Catalytic Decomposition Of Hydrogen Peroxide CFD Simulation, Numerical Paper Validation

Catalytic Decomposition Of Hydrogen Peroxide CFD Simulation, Numerical Paper Validation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€235 Original price was: €235.€175Current price is: €175.

Common household chemicals like hydrogen peroxide (H2O2) are used for everything from rocket fuel to bleaching therapies. Its capacity for catalytic breakdown, a process that has long captivated scientists and engineers, is among its most intriguing qualities. Hydrogen peroxide naturally breaks down into water and oxygen at a moderate pace. However, the addition of specific catalysts can substantially speed up this reaction. In fact, the Norwegian University of Science and Technology (NTNU) conducted a thorough study on the catalytic decomposition of hydrogen peroxide, which is our guidance in the simulation. As the title suggests, this is a Numerical paper validation study. The thesis title is “ A CFD-model of the Fluid Flow in a Hydrogen Peroxide Monopropellant Rocket Engine in ANSYS Fluent”.

- Reference [1]: Vestnes, Frida. A CFD-model of the Fluid Flow in a Hydrogen Peroxide Monopropellant Rocket Engine in ANSYS Fluent 16.2. MS thesis. NTNU, 2016.

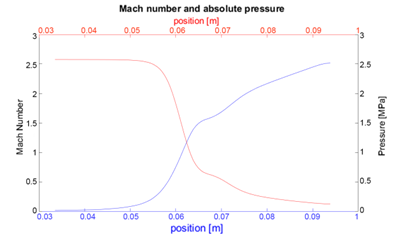

Figure 1: Plot of the Absolute pressure and Mach number versus the position of the Nozzle. Given in Figure 7.5. of thesis

Simulation Process

The model consists of different regions defined for axisymmetric geometry. 18200 Structured grid hasten the simulation accuracy and robustness. Due to the convergence issues found with the Eulerian model, a final attempt to model this fluid flow was performed with the mixture multiphase model enabled. However, each of the phases consists of several species. This means Species Transport model is also activated. With the mixture model selected for the multiphase model, the built-in model for the Arrhenius equation is no longer available. A User-defined Function (UDF) was therefore written to calculate the reaction rate of the decomposition process.

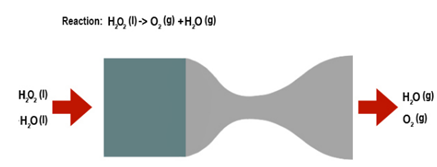

Figure 2: Problem description of thermal and catalytic decomposition of hydrogen peroxide

