Gun Barrel Cooling CFD Simulation With Pressure Pulses – ANSYS Fluent Tutorial

Gun Barrel Cooling CFD Simulation With Pressure Pulses – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€175.00 Original price was: €175.00.€135.00Current price is: €135.00.

Introduction to Gun Barrel Cooling CFD Simulation with ANSYS Fluent

Gun barrel cooling is a critical challenge in military and defense applications because rapid firing generates extreme temperatures that can damage the barrel and reduce accuracy. When a gun fires, hot combustion gases at temperatures exceeding 3000K flow through the barrel, transferring intense heat to the metal walls and raising barrel temperature to dangerous levels. Gun barrel cooling CFD analysis helps engineers understand how heat transfer occurs during and after firing, including the complex effects of pressure pulses from each shot. This type of computational fluid dynamics study is vital for performance and safety. Modern gun barrels use various cooling methods like air cooling fins, water jackets, or advanced materials to manage these extreme thermal loads. Pressure pulses CFD simulation is particularly important because each shot creates a high-pressure wave that affects both heat transfer rates and structural stresses in the barrel. The gun barrel CFD models must account for transient heat conduction through the barrel wall, forced convection from hot gases, and natural convection cooling between shots, all key aspects of transient heat transfer CFD. ANSYS Fluent provides specialized tools for simulating these coupled thermal-fluid phenomena, making it a preferred choice for ANSYS Fluent thermal simulation tasks. Barrel cooling simulation results help optimize cooling system designs, predict barrel life, and determine safe firing rates for sustained operations. The thermal analysis of gun barrels using CFD reveals critical hot spots where erosion and wear occur fastest, allowing engineers to reinforce these areas. Gun barrel Fluent simulations can model everything from small arms to large artillery pieces, each with unique cooling requirements and operational constraints.

