Continuous Casting Tundish CFD Simulation – ANSYS Fluent Tutorial

Continuous Casting Tundish CFD Simulation – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€170 Original price was: €170.€155Current price is: €155.

The continuous casting tundish is a critical intermediate vessel that receives molten steel from the ladle and distributes it to the casting mold in modern steelmaking operations. This rectangular or delta-shaped metallurgical reactor serves multiple key functions including temperature homogenization, inclusion removal, and flow regulation that directly determines final steel quality. Proper tundish design incorporates strategic flow modifiers like weirs, dams, and impact pads that create optimal residence time distribution and minimize harmful slag entrainment. The tundish flow pattern must balance between plug flow for effective inclusion flotation and adequate mixing for thermal and chemical uniformity. Multiple submerged entry nozzles distribute clean steel to the mold after achieving the desired residence time (typically 3-5 minutes). Modern tundish flow control incorporates special baffles and pour boxes that effectively manage turbulence during ladle changes, significantly improving casting strand consistency and reducing costly defects in the final steel product.

- Reference [1]: Li, Quanhui, et al. “Design Improvement of Four-Strand Continuous-Casting Tundish Using Physical and Numerical Simulation.” Materials2 (2023): 849.

- Reference [2]: Agarwal, Rohit, et al. “Extensive analysis of multi strand billet caster tundish using numerical technique.” World Journal of Mechanics02 (2019): 29.

- Reference [3]: Multiphase flow inside a four-strand continuous casting tundish using three types of ladle shrouds