Post-processing

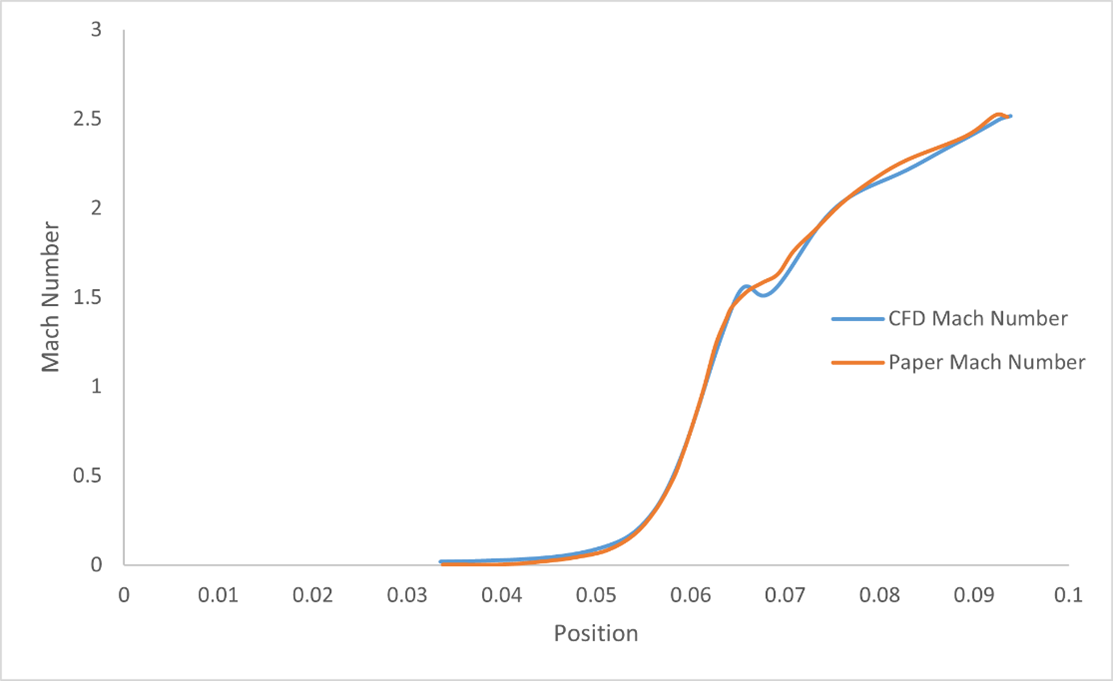

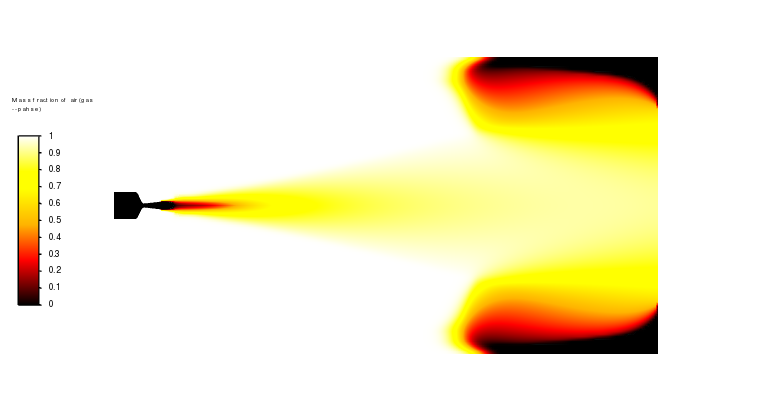

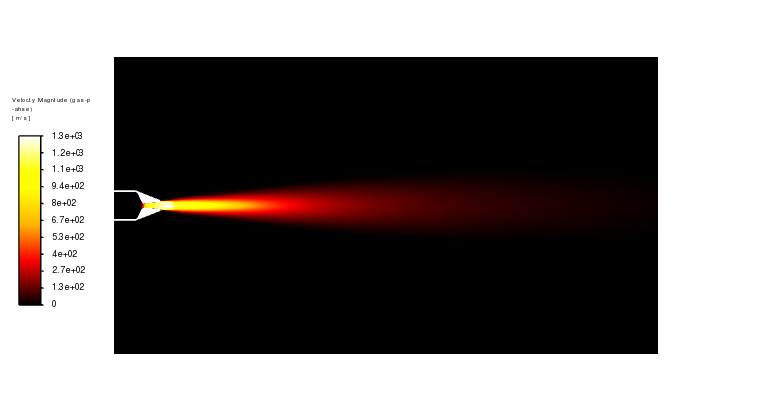

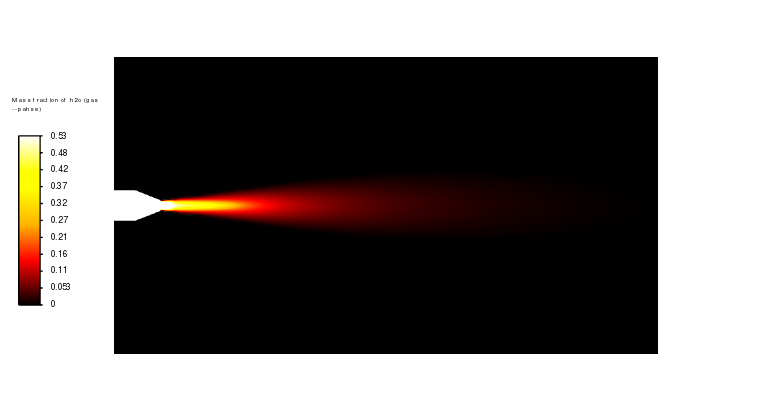

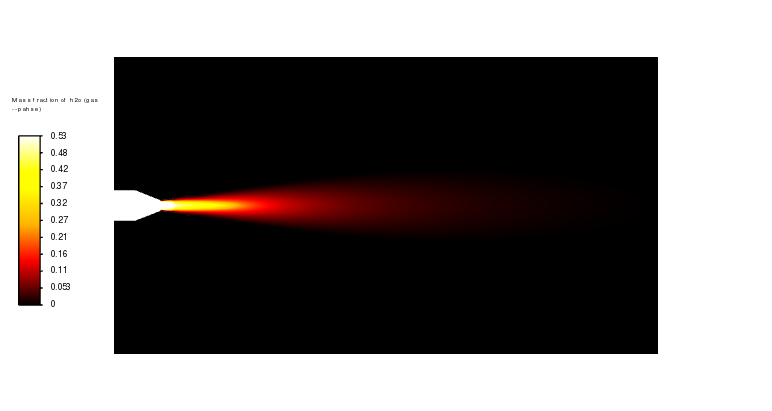

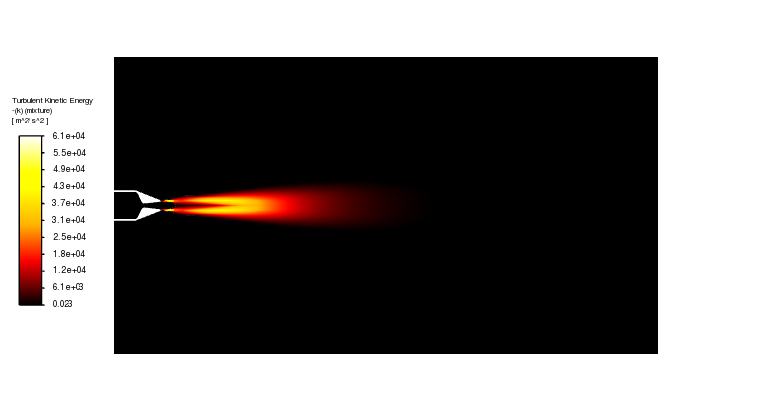

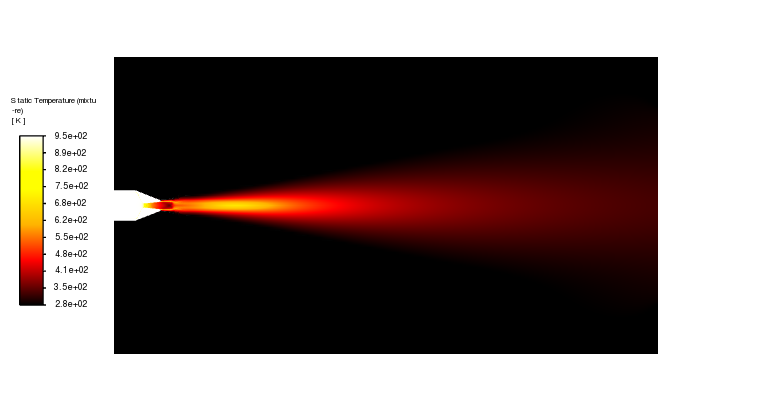

The simulation results for the catalytic decomposition of hydrogen peroxide seem to be well-validated based on the photos that have been presented. Figure 3, which compares the Mach number values between a reference paper and a CFD simulation, provides the most important proof for this claim. The graph shows excellent agreement at different positions between the Paper Mach number (orange line) and the CFD Mach number (blue line). This strong correlation suggests that the simulation correctly represents the flow behavior, especially the supersonic expansion that happens when the hydrogen peroxide breaks down and leaves the nozzle. The flow field is visualized in the remaining contours, which display the typical patterns of temperature, velocity, and perhaps pressure or density distributions of a supersonic exhaust plume. The validity of the overall simulation results for the catalytic decomposition process is strongly supported by the consistency between the simulated Mach number profile and the reference data.

Figure 3: Mach number comparison

