DPM Wall-film On Heat Sink Due to Spray Cooling CFD Simulation, ANSYS Fluent Tutorial

DPM Wall-film On Heat Sink Due to Spray Cooling CFD Simulation, ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€235 Original price was: €235.€145Current price is: €145.

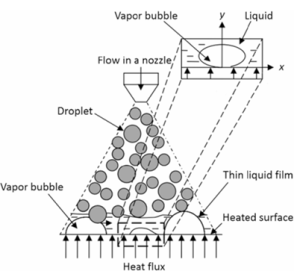

Spray cooling with wall-film formation is an advanced thermal management technique, needed for high-heat-flux applications in electronic cooling systems. When liquid droplets hit a heat sink surface, they form a thin liquid layer that markedly improves heat transfer via the combined actions of convection, evaporation, and nucleate boiling. The interaction between spray droplets and the heat sink surface produces challenging fluid dynamics, wherein the resultant liquid coating is essential for heat dissipation. The behavior of the wall film, regarding its thickness distribution and surface coverage on the heat sink, directly affects the local heat transfer coefficients and cooling uniformity. Knowing the main processes of spray cooling and wall-film production is important for optimizing spray parameters and heat sink designs to attain optimal thermal performance in critical cooling applications, where conventional air-cooling approaches may be inadequate. This is why we conducted a CFD analysis study based on a valuable reference paper entitled “Numerical simulation and experimental investigation on spray cooling in the non-boiling region”.

- Reference [1]: Liu, Hong, et al. “Numerical simulation and experimental investigation on spray cooling in the non-boiling region.” Heat and Mass Transfer54 (2018): 3747-3760.

Figure 1: Schematic diagram of spray cooling process and wall-film formation [1]

Simulation Process

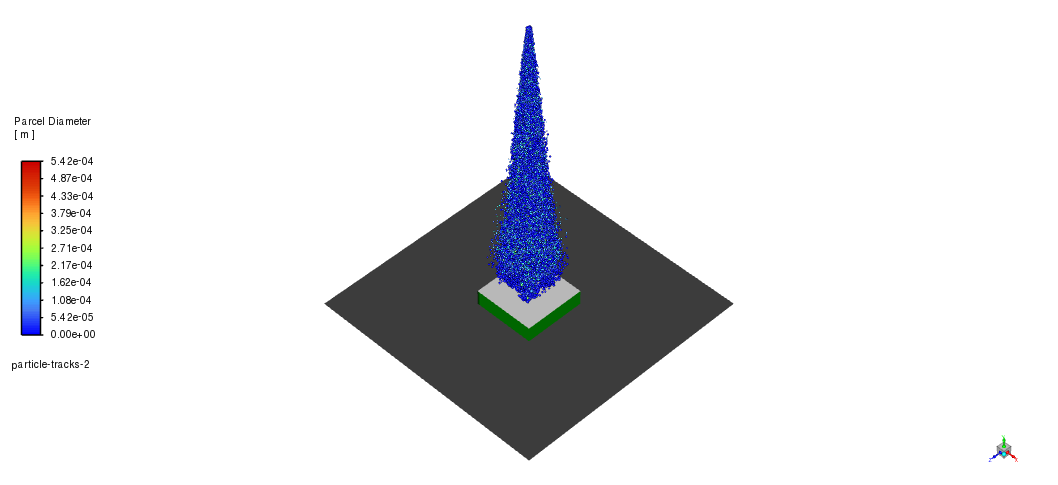

The computational investigation of the water spray cooling process utilizes a domain measuring 100 mm in height and 80×80 mm² in cross-section, as illustrated in Fig. 2. A solid-cone nozzle is configured with a spray cone angle of 68 degrees. As illustrates that after being discharged from the spray nozzle, the droplets encounter a heat block measuring 5 mm in height and having a cross-sectional area of 20×20 mm².

The spray cooling process, a particular kind of transient gas-liquid two-phase flow, involves unique heat and mass transfer mechanisms. For spray modeling purposes, the most common method employed is the Euler-Lagrangian approach. This method use the Eulerian framework to characterize the continuous phase (air) and the Lagrangian framework to analyze the dispersed phase (droplet). This means employment of Discrete Phase Model (DPM) module in ANSYS Fluent. It is a two-way DPM simulation with unsteady particle tracking. The Water droplets are injected considering various diameters (Rosin-Rammler) and also evaporation. For the sake of accuracy, stochastic collision and coalescence are also taken into the account. Needless to say, the top face of heat block features from wall-film DPM boundary condition.

