Ansys Fluent VOF-To-DPM Tutorial, Liquid Jet Breakup CFD

Ansys Fluent VOF-To-DPM Tutorial, Liquid Jet Breakup CFD

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€215 Original price was: €215.€165Current price is: €165.

The process of breaking a continuous liquid stream into a fine spray of droplets—is a fundamental engineering process that is critical to countless modern technologies. It is the core principle behind fuel injectors in car engines, cooling sprays for high-power electronics, coating processes for manufacturing, and even agricultural systems for crop spraying. The engineering challenge is immense because Liquid Jet Breakup is a multi-scale phenomenon. It begins with a large, coherent liquid jet (a macroscopic event) and ends with millions of tiny, individual droplets (a microscopic event). Simulating this entire process with a single model is computationally impossible. The Volume of Fluid (VOF) model is excellent for the large jet, but terrible for tracking individual droplets. Conversely, the Discrete Phase Model (DPM) is perfect for droplets but cannot handle the continuous jet. The solution is an advanced, hybrid technique called VOF-to-DPM conversion. This Atomization Spray CFD tutorial demonstrates how this powerful feature in ANSYS Fluent, combined with Mesh adapting Fluent technology, provides a highly accurate and efficient solution.

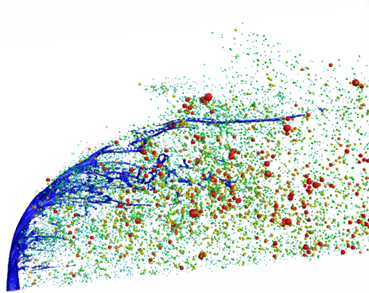

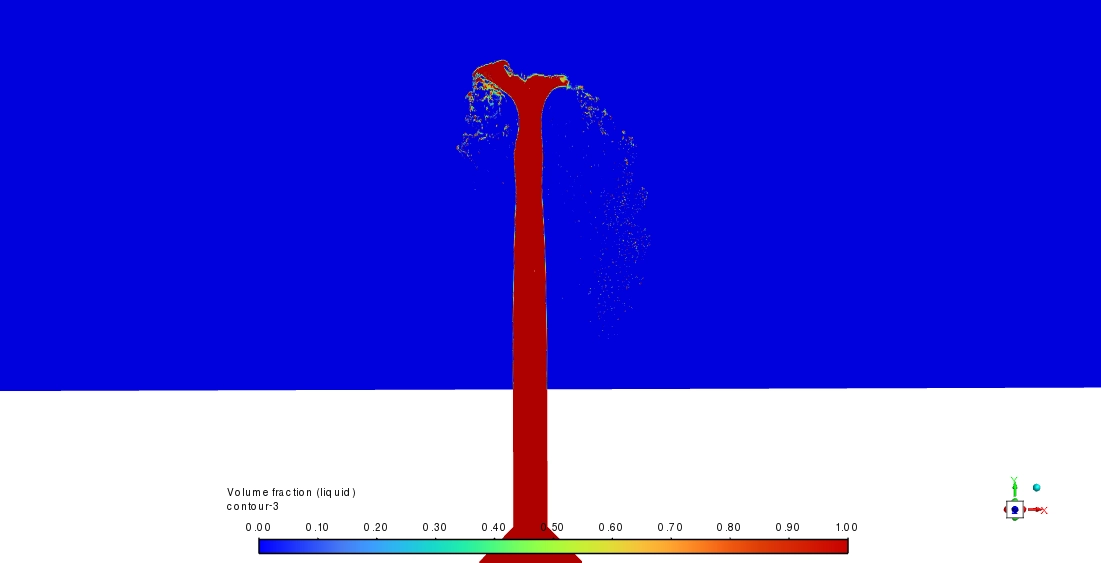

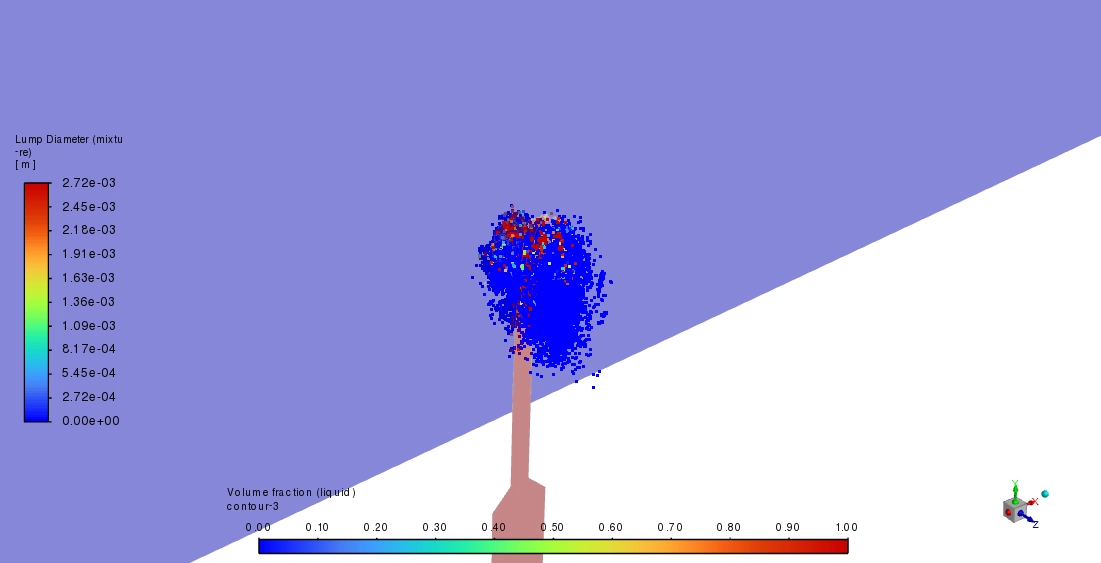

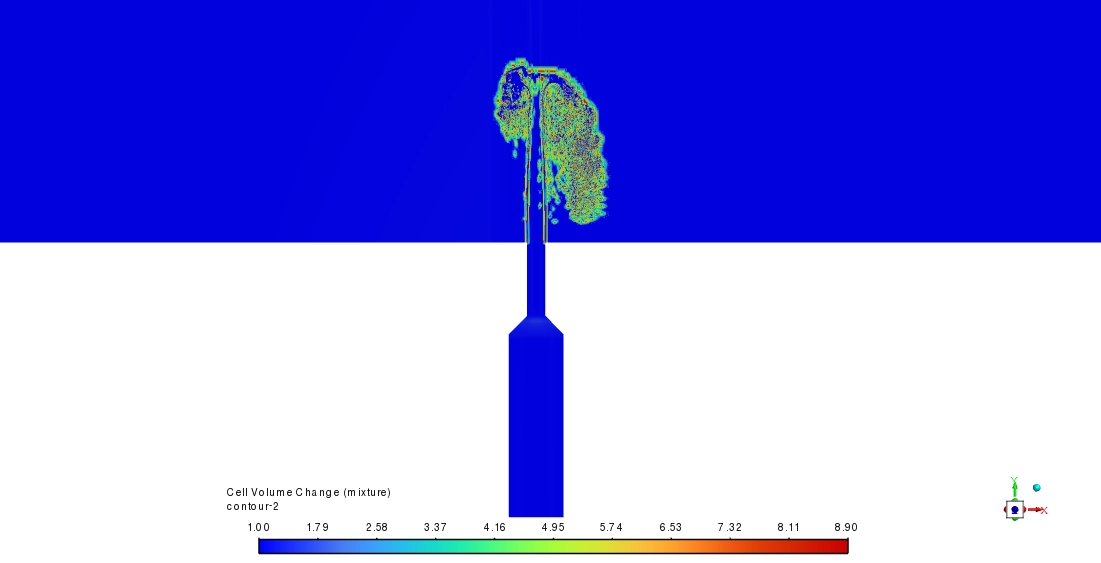

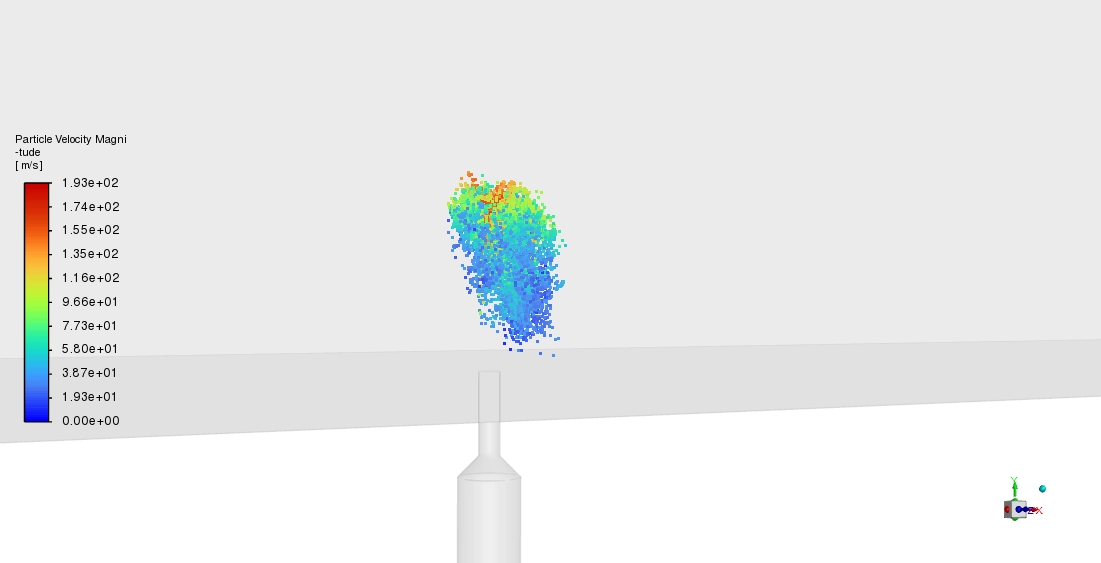

Figure 1: The VOF to DPM transition, where the continuous liquid jet (VOF) breaks apart into discrete droplets (DPM).

