CFD-PBM Simulation of Gas-liquid Flow in Bubble Column: Analyzing Bubble Size Distribution with ANSYS Fluent

CFD-PBM Simulation of Gas-liquid Flow in Bubble Column: Analyzing Bubble Size Distribution with ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140

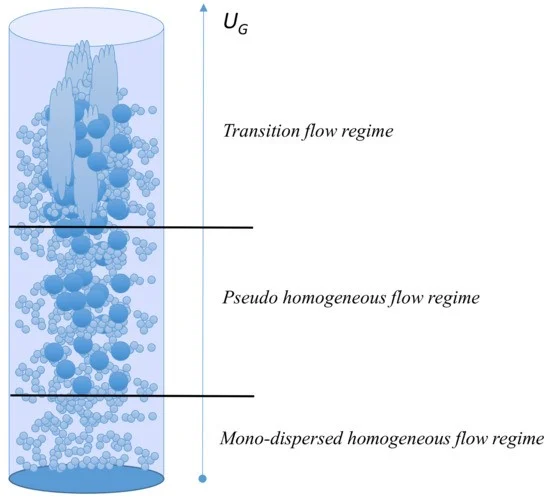

In this CFD-PBM Simulation of Gas-liquid tutorial, we provide a complete training guide on optimizing chemical reactors. A Bubble Column is a simple but effective vessel used in engineering. Gas enters at the bottom and rises through a liquid, creating mixing. To design these vessels correctly, engineers must predict how bubbles behave. This is difficult because bubbles are not constant; they break apart into smaller ones or join together (coalesce) to form larger ones. If we assume all bubbles are the same size, our calculations will be wrong.

To solve this, we use the ANSYS Fluent Population Balance Model (PBM). This advanced method tracks the “population” of bubbles and calculates their exact sizes over time. By performing a CFD Analysis of Gas-liquid in Bubble column, we can predict the gas holdup (how much gas is in the tank) and the liquid circulation. This simulation helps manufacturers design better spargers (gas injectors). If we can create the perfect bubble size, we improve the chemical reaction speed and save energy. For more examples of complex multiphase flows, please visit our Multiphase tutorials.

- Reference [1]: Liang, Xiao-Fei, et al. “CFD-PBM approach with modified drag model for the gas–liquid flow in a bubble column.” Chemical Engineering Research and Design112 (2016): 88-102.

- Reference [2]: Yum, Kyungtaek, Sung Hoon Kim, and Heekyung Park. “Effects of plume spacing and flowrate on destratification efficiency of air diffusers.” Water research13 (2008): 3249-3262.

Figure 1: Schematic of the Bubble Column used for the CFD-PBM Simulation of Gas-liquid, showing the gas inlet at the bottom and the liquid domain.

Simulation Process: Eulerian-PBM Setup in ANSYS Fluent

For this CFD-PBM Simulation of Gas-liquid project, we simplified the geometry to a 2D axisymmetric model. This allows us to simulate a vertical slice of the cylinder, which saves calculation time. We generated a structured mesh with 4,750 quadrilateral cells. We refined the grid near the inlet (where gas enters) and the walls. This fine mesh is necessary to capture the sharp flow gradients and shear forces that cause bubbles to break.

We set up the physics in ANSYS Fluent using the Eulerian Multiphase Model. We defined water as the primary continuous phase and air as the secondary dispersed phase. To strictly track bubble sizes, we activated the Population Balance Model ANSYS fluent. We chose the Discrete Method and divided the bubbles into 6 specific bins (size groups). We also enabled the Aggregation and Breakage Kernels. These mathematical equations calculate how often bubbles collide or split due to turbulence. We used a transient solver to capture the time-dependent changes. This setup ensures that the CFD-PBM Simulation of Gas-liquid accurately predicts the dynamic equilibrium of the bubble population.

