Non-newtonian Fluid Fluent, CFD Simulating Heat Transfer in a Corrugated Channel

Non-newtonian Fluid Fluent, CFD Simulating Heat Transfer in a Corrugated Channel

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€265 Original price was: €265.€135Current price is: €135.

Many fluids we see every day, like ketchup, paint, and blood, are non-Newtonian. This means their thickness (viscosity) changes depending on how much force is applied to them. Studying these fluids is very important for designing better systems in many industries, from food processing to medicine. A corrugated channel, which has wavy walls, is often used to improve mixing and heat transfer. Therefore, a Non-newtonian Fluid in Corrugated Channel CFD simulation gives us a powerful way to see and understand these complex processes.

This project presents a detailed simulation of a Non-newtonian Fluid Fluent analysis. Our main goal is to study the unique flow patterns and heat transfer that happen inside a corrugated channel. Our work is guided by the experimental study in the reference paper “Experimental characterization of Newtonian and non-Newtonian fluid flows in corrugated channels” by Bereiziat, and Devienne [1].

- Reference [1]: Bereiziat, D., and R. Devienne. “Experimental characterization of Newtonian and non-Newtonian fluid flows in corrugated channels.” International journal of engineering science11 (1999): 1461-1479.

Figure 1: The geometric details of the corrugated channel used for the simulation [1].

Simulation Process: CFD Modeling of Non-newtonian Fluid in Fluent

The first step was to build the geometry. The wavy, sinusoidal walls of the channel were carefully drawn in ANSYS Design Modeler. Because the forces near the walls are very important for a Non-newtonian Fluid CFD simulation, we needed a very good mesh in that area. So, a high-quality, structured grid was created, as you can see in Figure 2.

Next, the physics of the simulation were set up in ANSYS Fluent. The flow was assumed to be laminar, which means it is smooth and not chaotic. The most critical part was defining the fluid’s behavior. We used the Herschel-Bulkley model to describe the shear rate dependent viscosity. This model is great for fluids that act like a solid until a certain amount of force is applied, after which they begin to flow. Also, we set the channel walls to be warmer than the fluid to study the heat transfer from the walls into the fluid.

Figure 2: The structured mesh used for the Non-newtonian Fluid in Corrugated Channel Fluent simulation.

Post-processing: Flow Recirculation and Enhanced Heat Transfer in Wavy Channel

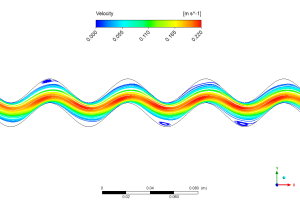

An in-depth analysis of the results shows the fascinating behavior of the non-Newtonian fluid. The velocity streamlines in Figure 3 reveal two key features. First, the fluid moves fastest along the center of the channel, reaching a peak velocity of approximately 0.22 m/s. Second, and more importantly, we can see clear recirculation zones, which are like small whirlpools, that form in the valleys of the wavy channel. This happens because as the main flow moves over the “hills” of the channel, it separates from the wall and traps some of the slower-moving fluid in the “valleys” below, causing it to spin. This creation of recirculation zones is a classic feature of flow in corrugated channels.

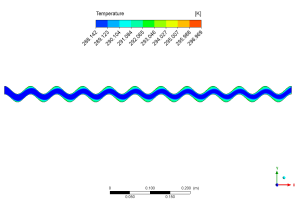

Furthermore, the temperature contour shows how these flow patterns dramatically improve heat transfer. The channel walls are hot (around 296 K), and the fluid enters cool (around 288 K). The recirculation zones we saw in the flow analysis act like powerful, built-in mixers. They constantly pull the cooler fluid from the center of the channel down towards the hot walls and push the heated fluid from the walls back out into the main stream. This continuous mixing process breaks up the thermal boundary layers and transfers heat much more effectively than a simple straight pipe could. This powerful mixing effect is exactly why corrugated channels are so valuable in engineering applications like advanced Heat Exchangers and polymer processing systems.

Figure 3: Velocity streamlines and temperature contours from the Non-newtonian Fluid in Corrugated Channel CFD simulation, showing the relationship between flow patterns and heat transfer.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€110Current price is: €110.

€190 Original price was: €190.€95Current price is: €95.

€240 Original price was: €240.€125Current price is: €125.

€240 Original price was: €240.€135Current price is: €135.

€200 Original price was: €200.€115Current price is: €115.

€245 Original price was: €245.€199Current price is: €199.

Reviews

There are no reviews yet.