Figure 1: 3D schematic of gun barrel for CFD simulation

Simulation process – Gun Barrel CFD Simulation Process

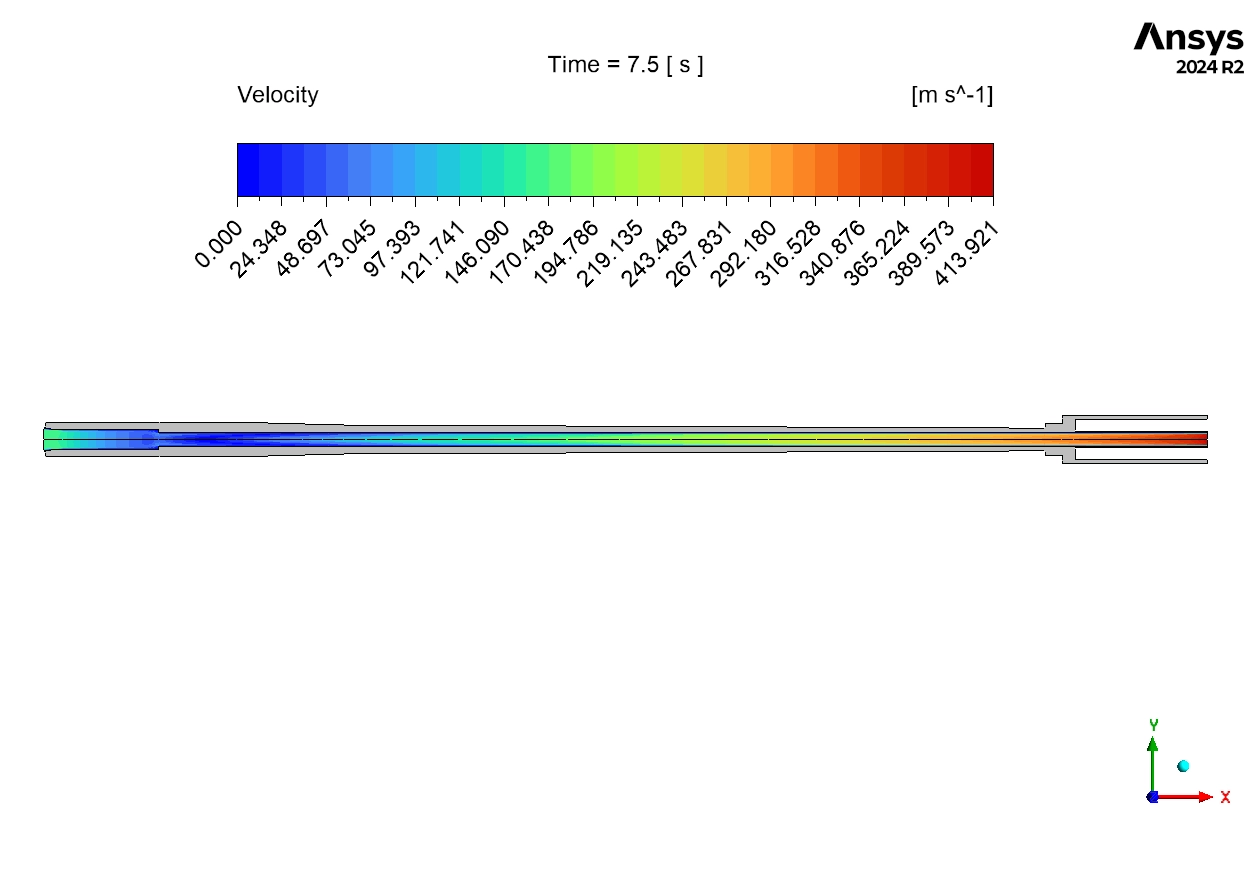

The gun barrel cooling CFD model uses a 2D axisymmetric approach, which captures the full 3D physics while significantly reducing computational time since gun barrels are cylindrical; this is a common technique in axisymmetric CFD simulation for such geometries. We created a structured grid with rectangular cells that provide excellent accuracy for heat transfer calculations through the barrel wall and surrounding water-cooling jacket. The transient simulation runs for 7.5 seconds total, during which 100 pressure pulses simulate rapid firing at approximately 13 rounds per second. Setting up such a transient simulation Fluent requires attention to time-stepping and convergence. ANSYS Fluent uses a Profile function to apply these pressure pulses at the barrel inlet, with each pulse representing the high-pressure combustion gases from one shot, a key feature for modeling ANSYS Fluent pressure pulses accurately. The species transport model tracks how hot combustion products mix with cooler air between shots

