Combustion with Water Cooling CFD Simulation – ANSYS Fluent Tutorial

Combustion with Water Cooling CFD Simulation – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€175 Original price was: €175.€150Current price is: €150.

Want to see how water cooling affects burning? This CFD study shows you how to model combustion with water cooling using ANSYS Fluent! Water cooled combustion is super important in engines, power plants, and industrial burners where controlling heat is critical. Our step-by-step guide helps you set up a complete CFD simulation to show how water cooling systems keep combustion chambers from melting down. You’ll learn how to model the hot flame and the cooling jacket working together to manage temperature. This type of cooling for combustion simulation helps engineers design better water cooling systems that prevent dangerous overheating while maximizing efficiency. Using computational fluid dynamics for combustion cooling saves thousands in testing costs and helps spot problems before building anything real. This tutorial explains combustion modeling and heat transfer in simple terms and shows how water cooled combustion chambers maintain the perfect temperature distribution. Whether you’re designing industrial burners, studying flame cooling techniques, or improving thermal management in engines, this guide makes complicated combustion CFD with cooling easy to understand!

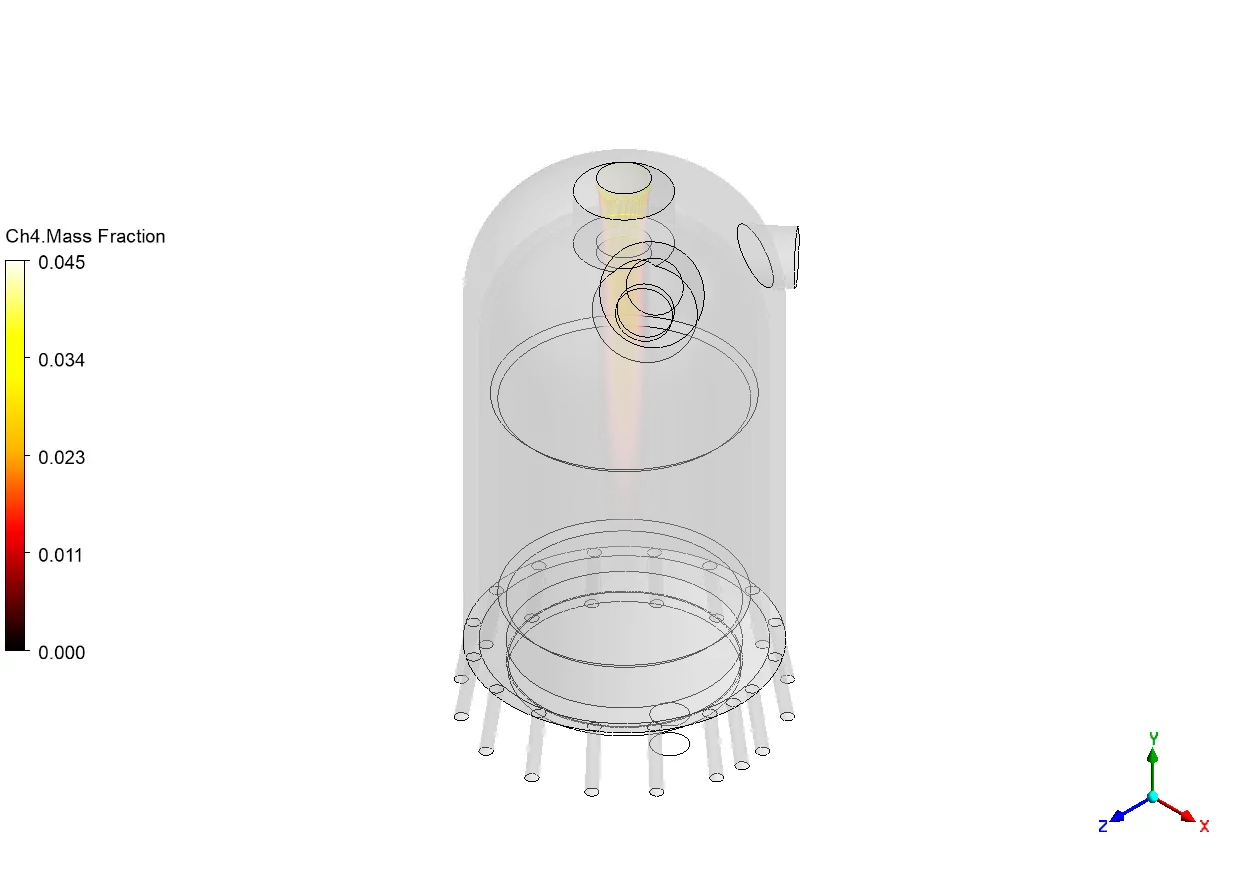

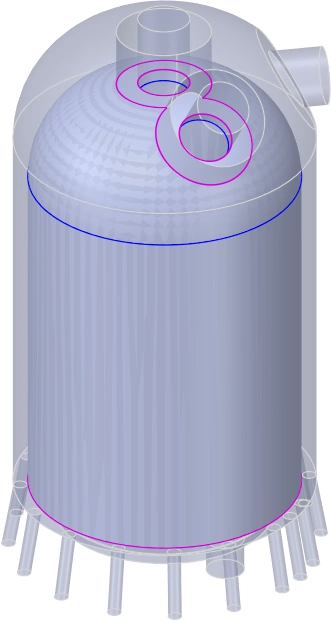

Figure 1: Schematic of water cooling jacket around combustion chamber

Simulation Process

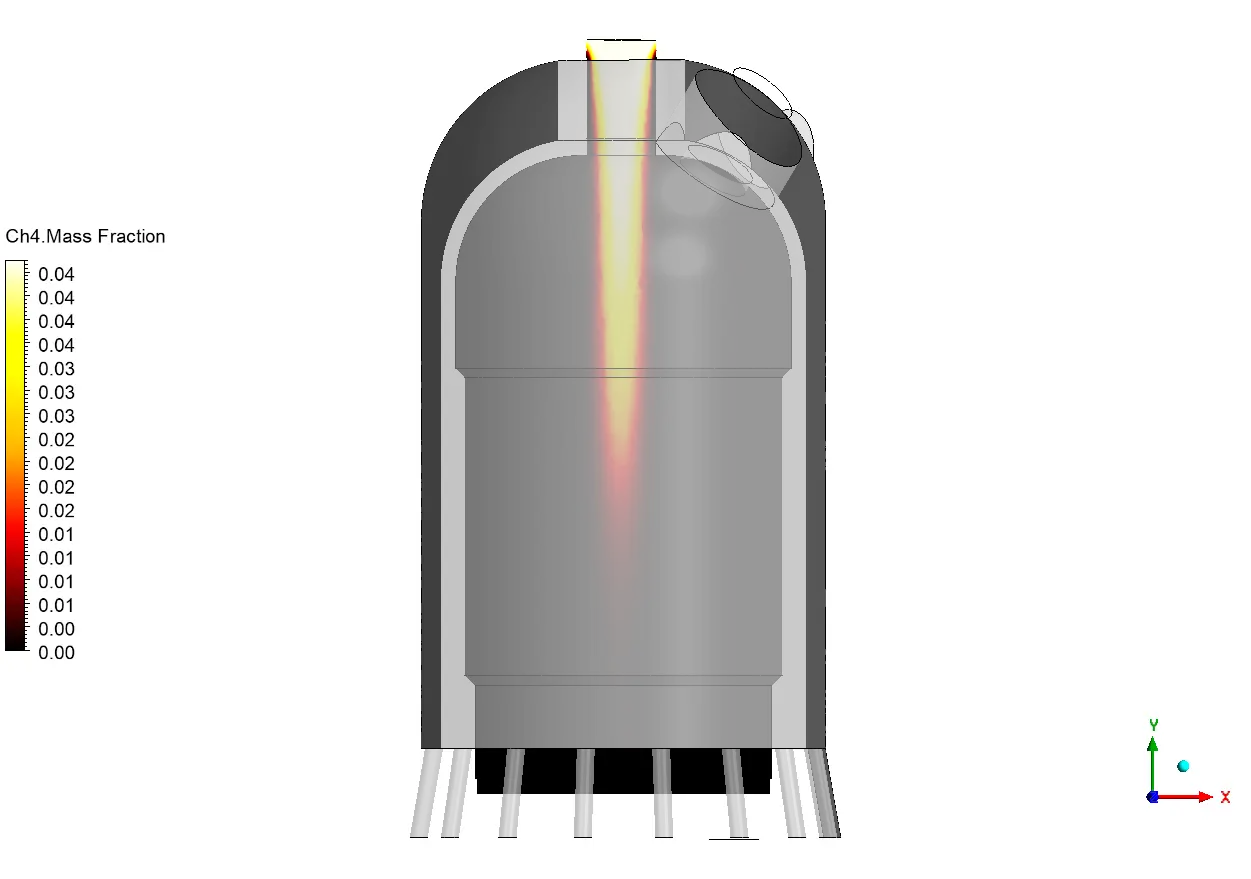

For our water-cooled combustion model, we started by creating the geometry in ANSYS SpaceClaim, making sure to include both the main combustion chamber and the surrounding water cooling jacket. This two-domain approach lets us simulate both fluids at once. After building the model, we created a high-quality mesh in Fluent Meshing with special attention to the interface between the hot combustion gases and cooling water walls where most heat transfer happens. For the physics setup, we activated the Species Transport model to track the combustion reaction of CH4 + 2O2 → CO2 + 2H2O, which creates all that heat. The conjugate heat transfer between domains was handled automatically by Fluent, letting us see exactly how water cooling removes heat from the hot combustion chamber walls through conduction and convection processes.

