Droplet Formation in Microfluidic Device CFD: A Fluent VOF Tutorial

Droplet Formation in Microfluidic Device CFD: A Fluent VOF Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€220 Original price was: €220.€135Current price is: €135.

A Droplet Formation In Microfluidic Device CFD simulation is a key technology for designing “lab-on-a-chip” systems used in medicine, chemistry, and biology. These devices create thousands of tiny, identical droplets that can act as individual test tubes for high-speed experiments. By simulating this process, we can perfect the design without costly and time-consuming physical prototypes. This report details a CFD simulation using ANSYS Fluent to analyze the precise mechanism of droplet formation in a T-junction microchannel, following the principles discussed in the reference paper by Qian et al. [1].

- Reference [1]: Qian, Jin-yuan, et al. “Mixing efficiency analysis on droplet formation process in microchannels by numerical methods.” Processes1 (2019): 33.

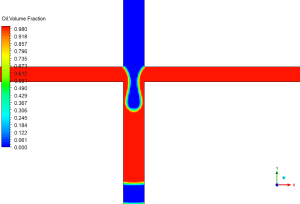

Figure 1: Diagram showing the T-junction geometry for the Microfluidic Device CFD simulation.

Simulation Process: Modeling the Droplet Formation Fluent Simulation

The simulation was performed using a 2D model of a T-junction microchannel. The key to accurately capturing the physics of two liquids that do not mix (like oil and water) is the Volume of Fluid (VOF) multiphase model. This model excels at tracking the sharp, clear interface between the two fluids. Because droplet formation is a dynamic event that happens over time, a transient simulation was required. A very fine mesh was used, especially around the T-junction, to ensure that the small-scale fluid interactions and the curvature of the droplet surface were resolved with high precision.

Post-processing: CFD Analysis, How Shear Force Pinches Off Perfect Droplets

The simulation results provide a clear and fully substantiated story that begins with the fluids meeting at the T-junction. The fundamental “cause” of droplet formation is the viscous shear force exerted by the main fluid (the continuous phase, shown in blue) on the fluid entering from the side channel (the dispersed phase, shown in red). As the continuous phase flows past the junction, it grabs onto and drags the dispersed phase, stretching it out into the main channel. The time-sequence in Figure 2 is the visual proof of this action, showing the red fluid being pulled from the side channel into a long, thin filament.

Figure 2: A time-sequence of VOF contours from the Droplet Formation Fluent simulation, showing the stages of (a) intrusion, (b) stretching, © necking, and (d) pinch-off.

This stretching force has a direct and predictable “effect”: it causes the filament to become unstable and “pinch off,” forming a distinct droplet. This pinch-off happens because of a second force: interfacial tension. Interfacial tension is a natural force that tries to minimize the surface area of the red fluid, pulling it into a spherical shape. When the stretching from the shear force becomes too great, interfacial tension wins at the thinnest point of the filament (the “neck”), causing it to break and release a self-contained droplet. The sequence in Figure 2 perfectly captures this “effect,” showing the filament necking down and then snapping apart to create a perfectly formed droplet that then flows downstream. The most significant achievement of this study is the clear demonstration of how the shear force from the continuous phase (the cause) works against interfacial tension to produce a predictable droplet pinch-off (the effect), validating the CFD model as an essential design tool for controlling droplet size and generation frequency in advanced Microfluidic Device Fluent simulations simply by adjusting the fluid flow rates.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€155 Original price was: €155.€99Current price is: €99.

€145 Original price was: €145.€65Current price is: €65.

€310 Original price was: €310.€175Current price is: €175.

€145 Original price was: €145.€115Current price is: €115.

€195 Original price was: €195.€150Current price is: €150.

€190 Original price was: €190.€145Current price is: €145.

Reviews

There are no reviews yet.