Simulation Process: Simulating Liquid Jet CFD with VOF-To-DPM technique

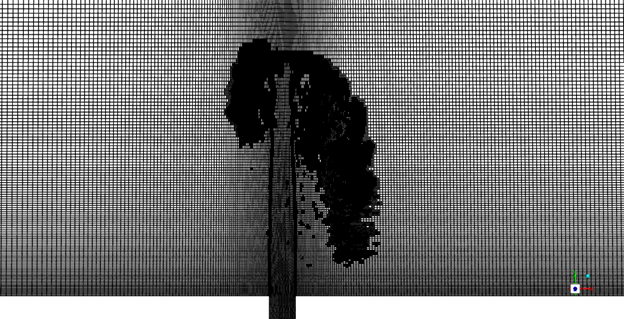

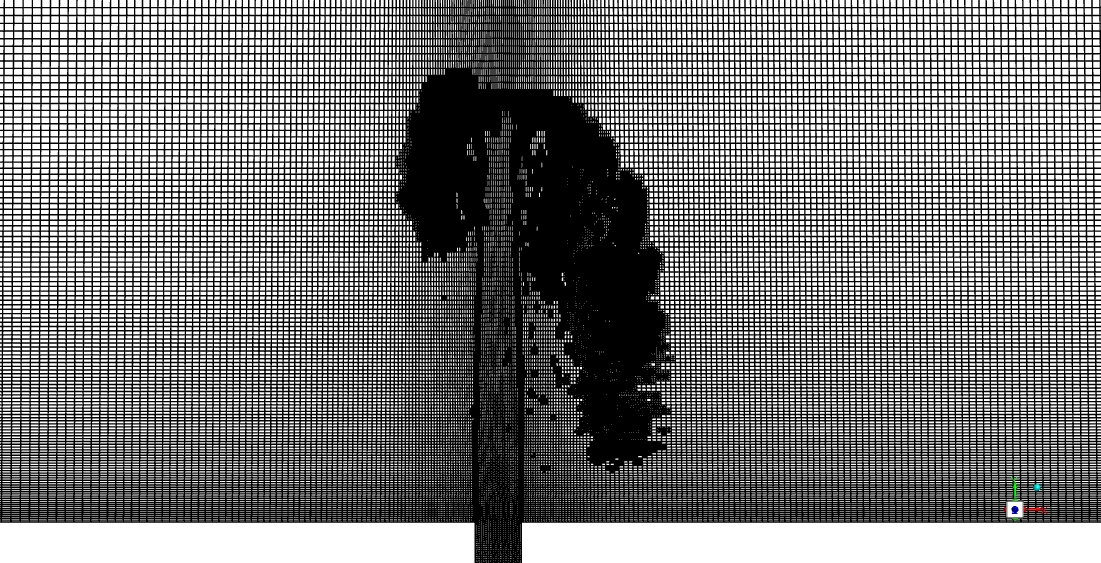

The key to a successful Atomization CFD simulation is resolving the incredibly fine details at the interface between the water and the air. To achieve this, a massive initial structured grid containing 36,698,446 cells was created. However, a static mesh of this size would be computationally wasteful. Therefore, the most critical technology used in this Spray Fluent simulation was Dynamic Mesh Adaptation. This intelligent feature automatically refines the mesh cells in regions with a high VOF gradient—meaning, right where the chaotic breakup is happening—and coarsens the mesh in calm regions far from the jet.