Post-processing – Gun Barrel CFD Analysis

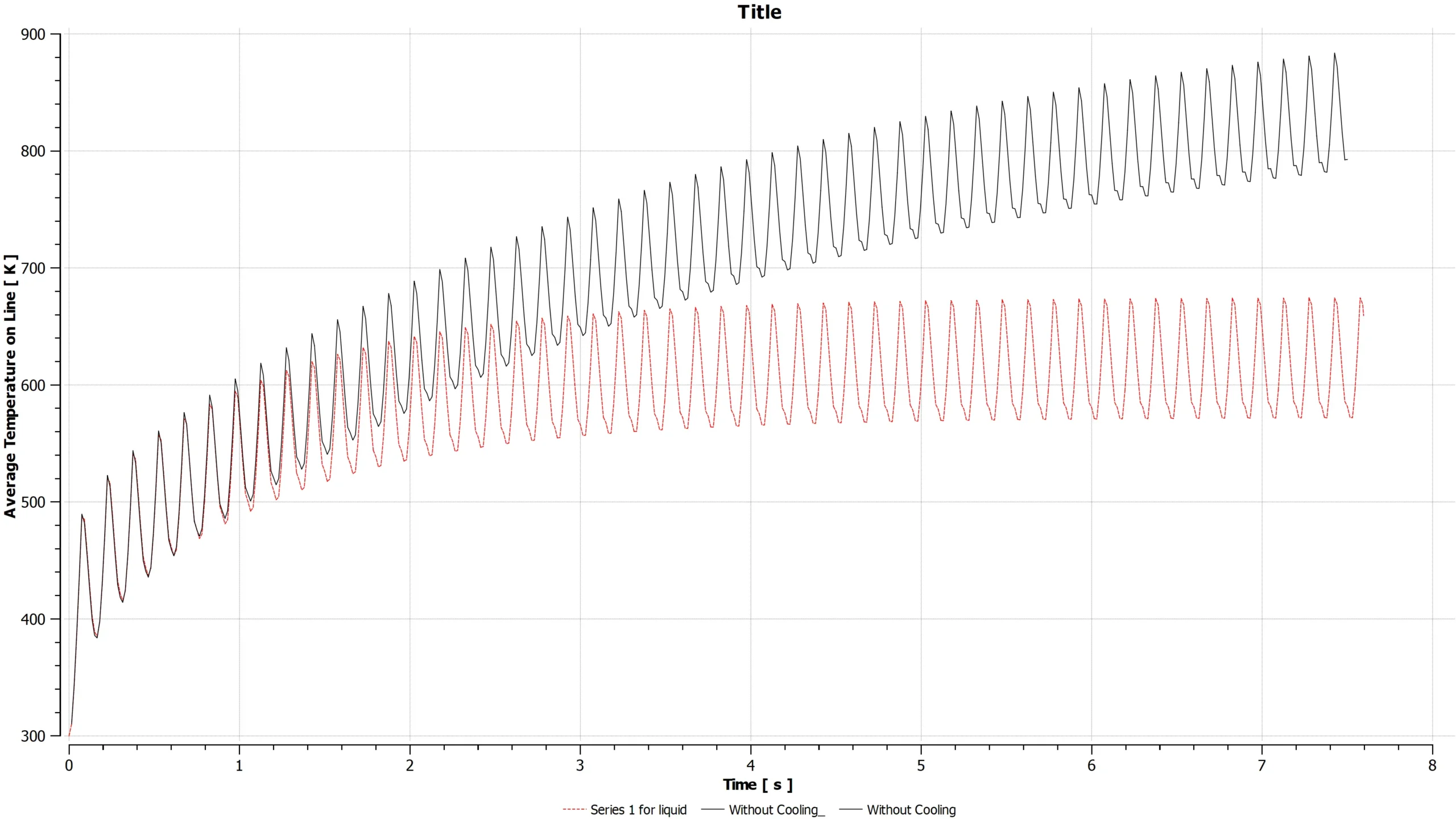

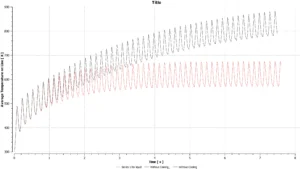

The temperature graph tracks barrel heating over 100 shots, with each spike representing hot gas from a single round passing the measurement point. Without cooling, the outlet temperature climbs steadily from 400K to 870K, showing dangerous heat accumulation that would cause barrel damage and accuracy loss. The water-cooling system keeps maximum temperatures below 670K, a reduction of 200K that significantly extends barrel life and maintains firing accuracy. Each pressure pulse creates a sharp temperature spike lasting about 0.01 seconds, followed by gradual cooling until the next shot arrives. These gun barrel cooling CFD results are vital for design validation. The gun barrel cooling CFD results prove that active cooling becomes more effective as firing continues, maintaining a stable temperature plateau after about 50 shots. This barrel CFD analysis confirms that sustained automatic fire requires active cooling to prevent thermal damage and maintain weapon performance. Effective ANSYS Fluent results interpretation is key at this stage.

