Biomass Pyrolysis CFD, A Fluent Simulation of a Conical Spouted Bed Reactor

Biomass Pyrolysis CFD, A Fluent Simulation of a Conical Spouted Bed Reactor

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€195 Original price was: €195.€150Current price is: €150.

A Conical Spouted Bed Reactor is a special type of container designed to efficiently turn biomass, like wood chips or agricultural waste, into valuable bio-oil and syngas through a process called pyrolysis. The reactor’s cone shape and a high-speed jet of gas from the bottom create a “spouting” fountain of particles. This action ensures everything is mixed well and heated evenly, which is critical for a successful reaction. A Biomass Pyrolysis in Conical Spouted Bed Reactor CFD simulation is the best way to see this complex process in action and to prove the design works as intended. This simulation is based on the important experimental work from the reference paper by Hooshdaran, et al. [1].

- Reference [1]: Hooshdaran, Bahar, et al. “CFD modeling and experimental validation of biomass fast pyrolysis in a conical spouted bed reactor.” Journal of Analytical and Applied Pyrolysis154 (2021): 105011.

Figure 1: The 2D geometry and boundary conditions for the Conical Spouted Bed Reactor CFD model [1].

Simulation Process: Modeling the Multiphase Pyrolysis Process

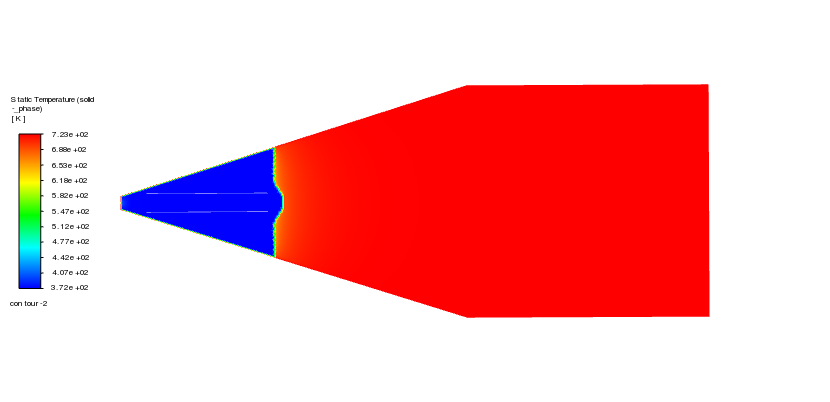

To begin our Conical Spouted Bed Reactor fluent simulation, we first created a 2D axisymmetric model. This is a smart way to represent the 3D cone shape that saves a lot of computational time. We then used blocking to create a high-quality structured grid, which is essential for getting accurate results in multiphase flow.The most challenging part of this simulation was setting up the physics in ANSYS Fluent. Because Biomass Pyrolysis happens over time, we ran a Transient (unsteady) simulation. We used the Eulerian-Eulerian multiphase model to track two different phases: the hot gas and the solid biomass particles, which were modeled as a granular material. Finally, the Species Transport model was activated to handle the chemical reactions that break down the biomass.

Post-processing: How the Spouting Action Drives Pyrolysis

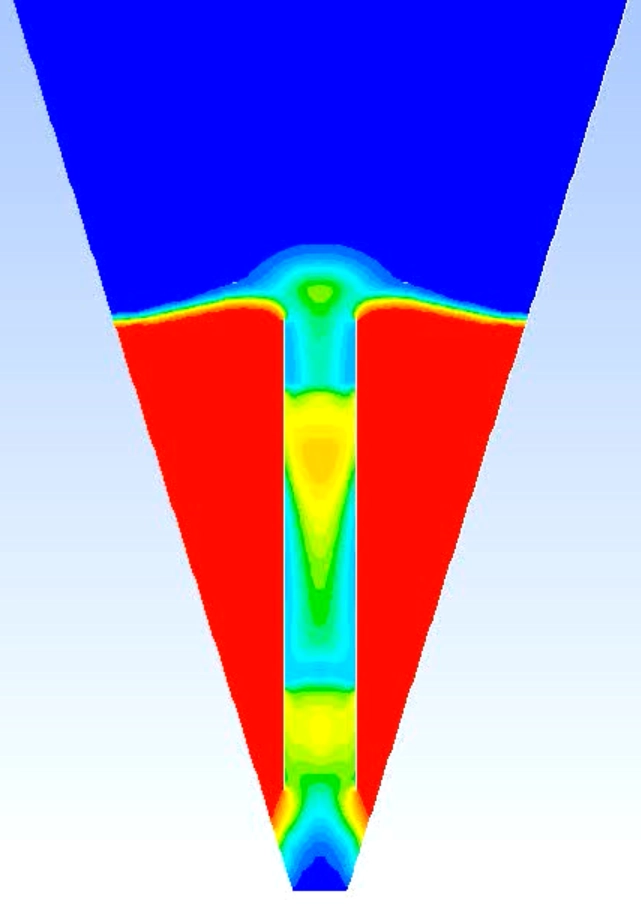

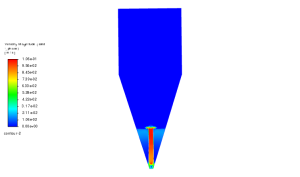

A detailed analysis of the results clearly shows the unique and powerful fluid dynamics inside the reactor. The velocity contour in Figure 3 reveals a high-speed gas jet in the center, with speeds reaching up to 10.6 m/s. This central spout acts like a fountain, shooting the biomass particles upwards. The volume fraction contour in Figure 2 shows these particles being carried up in the middle and then slowly sliding down the angled walls of the cone. This creates a continuous particle circulation loop, which is the most important feature of this reactor. This constant motion guarantees that every particle is exposed to the hot gas, preventing cold spots and ensuring the process is efficient.

Figure 2: Solid particle volume fraction showing the classic “spouting” pattern in the Biomass Pyrolysis Fluent simulation.

Figure 3: Velocity field, highlighting the high-speed central jet that drives the particle circulation.

Furthermore, this excellent mixing directly leads to the ideal temperature conditions needed for pyrolysis. The temperature field shows a stable and high-temperature zone, ranging from 372 K to over 729 K, especially in the upper parts of the reactor where the reactions happen. This high temperature, combined with the excellent particle mixing, ensures that the biomass breaks down evenly and completely. The most significant achievement of this simulation is proving the direct link between the spouting hydrodynamics and the stable thermal environment. This detailed Biomass Pyrolyis CFD analysis successfully demonstrates why the conical spouted bed design is a highly effective technology for converting waste biomass into renewable energy.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€140 Original price was: €140.€105Current price is: €105.

€310 Original price was: €310.€175Current price is: €175.

€155 Original price was: €155.€135Current price is: €135.

€360 Original price was: €360.€185Current price is: €185.

€195 Original price was: €195.€135Current price is: €135.

2 reviews for Biomass Pyrolysis CFD, A Fluent Simulation of a Conical Spouted Bed Reactor

faezenobakht –

great

sam –

This is great, thank you.