The multiphase physics were governed by the VOF model to capture the large-scale liquid jet core. The simulation was run in transient mode because Breakup CFD is an inherently time-dependent process. The final, crucial step was activating the VOF-to-DPM transition model. This model constantly monitors the simulation and, when a piece of the liquid VOF body becomes small and detached enough, it is automatically converted into a Lagrangian particle, or a Breakup DPM parcel, which is then tracked individually.

Figure 2: The dynamically adapted mesh, showing high refinement at the Water Jet Breakup CFD interface to maximize accuracy.

Post-processing: CFD Analysis of Atomization: From Primary Breakup to Droplet Distribution

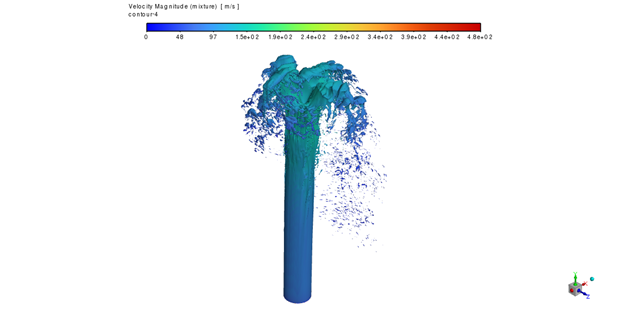

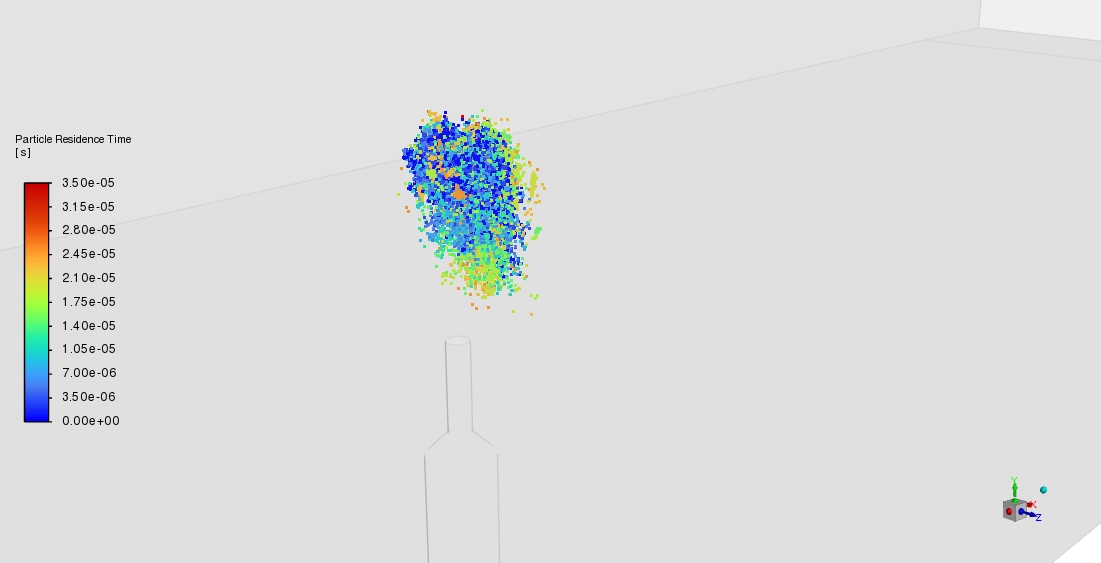

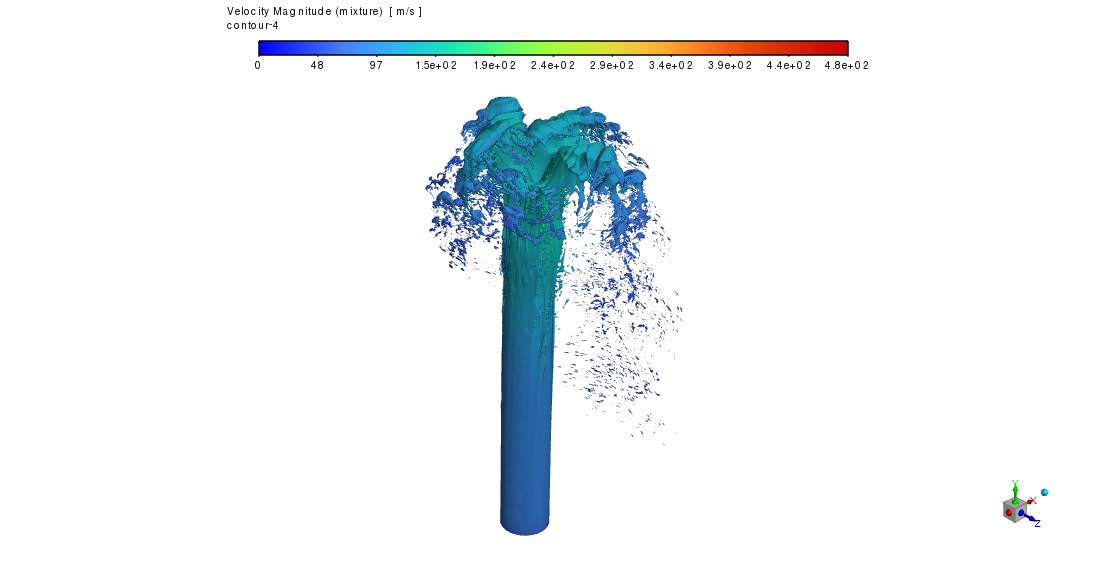