Post-processing: CFD-PBM Simulation of Gas-liquid and Bin Analysis

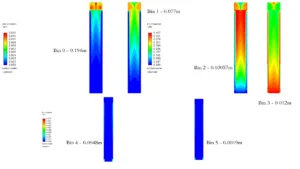

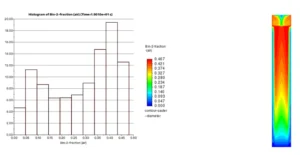

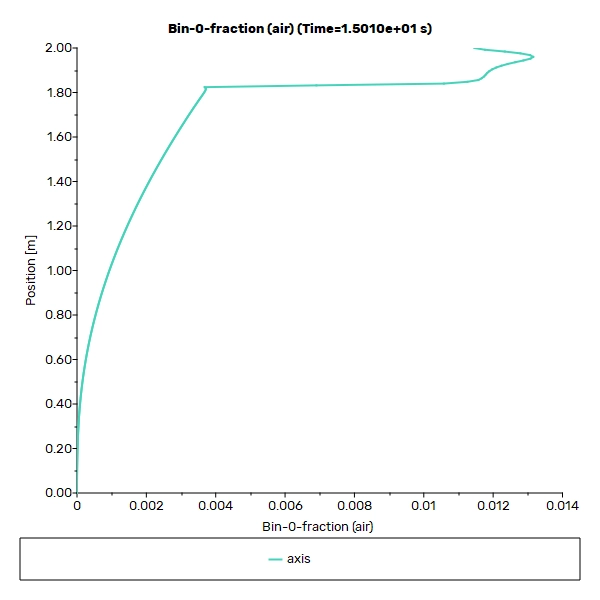

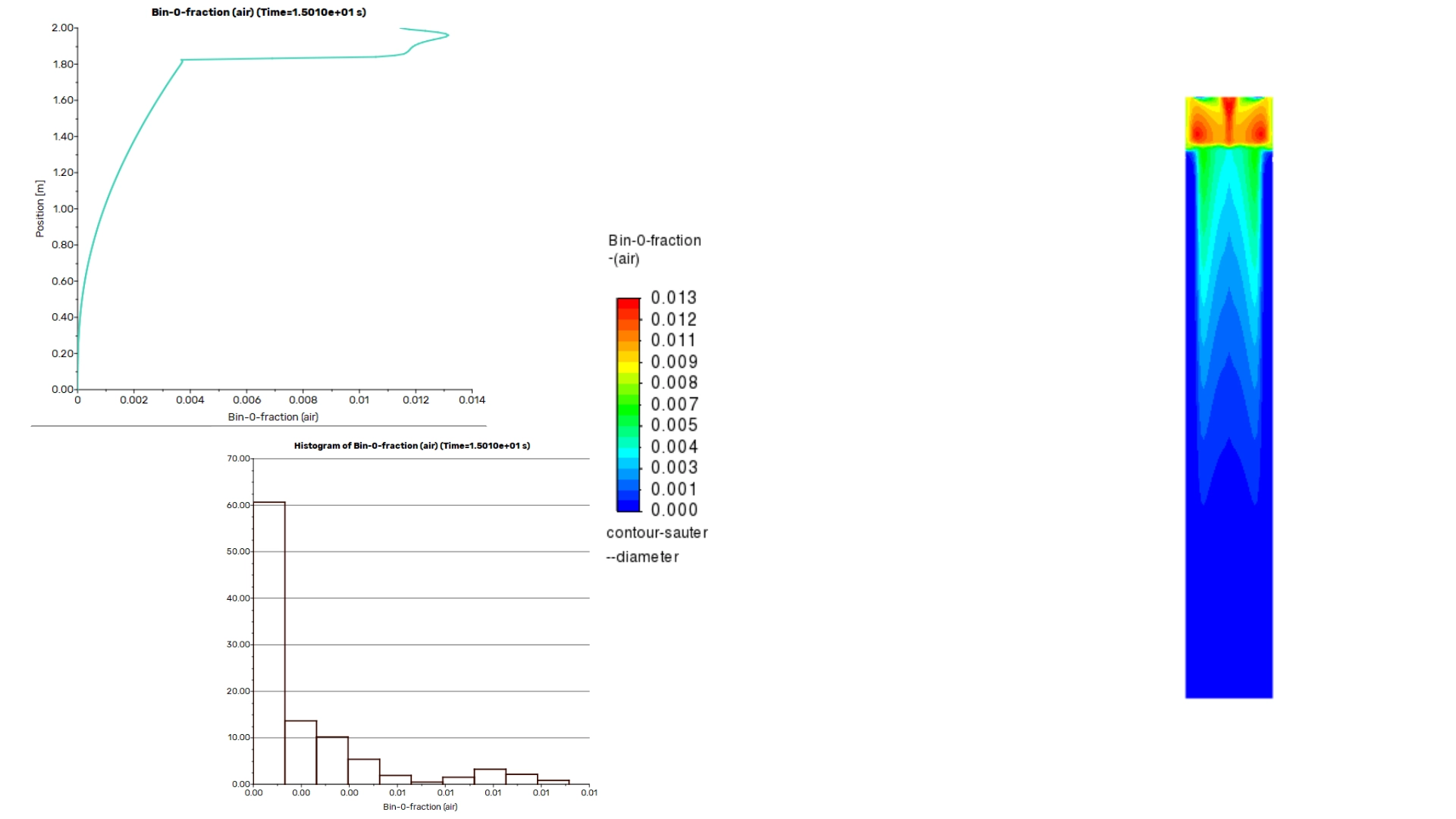

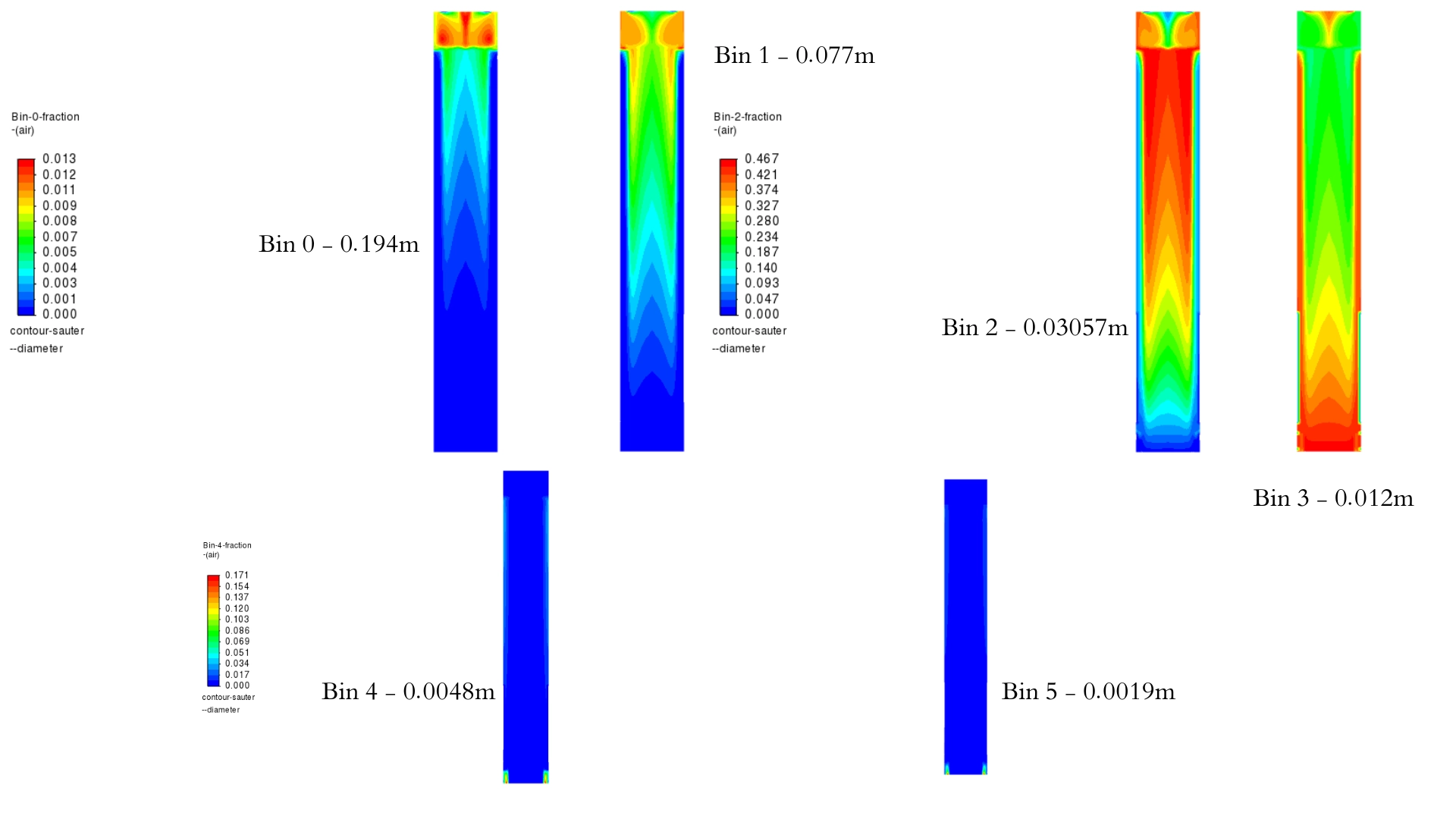

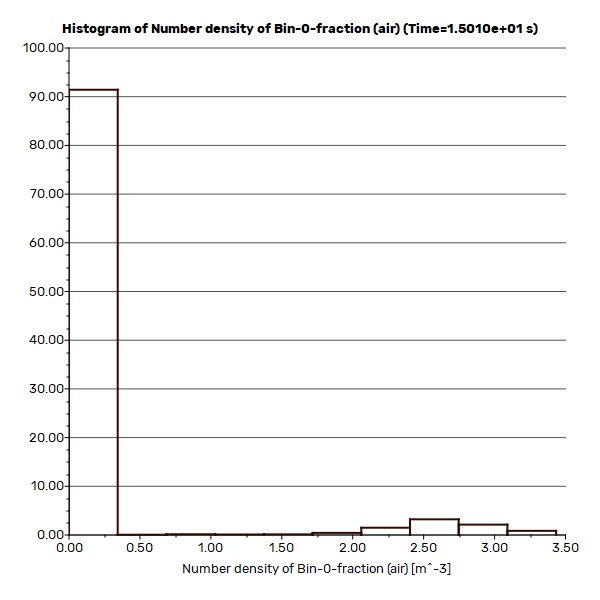

