Blade-shape Turbulator CFD: A Fluent Guide to Heat Exchanger Enhancement

Blade-shape Turbulator CFD: A Fluent Guide to Heat Exchanger Enhancement

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€185 Original price was: €185.€125Current price is: €125.

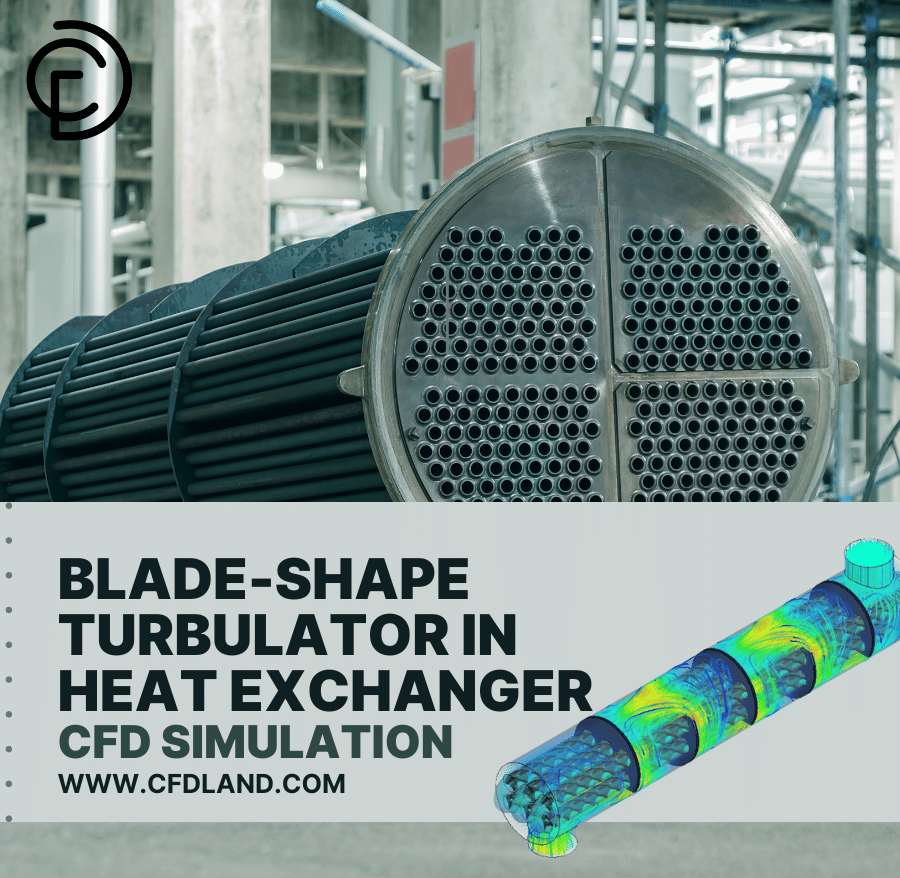

In many industries, heat exchangers are essential for controlling temperature in processes. A common type is the shell and tube heat exchanger. However, a major challenge hurts their performance. Inside the tubes, a thin layer of slow-moving fluid, called the thermal boundary layer, forms along the walls. This layer acts like a blanket, blocking heat from moving efficiently. A smart solution to this problem is to use inserts called turbulators. A Blade-shape Turbulator in Heat Exchanger CFD simulation is the best way to study these devices. These small, wing-like pieces are placed inside the tubes to break up that insulating boundary layer. They create turbulence, or swirling flow, which forces the fluid to mix better. This report details a Heat Exchanger CFD analysis using ANSYS Fluent to see exactly how a Blade-shape Turbulator improves thermal performance, guided by the methods in the reference paper [1].

Figure 1: The 3D geometry used for the Blade-shape Turbulator CFD simulation.

Simulation Process: Modeling the Heat Exchanger with Blade-shape Turbulators in Fluent

To build an accurate simulation, the complex geometry was first created in Design Modeler. This included the main shell with its baffles and the tubes containing the special blade-shaped inserts. Because the shape is complicated, an unstructured tetrahedral mesh was generated, containing 6,500,644 cells. This large number of cells is needed to capture the fine details of the flow around each Turbulator CFD model.

In ANSYS Fluent, the physics was set up to match real-world conditions. The energy equation was enabled to calculate heat transfer. Hot water at 353 K was set to flow in the shell, and cold water at 293 K was set to flow through the tubes. The tubes themselves were modeled as steel, a common material that allows heat to pass through it easily.

Post-processing: How the Turbulator CFD Improves Heat Transfer

The simulation results provide a clear and fully substantiated story of cause and effect, which begins with the fluid dynamics. In a plain, empty tube, the water would flow in smooth layers. The water near the wall would be slow and cold, while the water in the center would be faster and warmer. The velocity contour in Figure 2 shows how the Blade-shape Turbulator completely changes this. The blades act like small wings in the flow. They force the water to speed up and flow around them, creating wake zones and swirling vortices behind each blade. These vortices act like small, powerful mixing paddles. They aggressively scrape the slow, cold fluid away from the tube walls and mix it into the main, faster-moving stream. This turbulent mixing is the direct physical cause of the heat transfer enhancement.

Figure 2: Velocity and temperature fields from the Heat Exchanger CFD simulation, showing the effect of the Blade-shape Turbulator.

This dramatic change in flow has a direct and measurable effect on the thermal performance. Because the cold boundary layer has been destroyed, heat from the hot steel walls can now transfer into the moving water much more effectively. The temperature contour in Figure 2 shows this in action; the temperature distribution inside the tube is much more uniform compared to how it would be in a plain tube. The final numbers prove the success of the design. The water leaving the tubes with turbulators reached a temperature of 318.15 K. A comparison simulation with clean tubes showed an outlet temperature of only 314.73 K. The most significant achievement of this Blade-shape Turbulator in Heat Exchanger Fluent simulation is the clear link between the turbulence shown in the velocity field and the resulting 3.42 K increase in outlet temperature. This provides a complete engineering understanding of how these simple devices can make a heat exchanger work much better.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€145 Original price was: €145.€95Current price is: €95.

€190 Original price was: €190.€99Current price is: €99.

€120 Original price was: €120.€75Current price is: €75.

€160 Original price was: €160.€75Current price is: €75.

€130 Original price was: €130.€85Current price is: €85.

Reviews

There are no reviews yet.