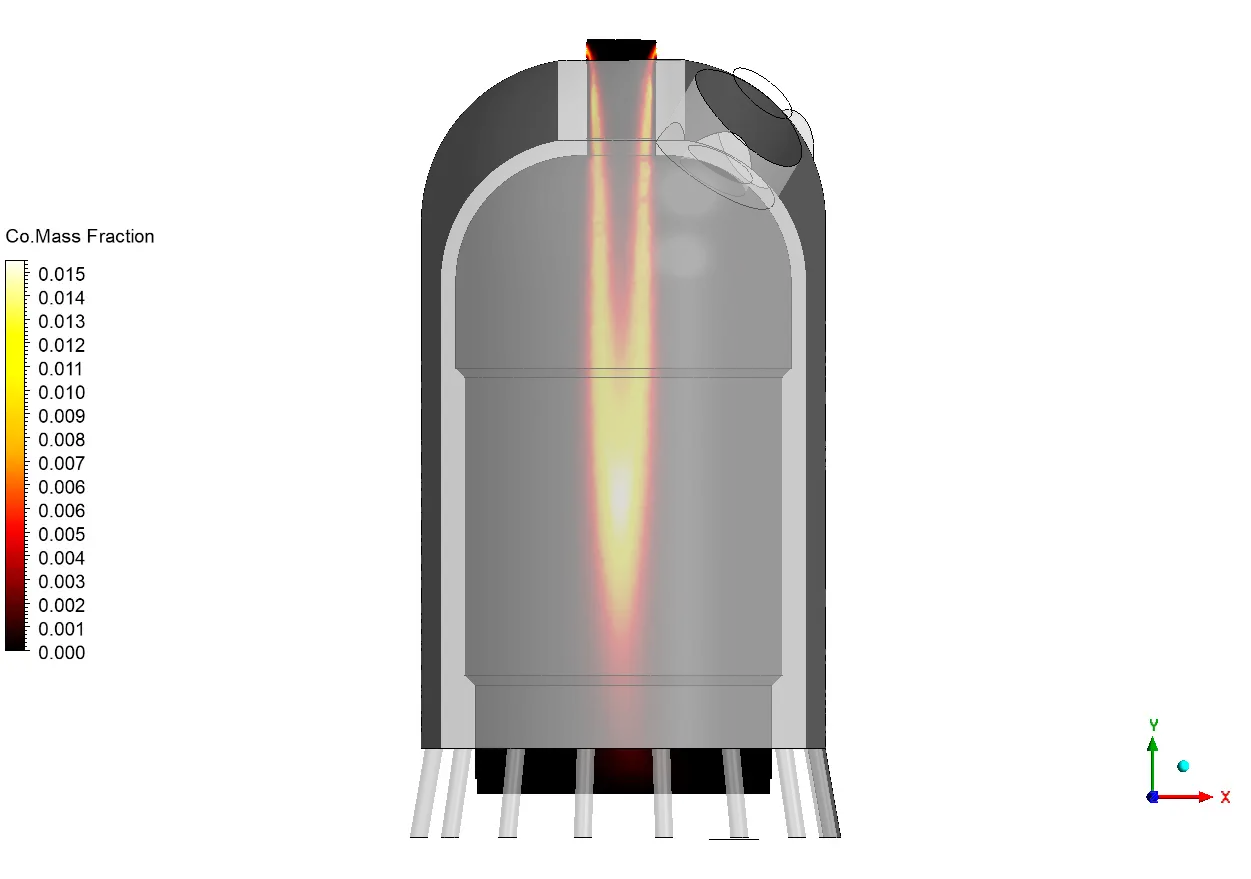

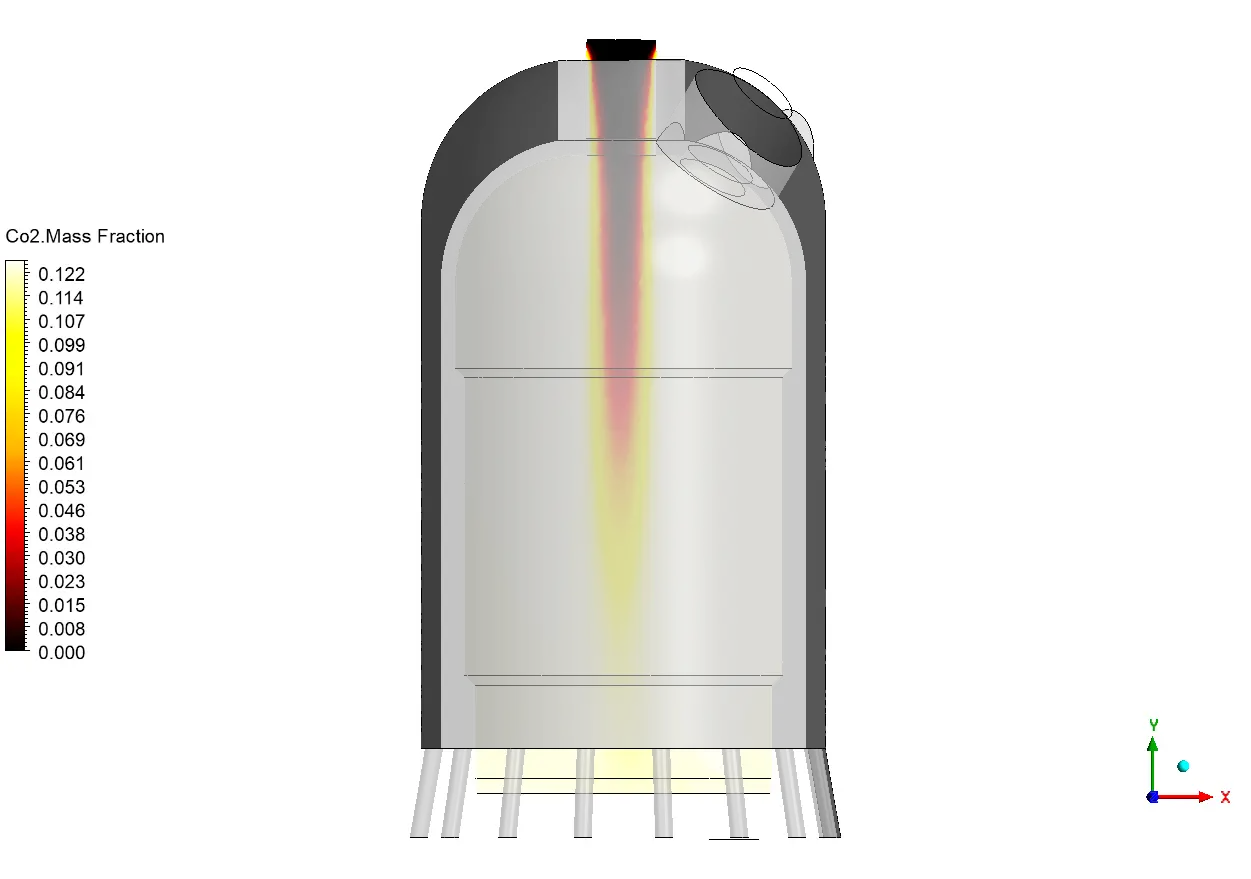

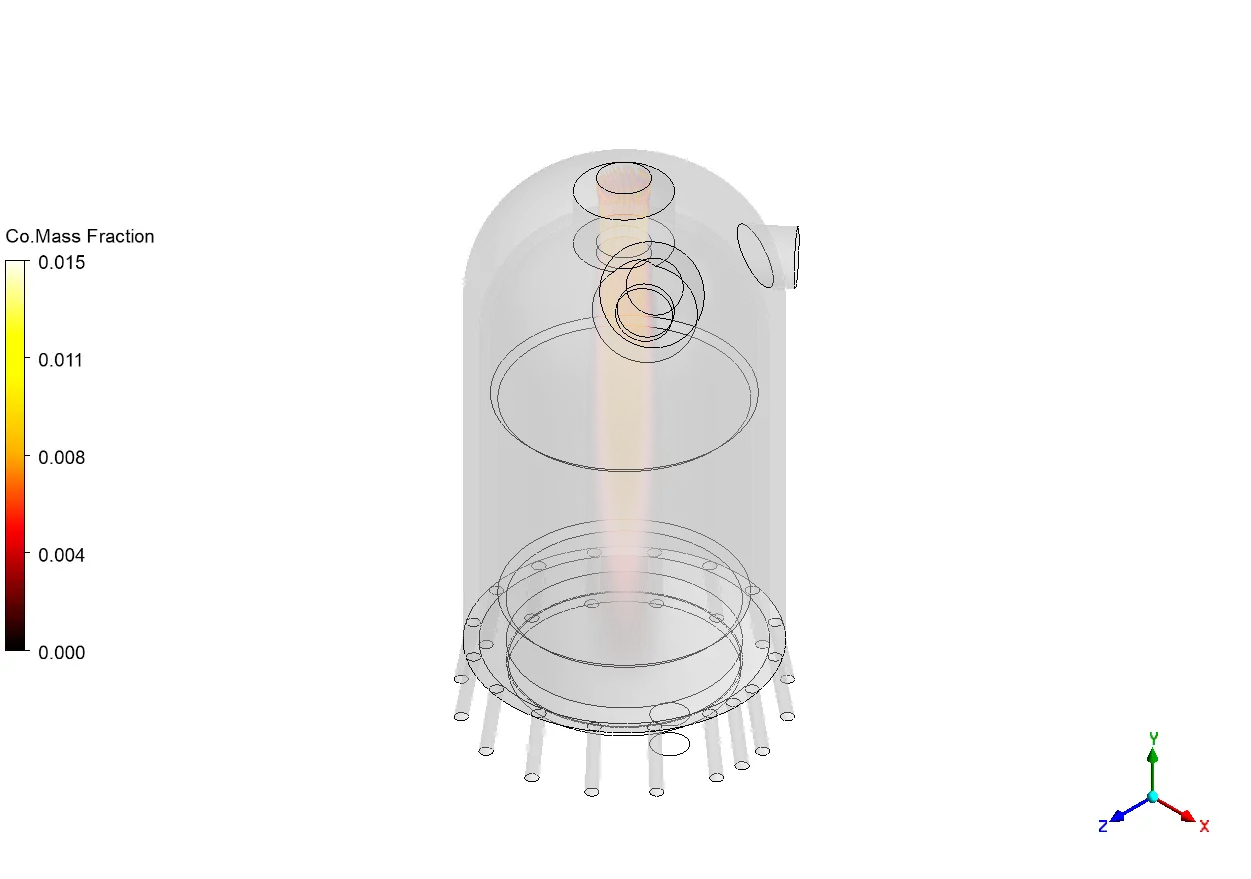

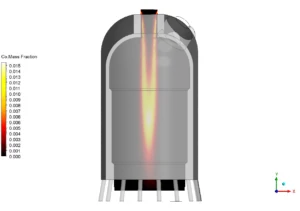

Figure 2: Flame visualization in terms of Co mass fraction contour

Post-processing

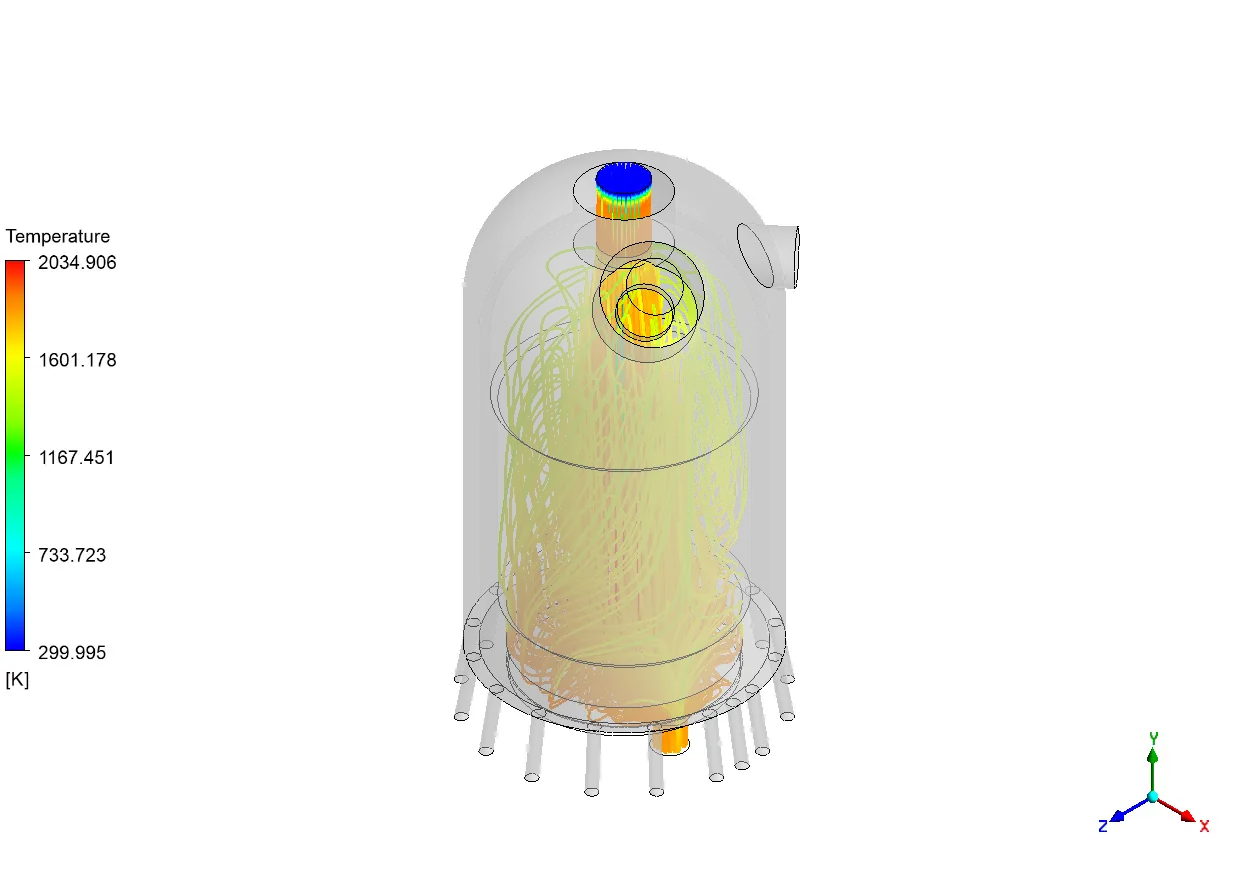

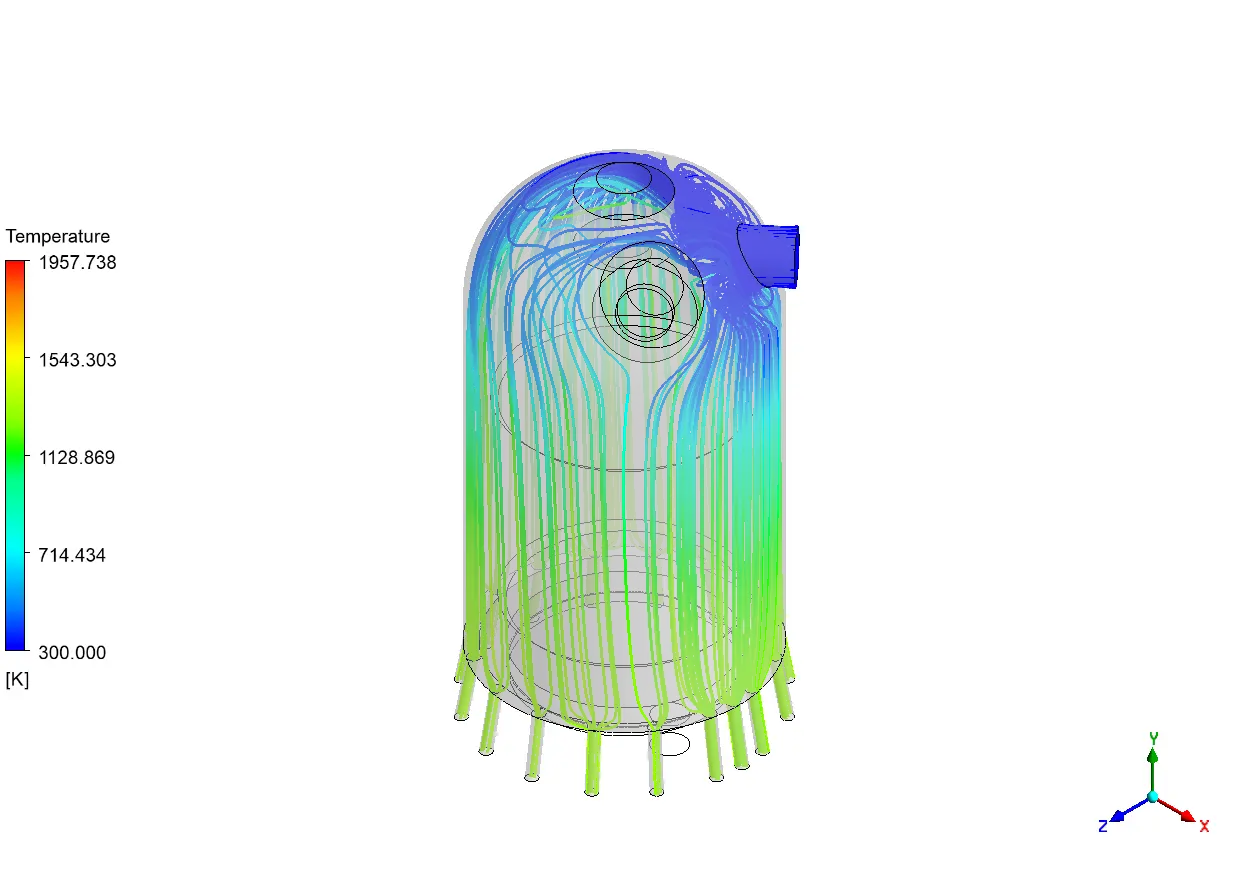

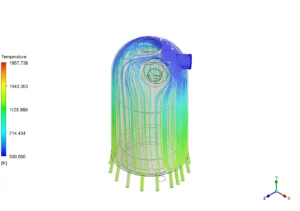

The temperature contours clarify the dramatic cooling effect of our water jacket design. Looking at the central chamber, we can see temperatures reaching nearly 2000K (bright orange) in the main combustion zone where the methane-air reaction is most intense. What’s fascinating is how quickly temperatures drop near the walls (green areas) where the water cooling extracts heat. The streamlines show hot gases moving upward while gradually cooling, creating a temperature gradient of over 1000K from center to wall. Our simulation predicts outlet gas temperatures of 1792K compared to inlet temperatures of 300K, confirming the intense heat generation from combustion. The most impressive finding is that despite this extreme heating, the chamber walls stay relatively cool thanks to effective heat transfer to the cooling water. This explains why properly designed water cooling systems are absolutely critical for preventing material failure in high-temperature combustion applications.