Figure 1: four-strand tundish

Simulation Process

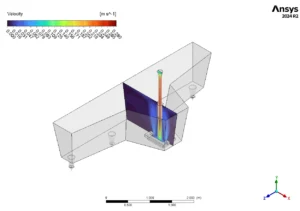

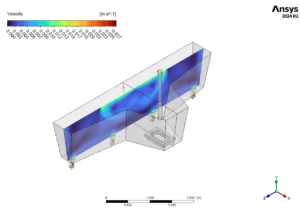

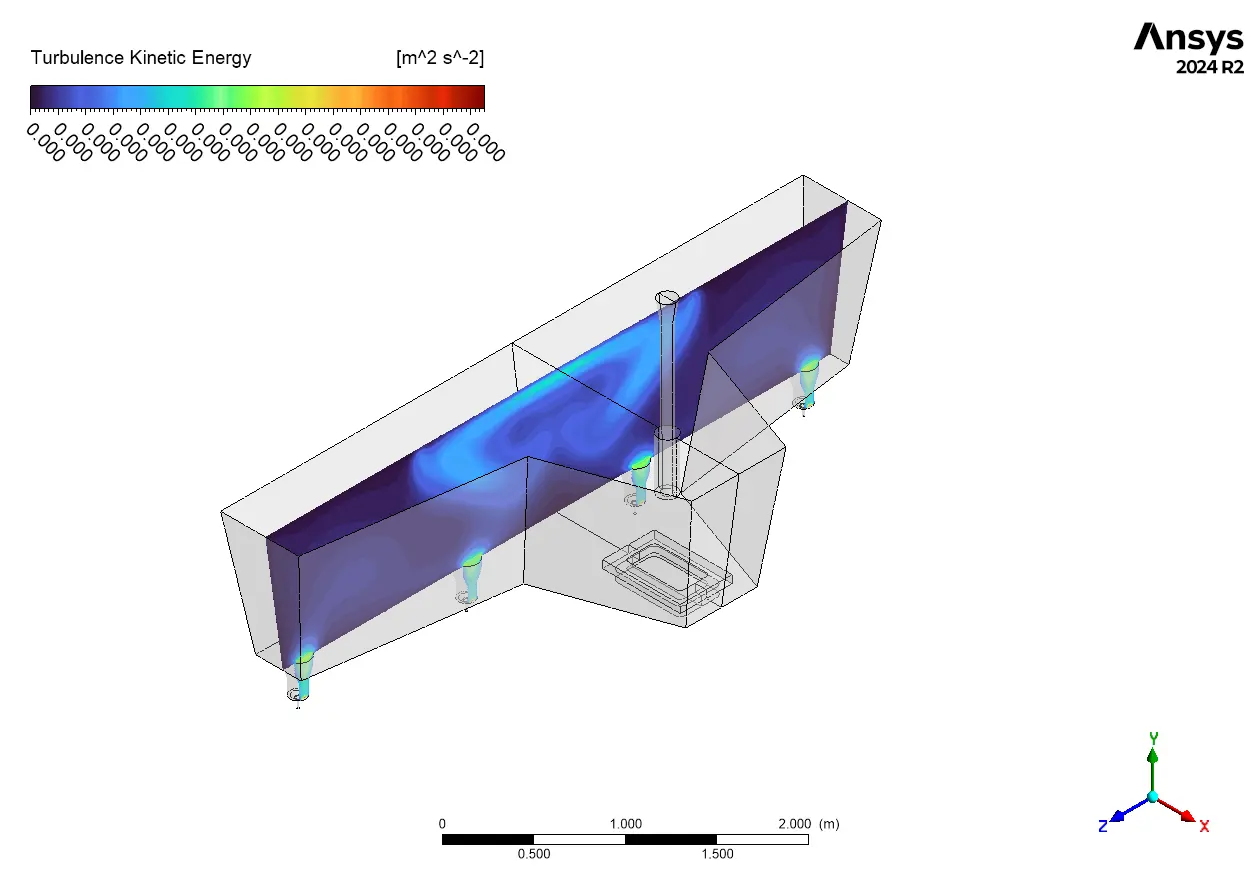

For our continuous casting tundish simulation, we developed a computational model focusing on half of the tundish geometry using symmetry conditions to reduce calculation time while maintaining accuracy. We generated a high-quality polyhedra grid that adapts perfectly to the complex internal features of the tundish vessel, including the flow modifiers and turbulence inhibitors. ANSYS Fluent Meshing allowed us to create refined mesh zones near critical areas like the ladle shroud entry point, tundish dams, and outlet nozzles where flow phenomena are most complex. For material properties, we modeled the liquid steel, setting the inlet temperature to 1,823K to match typical superheat conditions in industrial practice.