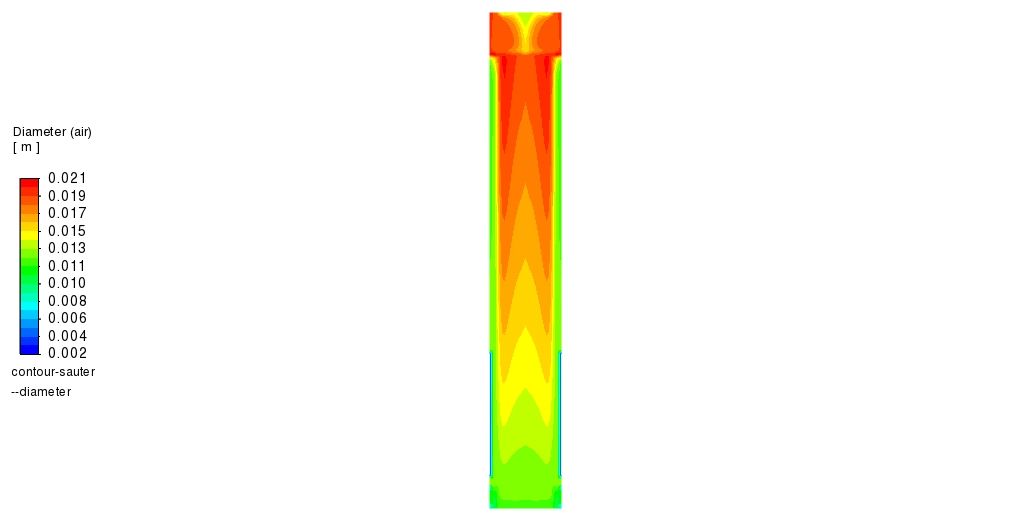

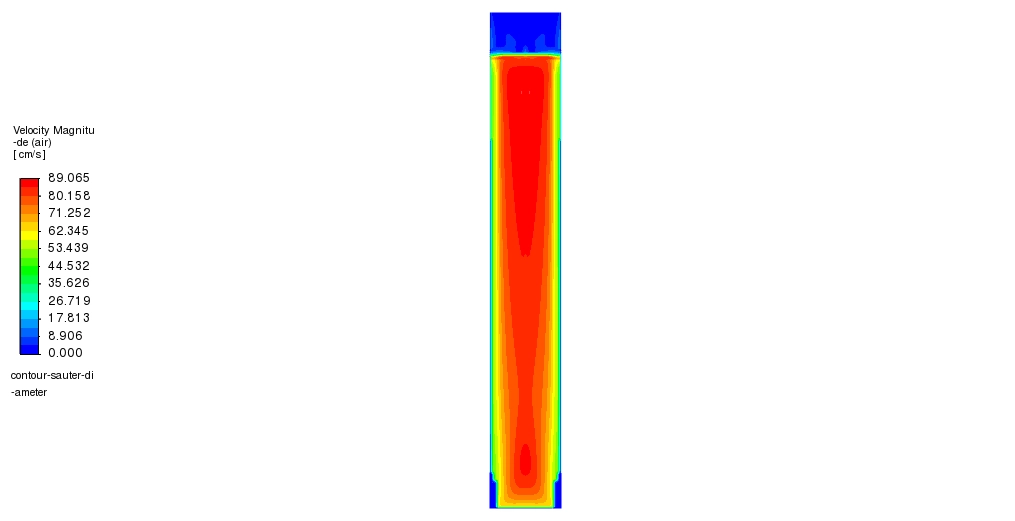

In this section, we provide a deep engineering analysis of the results. Instead of looking at average properties, we analyze specific Bins to see which bubble sizes dominate the flow. First, we analyze the Large Bubble Distribution (Bin 0) in Figure 2 and Figure 3. Bin 0 represents the largest bubbles with a diameter of 0.194 m. The contour for this bin is mostly blue, and the maximum volume fraction is only 1.3%. From an engineering perspective, this low percentage is expected. Large bubbles are very unstable. The high turbulence in the column shears them apart quickly. Furthermore, large bubbles have high buoyancy, so they rise to the top and exit the domain instantly. This is a positive result for the designer because large bubbles have a low surface-area-to-volume ratio, making them poor for mass transfer.