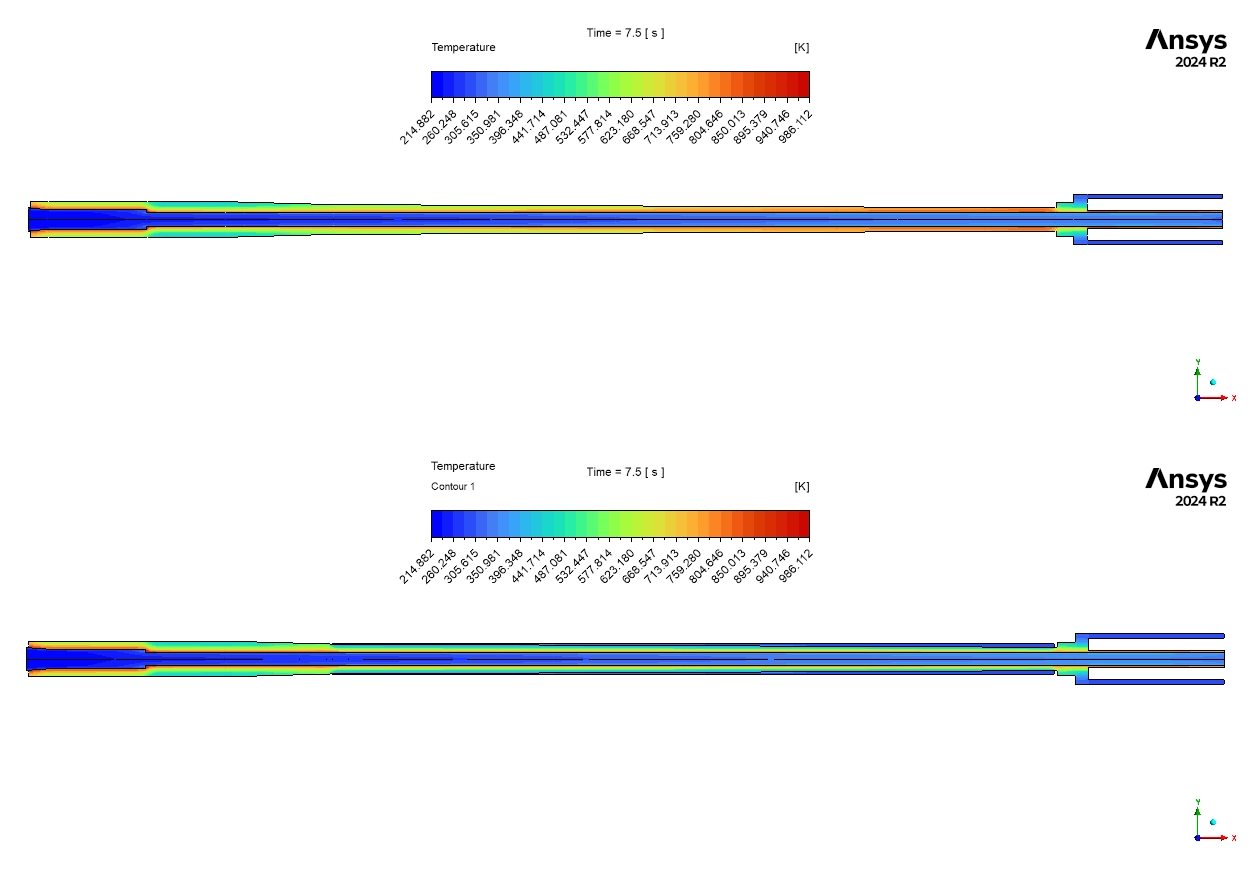

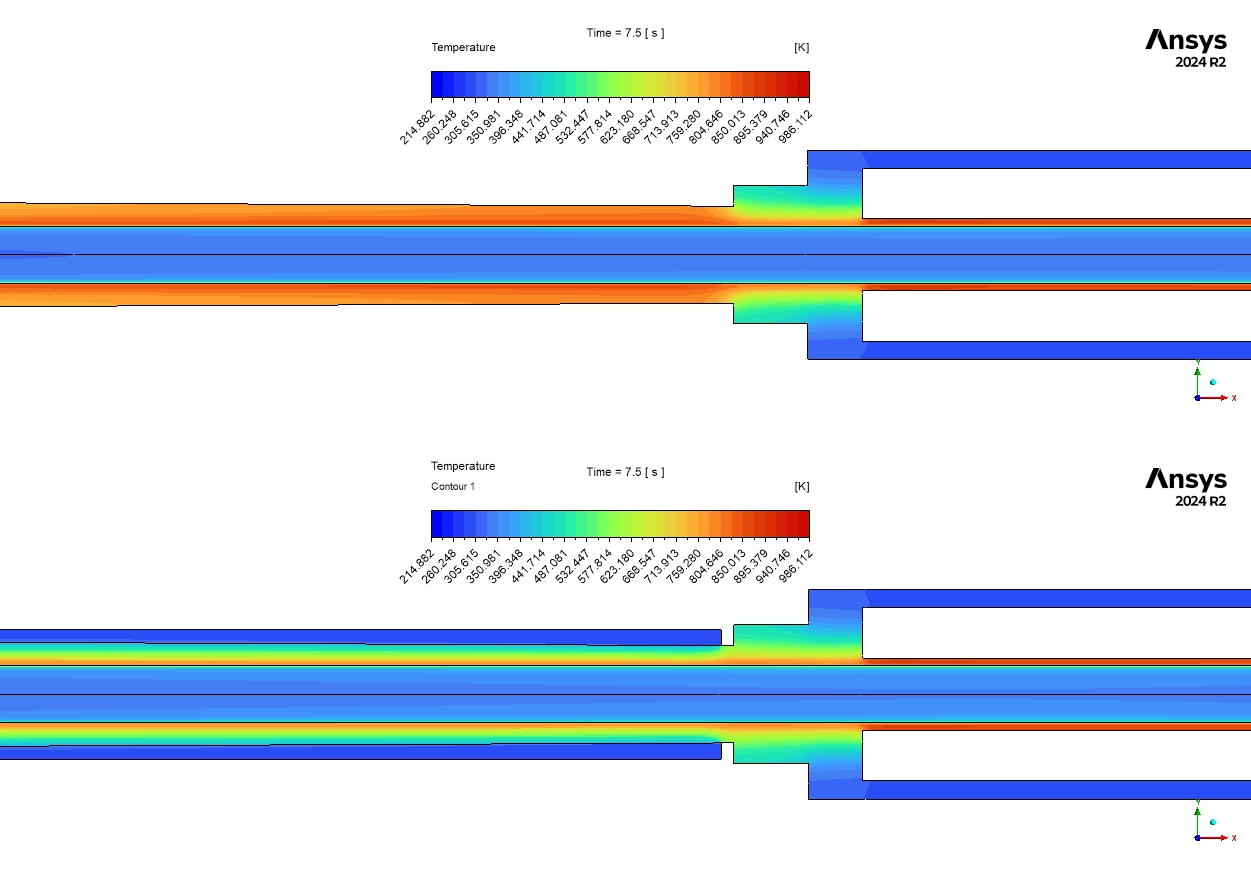

Figure 2: Temperature History at Gun Barrel Outlet

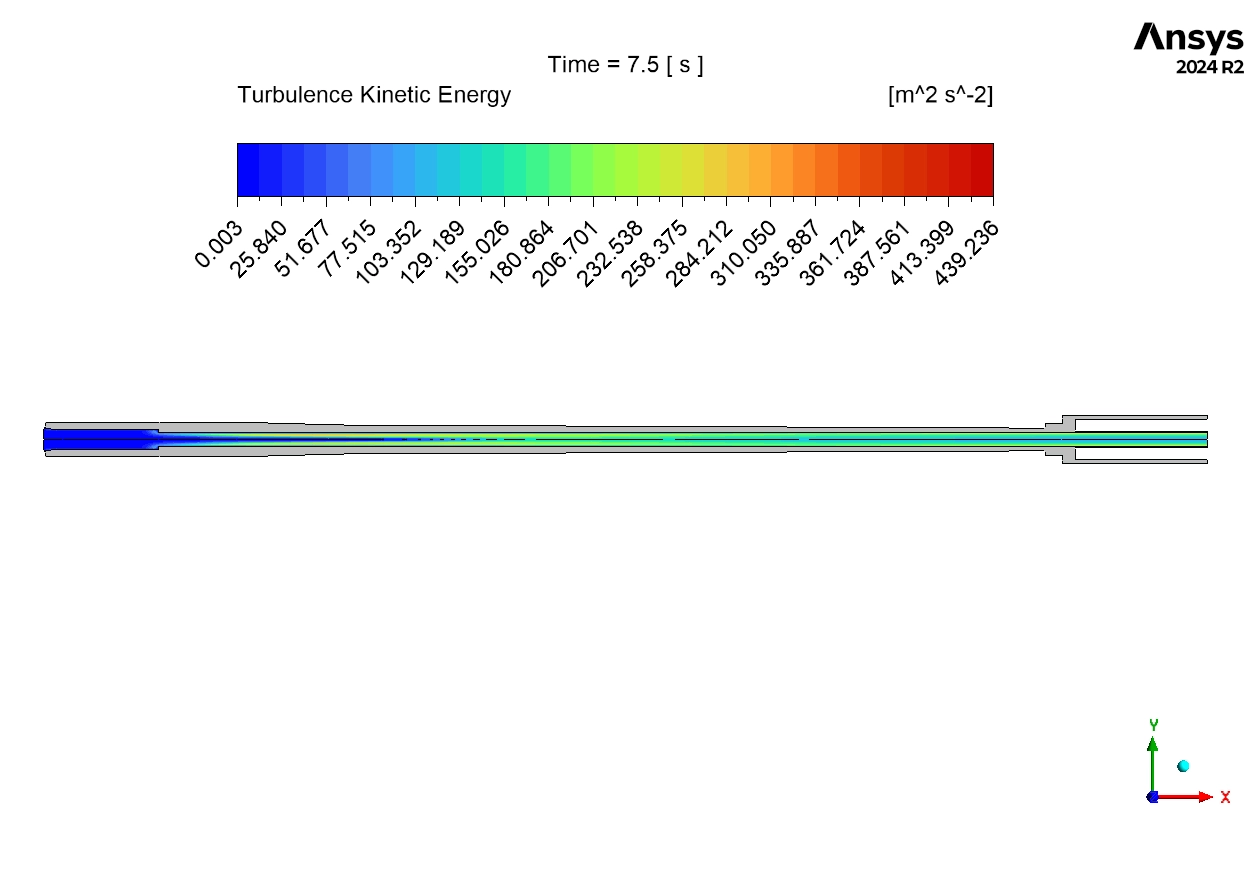

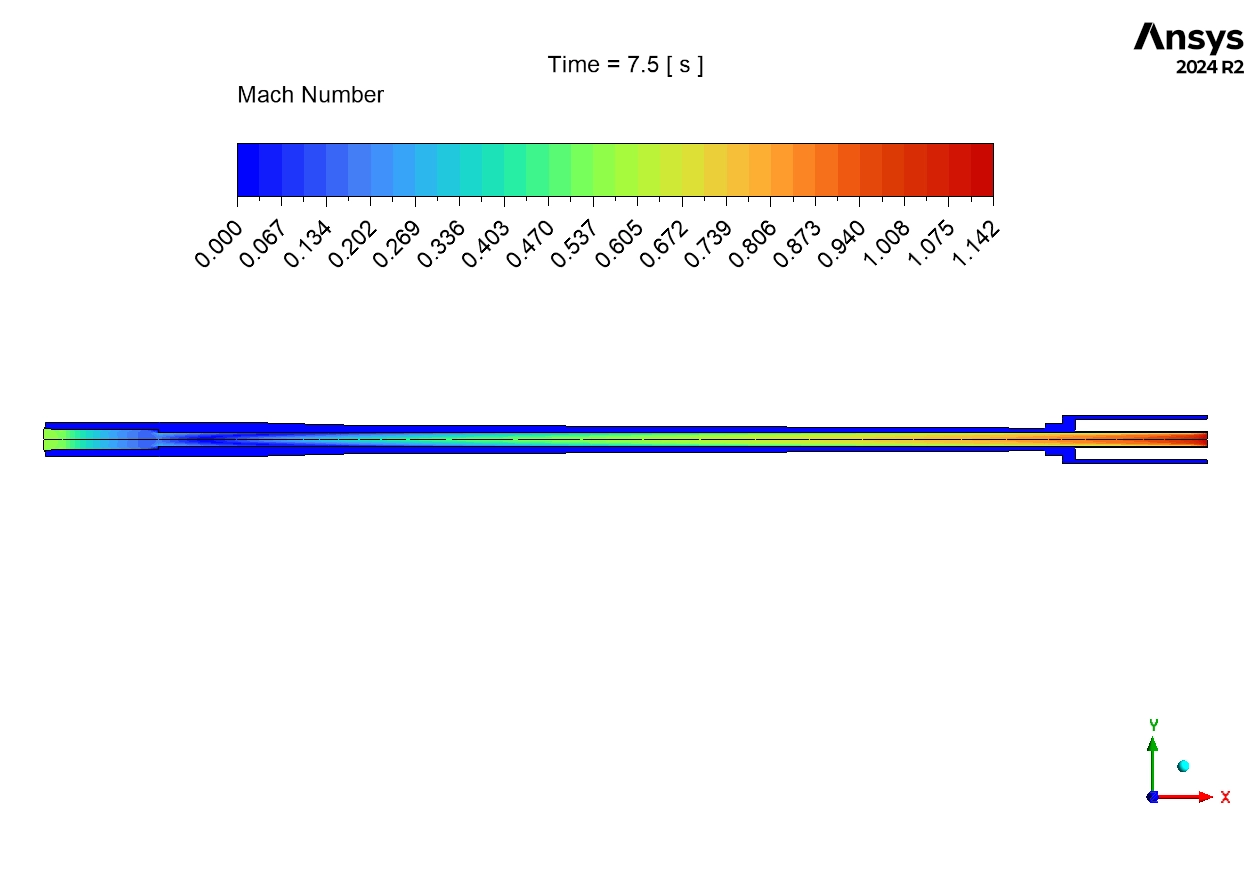

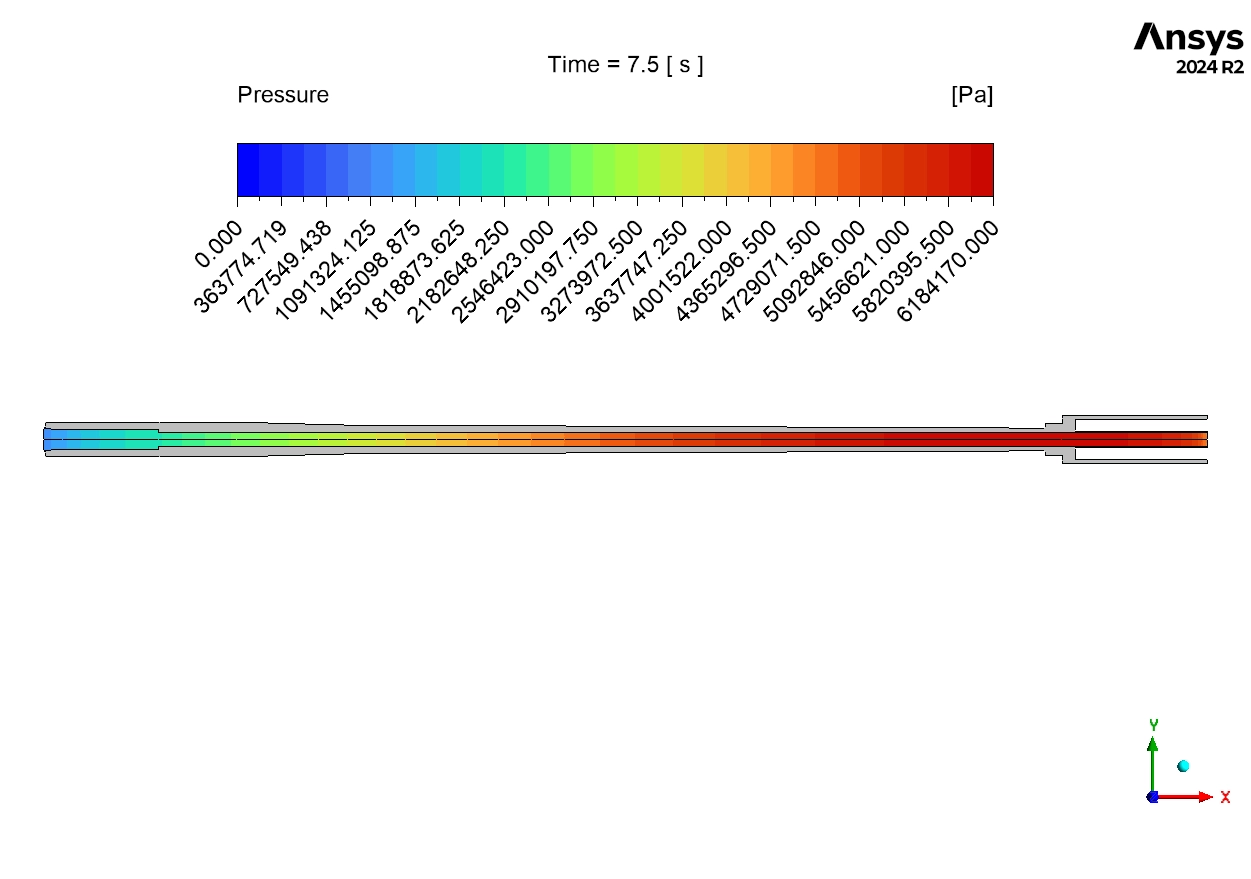

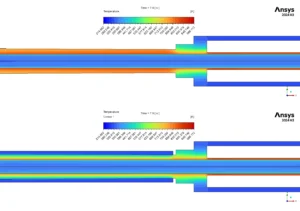

The temperature contours highlight critical thermal management challenges in gun barrel design, with the