Solar Still CFD: A CFD Analysis of a Solar Distiller in ANSYS Fluent

Solar Still CFD: A CFD Analysis of a Solar Distiller in ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€195 Original price was: €195.€145Current price is: €145.

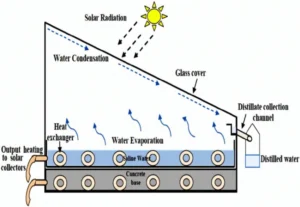

Access to clean drinking water is one of the world’s most important challenges. A solar still is a simple but brilliant device that uses the sun’s free energy to purify water. It works by copying the natural rain cycle on a small scale. A Solar Still CFD simulation is the best engineering tool to study and improve these devices. By using a computer model, we can see exactly how the water turns into vapor and then back into clean liquid water. This report presents a detailed Evaporation/Condensation in a Solar Still (Distiller) CFD simulation, performed with ANSYS Fluent, to analyze the entire purification process over time.

Figure 1: The basic design of a Solar Distiller CFD model.

Simulation Process: Modeling the Solar Distiller Fluent Simulation

To begin, a 3D model of the Solar Distiller Fluent geometry was created. This model was then meshed to prepare it for the simulation. Because the process involves liquid water, water vapor, and air all existing together, the Mixture multiphase model was chosen. This model is perfect for tracking the different fluids as they interact.

Two crucial physics models were activated to capture the sun’s effect. The Rosseland radiation module and Solar Ray Tracing model was used to simulate the sun’s rays passing through the glass cover and heating the water basin. To model the Evaporation CFD and Condensation CFD processes themselves, the Lee Model was implemented. This model tells Fluent when and how fast the liquid water should turn into vapor (evaporation) and when the vapor should turn back into liquid (condensation). The entire simulation was run in a transient mode, which means we can watch the purification process happen step-by-step over time.

Post-Processing: CFD Analysis of the Evaporation-Condensation Cycle

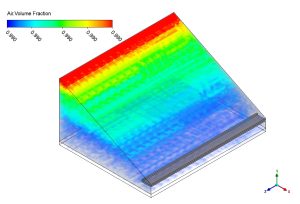

The simulation results provide a clear and fully substantiated story of the purification process, which is driven entirely by the sun’s energy. The first step is evaporation. The Solar Ray Tracing model shows that the sun’s energy passes through the glass and is absorbed by the basin of dirty water at the bottom, increasing its temperature. As the water gets hot, the Lee Model activates the Evaporation Fluent process, causing the water molecules at the surface to change into hot water vapor. The air volume fraction contour in Figure 2 proves this is happening: the concentration of air is lowest right above the water surface because it is being pushed away by the newly created vapor. This hot, moist vapor is less dense than the surrounding air, so it naturally rises. This is the “cause” of the entire cycle.

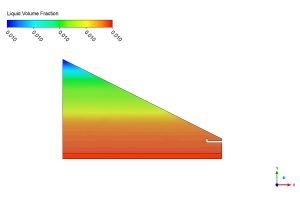

Figure 2: Volume fraction of air (left) and water (right) from the Solar Still Fluent simulation, visualizing the distinct zones of evaporation and condensation.

The second step is condensation, which is the direct “effect” of the first step. As the buoyant water vapor rises, it travels upwards until it hits the inner surface of the sloped glass cover. This glass is much cooler because it is exposed to the outside air. When the hot vapor touches the cold glass, the Lee Model activates the Condensation Fluent process. The vapor rapidly cools down and changes back into pure, liquid water droplets. The water volume fraction contour confirms this, showing a high concentration of liquid water at the bottom basin and almost zero liquid water in the vapor-filled space above. Gravity then completes the job, pulling the clean water droplets down the sloped glass where they are collected in a separate channel, leaving all the salt and contaminants behind in the basin. The most significant achievement of this transient CFD simulation is the clear visualization of the complete purification cycle, proving how solar radiation drives evaporation at the basin and how the temperature difference at the sloped glass cover drives condensation, resulting in a continuous production of fresh water.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€235 Original price was: €235.€175Current price is: €175.

€140 Original price was: €140.€105Current price is: €105.

€145 Original price was: €145.€115Current price is: €115.

€220 Original price was: €220.€135Current price is: €135.

€190 Original price was: €190.€145Current price is: €145.

€245 Original price was: €245.€199Current price is: €199.

Reviews

There are no reviews yet.