Figure 3: Temperature Distribution with Flow Streamlines

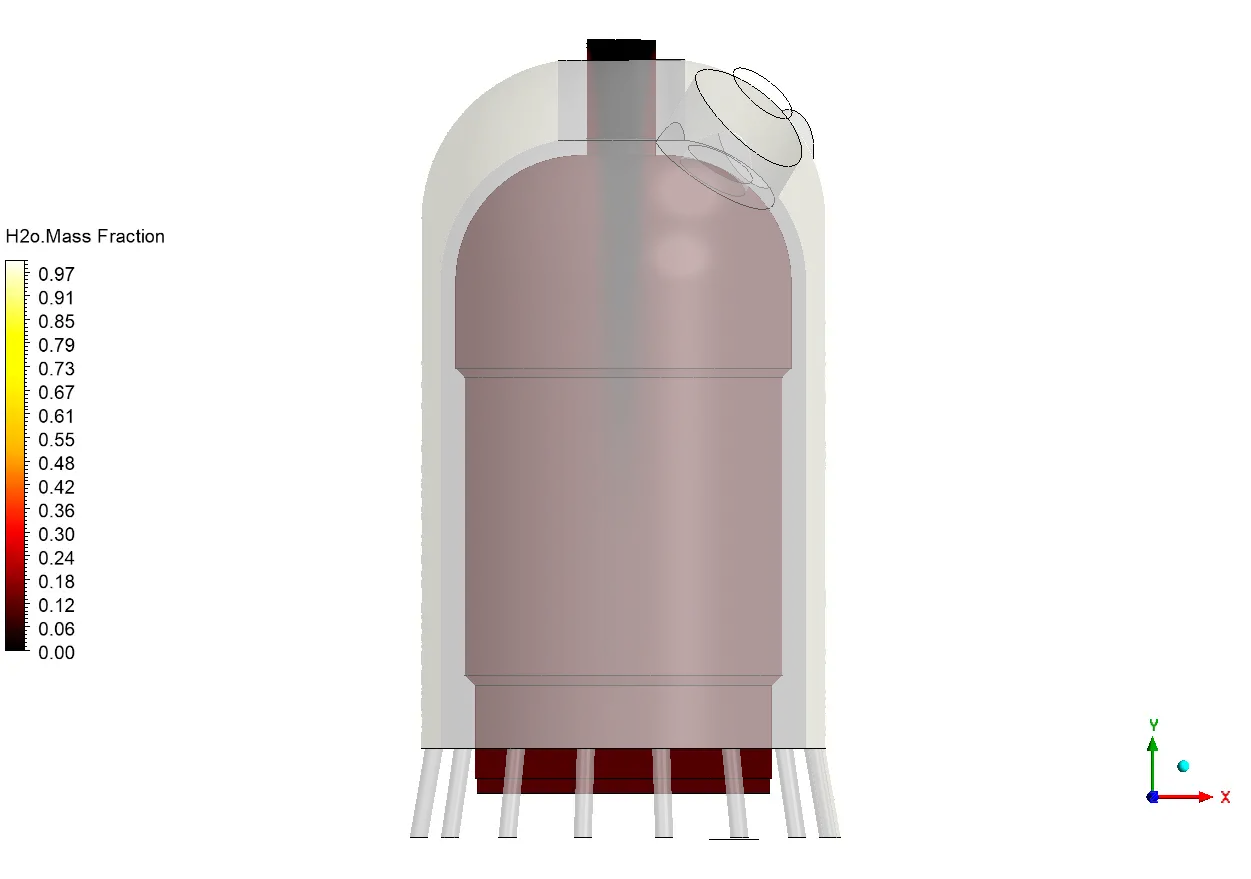

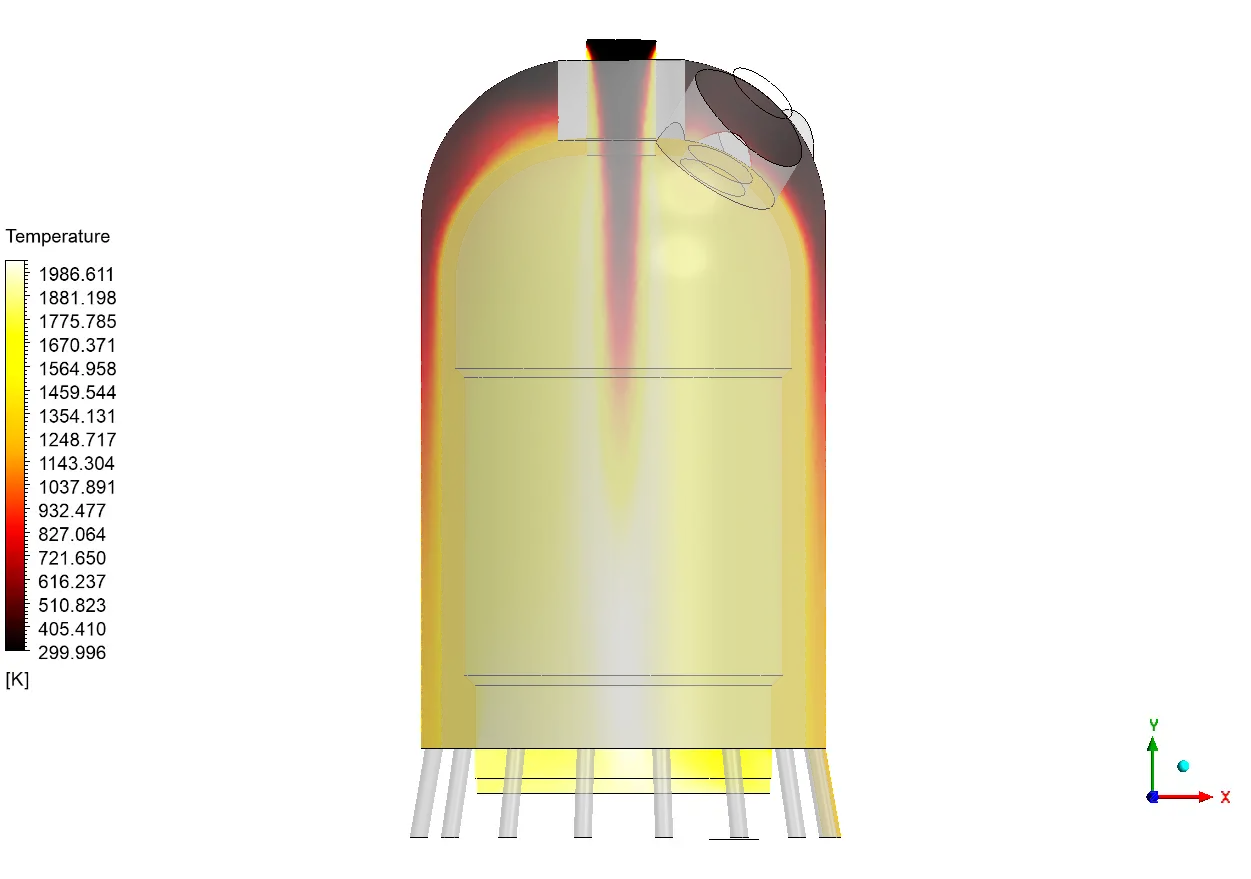

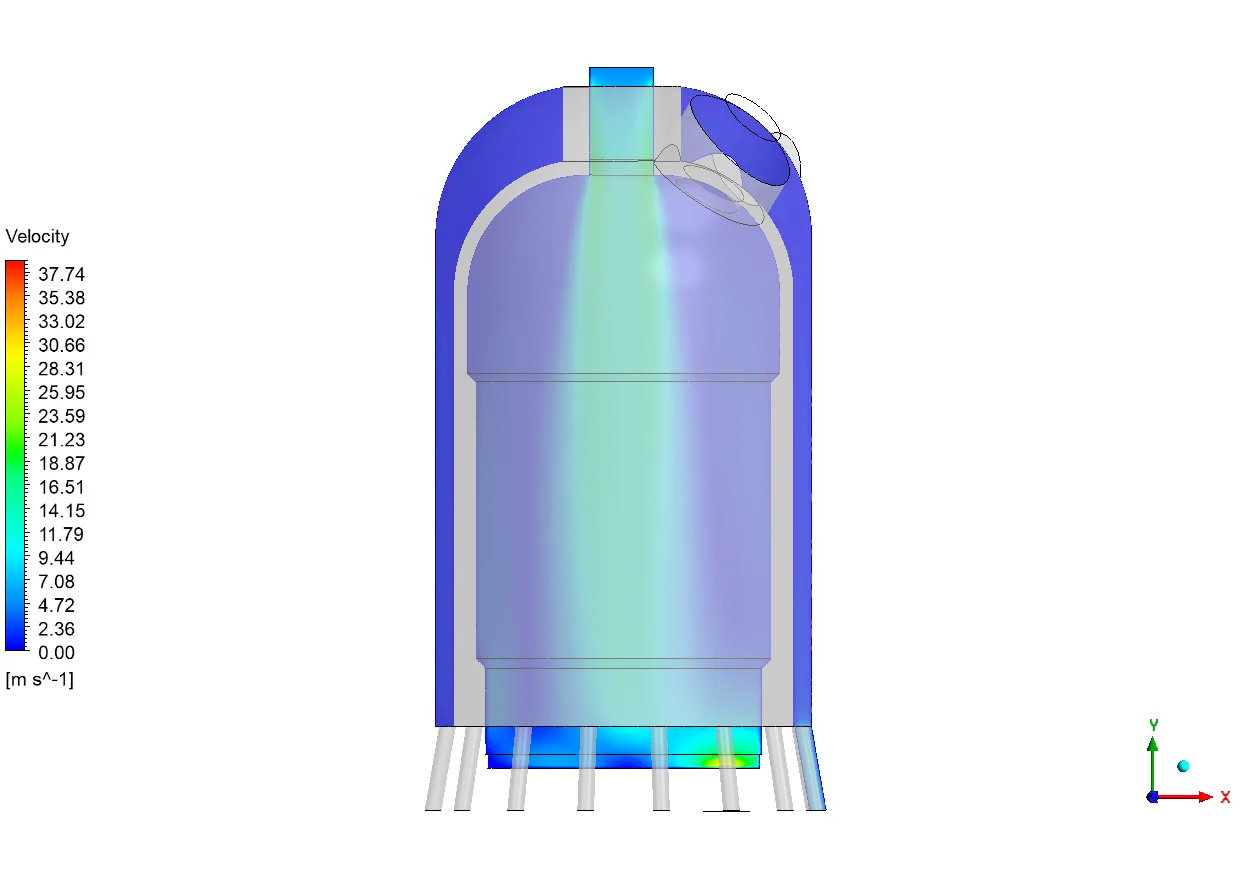

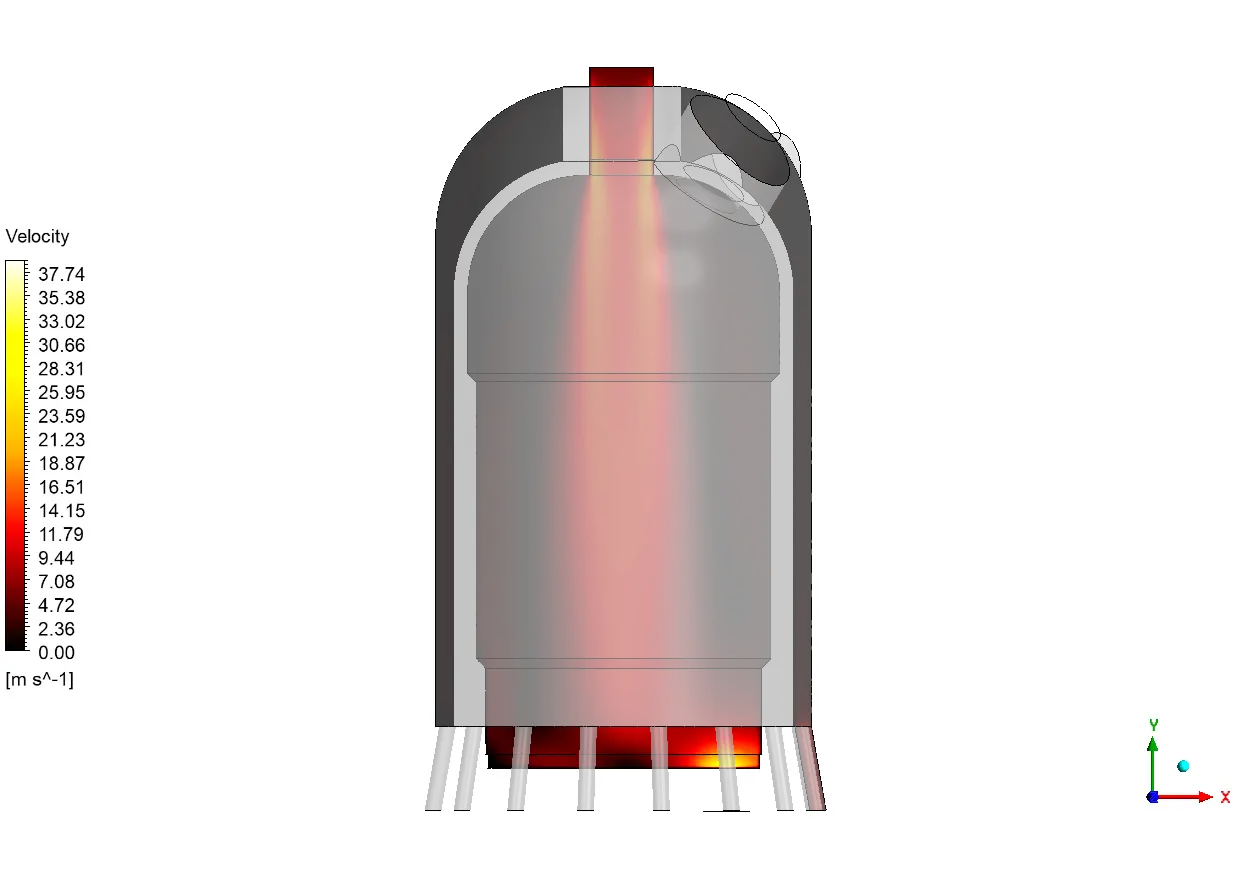

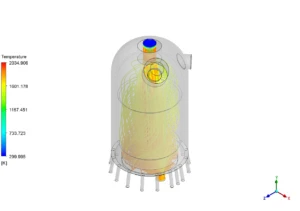

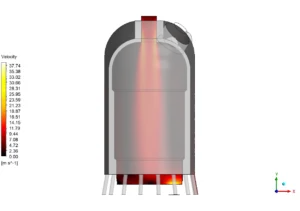

The second figure shows the remarkable thermal management capability of the water cooling system. The water enters at 300K but exits at 1320K, absorbing over 1000K of heat energy that would otherwise damage the combustion chamber. Looking at the cooling passages, we can identify several critical design insights. First, the water velocity (shown in the velocity contour) directly correlates with cooling effectiveness – faster water flow in the narrower passages creates better convective heat transfer. Second, the temperature gradient in the water jacket isn’t uniform, with hotspots forming in regions where water velocity is lower or where the combustion is most intense. From an engineering perspective, this suggests we could optimize the cooling channel design by ensuring more uniform water flow or adding extra cooling capacity near the peak reaction zones. The asymmetric heating pattern in the water jacket also indicates that the CH4 combustion isn’t perfectly centered, likely due to the inlet configuration. This type of detailed insight is exactly why CFD simulation of water-cooled combustion is so valuable for designers – it reveals complex thermal interactions that would be impossible to predict with simple calculations.

Figure 4: Water Jacket Temperature and Velocity Profile

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€75Current price is: €75.

€240 Original price was: €240.€125Current price is: €125.

€240 Original price was: €240.€135Current price is: €135.

€245 Original price was: €245.€199Current price is: €199.

€360 Original price was: €360.€180Current price is: €180.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.