breach area reaching 869K while the muzzle stays relatively cool at 335K with cooling versus 347K without cooling. The water-cooling jacket creates a dramatic temperature gradient through the barrel wall thickness, removing heat fast enough to keep the inner surface below critical erosion temperatures. Hot zones concentrate near the chamber where pressure pulses are strongest and gas temperatures highest, requiring extra cooling capacity in this region. The gun barrel CFD simulation captures how heat conducts along the barrel length, creating the characteristic temperature profile that affects bullet trajectory and accuracy, offering deep gun barrel CFD simulation insights. ANSYS Fluent results show that cooling reduces peak barrel temperatures by approximately 15% while maintaining more uniform temperature distribution along the barrel length. This pressure pulses CFD analysis impact is significant, providing engineers with precise thermal data needed to optimize cooling system design and predict barrel erosion rates under different firing conditions.

Figure 3: Temperature Distribution in Gun Barrel at 7.5 Seconds

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€190.00 Original price was: €190.00.€95.00Current price is: €95.00.

€240.00 Original price was: €240.00.€175.00Current price is: €175.00.

€245.00 Original price was: €245.00.€185.00Current price is: €185.00.

€360.00 Original price was: €360.00.€185.00Current price is: €185.00.

€185.00 Original price was: €185.00.€135.00Current price is: €135.00.

€240.00 Original price was: €240.00.€115.00Current price is: €115.00.

Reviews

There are no reviews yet.