient (h) is not a single number. Its value changes a lot depending on the fluid, the type of flow, and the specific conditions. The table below shows typical ranges for ‘h’ in different common situations. These values help engineers quickly estimate how effective a heating or cooling process will be.

It is important to remember that these are general values for quick reference. For precise engineering design, you must calculate ‘h’ using the methods we discussed before, such as empirical correlations or CFD simulation.

Table 1. Typical values of the convection heat transfer coefficient. From Incropera et al., Fundamentals of Heat and Mass Transfer, 6th edition, Wiley, 2007.

| Process Type | Fluid | Typical ‘h’ value (W/m²K) |

|---|---|---|

| Natural (Free) Convection | Gases (e.g., Air) | 2 – 25 |

| Liquids (e.g., Water, Oil) | 50 – 1,000 | |

| Forced Convection | Gases (e.g., Air) | 25 – 250 |

| Highly viscous liquids (e.g., Oil) | 50 – 2,000 | |

| Water | 1,000 – 20,000 | |

| Convection with Phase Change | Boiling of Water | 2,500 – 100,000 |

| Condensation of Steam | 5,000 – 100,000 |

Here is why the heat transfer coefficient values vary so much:

- Fluid Type Matters: Liquids are much better at transferring heat than gases. You can see that the ‘h’ value for water is much higher than for air. This is because liquid molecules are packed more closely together.

- Forced vs. Natural Convection: Using a fan or pump to create forced convection always results in a higher ‘h’ value than relying on natural convection, where fluid moves due to density changes alone. More speed means more heat transfer.

- Phase Change is Most Powerful: The highest ‘h’ values occur during boiling and condensation. This is because a huge amount of energy (called latent heat) is needed to change the state of a fluid (e.g., from liquid to gas). This makes phase change a very effective way to transfer large amounts of heat quickly.

Convective heat transfer coefficients of water and air

Water and air are two of the most common fluids used for heating and cooling, but they behave very differently. The most important thing to know is that the convective heat transfer coefficient (h) of water is much, much higher than the convective heat transfer coefficient of air.

This means water is a much more effective fluid for transferring heat than air is. Let’s explore why. The difference comes down to three key fluid properties:

- Thermal Conductivity: Water has a much higher thermal conductivity than air. This means heat can move through water more easily and quickly.

- Density: Water is about 800 times denser than air. A denser fluid has more molecules in the same amount of space, so it can carry more heat energy as it flows.

- Specific Heat Capacity: Water has a very high specific heat capacity. This means it can absorb a lot of heat without its own temperature increasing by much. Air cannot hold as much heat.

Because of these properties, the ‘h’ value for water can be 20 to 100 times greater than for air, even in similar flow conditions.

This huge difference explains why we use them for different jobs:

- Water Cooling (High ‘h’ value): Because water is so efficient, we use it for high-power cooling applications where a lot of heat must be removed quickly. Good examples are car engine radiators and cooling systems in large power plants.

- Air Cooling (Low ‘h’ value): Air is used when the amount of heat is smaller and simplicity is important. We see air cooling everywhere, from the fans that cool our computers to the ventilation systems that heat and cool our homes.

Convective heat transfer coefficient in CFD simulations

In Computational Fluid Dynamics (CFD) simulations, convective heat transfer is directly calculated without the need to explicitly define the convective heat transfer coefficient. Through the solution of governing equations such as the Navier-Stokes equations and the energy equation, CFD software computes fluid flow characteristics and temperature distributions, allowing for the direct calculation of convective heat transfer rates at each point in the domain. This process inherently accounts for convective heat transfer, eliminating the requirement for specifying h separately. However, the accuracy of convective heat transfer predictions in CFD simulations depends on factors such as the numerical methods, turbulence modeling approaches, and boundary conditions used. Validation against experimental data remains crucial to ensure the reliability of CFD predictions.

Convection heat transfer examples

Convection heat transfer is a common phenomenon encountered in various everyday situations as well as in industrial processes. Here are some examples:

- Cooking: Convection heat transfer plays a crucial role in numerous cooking techniques. For example, in an oven, hot air circulates around food, transferring heat and cooking it evenly.

- Cooling of Electronic Devices: Convection serves a vital role in cooling electronic devices like computers and servers. Fans or heatsinks aid in convection by directing airflow over heated components, enabling the dissipation of heat.

- Air Conditioning Systems: Air conditioners utilize convection in various ways to regulate indoor temperature and humidity.

- Atmospheric Circulation: Convection drives large-scale atmospheric circulation patterns, such as the Hadley, Ferrel, and Polar cells, which influence weather systems and climate around the globe.

- Boiling Water: When water is heated in a pot, convection currents form as hotter water rises to the surface, cools, and then sinks back down. This circulation helps distribute heat throughout the liquid.

How to improve convection heat transfer?

Here are some strategies to improve convection heat transfer:

- Increase Fluid Velocity: Increasing fluid velocities enhances convective heat transfer rates by encouraging more fluid mixing and minimizing thermal boundary layer thickness. Achieving this can involve employing fans, pumps, or other mechanical devices to augment fluid flow.

- Use Turbulent Flow: Turbulent flow boosts convective heat transfer coefficients relative to laminar flow by improving fluid mixing and disrupting thermal boundary layers. Promoting turbulent flow can be accomplished by increasing flow velocities or introducing obstacles.

- Enhance Surface Roughness: Surface roughness can disrupt laminar boundary layers and promote turbulence, thereby improving convective heat transfer. Textured or rough surfaces are utilized to increase heat transfer coefficients.

- Optimize Surface Geometry: Surface geometry is pivotal in convective heat transfer. Shapes and configurations that encourage fluid mixing while minimizing flow separation can enhance heat transfer coefficients. Incorporating surface features such as dimples, grooves, or other structures can significantly improve heat transfer performance.

Any approach that amplifies turbulence in the flow, enlarges the contact surface, and prevents the formation of separation zones on the surface is effective.

Conclusion

In conclusion, convective heat transfer is a very important process that explains how heat moves through the flow of fluids. We see it happening all around us, from boiling water to the wind that cools us down.

This entire process is described by Newton’s Law of Cooling. The most critical part of this formula is the convective heat transfer coefficient (h), which tells us how effectively heat is transferred. We learned that this coefficient can be found using experiments, engineering formulas, or powerful CFD simulations.

A key takeaway is that the type of fluid makes a huge difference. Water is a much more powerful heat transfer fluid than air, which is why it is used for demanding cooling jobs like in car engines. Understanding the principles of convection is absolutely essential for engineers who design and improve thermal systems in almost every industry.