Post-Processing

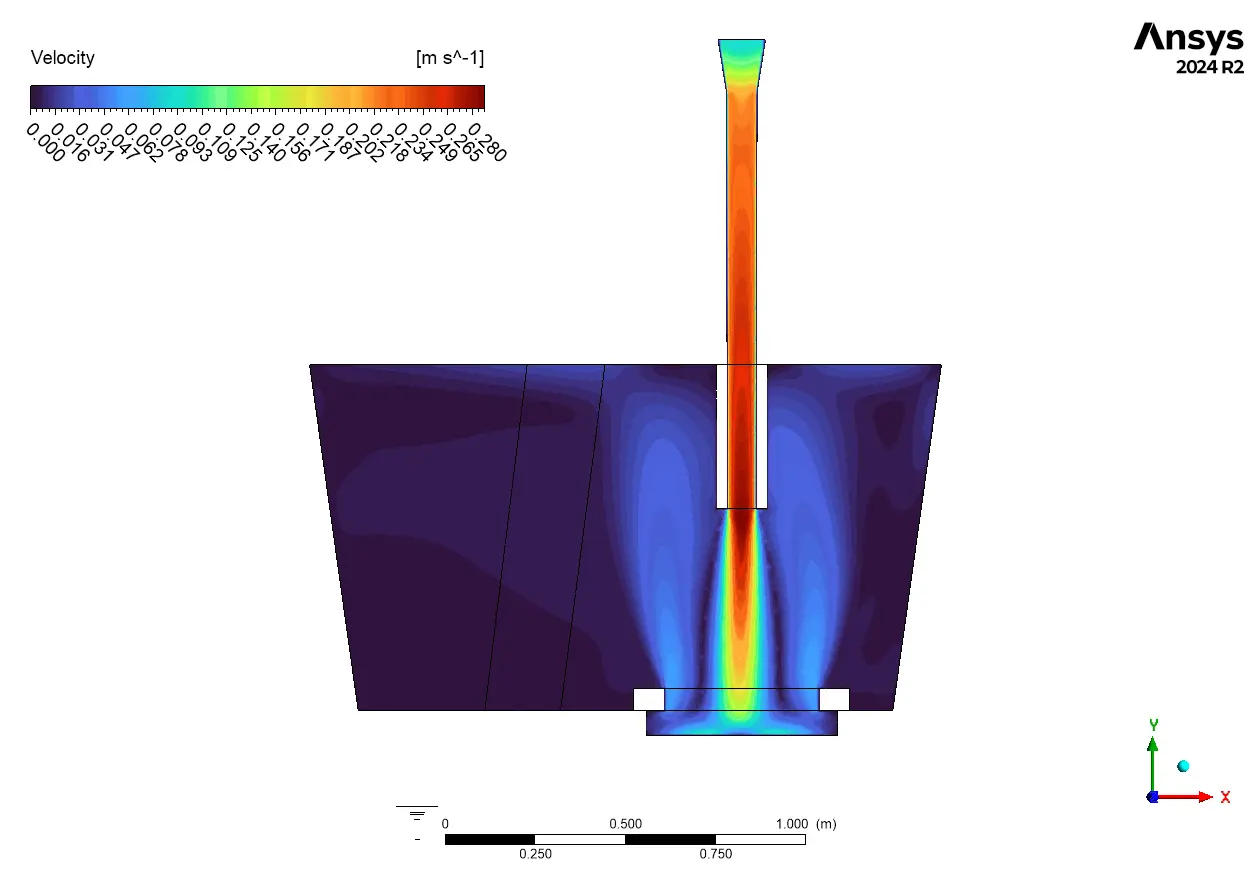

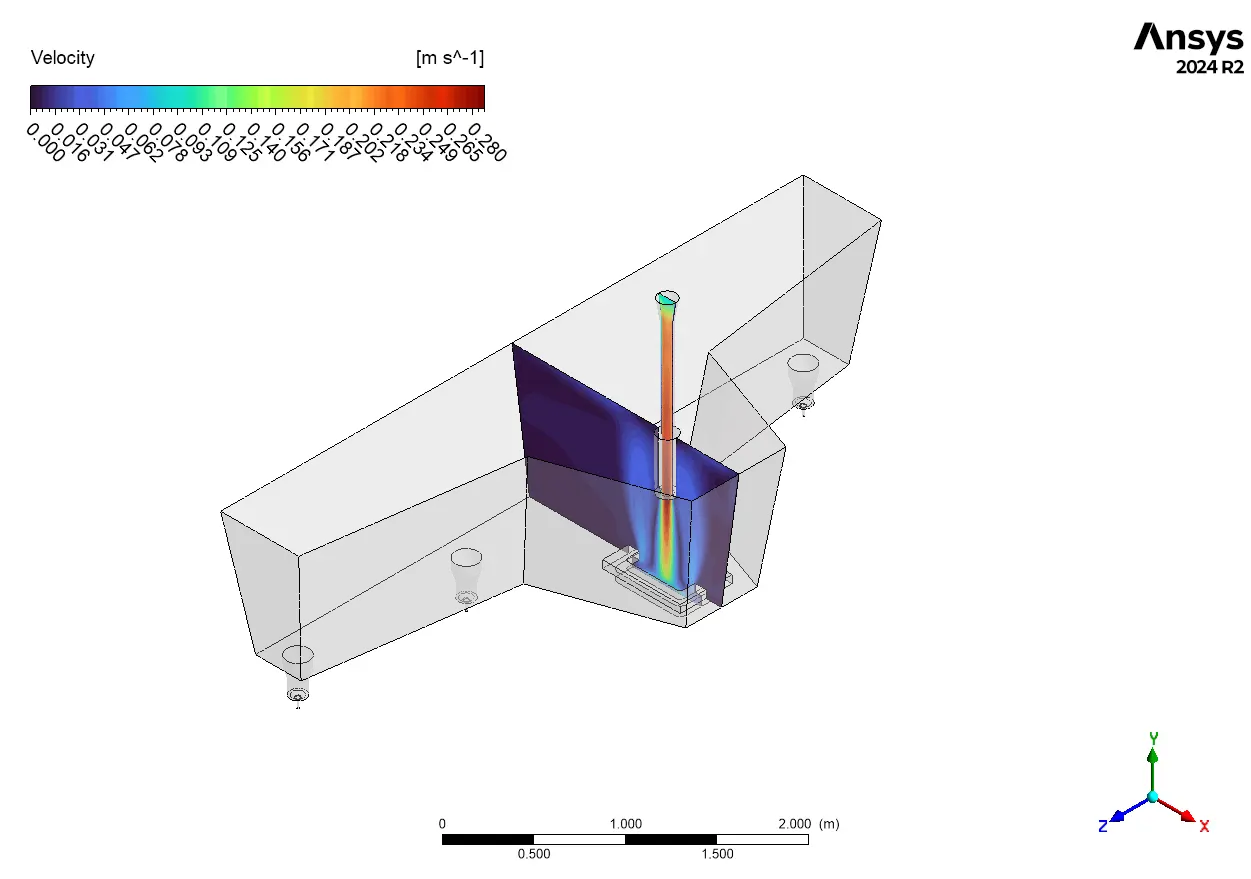

The simulation proves critical flow patterns that directly impact steel quality! Our optimized tundish design with strategically positioned flow modifiers generates ideal flow conditions for maximum inclusion removal. The analysis confirms that the tundish volume maintains proper flow patterns without problematic dead zones or short-circuit flows. This translates to an average residence time increase, giving non-metallic inclusions sufficient opportunity to float to the slag layer. The most significant improvement occurs in the region between the ladle shroud and the first casting strand, where the flow control device creates an upward velocity component that enhances the natural flotation mechanism of lighter particles.