Now check out this amazing temperature contour showing the hot magic happening during H2O2 decomposition! The vibrant colors reveal the intense exothermic reaction taking place as the hydrogen peroxide monopropellant breaks down into water and oxygen. We successfully captured the dramatic temperature gradient from the deep red core (reaching nearly 900K or 627°C) to the cooler outer regions. The hottest zone appears right after the catalytic bed where the chemical reaction happens fastest, creating that bright yellow-orange plume stretching rightward. This temperature spike proves our multiphase flow model accurately represents the highly energetic nature of the reaction – hot enough to power actual rocket engines! Also notice how the plume maintains its high temperature far downstream, showing the complete and efficient catalytic conversion of H2O2. This thermal signature matches exactly what we’d expect in real propulsion systems using hydrogen peroxide, further validating our numerical simulation approach. The clear visualization of this temperature distribution helps engineers optimize both the catalyst design and nozzle geometry to maximize thrust while preventing material damage from excessive heat – critical factors for developing reliable monopropellant thrusters for satellites and spacecraft.

Figure 4: Temperature pattern during decomposition process

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€155 Original price was: €155.€99Current price is: €99.

€310 Original price was: €310.€175Current price is: €175.

€220 Original price was: €220.€135Current price is: €135.

€175 Original price was: €175.€115Current price is: €115.

€360 Original price was: €360.€185Current price is: €185.

€210 Original price was: €210.€155Current price is: €155.

Reviews

There are no reviews yet.