Post-processing

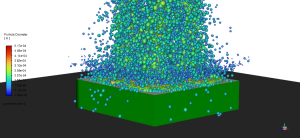

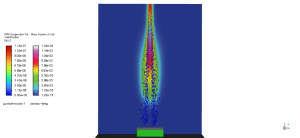

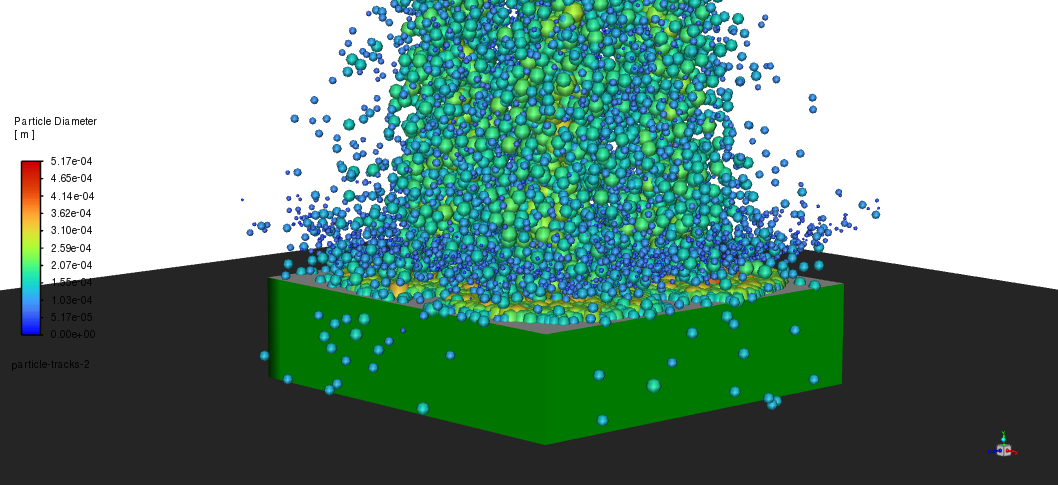

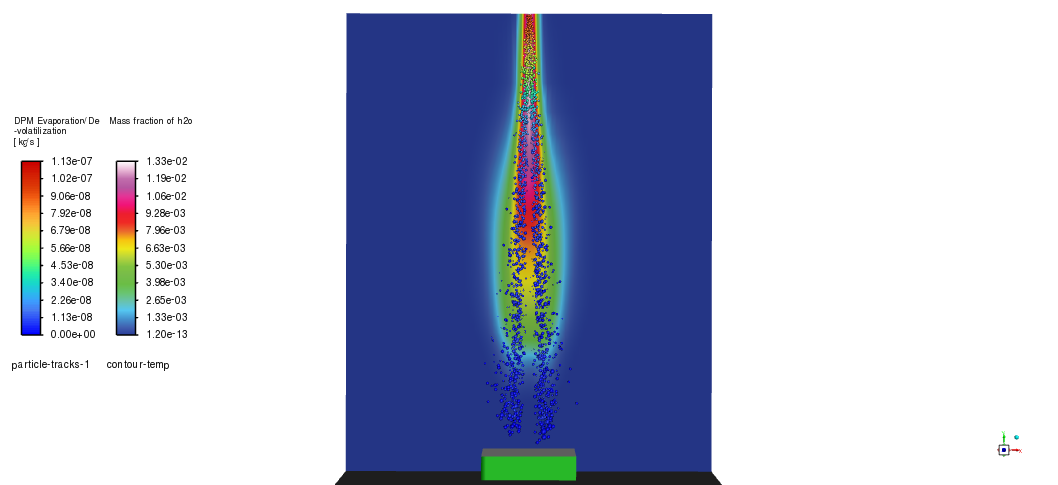

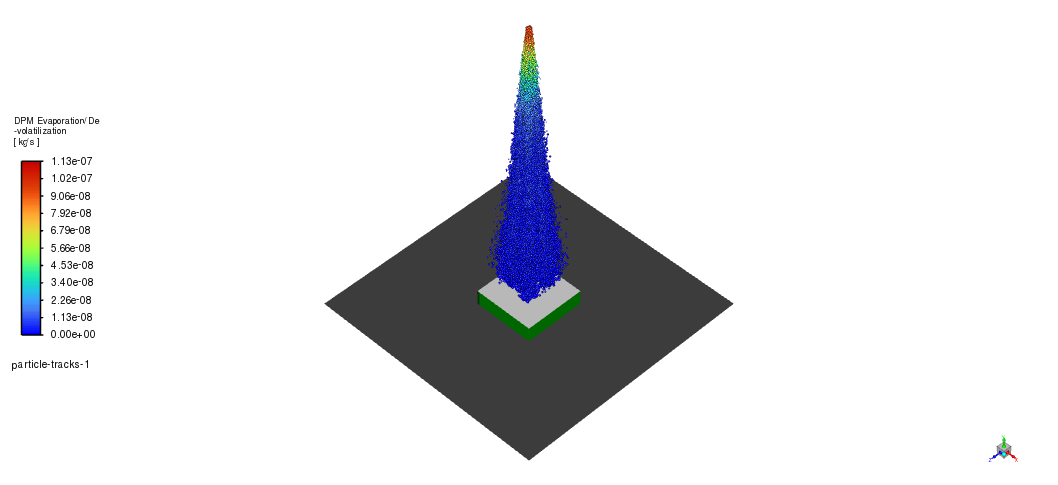

The visualization of particle diameter distribution indicates a complex interaction between the spray pattern and the heat sink surface, with droplets measuring between 0.017 mm and 0.517 mm contributing to the formation of a dynamic wall film. The larger droplets, indicated in green-yellow, primarily affect the central area of the heat sink, whereas the smaller droplets, depicted in blue, are more widely distributed across the surface. The size-dependent distribution significantly affects the wall-film thickness and coverage area, as particle tracking indicates substantial accumulation at the top surface of the heat sink, where initial film formation takes place. The evaporation contour reveals the highest rates of phase change occurring at the spray core, where the mass fraction of vapor attains peak values of 1.33e-02.