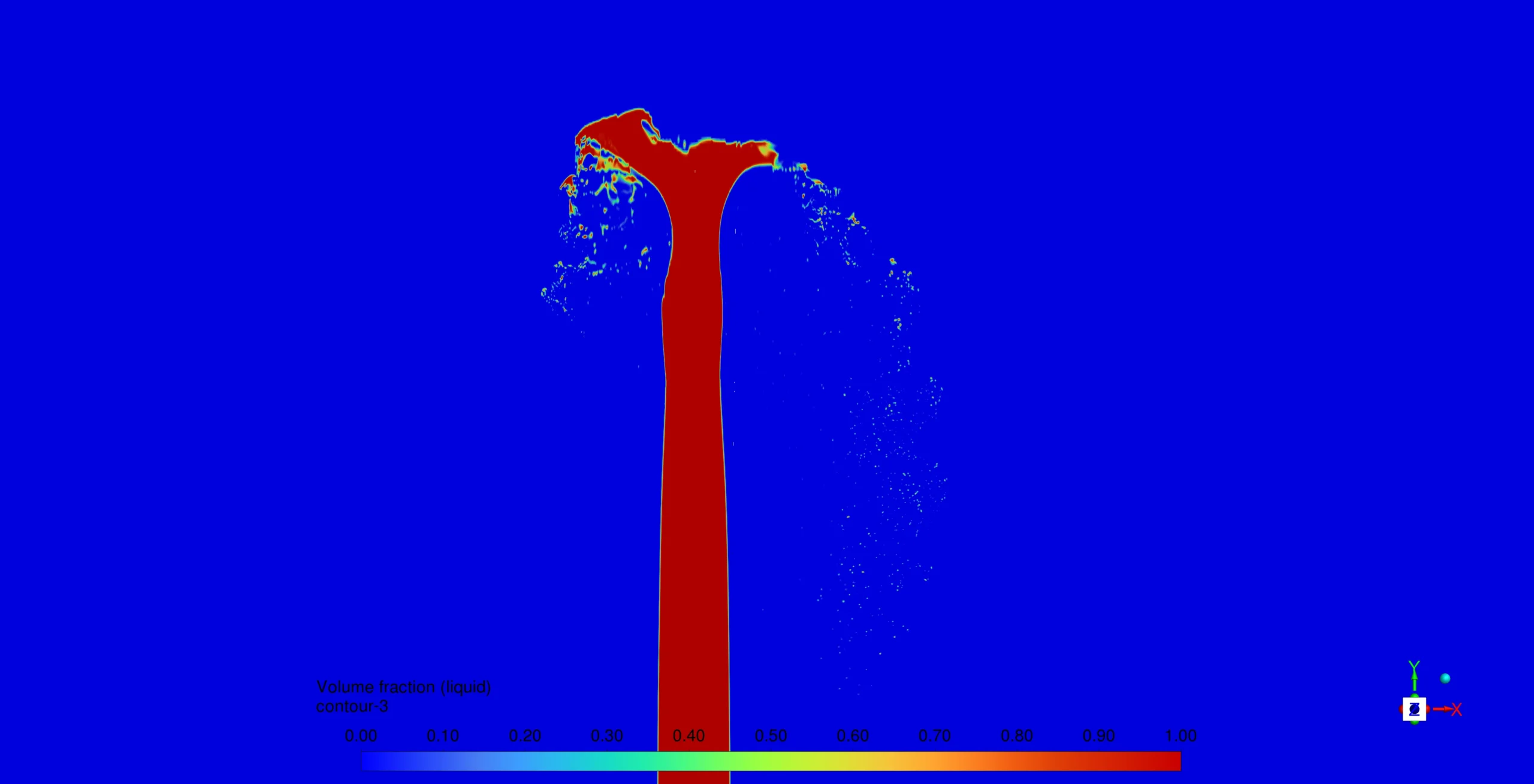

The simulation results provide a clear and detailed story of the violent process of atomization. The engine of this process is the immense velocity difference between the water jet and the surrounding air, as shown in Figure 4. The jet exits the nozzle at an incredibly high speed of 486 m/s, shearing against the stationary air. This extreme shear creates instabilities on the surface of the liquid core, causing large ligaments and chunks of water to be torn away. This initial, violent stage is known as primary breakup. The velocity contour clearly shows how the jet’s momentum is transferred to the air, creating a turbulent wake that further fuels the breakup process. The VOF-to-DPM model is essential here; it tracks these large, torn-off ligaments using the efficient VOF method while they are still connected or very large.