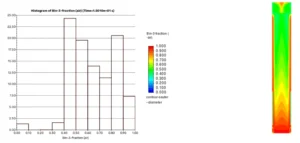

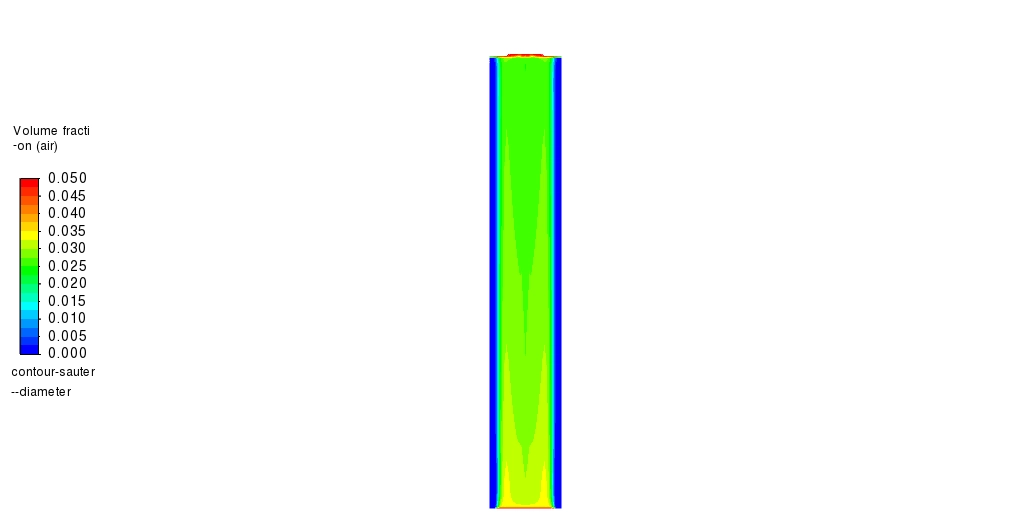

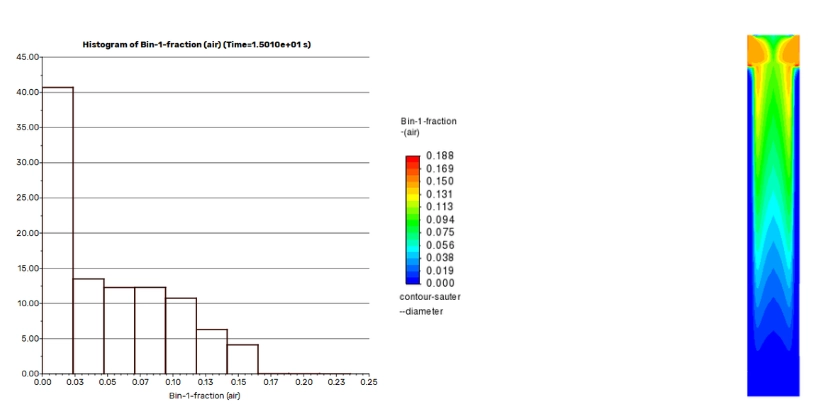

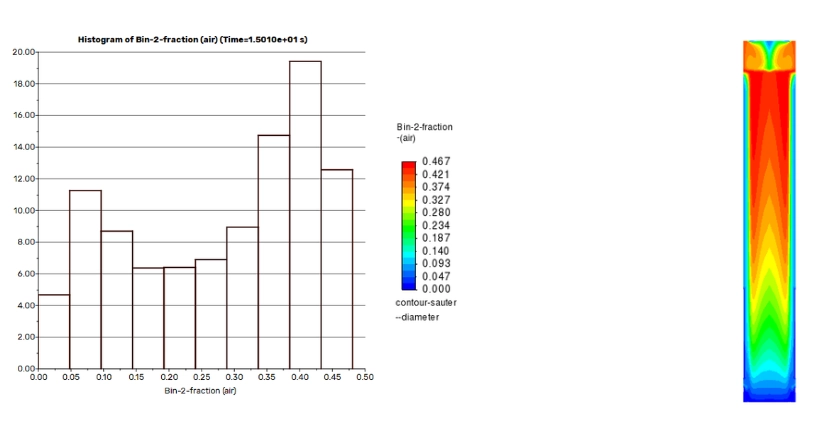

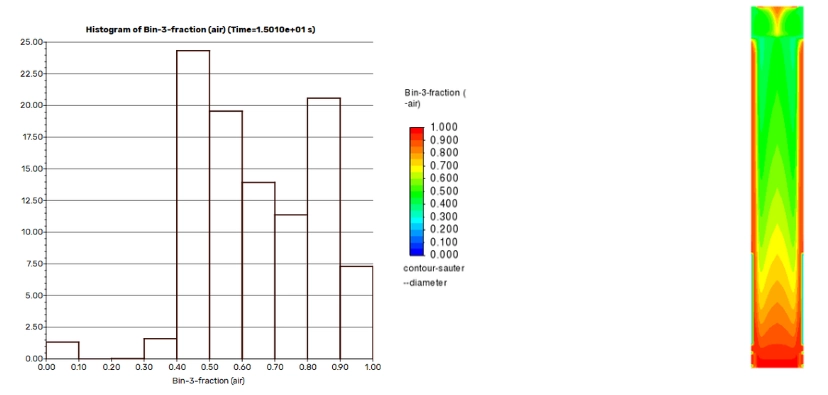

Next, we identify the Dominant Sweet Spot (Bin 2 and Bin 3) shown in Figures 4 and 5. The contours here are Red and Orange, indicating high concentration. Bin 2 (0.03 m) and Bin 3 (0.012 m) reach volume fractions of 46.7% and >50% respectively. The CFD-PBM Simulation of Gas-liquid reveals that the flow naturally favors these medium sizes. This occurs because the breakage and coalescence rates balance out at this diameter. For a manufacturer, this is the ideal operating range. These medium bubbles rise slower than the large ones, giving them more Residence Time in the liquid to react chemically.

