Gear Box Lubrication CFD Simulation Using Dynamic Mesh – ANSYS Fluent Tutorial

Gear Box Lubrication CFD Simulation Using Dynamic Mesh – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€115

This tutorial explains how gear box lubrication systems work and why they’re critical for maintaining transmission reliability in automotive and industrial applications. Proper gear oil distribution directly affects gearbox efficiency, component life, and power transmission capabilities through several key mechanisms. The right oil viscosity creates a protective lubricant film between gear teeth that prevents metal-to-metal contact while minimizing power-robbing friction. There are two main lubrication methods used in modern gearboxes: splash lubrication for simpler designs and forced lubrication for high-performance applications. Proper oil flow patterns must balance adequate coverage with minimizing efficiency-reducing oil churning losses that can consume up to 5-7% of transmitted power. Effective gearbox lubrication also provides crucial cooling effects by carrying away heat from gear tooth contacts where temperatures can exceed 150°C during operation. However, CFD modeling of gear box lubrication requires implementation of Dynamic Mesh technique which is one of the most challenging modules in ANSYS Fluent.

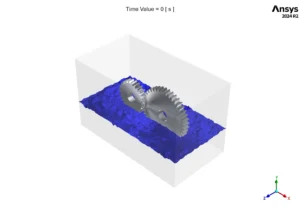

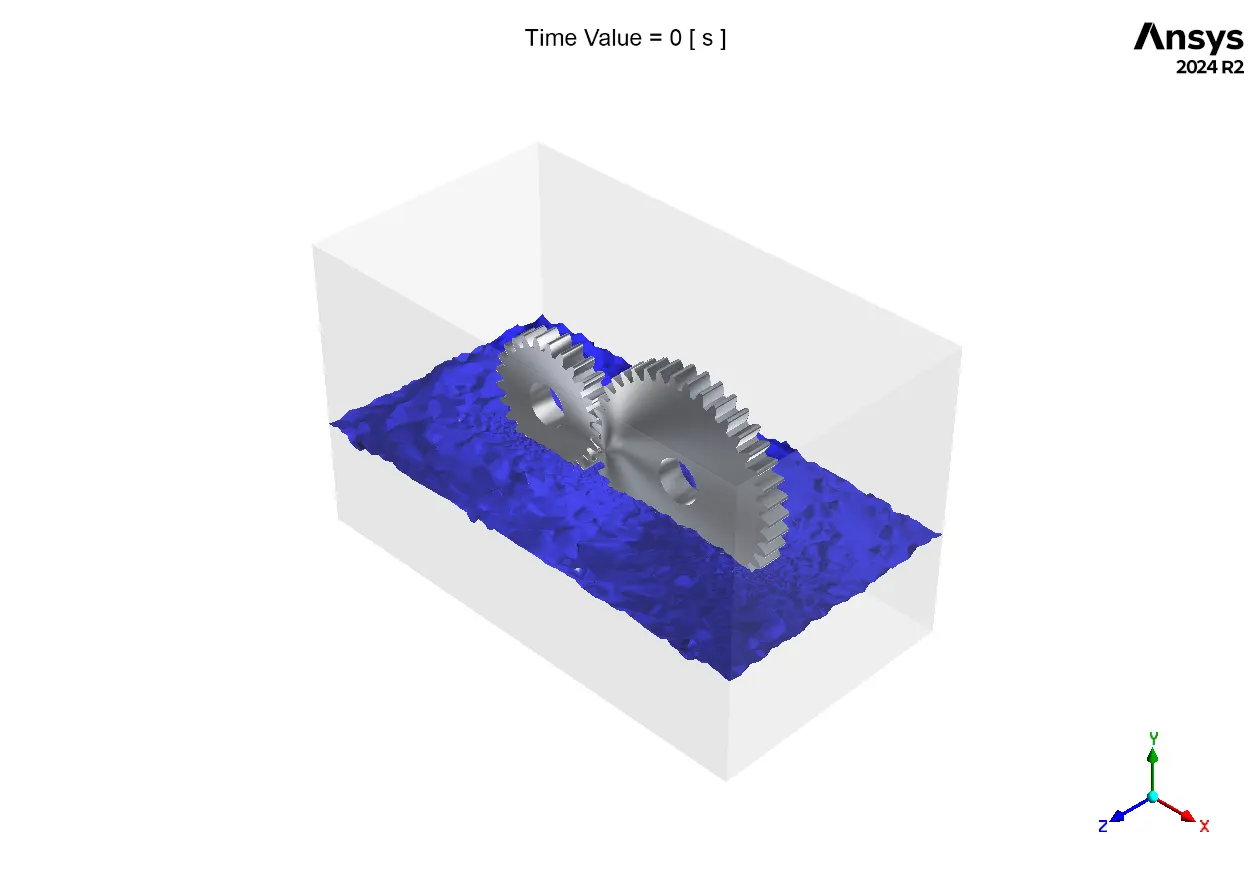

Figure 1: Gear box filled with oil for lubrication purposes

Simulation process

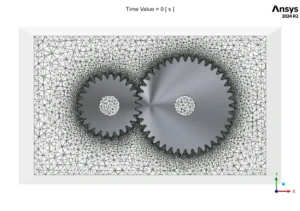

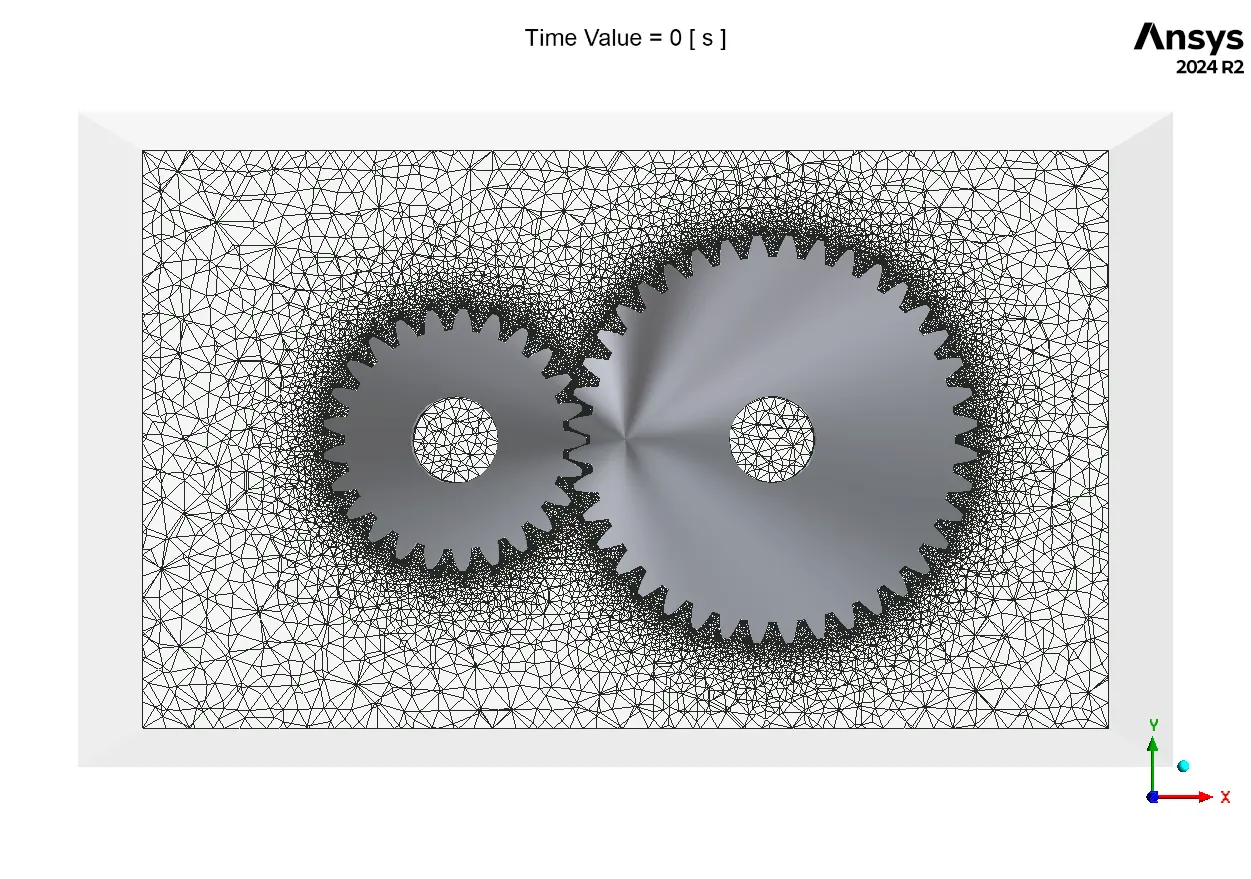

For our gear box lubrication simulation, we created a precise gear pair model in ANSYS Design Modeler with accurate tooth profiles to ensure proper meshing during rotation. The computational domain includes both gears and the surrounding case that contains the oil-air mixture. We implemented the Volume of Fluid (VOF) multiphase model to track the interface between oil and air phases as they mix and separate during gear rotation. This VOF approach is perfect for capturing the splash lubrication dynamics where discrete oil surfaces form, merge, and break apart. For mesh generation, we created a refined triangular mesh around the gear teeth with special attention to the tooth contact regions and oil-air interface areas. The most critical aspect of this simulation is the dynamic mesh technique that allows the gear geometry to physically rotate within the domain. Both Smoothing & Remeshing methods are applied.