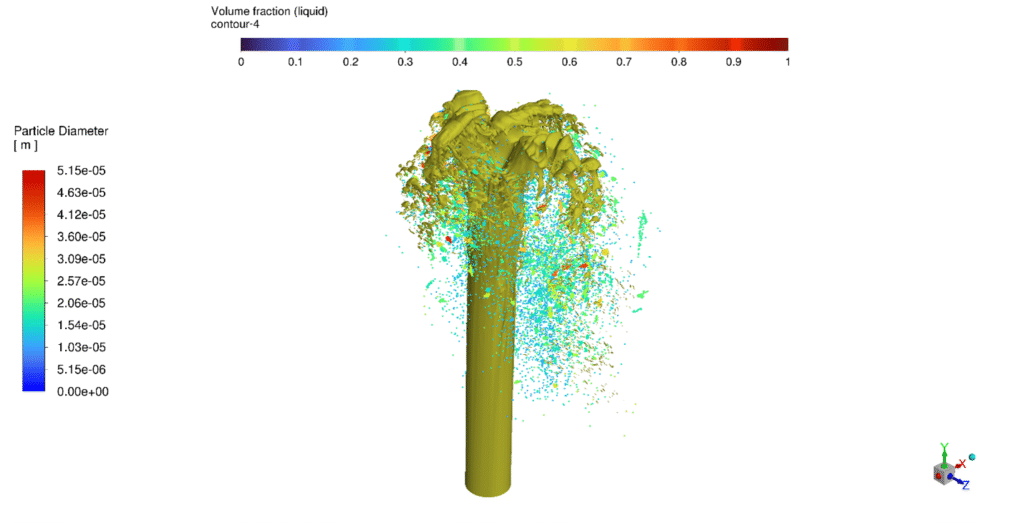

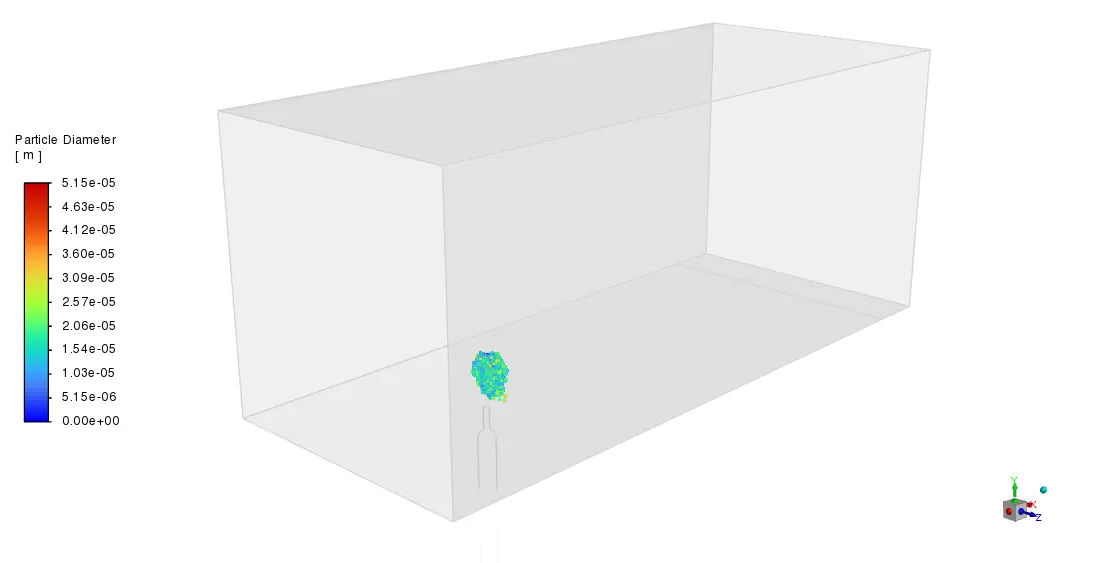

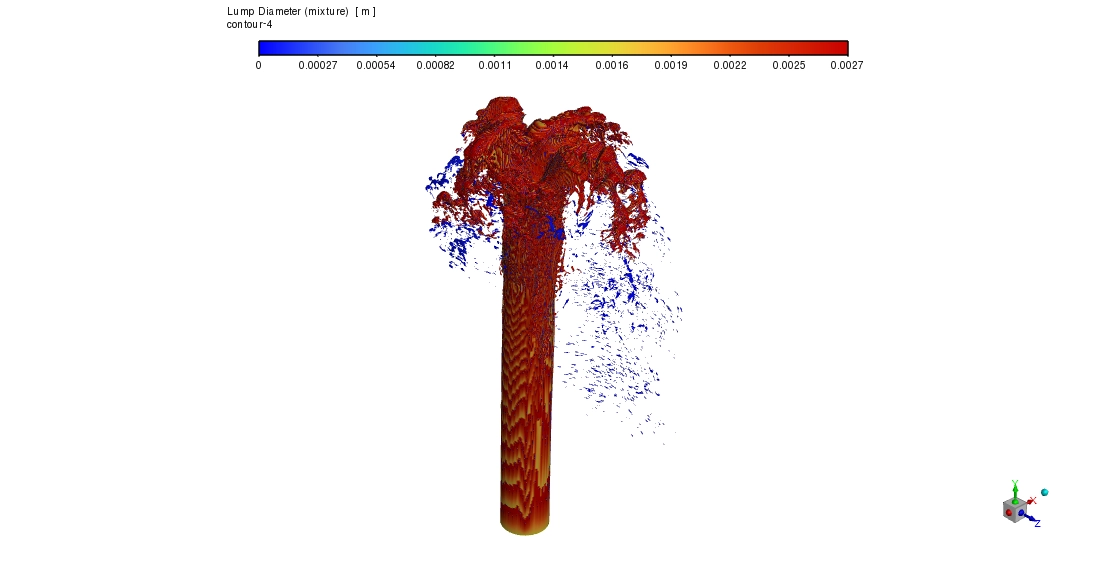

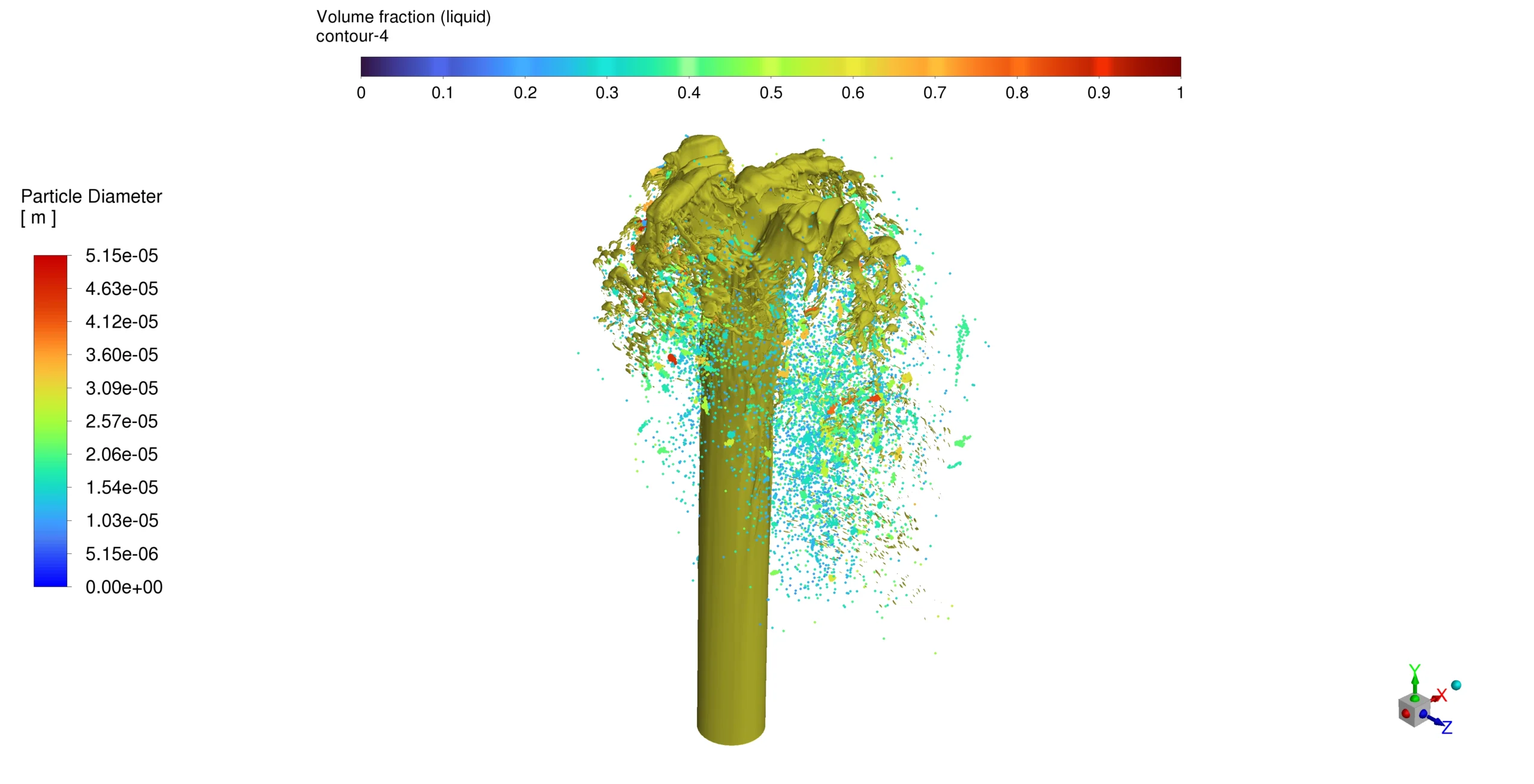

Figure 3: Particle diameter distribution and the successful VOF-to-DPM transition in the Atomization Spray CFD simulation.

Once these ligaments are fully detached and continue to tumble through the high-velocity air, they undergo secondary breakup, shattering into even smaller pieces. It is at this stage that the genius of the hybrid model comes into play. As these liquid structures become small and numerous, the VOF-to-DPM model automatically converts them from VOF bodies into efficient DPM particles, as seen in the transition in Figure 3. This saves enormous computational resources. The final result is a fully developed spray, and the particle size distribution plot provides the key engineering data. The analysis shows a range of droplet diameters from 0 to 51.5 μm, with the smallest droplets forming at the outer edges of the spray where the shear forces were strongest. The most significant achievement of this Atomization Fluent simulation is the successful application of the VOF-to-DPM model to capture the entire multi-scale physics of atomization—from a coherent jet to a fully dispersed spray—a feat that would be computationally prohibitive using either VOF or DPM alone.

Figure 4: Velocity distribution in the Water Jet Breakup CFD, showing the high-speed core that drives the atomization process.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€155 Original price was: €155.€135Current price is: €135.

€220 Original price was: €220.€125Current price is: €125.

€360 Original price was: €360.€185Current price is: €185.

€245 Original price was: €245.€199Current price is: €199.

€205 Original price was: €205.€155Current price is: €155.

Reviews

There are no reviews yet.