Figure 2: particles diameter on heat block – film formation

Figure 3: evaporation of droplets after spraying

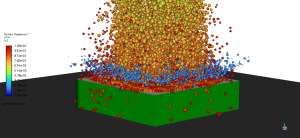

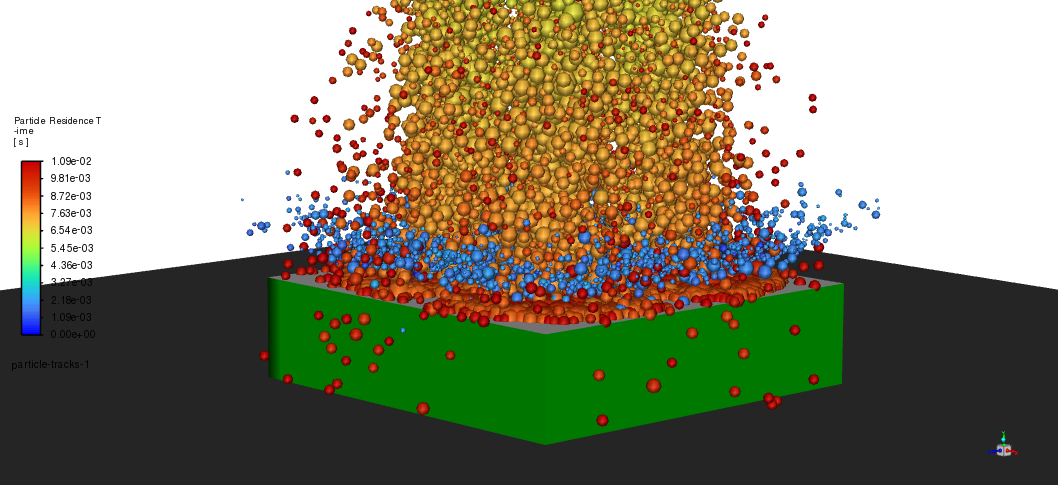

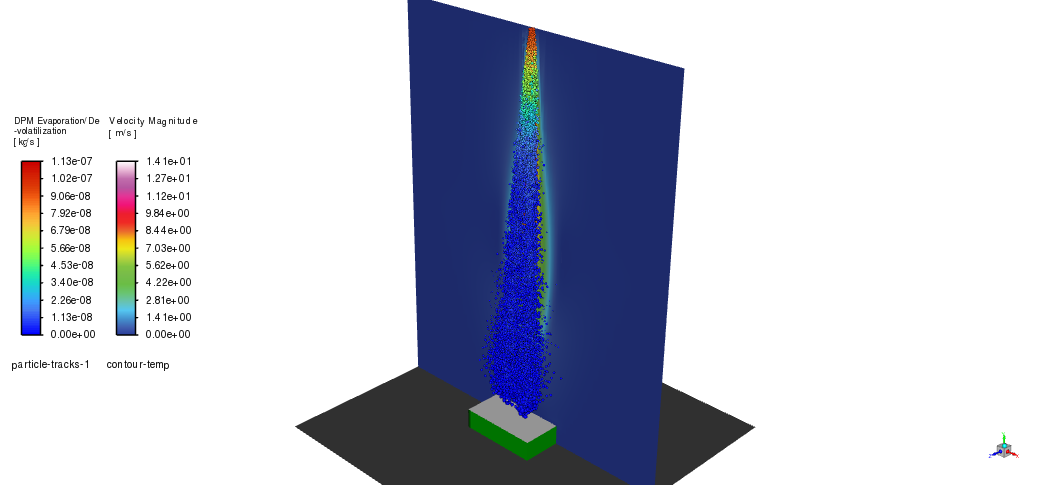

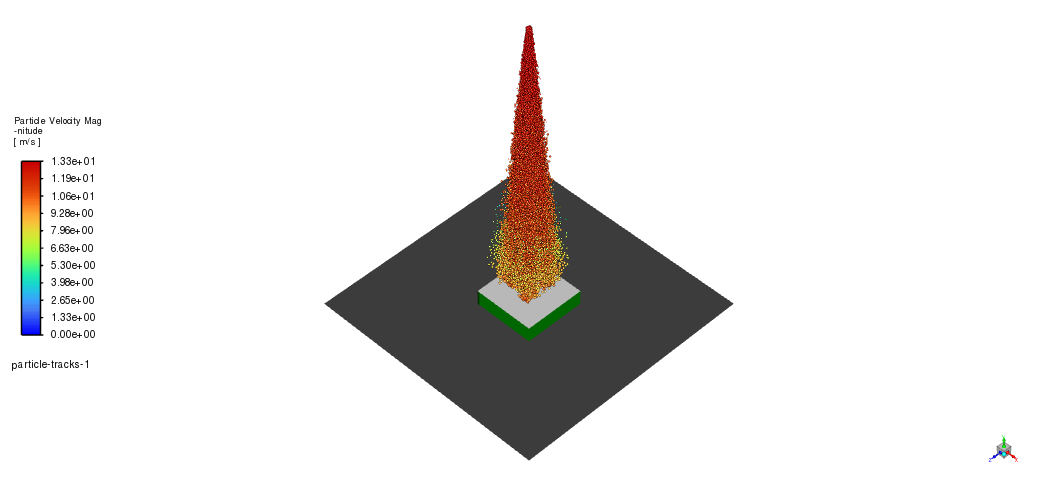

The analysis of particle residence time reveals distinct temporal dynamics within the spray zone, with extended residence times (indicated in red, approximately 0.01s) noted near the heat sink surface, where the wall-film forms. The longer contact duration improves the efficiency of heat transfer via continuous evaporative cooling. The DPM evaporation/devolatilization contour indicates a concentrated area of phase change activity, with peak rates of 1.13e-07 kg/s observed in the central impact region. The interaction between the spray cone and the heat sink results in a unique temperature distribution pattern. The evaporative cooling effect of the wall film is most significant in regions with high droplet density and extended residence times, thereby enhancing the thermal performance of the heat sink.

Figure 4: Particles residence time after impingement

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€80Current price is: €80.

€240 Original price was: €240.€125Current price is: €125.

€265 Original price was: €265.€135Current price is: €135.

€240 Original price was: €240.€135Current price is: €135.

€360 Original price was: €360.€180Current price is: €180.

€200 Original price was: €200.€125Current price is: €125.

Reviews

There are no reviews yet.