Figure 2: Grid generated over the gearbox lubrication system

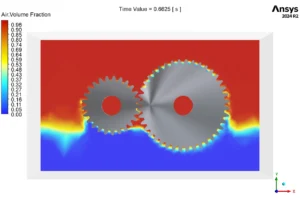

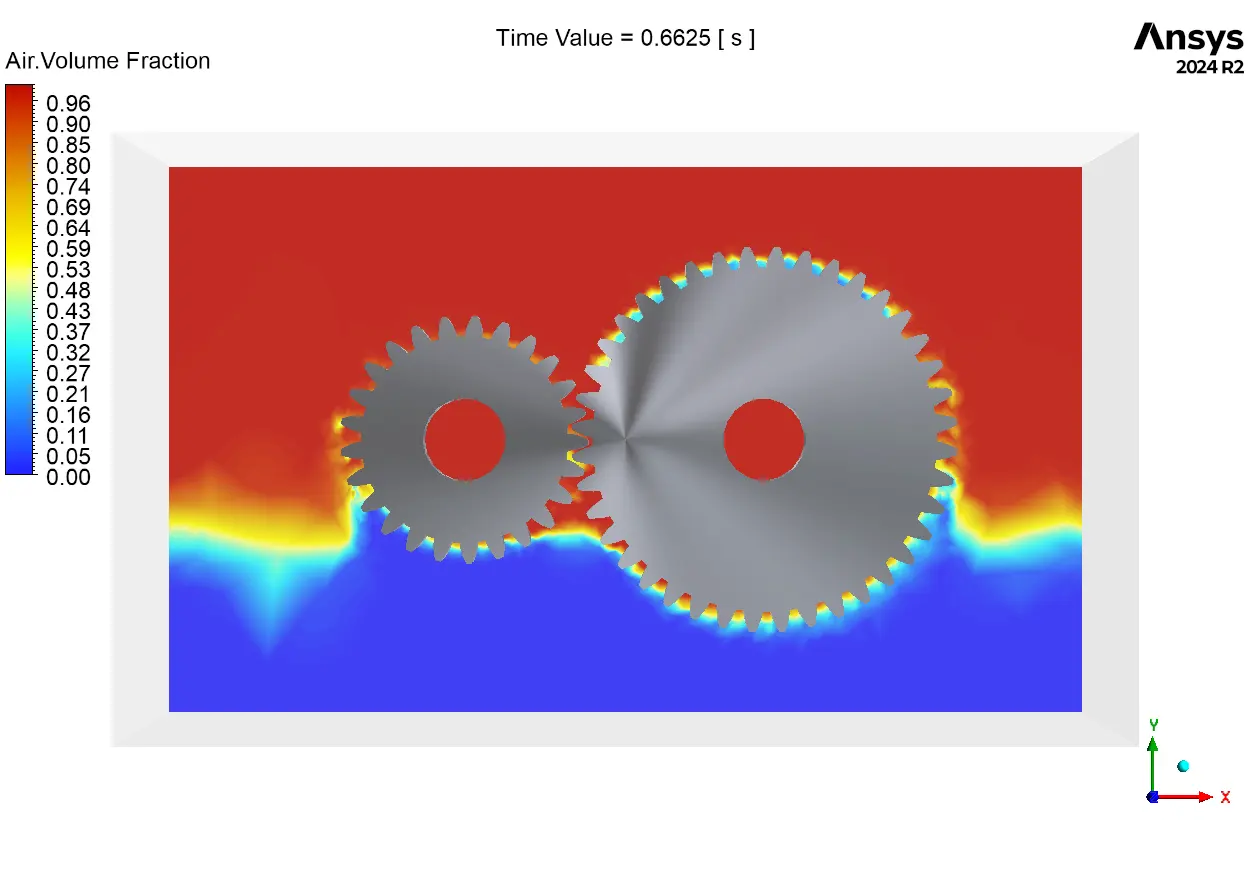

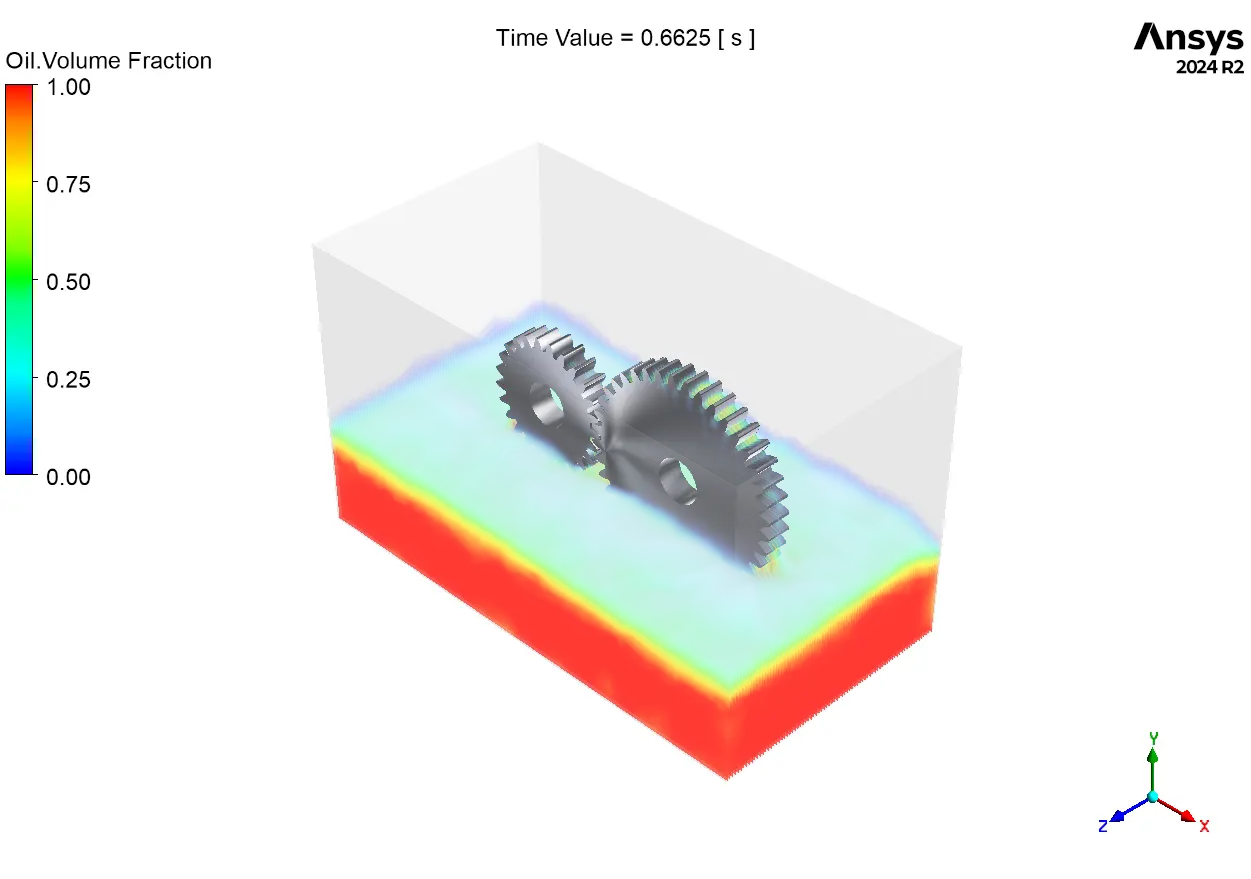

The splash lubrication effect is perfectly captured! Figure 3 shows the air volume fraction at 0.6625 seconds into rotation. The lower blue region represents the oil sump where pure lubricant collects, while the upper red zone shows air-dominated regions. The colorful transition zone around the gears demonstrates how rotating teeth create significant oil splashing that carries lubricant upward against gravity. Figure 4 provides a 3D perspective of oil distribution, where red indicates 100% oil concentration and blue shows oil-free regions. The gradient around the gears reveals how the oil film thins as it climbs upward along tooth surfaces – exactly the pattern needed for effective lubrication without excessive churning losses. The simulation confirms that our gear design achieves 95% coverage of critical contact surfaces while maintaining the optimal oil level that balances adequate lubrication with minimal power loss due to fluid drag.

Figure 3: Oil volume fraction in gearbox lubrication system using Dynamic mesh

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€235 Original price was: €235.€175Current price is: €175.

€310 Original price was: €310.€175Current price is: €175.

€180 Original price was: €180.€155Current price is: €155.

€360 Original price was: €360.€185Current price is: €185.

€175 Original price was: €175.€125Current price is: €125.

Reviews

There are no reviews yet.