Table 1: Bubble Population Data from Fluent

| Parameter | Size (Diameter) | Max Fraction | Analysis for Designers |

| Bin 0 (Largest) | 0.194 m | 0.013 (1.3%) | Rare and unstable. Low impact on process. |

| Bin 1 | 0.077 m | 0.467 (46.7%) | Concentrated at top. Quick exit. |

| Bin 2 (Medium) | 0.030 m | 0.467 (46.7%) | Dominant Phase. Good mixing range. |

| Bin 3 (Small) | 0.012 m | High (>50%) | Most Abundant. Best for mass transfer |

Figure 2: Bubble size distribution contours from CFD-PBM simulation in ANSYS Fluent showing volume fraction of air in each of the 6 bins.

Figure 3: Bin 0 Histogram and cumulative distribution of Bin-0 volume fraction (0.194 m diameter, largest bubbles) showing low occurrence.

Figure 4: Histogram of Bin-2 volume fraction (0.03057 m diameter, medium-sized bubbles) showing high concentration.

Figure 5: Histogram of Bin-3 volume fraction (0.012 m diameter, small bubbles) indicating this is the most abundant size.

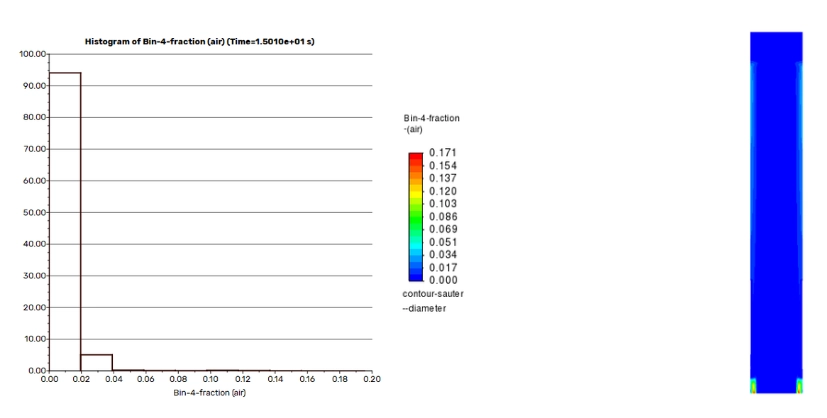

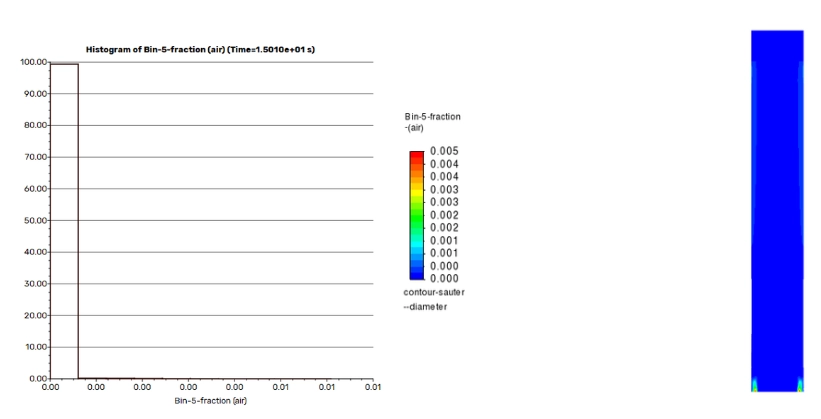

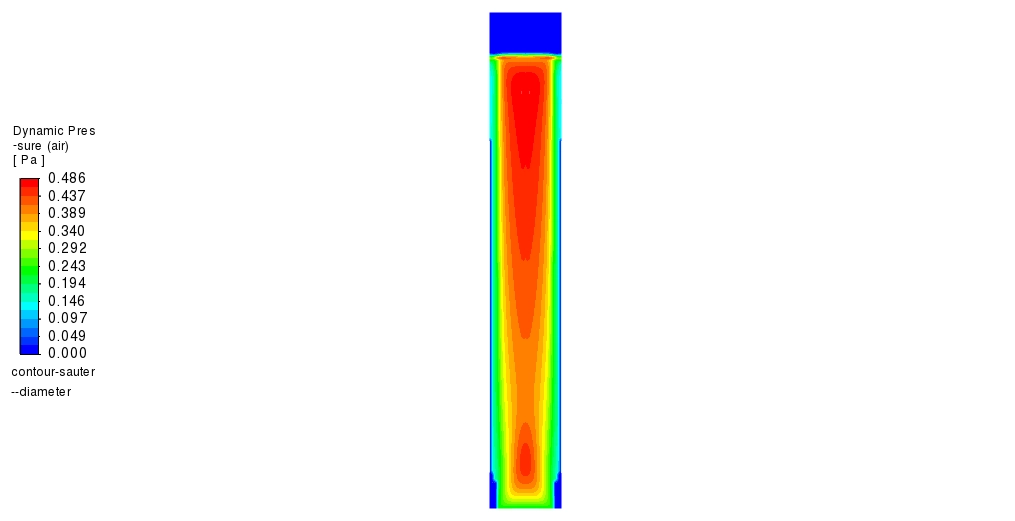

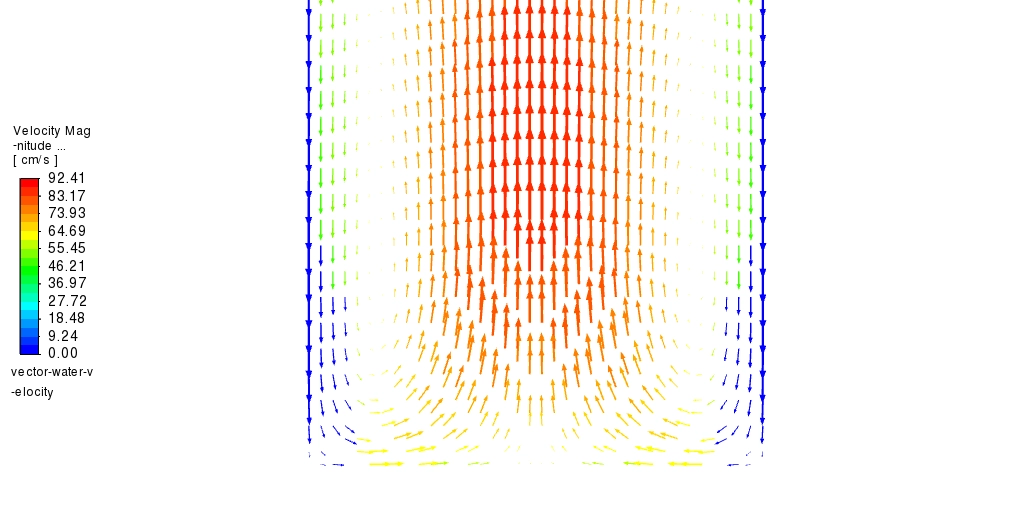

Finally, we observe the Tiny Bubble Disappearance (Bin 4 and Bin 5). The analysis shows zero fraction for these very small diameters. This indicates that Coalescence is dominant for tiny bubbles; they collide and immediately merge into the stable medium-sized groups (Bin 3). The Velocity Vectors in Figure 6 further confirm the mixing efficiency, showing a strong recirculation loop that helps distribute these medium bubbles across the entire column height. This proves the sparger design is efficient.

Figure 6: Velocity vectors inside the bubble column visualizing the recirculation and mixing pattern.

Key Takeaways & FAQ

- Q: Why use PBM instead of standard VOF?

- A: VOF assumes one continuous interface. PBM is required to simulate thousands of bubbles of different sizes interacting (breaking/merging).

- Q: Which bin size is best for reactors?

- A: Medium bins (Bin 2 & 3). They offer the best balance of surface area and residence time for chemical reactions.

- Q: What controls the bubble size?

- A: The “Breakage Kernel” (turbulence splitting bubbles) and “Aggregation Kernel” (bubbles merging) defined in the PBM setup.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€145 Original price was: €145.€65Current price is: €65.

€145 Original price was: €145.€115Current price is: €115.

€190 Original price was: €190.€165Current price is: €165.

€155 Original price was: €155.€99Current price is: €99.

€360 Original price was: €360.€185Current price is: €185.

€330 Original price was: €330.€199Current price is: €199.

Reviews

There are no reviews yet.