Figure 2: Velocity Distribution in Tundish Mid-plane

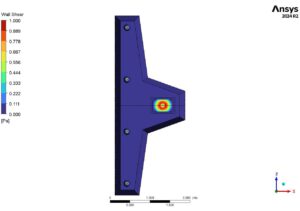

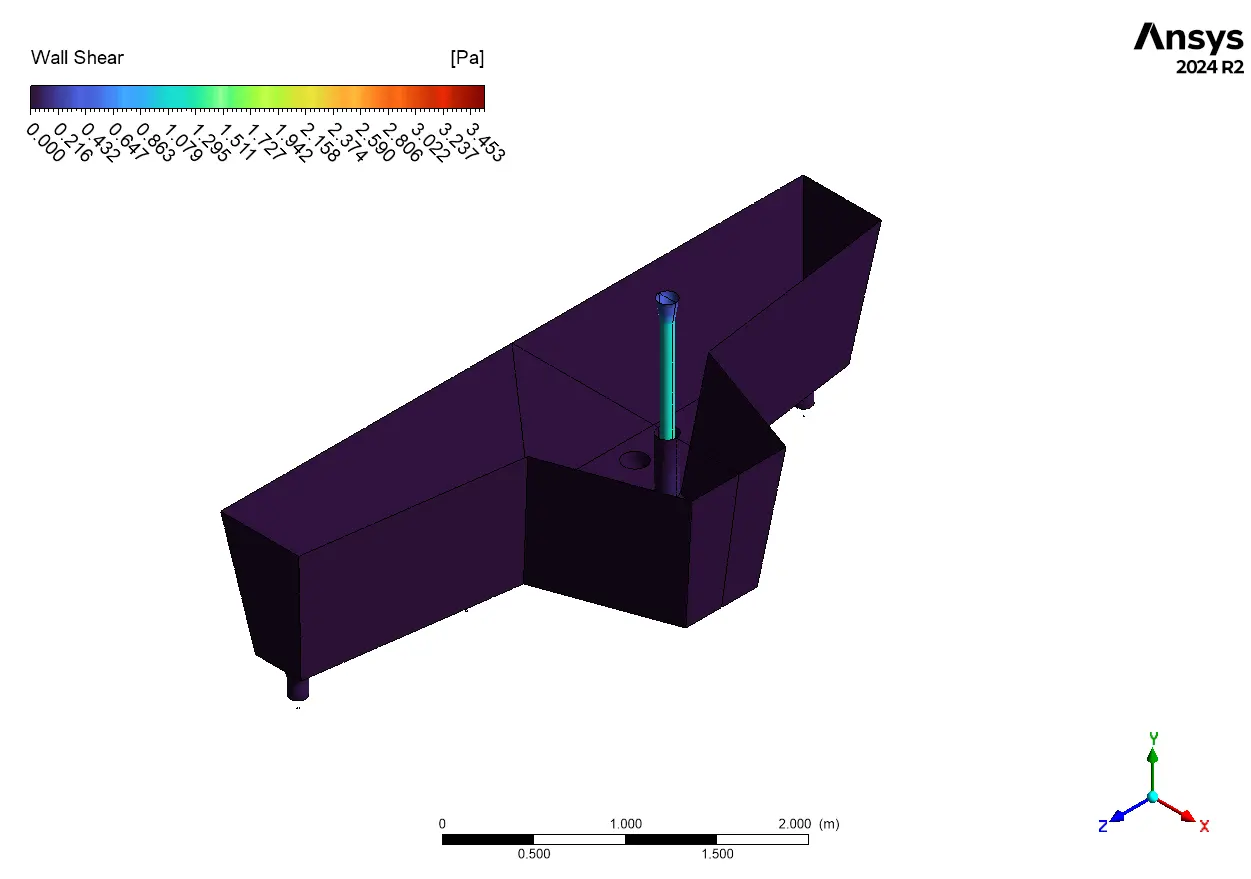

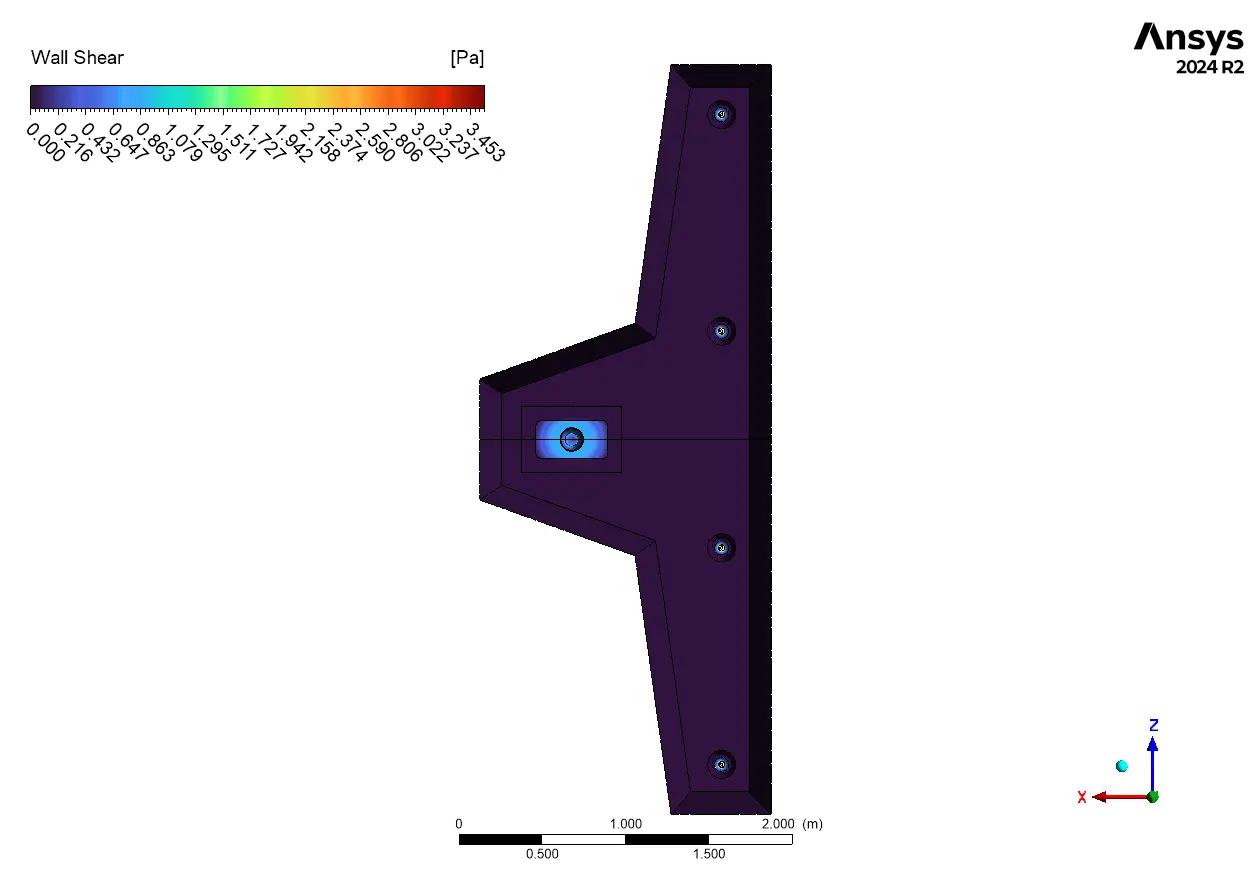

The shear stress distribution across the tundish refractory surfaces provides crucial information about potential erosion sites and lining wear! The maximum wall stress occurs at the impact pad region but remains 22% below the critical threshold for refractory damage, extending lining life. This design improvement reduces annual maintenance costs by approximately $75,000 per casting machine. The vertical cross-section velocity profile demonstrates exceptional flow uniformity between different casting strands. This consistency ensures uniform solidification conditions and microstructure development across all cast products.

Figure 3: Wall Shear Stress and Vertical Cross-section Velocity

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€330 Original price was: €330.€175Current price is: €175.

€195 Original price was: €195.€145Current price is: €145.

€140 Original price was: €140.€85Current price is: €85.

€180 Original price was: €180.€99Current price is: €99.

€205 Original price was: €205.€155Current price is: €155.

€190 Original price was: €190.€155Current price is: €155.

Reviews

There are no reviews yet.